CRASSOSTREA RIVULARIS

HISTORY

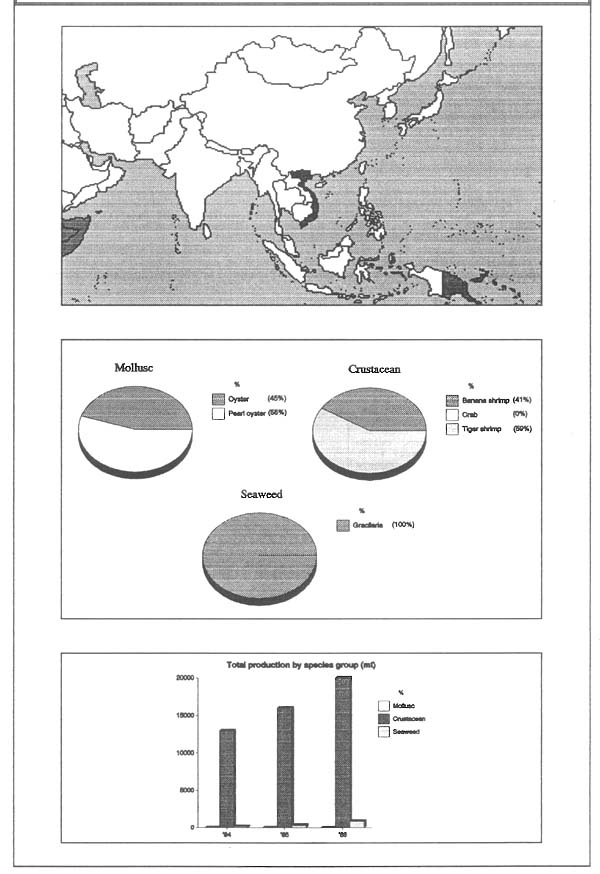

Vietnam has a coastline of 3,260 km with tidal, estuarine and mangrove areas covering over 300,000 hectares, most of which are suitable for mariculture development. There are 10 species of oyster found in the coastal waters of Vietnam. At present, oyster seafarming is still in the early stages of development and most oyster production is derived from the exploitation of wild stocks. Local fishermen collect oysters mainly from estuaries which have settled on hard substrates. The culture of Crassostrea rivularis was first attempted in 1963 by the staff of the Marine Product Research Institute, and the first oyster farm was established along the coast of Quabg Ninh Province. Since 1972 experimental trials on the hanging culture method have been carried out. In order to effectively promote and develop seafarming activities, including oyster farming, as means of increasing foreign exchange earnings, creating employment and generating income for the farmers, the Government of Vietnam has enacted laws on the conservation and development of fishery resources, policy incentives to seafarming development (such as tax exemption for the first years of operation; priority in providing materials, equipment and marketing of products, etc.), and a policy to mobilize funding resources, including private ones, for the development of the industry. It is believed that the oyster industry in Vietnam will certainly expand in the future as there is considerable room for expansion, labour is still relatively cheap, and foreign markets remain unsaturated or untapped. The Government is also taking care in setting up a network for research work, dissemination of scientific-technical knowledge and technical guidance for farmers.

