Swick, R.A. & Cremer, M.C. 2001. Livestock production: a model for aquaculture?,

Guest Lecture. In R.P. Subasinghe, P. Bueno, M.J. Phillips, C. Hough, S.E. McGladdery

& J.R. Arthur, eds. Aquaculture in the Third Millennium. Technical Proceedings

of the Conference on Aquaculture in the Third Millennium, Bangkok, Thailand,

20-25 February 2000. pp.49-60. NACA, Bangkok and FAO, Rome.

ABSTRACT: The broiler industry has been a vision of success

to those producing and marketing other animal proteins of terrestrial, fishery

or aquaculture origin. The broiler industry has evolved over the past 30 years

to be a major source of animal protein in the human diet. Growth has been massive

in recent years, having increased some 42 percent since 1992 alone. The United

States has led the way in broilers, and now produces over 34 percent of the

world’s supply of 56 million mt of live broiler. The formula for success

in broilers has been an abundant and affordable supply of corn and soybean meal

and a business organization where birds are produced and finished meat products

are marketed by the same company. Commercial fish production, in contrast, consists

of many fragmented marketing arms for a wide array of finfish, molluscs and

crustaceans involving both wild catch and managed culture. Of the total estimated

142 million mt of fish produced globally in 1999, the capture fisheries accounted

for 102 million mt, with 30 million mt of that converted to fishmeal and oil.

Aquaculture is estimated to have produced nearly 40 million mt in 1999, with

over 90 percent of the production in Asia. China is by far the leader, with

an estimated 1999 production of 27 million mt. China produces mainly carp and

tilapia grown on a sustainable basis in small holdings with little or no feeding.

Fish are collected and sold in traditional wet markets by third parties. Although

Chinese aquaculture lacks capital and organization, the use of processed feed

has recently caught the attention of the more progressive growers as a way to

increase profit.

Shrimp and salmon on the other hand, because of their relatively high value among the cultured fish species, stand out for their potential to be grown the way broilers are, that is, in vertically integrated businesses. In Taiwan Province of China and Southeast Asia, several large feed and poultry companies made significant strides in the late 1980s and early 1990s toward vertical integration in shrimp production. This led the way to upstarts in South and Central America, the Indian subcontinent and now Africa. In most locations, however, early successes have been punctuated with disease failures. The outbreaks of disease, more often than not, have been the consequence of a deteriorated environment caused by the farms themselves and poor practice of biosecurity. Technical advances in disease control, genetics, nutrition and ecology all have the potential to overcome many of these problems. The value and demand of these food products in the market warrant strong development effort. Business integration and technological development will lead the way for cultured aquatic species to become major protein sources in the human diet. Opportunities and obstacles in aquaculture are considered in this paper relative to the parallels and differences in livestock production.

KEY WORDS: Agriculture, Animal Production, Aquaculture, Feed, Feed Conversion, Shrimp Production

|

|

49

|

IntroductionAquaculture is contributing to an increasing share of the world’s seafood supply. Figures provided by the Food and Agriculture Organization of the United Nations (FAO) show that aquaculture has increased in importance, with a global growth rate outstripping that of livestock meat production by a factor of two to four. In Asia, particularly in countries like China (1.23 million mt in 1979 to 15.31 million mt in 1996), Bangladesh, India, Indonesia, The Philippines, Thailand and Vietnam, the growth of aquaculture has greatly outpaced growth in livestock production. As the scope for increasing the supply of seafood from traditional fisheries is limited, aquaculture is seen as having an important role to play in feeding the growing populations of many developing countries. Despite the high international profile of aquaculture products such as shrimp and salmon, world aquaculture production is dominated by freshwater fish, particularly in Asia, which is estimated to produce over 90 percent of the world’s aquaculture output. Much of this is produced by small-scale rural aquaculturists. Small-scale rural aquaculture, like its terrestrial counterpart, is likely to benefit indirectly from developments in technology. Improvements in the characteristics of farmed ish as a result of genetic improvements, and in health management and disease control will filter through to the small-scale farmer.

|

Recent advances in selective breeding and sex control technologies

for tilapia, for example, have had a considerable impact on tilapia production.

(G.C. Mair, pers. comm.).

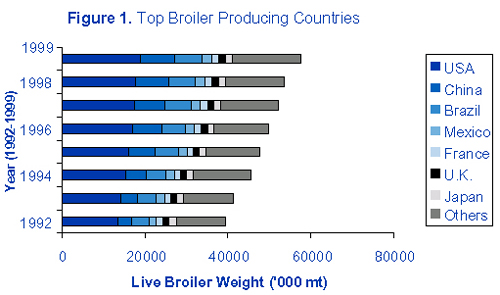

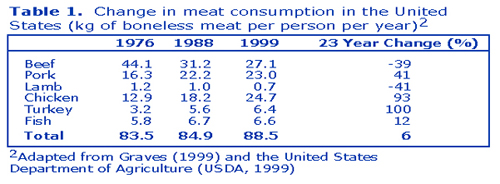

However, it is in the production of high-value species such as salmon and shrimp that parallels may be more clearly drawn in the large-scale production of livestock such as broilers. Without downplaying the importance of rural aquaculture in food production and provision of rural livelihoods, it is this type of commercial, large-scale aquaculture that may benefit most from a comparison with trends in agriculture production. In the United States, per capita consumption of broiler meat has surpassed that of beef, lamb, fish and pork. Since 1976, the per capita consumption of fish increased by a modest 12 percent and pork by 41 percent, while beef decreased by 33 percent and lamb decreased by 41 percent (Graves, 1999). Broiler chicken and turkey meat were the star performers, with increases of 93 percent and 100 percent over the same period. Table 1 shows the United States consumption patterns for these animal proteins. Broiler production has followed similar trends in other countries, as shown in Figure 1, with large increases in China, Brazil, Mexico, France, the United Kingdom and Thailand. In most countries, a majority of the production is consumed domestically. Coupled with the increase in consumption of broiler meat has been a fantastic increase in profit performance of the chicken companies involved. What caused this shift in consumption pattern favouring chicken? What made these companies so successful? |

|

|

||

|

||

| 50 |

|

What is the take home message for the other livestock and

aquaculture industries? The answers are: 1) successful marketing of attractive,

high quality, branded finished products; 2) vertical business integration

that resulted in decreased costs with improved quality; and 3) technological

breakthroughs and innovations in production. The single major factor that

increased profit in these companies was being able gain control over many

if not all of the aspects of chicken production and marketing. In its most

evolved form, this integration involves control of primary breeding, hatching,

growout, feed production, processing, shipment of raw materials, delivery

of finished meat products, marketing, restaurant chains, retail outlets,

grain farming and soybean processing. Teams of highly trained technical

and management specialists are required to manage operations under one entity.

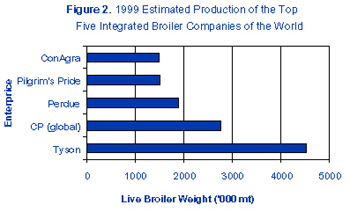

Figure 2 shows the estimated production of the top five integrated broiler

companies in the world. The largest, Tyson Foods, produces more broiler

meat per year than the countries of Mexico, France, the United Kingdom or

Thailand.

|

Integration allows companies to produce what consumers prefer

without losing concentration on the cost aspect. The balance of product

quality versus cost is a constant, never ending, internal battle for an

integrated company.

The contract growing system has been considered one of the most important core aspects for successful operation of an integrated broiler company (Aho, 1988). Broiler husbandry is an occupation that requires a 24-hour dedication to the task. This is the main reason why the contract system has been found to be more successful than company-owned farms. Such dedication is easier to find in a farmer-owner with a stake in the profit outcome than in a salaried worker. A large bank loan has a way of concentrating the mind to proper priorities at 3.00 a.m. when the weather is bad. While there are many variations to the theme, in most contract-grower operations, the independent farmer owns the land, buildings and equipment, and the integrated broiler company supplies the day-old chicken stock, feed, fuel, vaccination and technical assistance and guarantees buy-back of hatching eggs or broilers at a set price. Integrators continually rate the performance of their growers regarding superior performance and penalise those that are below average. Good management and feed conversion is rewarded with a cash bonus, while the poorest growers are dropped from the company. The integrated company may provide loans for improvements and new buildings provided they are built to company specifications. This has been a win-win situation for both the growers and integrators. By employing vertical integration, a company can effectively control cost, reduce outbreak of disease and improve overall quality of finished product.

|

|

|

51

|

| Some companies have also started vertical integration in aquaculture

operations. Salmon producers have embraced this concept, but there are major

differences in the structure of the salmon industry (in particular, the

fact that salmon farm concessions are granted by governments and are not

privately owned freeholds) that limit the extent to which this model can

be applied (Forster, 1999). Farmed shrimp shows a greater similarity to

the situation with chickens, as shrimp farms are usually located on private

property or on land for which a long-term freehold is available. As a result,

shrimp exporters in some countries have developed farm and hatchery operations

to ensure supplies of good quality product and, in some cases, have developed

further integration with marketing operations in major markets.