CULTURE PRACTICES

There are two methods of oyster culture presently practiced along the coast of Vietnam: the bottom and hanging methods. The former method is the most widely practiced probably as a result of the low capital investment required. During the peak spat season, cultch materials such as stones, empty adult oyster shells and other hard objects are scattered over the bottom surface of the culture areas. Harvesting is carried out manually by collecting the cultch objects from the bottom and removing the marketable size oysters. In the hanging culture method, spatted oyster shells, plastic discs and other suitable cultch materials are strung together using a wire to make a culture unit. These culture units, which vary in length depending upon the depth of the water column, are then hung from a bamboo raft or bamboo stake structure usually located near the mouth of rivers and other productive areas. The floating rafts are made of thick bamboo poles (10–12 cm in diameter) and are moored to the four corner posts with enough slack to allow the raft to float at different water levels. The bamboo stake structure is usually made of three or more parallel bamboo poles (5–9 cm in diameter) fixed at a suitable distance from one another on the top of several supporting vertically embedded poles. The supporting poles are driven into the bottom in parallel rows and roughly spaced 0.5 m apart. This method is usually used in areas with relatively shallow waters and soft muddy bottoms. Harvesting is usually carried out after a culture period of 12– 18 months. One major constraint affecting this culture method is the biofouling and food competition from barnacles (Balanus sp.). Other disadvantages are that predators such as crab, starfish, and burrowing snails can crawl up the supporting stake and reach the oysters, and the relatively short life-span of the poles (1–2 years). Further research into adapting established culture methods and techniques, particularly with regard to spat monitoring and collection, from countries in the region, will certainly help towards the commercial propagation of oysters in Vietnam.

| STATUS | SPECIES |

|---|---|

| Crassostrea rivularis | |

| Source of seed | Wild |

| Culture method | Bottom and suspended (raft & stake) |

| Yield/ha | 7 mt/ha (flesh) |

| Marketing | Domestic |

| Production area | 10,000 ha (potential area) |

| Level of culture | Developing |

| Major constraints | Limited seed supply; Biofouling |

PINCTADA spp., PTERIA sp.

HISTORY

There are numerous species of pearl oysters found along the coastal waters of Vietnam. The major species are Pinctada fucata martensil, Pteria penguin, Pinctada margaritifera, Pinctada formosa and Pinctada maxima. The first research project on pearl culture was initiated in 1965 by the Marine Products Research Institute off the coast of Quang Ninh Province. The technique of inserting 1 or 2 nuclei with a piece of mantle from donor oysters into mother oysters was adopted. In 1970 the first pearl oyster culture cooperative was established at CoTo Island (Quang Ninh Province). Later, experiments on the production of half-pearls using the wing-oyster (Pteria penguin) were also carried out. In order to effectively promote and develop seafarming activities, which includes pearl oyster farming, as means of increasing foreign exchange earnings, creating employment and generating income for the farmers, the Government of Vietnam has enacted laws on the conservation and development of fishery resources, policy incentives to seafarming development (such as tax exemption for the first years of operation; priority in providing materials, equipment and marketing of products, etc.), and a policy to mobilize funding resources, including private ones, for the development of the industry. It is believed that the pearl oyster industry in Vietnam will expand in the future as there is considerable room for expansion, labour is still relatively cheap, and a high foreign market demand exists. The Government is also taking care in setting up a network for research work, dissemination of scientific-technical knowledge and technical guidance for farmers.

CULTURE PRACTICES

Although many species of pearl oyster are found in Vietnam, only Pinctada fucata martensii and Pteria penguin produce pearls of high quality. Mother pearl oyster are collected from the sea at the depths ranging from 10–12 m usually by skin diving. Collection is done by hand. The nuclei are spherical in shape (usually 4–6 mm in diameter) and are made from the shells of Lamprotula. Dimensional accuracy, smooth finish and high polish are important factors in the preparation of the beads. The beads are carefully cleaned and dried before they are used. The pearl mother oysters are usually selected according to their weight, reproductive stage of development and overall health. A weight of 25 g or more is the ideal size for nucleus implantation. Fully matured individuals are not used, since during surgery the gametes tend to flow out and block the visibility of the implantation site so that proper orientation of the mantle piece and nucleus cannot be ensured. After the insertion of the nucleus, usually carefully placed in the ventral portion of the gonad tissue, the operated pearl oysters are transferred into netcages at a density of about 50–70 oysters/cage. The netcages are then hang from floating rafts at depths ranging from 3–5 m. The rafts are anchored in areas which are relatively well sheltered, such as bays, and also characterized by a high phytoplankton productivity. Maintenance of the rafts and netcages is carried out periodically, particularly to remove biofouling organisms and predators. Culture period is about 36 months. Harvesting of the cultured pearls is carried out manually by separating the two shell valves, making an incision on the gonad and squeezing the pearl out. Pearl harvesting is done during periods of low temperature (cold season) as the pearls tend to be of higher quality due to a thick and compact outer nacreous layer. The harvested pearls are washed in distilled water, polished and sorted according to size, colour, shape, lustre and other external characteristics. The colour and quality of the pearls are closely correlated to the environmental conditions of culture area.