Contract farming in aquaculture is less common, partly due to the high cost of entry into the farming operation itself. Many integrated operations are based on corporate farming, and where contract farming has been tried, it has shown mixed results. Several groups have attempted to establish contract-farming operations for shrimp, especially in Southeast Asia. One of the problems experienced, however, is that the shrimp industry is not yet at a stage of development where risks are understood and can be spread across the production chain. The supply chain is still fragmented and, as in the early days of chicken production, there is an “every man for himself” attitude in which each level in the supply chain has to look after its own profits. The market lacks predictability, further impacting on continuity. There are signs that this may change but, with disease still having a major impact on product availability and price, there is still some way to go before the conditions will be conducive to efficient contract-farming operations.

|

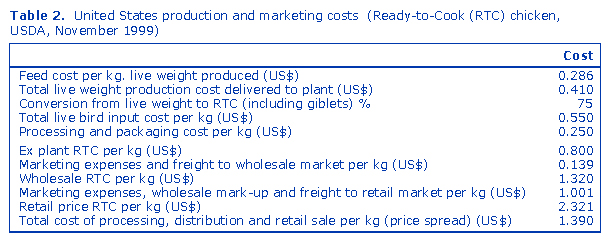

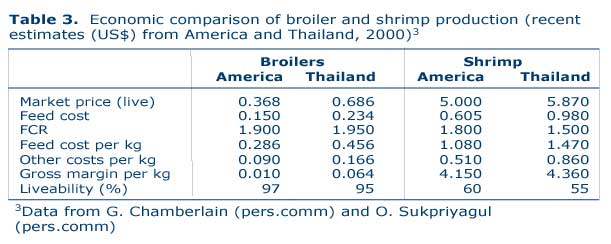

Economic estimates comparing broiler and shrimp production

“on the farm” in the United States and Thailand are interesting

(Table 3). On a live weight basis, the market price received for broilers

in the United States is cheaper than the feed cost to produce the same weight

in Thailand. Live shrimp command a market price roughly ten times higher

than live broilers. The gross margin for “on the farm” shrimp

produced in Thailand is several orders of magnitude greater than the “on

the farm” profit for broilers in the United States or Thailand. These

numbers suggest that unlike shrimp, much of the profit in broiler production

is not derived from farm growout but rather, by adding value as in further

processing. The data also demonstrate the large potential for reducing the

price of shrimp. That would increase both consumption and economies of scale

in shrimp production and processing. The major costs in salmon farming are usually smolts (juvenile fish, or seedstock) and feed, with labour, insurance and other costs making up the rest of the production cost. Feed is the largest expense, ranging between 35 to 50 percent of total cost. It is anticipated that continued improvements, especially in feed utilisation (food conversion rate), will contribute to a reduction in production cost. Smolts are another large expense, but the cost has come down in recent years because of better survival at sea and lower costs of smolt production. Further technical improvements will continue to move costs down, but savings will become harder to achieve (Forster, 1995). As with the poultry industry, farmed salmon has already come some way towards reducing costs, with production costs declining substantially and likely to continue to do so as a result of increasing efficiency (Forster, 1995). Feed costs are still a substantial cost component in salmon production, and have been estimated at 2.8 times the cost of feed to produce an equivalent weight of chicken. However, if yield and the cost of holding breeding stocks are taken into account, this can be reduced by half, with further reductions expected as a result of future improvements in nutrition and genetics.

|

| 52 |

|

| The industry largely ignores its consumers and continues

to offer raw pieces of beef flesh described anatomically using an antiquated

grading system that favours a high fat product. Each segment of the industry

operates as if it were an island. The cow-calf breeding operation, feedlot,

meat packing plant, truck lines, merchandising and retailing are all independent

businesses, each responsible for making as much profit as possible. Once

the product is off the truck or out the door and the money changes hands,

all care and much of the responsibility is finished.