| STATUS | SPECIES |

|---|---|

| Pinctada fucata martensii | |

| Source of seed | Wild |

| Culture method | Suspended (raft) |

| Yield/ha | 2–3 mt/ha (shell-on) |

| Marketing | Domestic |

| Production area | NA |

| Level of culture | Experimental/Developing |

| Major constraints | Limited seed supply; Low price; Poor culture technique |

SCYLLA SERRATA

HISTORY

Scylla serrata, commonly referred to as the mangrove, green or mud crab can live in a wide range of salinity. In Vietnam the mud crab is considered a by-product of various brackishwater pond culture activities. The crab juveniles come into the pond with shrimp and fish during pond-flooding at high tide. Crab fattening is essentially a holding operation during which immature females crabs are kept in some kind of enclosure and fed until their gonads develop and fill the mantle cavity. The product is consumed mainly in the domestic market. Since 1988, as a result of increasing export demand, crab culture has expanded in earth ponds, concert tanks as well as floating cages. In 1990 a total of 10 tonnes of mangrove crabs were fattened. The culture expansion of the crab is at present constrained by the lack of stockable young ones, because of various problems encountered in the hatchery propagation for this species. Hai Phong, Than Hoa, Minh Hai, Kien Giang and Hau Giang are the major provinces that have potential in crab culture. In order to effectively promote and develop seafarming activities as means of increasing foreign exchange earnings, creating employment and generating income for the farmers, the Government of Vietnam has enacted laws on the conservation and development of fishery resources, policy incentives to seafarming development (such as tax exemption for the first years of operation; priority in providing materials, etc.), and a policy to mobilize funding resources, including private ones, for the development of the industry. The Government simultaneously is taking care of setting up a network for research work, dissemination of scientific-technical knowledge and technical guidance for farmers.

CULTURE PRACTICES

The mangrove crab (Scylla serrata) is not cultured in the strict sense of the word. They are cultured or fattened in earth ponds, concrete tanks and floating wooden or bamboo cages. Crabs are cultured in rather small brackishwater ponds with surface areas ranging from 50–100 m2. These ponds are equipped with reinforced dikes and water exchange is usually by tide. The juvenile crabs (female crabs) are collected from the wild (body weight ranges from 20 to 100 g). The stocking rate is 2–3 individuals/m2. Floating cages are usually not large in size and are usually stocked with higher densities. The feed usually provided is in the form of live fresh and brackishwater snails, trash fish or any kind of animals (mud crabs do not accept currently available pelleted feeds). After 2–4 months of culture, crabs reach the marketable size of 200– 250 g. The adults that have just molted are fattened to the stage of full gonad so as to command a better price. For this purpose bamboo floating cages and concrete tanks (10–40 m2) are used. Bricks, cement pipes or other hard objects are placed on bottom of the concrete tanks so as to provide shelter for the crabs and reduce mortality and losses through cannibalism. The culture period is usually between 10–50 days depending on the initial stocking size. In estuaries, mud-flats and ponds, crabs are harvested by hand or by using traps and a variety of nets including dip nets. Crabs cultured in Vietnam are also being exported as this particular marine crustacean is becoming increasingly popular as a gourmet seafood. The mud crabs are very hardy and can survive several days out of water if kept moist. In view of the rapidly developing demand and export market for this product, there is an urgent need for a concentrated effort to investigate the biology, ecology, and other aspects, aimed at increasing its production. Vietnam still has a great potential for expansion of this seafarming practice. In the forthcoming years the seafarming programme in Vietnam will concentrate on applied research in seed production and culture methods and measures to conserve this marine resource.