In contrast, since the 1970s, large chicken companies such as Tyson Foods, Charoen Pokphand, ConAgra and Perdue Farms have become relentless in developing products such as chicken nuggets, processed meat, precooked turkey ham and other specialities. Innovative ideas such as chicken shops, franchise restaurants, and retail outlets have become part of these integrated broiler operations. Branding and brand recognition of poultry products has been an essential element, allowing these companies to gain control of the entire business from grain plow to dinner plate. Consequently, more consumers have switched to chicken and have decided to eat less beef. The swine industry in the United States in the past five to eight years has begun to follow the lead of the poultry industry. |

Major acquisition and consolidation has taken place, similar

to what happened in the poultry industry 15 to 20 years ago. Consumers’

preference for lean meat and creative processing is being heard by pork

producers, and consumption is on the upswing.

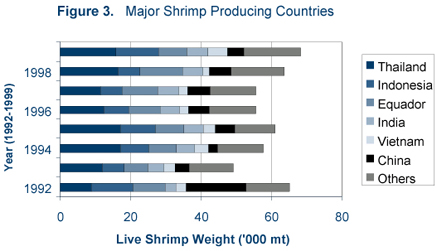

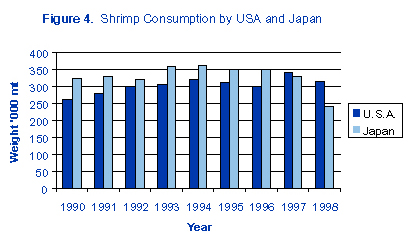

Aquaculture, especially shrimp and salmon, appears to be well suited to vertical integration and well suited to producing attractive food products for the consumer. In the search to improve genetics, disease resistance and pollution control, the aquaculture industry must not lose sight of the end consumers and their preferences. Consumers will be loyal to a product that is wholesome, healthy, tasty, consistent, versatile, provided in attractive packaging and is available consistently throughout the year. Marketing in the shrimp industry is different than in the broiler industry in that the major consumer markets are in countries different than production. Figures 3 and 4 show the major shrimp culture countries and the market consumption by the United States and Japan. Indonesia and Thailand are major producers, while the United States and Japan, followed by European countries are the major consumers (Csirke et al. 1998). |

|

|

||

|

||

|

|

53

|

| In the late 1980s and early 1990s, the Asian shrimp aquaculture

industry was focussed mainly on Japan. However, a decline in exports to

Japan due to the protracted economic slowdown and an increase in export

to and demand by the United States has created substantial problems due

to sanitary issues and quarantine concern over viruses that might potentially

affect natural United States shrimp fisheries. A concerted effort between

exporting and importing governments, as well as sellers and buyers, is required

to overcome these problems and concerns. Clearly, if the shrimp disease

problems can be remedied, the industry will continue to advance. The shrimp

industry in Thailand and Indonesia has already begun a creative international

marketing campaign to promote shrimp consumption in Japan and the United

States and in this respect, is already ahead of broiler producers.

The market for farmed salmon has grown tremendously over the past 10-15 years to where salmon is now regarded as a much more affordable food item and has penetrated newer, nontraditional, markets such as Asia. Further expansion of the market for farmed salmon will depend on its ability to compete with other foods, either fish or meat items. Frozen salmon products, rather than fresh or chilled salmon, are easier and cheaper to distribute and can increase the market penetration. Like chicken, there is considerable potential for brand identification in marketing salmon. This has already happened to some extent, on a national basis, with strong “branding” efforts being developed for farmed Canadian, Scottish and Norwegian salmon. Value-added processing, particularly of smoked product and salmon steaks, is a significant feature in salmon marketing, and there is considerable potential to widen this to include other salmon-based products. |

The growth of the United States market for tilapia has also had a significant impact on the way in which this fish species is marketed. Before 1986, demand for tilapia in the United States was mainly centred around localized demand in Asian communities for live product and was met by domestic producers (Fitzsimmons, pers. comm.). The import of frozen whole tilapia from Taiwan Province of China in the

mid-1980s, coupled with a greater awareness of the fish among United States

consumers, led to an expansion of the market, with annual consumption

of tilapia now estimated at over 51 000 mt. Although Taiwan Province of

China continues to be the main exporter to the United States, mainland

China, Thailand and Indonesia have become significant sources of frozen

fillets and some Caribbean and Central and South American countries have

also become important suppliers of fresh tilapia. In order to position

tilapia products better in the United States market, the Tilapia Marketing

Institute (TMI) was established in 1998 by a group of large producers

and marketers. The TMI intends to pursue a generic marketing campaign

to benefit all producers and product forms, both domestic and foreign,

and will seek to encourage producers to meet high standards of quality.

This follows the beef marketing model more than that for chicken, and

it remains to be seen whether it will be more successful for tilapia than

it has been for beef. |

|

|

||

| 54 |

|

|

||

|

||

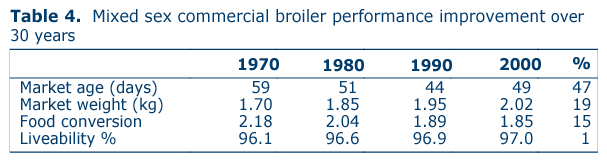

Technological advancesThe growth rate of commercial broiler chickens has increased from a 1.70 kg bird grown for 59 days in 1970 to a 2.02 kg bird grown in 40 days today, as shown in Table 4. This could not have been possible without the continued improvement in genetics, disease control, management and nutrition over the years.

|

More recently, selection for feed conversion has been found

to further improve economics and carcass quality (Pym and Nichols, 1979).

Shrimp culture, in contrast to broilers, has much catching up to do in the area of domestication, selective breeding, gene mapping, and biology in general. An excellent review of this topic was recently published by Argue and Alcivar-Warren (1999). At present, shrimp culture depends largely on wild capture of postlarvae or broodstock. This does not allow selection pressure for desired traits and is risky, as diseases may be transmitted. Selection pressure has been found to be effective in improving performance in penaeid shrimp, with heritability for growth rate ranging from 0.34 to 0.98 in Penaeus vannamei (Carr et al. 1997), and significant for P. monodon (Jarayabhand et al., 1998). Little work has been done in the area of cross-breeding or development of pedigree shrimp. Work at the Oceanic Institute in Hawaii has shown potential for breeding shrimp resistant to Taura syndrome virus (TSV), although it may be more practical to select shrimp for general immune response or osmoregulatory capacity than for a specific disease. Production of specific-pathogen free nauplii has begun at the Oceanic Institute and, although it appears to be an effective way to limit disease transfer, there is concern that such programmes may decrease genetic variation because only a few female shrimp are required to produce large numbers of nauplii. |

|

|

|

55

|

|

DNA techniques using PCR technology have improved ability to follow generations of shrimp, and work in the area of polyploidy, sex reversal and interspecific hybridisation have shown early promising results (Argue & Alcivar-Warren, 1999). Triploid penaeid shrimp appear to have faster growth, better survival rates and may be sterile, which would protect the investment of breeding companies and the environment by not allowing exotic species to spawn. Breeding and genetics of shrimp is an area where much greater study is warranted. Genetic improvements have played a major role in the development of the finfish industry. The application of breeding and selection programmes in salmon, tilapia and carp has led to considerable improvements in growth and productivity in these species (Gjedrem & Fimland, 1995). Improvements in genetics and breeding of salmon, along with major improvements in feed and health care for farmed salmon have, for example, considerably reduced the production time for salmon in sea water.

|

In addition, the drug and pharmaceutical industry has had

numerous breakthroughs during this time, including the development of ionophore

antibiotics to control coccidial parasites and improved antibiotics and

new antimicrobials such as fluoroquinolones.