| STATUS | SPECIES |

|---|---|

| Scylla serrata | |

| Source of seed | Wild |

| Culture method | Pond |

| Yield/ha | 5 mt/ha/year |

| Marketing | Domestic and export |

| Production area | NA |

| Level of culture | Developing |

| Major constraints | Limited seed supply |

PENAEUS MERGUIENSIS

HISTORY

Banana shrimp (Penaeus merguiensis) in Vietnam is traditionally cultured in rather large brackishwater ponds. The form of culture of this shrimp species can be briefly described as: Trapping-Holding (Fattening)-Harvesting. Thanks to the favourable climatical conditions along the southern part of the country there is a great abundance of natural food and seed. Banana shrimps are mainly cultured in the southern part of the country, although a few medium-scale operations are also located in the northern provinces (eg Hai Phong, Thai Binh, Ha Nam Ninh). The traditional period for capturing wild seed is between February to May. Farmers open the pond gates when local waters have the highest densities of juvenile shrimp. In 1987 the Marine Products Research Institute succeeded in the artificial rearing of the banana shrimp. The first trials in controlled reproduction were started in the early 1970s. In 1975 a small hatchery was set up in Qui Nhon with the financial and technical support of the Food and Agriculture Organization of the United Nations. Currently, Vietnam has at least 100 large, medium and small hatcheries, however most of these hatcheries work with P. monodon. Since 1986 most of the banana shrimp fry have been artificially produced. Intensive and semi-intensive banana shrimp farms have also been established since 1986. In general, Vietnam still has much possibilities for the expansion of shrimp farming. In the forthcoming years the Seafarming Programme will concentrate on applied research in seed production of some commercial species, culture techniques, diagnosis and treatment of fish diseases, appropriate culture method and measures on conservation and reproduction of marine resources.

CULTURE PRACTICES

In the traditional culture form, the pond area is usually rather large ranging from 5 to 15–20 hectares. In each pond there are 1 to 2 sluice gates. The internal canal system is used as a hide for the shrimp. Harvesting is carried out by draining the ponds. Productivity is 50–70 kg/ha/year in the North and 300–1000 kg/ha/year in the South. In intensive and semi-intensive farms, the rearing pond area is usually 1–2 hectares, and the nursery ponds are located near the rearing ponds. Seed is supplied from hatcheries and stocked at a density of 10–20 PL/m2. At present there are more than 100 state-run, cooperative and private shrimp hatcheries of large (10– 20 million PL 15/year/hatchery), medium (3–5 million PL15/year/hatchery) and small size, most of which however produce P. monodon postlarvae. In 1990 over 100 million fry were produced, yet it does not meet the needs of the culture sector of the industry. The feed given are pellets, trash fish and animal by-products. After 3–4 months of culture, the shrimp attain a weight ranging from 10–12 g. The common diseases of culture shrimp is black gill, muscle necrosis and Vibrio infection. Water is changed during high tide. The major disadvantages of culturing banana shrimp are the small individual sizes of the cultured shrimp and the difficulty in increasing pond productivity. The area under shrimp culture in 1990 was approximately 170,000 hectares which yielded about 37,000 tonnes. With regard to feed development, some studies on artificial feeds have been carried out and the results applied in the production of shrimp feed for the various rearing and grow-out stages. The potential for shrimp culture development in Vietnam is still great, as large coastal brackishwater areas remain unexploited. One major constraint is the lack of capital investment for development of farms and food processing plants. Environmental issues and diseases affecting shrimp, have been studied, but still at a very limited extent due to lack and shortage of professional staff, facilities and necessary equipment. These particular aspects needs strengthening through international assistance and regional collaboration.