Management and facility layout in breeder farms, broiler farms and hatcheries has been found to be a key factor in disease control. The best and most obvious way to control disease is to avoid contact with sources of infection. Monitoring of pathogens is thus essential. Multi-age flocks are avoided on farms controlled by successful broiler companies. Routine and planned complete depopulation has been found to be the most effective way to control many diseases, as most disease-causing viruses cannot survive for more than a week or two outside of the chicken host. Those who disregard basic principles of disease prevention may succeed in times of favourable market conditions, but will go out of business when profit margins are small. Many devastating diseases have been encountered in shrimp culture. As shrimp are not visible under the water, disease may go unnoticed until disaster occurs. Furthermore, overfeeding of diseased and anorexic shrimp leads to water quality problems that further exacerbate the condition. As in poultry, pathogens are transmitted by transport containers, contaminated vehicles, wild animals and in air and water. Bacterial diseases, particularly those caused by Vibrio species, appear to be widespread. Vibrio spp. are generally regarded as opportunistic pathogens, although one, Vibrio harveyi, the cause of luminous disease, is regarded as a primary pathogen. Viral diseases, however, have been the most devastating. One particularly devastating viral disease that affects shrimp producers

in all parts of the world is white-spot disease, caused by white spot

syndrome virus (WSSV). This disease can cause losses of 90 percent or

more of shrimp being produced on a farm. The agent is a baculovirus-like

virus that is transmitted horizontally through seed stock, contaminated

feed, infected shrimp and other carriers, especially crustaceans such

as wild crabs. Vertical transmission is unlikely, although recently posthatched

stock are soon infected by the virus present in feed or water. |

| 56 |

|

| Other diseases that are devastating to shrimp producers are

yellowhead disease, caused by yellowhead virus complex (YHV), encountered

mostly in Asia, and Taura syndrome, caused by Taura syndrome virus (TSV),

which is most prevalent in the Americas. Recent developments in DNA assay

procedures using the polymerase chain reaction (PCR) are becoming useful

to detect infection of seedstock and contamination of feed ingredients,

although testing costs and utility of this procedure in the field are limiting

factors.

The transmission of WSSV to the Americas and reports of TSV in Asia have highlighted the dangers of uncontrolled and unregulated transfers of stocks between countries. Quarantine regulations and practices are not so highly developed for aquatic animals as they are for terrestrial ones, although the situation is expected to change with the 2000 revision of the International Aquatic Animal Health Code and the Diagnostic Manual for Aquatic Animal Diseases by the Office International des Epizooties (OIE) in Paris. The OIE, or World Organization for Animal Health, is the recognized agency responsible for informing governments of the occurrence and course of animal diseases throughout the world, of ways to control these diseases, for coordinating studies devoted to the surveillance and control of animal diseases and for the harmonization of regulations for trade in animals and animal products among OIE-member countries. The Fish Disease Commission of the OIE compiles information on diseases of fish, crustaceans and molluscs and on methods of control of these diseases, and harmonizes rules governing trade in aquaculture products, as well as the control of products for diagnosis or prophylaxis. Regional initiatives, under the guidance of NACA and FAO, are also under development to reinforce regional capacity to meet OIE recommendations.

|

Feed formulation on a digestible nutrient basis is being practised more often to reduce costs and allow transparent changes when ingredients are substituted for one another. Supplementation of diets with methionine as well as threonine, lysine and tryptophan is becoming more common in commercial practice. The practice of removing expensive fishmeal from diets is gaining ground as more nutritionists recognise that the unidentified growth factors have been identified as selenium, vitamin B12, methionine and omega-3 fatty acids. Shrimp nutrition and feed production have several major differences when compared to broilers. The ratios and requirements of nutrients are different, and cholesterol and ascorbic acid are required. Growth responses have been observed with addition of lecithin, and attractants from fishmeal appear to improve feeding rate. Grinding, conditioning and pelleting are more critical in production of shrimp feed than broiler feed, as pellets must be small and durable in water. Leaching of water-soluble vitamins and amino acids needs to be considered. Contamination of feed with disease-causing agents from marine meals and live sources is a major concern. Post-hatched juvenile shrimp must be fed algae, zooplankton and other marine-derived ingredients such as live artemia. Juvenile shrimp are considered to be particulate feeders, whether feeding on processed feed or natural sources of plankton. The use of flocculants in pond water has been shown to improve feeding and performance in shrimp, as organic particles such as algae and bacteria are aggregated and made available for consumption (Moss, 1995; Tacon et al., 1999). The use of soybean meal in shrimp feed has been studied extensively (Akiyama et al., 1989; Akiyama 1989). Fibre level of the meal is important, as excess fibre reduces pellet stability and energy density of the diet. Levels of 25-30 percent dehulled soybean meal have been demonstrated to give good performance in shrimp (Lim and Dominy, 1990). Reducing the reliance on fishmeal in shrimp feed will reduce cost and lower the possibility of diet-transmitted pathogens. Formulation on a digestible amino acid basis and the use of ideal amino acid ratios will reduce nitrogen loading of pond water and effluent. Use of phytase enzyme will have a beneficial impact on phosphorus levels in water if methods of application can be found to increase enzyme stability and reduce possibility of leaching. Ingredients such as porcine plasma protein, soy protein concentrate and partially hydrolysed vegetable protein may have future utility as attractants and nutrient sources. |

|

|

57

|

EnvironmentEnvironmental control and management are critical to the broiler industry. Of particular concern are litter (manure) control, water treatment and the handling of dead animals. Poultry litter contains excreta and bedding material such as rice hulls or wood shavings. The waste material litter is valuable as an organic fertiliser. In the United States, litter is removed from broiler houses only once per year unless there is a disease outbreak. Depopulation of broiler houses for several weeks after flock marketing is effective to eliminate viruses that cannot live outside their hosts. Starting new chicks on used litter helps populate the digestive flora quickly and excludes pathogens. Used litter is disposed as fertiliser in accordance with government soil and water conservation service guidelines to avoid runoff. Water used for processing carcasses is treated to remove organic material and other pollutants before being released into the environment. Equipment such as dissolved air flotation systems (DAF) is now being used to remove fat and particulate matter from processing wastewater. Dead bird carcasses are typically frozen and subsequently recycled and sterilised in rendering operations. The material is used as a feed ingredient along with other treated waste products such as feathers and offal collected during processing. Aquaculture and in particular, shrimp farming, differs from broiler farming in that the growout operations are typically located along ocean-front and estuarine areas and are, therefore, under environmental scrutiny. Semi-intensive culture requires large ponds, location on clay soil to reduce seepage, low soil acidity and low land elevation to reduce pumping costs. Problems with pollution and disease have occurred in shrimp culture areas because of concentrated development without coordination and the use of infected postlarvae. Improved pond management and development according to plans and guidelines will help the situation. In important culture areas such as Thailand, codes of conduct are being developed for shrimp farming to ensure sustainability and provide for environmental, social and economic benefits for present and future generations. Businesses, organizations and stakeholders involved in the industry are involved in generating, reviewing and commenting on the codes of conduct. |

The use of closed biosecure culture systems with reduced or

zero water exchange is an area under intense evaluation at the present time.

Such novel production systems have the potential to increase productivity,

reduce effluent and control disease. These systems have already been developed,

tested and proven to work on a prototype basis. At the present time however,

they are not cost effective on a commercial scale because of high electricity

costs necessary to run aerators and pump water through raceways and filters

(Leung and Moss, 1999). Further refinement of biofilters required to clarify

water and metabolise nitrogenous wastes, along with improvements in genetics

of shrimp, may make biosecure systems economically viable in the future.

This would allow farms to be located some distance away from the ocean and

would reduce the incidence of disease. Much like broiler production on litter

floors, several crops of shrimp could be grown in the same water, with time

allotted for depopulation between growouts.

|

| 58 |

|

ReferencesAho, P. 1988. Broiler grower contracts in the United States. Broiler Ind. October. 1988. pp. 26-31. Akiyama, D.M. 1989. The use of soybean meal to replace white fish meal in commercially processed Penaeus monodon Fabricius feeds in Taiwan Province of China. p. 289-299. Proceedings of the Third Symposium on Feeding and Nutrition in Fish, Toba, Japan, August 28 - September 1 Akiyama, D.M., Coehlo, S.R., Lawrence A.L. & Robinson, E.H. 1989. Apparent digestibility of feedstuffs by the marine shrimp Penaeus vannamei Boone. Nippon Suisan Gakkaishi, 55: 91-98. Argue, B.J. & Alcivar-Warren, A. 1999. Genetics and breeding applied to the penaeid shrimp farming industry. In R.A. Bullis & G.D. Pruder, eds. Controlled and biosecure production systems, Proceedings of a Special Session: Integration of Shrimp and Chickens Models, p. 29-53. World Aquaculture Society, Sydney, Australia, April 27-30, 1999. Boyle, M.L. III. 1999. Chicken breeding and genetics. In R.A. Bullis & G.D. Pruder, eds. Controlled and biosecure production systems, p. 23-28. Proceedings of a Special Session: Integration of Shrimp and Chickens Models, World Aquaculture Society, Sydney, Australia, April 27-30, 1999. Carr, W.H., Fjalestad, K.T., Godin, D., Swingle, J., Sweeny J.N. & Gjedrem, T. 1997. Genetic variation in weight and survival in a population of specific pathogen free shrimp, Penaeus vannamei. In T.W. Flegel & I.H. MacRae, eds. Diseases in Asian Aquaculture III, p. 265-271. Manila, Philippines. Fish Health Section, Asian Fisheries Society. Chambers, J.R., 1990. Genetics of growth and meat production in chickens. In R.D. Crawford, ed. Poultry breeding and genetics, p. 599-643. Amsterdam, Netherlands, Elsevier Scientific Publishing Co. Csirke, J., Grainger, R., Rana, K. & Josupeit, H. 1998. The State