| STATUS | SPECIES |

|---|---|

| Penaeus merguiensis | |

| Source of seed | Artificial |

| Culture method | Pond |

| Yield/ha | 1–2 mt/ha/year |

| Marketing | Domestic and export |

| Production area | 50,000 ha (potential area) |

| Level of culture | Developing |

| Major constraints | Low productivity; Small size |

PENAEUS MONODON

HISTORY

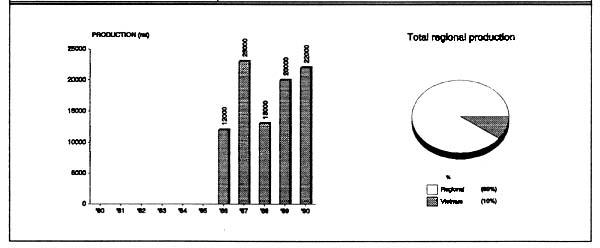

In Vietnam, most tiger shrimp (Penaeus monodon) farms are located in the central and southern portions of the country (only small-and medium-scale farms are in operation in the northern provinces of the country), and most use extensive traditional farming techniques. Ponds of family operations are typically 1 to 3 hectares, while those of large cooperatives and staterun farms range from 100 to 300 hectares (total area). Some large farms utilize several thousand hectares of tidal areas. Polyculture of the tiger shrimp with Gracilaria seaweed is also practiced in some localities. In 1987 the Marine Products Research Institute succeeded in the artificial mass rearing of the tiger shrimp fry. The first trials in controlled reproduction were started in the early 1970s. In 1975 a small hatchery was set up in Qui Nhon with the financial and technical support of the food and Agriculture Organization of the United Nations. Currently, Vietnam has at least 100 large, medium and small hatcheries. Most of these hatcheries work with P. monodon (and to a lesser extent on Penaeus merguiensis) and a few utilize imported technology and consultants from Japan. Most hatcheries are located in central Vietnam, near Nha Trang and Cam Ranh, where the most reliable sources of wild P. monodon are found. Today P. monodon has been acclimatized, stimulate to spawn and cultured also in the northern provinces of the country. The total culture area is estimated at about 40,000 hectares (total shrimp culture area in 1990 was approximately 170,000 hectares). Annual production is about 16,000 tonnes (40% of total cultured shrimp output. In 1990 total shrimp culture yielded about 37,000 tonnes).

CULTURE PRACTICES

During the past years satisfactory development has been attained with regard to shrimp farming. The main culture method remains the traditional extensive aquaculture which, although it has been improved, still yields low outputs (100–150 kg/ha, 400–600 kg/ha, 250–300 kg/ha in the northern, central and southern regions of the country, respectively). Semi-intensive culture (yielding 1–1.5 tonnes/ha/year) and intensive culture (yielding 4–10 tonnes/ha/year) have been tried in some locations. Shrimp fry are collected from the wild (mainly in estuaries) by using scissors nets. In the traditional extensive culture method the stocking density is 3–10 juveniles/m2 and fertilizers are used before stocking. The feed provided is mainly rice-bran supplemented with animal by-products. Intensive and semi-intensive farms utilize seed derived from hatcheries. The stocking density is 10–20 PL/m2. Concrete tanks, netcages and pens are becoming increasingly popular in intensive shrimp farms. At present there are more than 100 state-run, cooperative and private shrimp hatcheries of large (10–20 million PL15/year/hatchery), medium (3–5 million PL15/year/hatchery) and small size (backyard hatcheries). In 1990 over 100 million fry were produced. However, the amount of fry produced does not yet meet the needs of the culture sector of the industry. Shrimp broodstock used are both from the wild and ablated shrimp. With regard to feed development, some studies on artificial feeds have been carried out and the results applied in the production of shrimp feed for the various rearing and grow-out stages. The potential for shrimp culture development in Vietnam is still great, as large coastal brackishwater areas remain unexploited. One major constraint is the lack of capital investment for development of farms and food processing factory. Environmental issues and diseases affecting shrimp, have been studied, but still at a very limited extent due to lack and shortage of professional staff, facilities and necessary equipment. These particular aspects needs strengthening through international assistance and regional collaboration.