of fishery resources: trends in production, utilization and trade In The

State of World Fisheries and Aquaculture 1998, FAO Rome, http://www.fao.org/docrep/w9900e/ |

Forster, J. 1995. Cost trends in farmed salmon: a report prepared for the Alaska Department of Community and Economic Development, Division of Trade & Development, P.O. Box 110804, Juneau, Alaska. 40 pp. Forster, J. 1999. Aquaculture chickens, salmon - a case study. World Aquacult. 30(3): 33-70. Gjedrem, T. & Fimland, E. 1995. Potential benefits from high health and genetically improved shrimp stocks. In C.L. Browdy & S.J. Hopkins, eds. Swimming through troubled water, p. 60-65. Proceedings of the Special Session on Shrimp Farming, Aquaculture ‘95. Baton Rouge, Louisiana, World Aquaculture Society. Graves, M.H., 1999. Conception to consumption - an integrated poultry operation. Proceedings of the Fourth Annual Soybean Regional Conference, September 4-6, 1999, American Soybean Association, Istanbul, Turkey, p. 56-58. Jarayabhand, P.S., Uraiwan, S., Klinbunga, S., Tassanakajon, A., Srimukda, P., Pattanachan, P., Panakulchaiwit, R. & Menasveta, P. 1998. Estimated heritabilities for early growth rate of the black tiger prawn, Penaeus monodon, Fabricius. In T.W. Flegel, ed. Advances in shrimp biotechnology, p. 60-65. Bangkok, National Center for Genetic Engineering and Biotechnology. Leung, P.-S. & Moss, S.M. 1999. Economic assessment of a prototype biosecure shrimp growout facility. In R.A. Bullis & G.D. Pruder, eds. Controlled and biosecure production systems, p. 97-106. Proceedings of a Special Session: Integration of Shrimp and Chickens Models, World Aquaculture Society, Sydney, Australia, April 27-30, 1999. Lim, C. & Dominy, W. 1990. Evaluation of soybean meal as a replacement for marine animal protein in diets for shrimp (Penaeus vannamei). Aquaculture, 87: 53-56. Moss, S.M. 1995. Production of growth-enhancing particles in a plastic-lined shrimp pond. Aquaculture, 132: 253-260. Pym, R.A.E. & Nichols, P.J. 1979. Selection for food conversion in broilers: direct and correlated responses to selection for body-weight gain, food consumption and food conversion ration. Br. Poultry Sci. 20: 87-97. Shane, S.M. & H.M. Lasher. 1999. U.S. contributions to poultry health over seven decades. Zootechn. Int. February, 1999. 52-53. |

|

|

59

|

|

Tacon, A.G.J., Conklin, D.E. & Pruder, G. 1999. Shrimp feeds and feeding: at the crossroads of a cultural revolution. In R.A. Bullis & G.D. Pruder, eds. Controlled and biosecure production systems, p. 55-66. Proceedings of a Special Session: Integration of Shrimp and Chickens Models, World Aquaculture Society, Sydney, Australia, April 27-30, 1999. Thrusfield, M. 1995. Veterinary epidemiology, 2nd edn. Edinburgh, Blackwell Science Ltd. USDA. 1999. Livestock, dairy and poultry situation outlook. Economic Research Service, United States Department of Agriculture, LDP-M-65, November 23, 1999. pp. 15-37. http://usda.mannlib.cornell.edu/reports/erssor/livestock/ldp-mbb/1999/ldp-m65.pdf. |

________

| 60 |

|