| STATUS | SPECIES |

|---|---|

| Penaeus monodon | |

| Source of seed | Artificial |

| Culture method | Pond |

| Yield/ha | 1–3 mt/ha/year |

| Marketing | Domestic and export |

| Production area | 40,000 (potential area) |

| Level of culture | Developing |

| Major constraints | Lack of investment capital |

GRACILARIA VERRUCOSA

HISTORY

There are about 16 species of Gracilaria (known as Rong-cau in Vietnamese) distributed along the coastal region, including estuaries, brackishwater pond, canals of salt fields, mollusc beds, around mangroves or even on mud surfaces. Research programmes on the culture of G. verrucosa where first initiated in 1963, but its commercial culture was initiated in 1980. Culture of G. verrucosa is been practiced in numerous coastal ponds in the Central and Northern regions of Vietnam. From 1963–1973, general studies on the natural resources of this seaweed and its experimental culture were conducted. From 1973–1977, studies on G. verrucosa culture to provide raw material for agarprocessing were the main objectives. Seaweed culture and processing in Vietnam is becoming an important industry. Since 1987, the annual yield of Gracilaria has been about 700–800 mt (dried weight), of which 100–150 mt is used for agar-agar processing or for foodstuffs. The rest is exported to Asian countries. In general, levels of technology and productivity are low. Dried product of Gracilaria from culture was 250–300 mt in 1989 (⅓ of total annual production). Growing area for Gracilaria is around 350 ha. The potential area for Gracilaria farming is more than 10,000 ha in the north and central Vietnam. In 1988 a joint laboratory was established in Hai Phong City and operated by the Marine Products Research Institute and Institute of Fishery and Pacific Ocean Research (Vladivostok, USSR). Initial good results of this laboratory have been achieved. The Ministry of Fisheries has set the following targets: by 1990 there should be some 1,900 ha of culture area; dried product of Gracilaria 2000 mt; and agar product 100 mt. By 1995: 3000 ha, 4000–5000 mt, and 6000 mt, respectively.

CULTURE PRACTICES

Gracilaria is cultured by bottom culture using the vegetative reproduction technique. The method has 3 forms. Type 1: in a big pond/swamp with gates and additional seeds, small quantity of manure and control of undesirable species. Productivity is about 1 tonnes/ha/year (dried product). Type 2: in ponds; no additional seeding and no manure is applied. This is a form of natural harvest of Gracilaria with naturally recruited fish/shrimp. Productivity is 0.5 tonnes/ha/year (dried product). Type 3: in small ponds with reasonable amount of manure applied, increased water exchange in tidal periods. Productivity of this type is above 2–3 tonnes/ha/year (dried product). Type 3 is still only practiced on a limited scale. Technique of raft culture using spore is still at the testing stage. The commonly used Gracilaria growing technique includes the following steps: 1) Site selection: Site should be near sources of both sea and fresh water and protected from strong winds. Salinity of seawater is above 8–30 ppt. A salinity range of 15– 22 ppt has been found to be optimal. Pond bottom is mud, sand-mud or mud-sand; soil pH is 7.0– 8.6; 2) Pond construction: Pond bottom level is at 0 level of sea chart. Pond area is 0.3–1.0 ha. Smaller ponds are easier to manage than larger ones because in large ponds Gracilaria tend to accumulate at one side due to the influence of winds. Supply and drain gates are separated and depth of water pond is 0.7–1 m. Pond bottom should be treated; 3) Culture method: Use of organic manure. Before planting, seeds are treated in solution of inorganic manure. Seed density is 500–600 g/m2; 4) Pond management: In winter, water depth is maintained at 30–40 cm; in summer this level is raised to 50–60 cm. Water change is done utilizing tidal cycle. After every water change, organic or inorganic manure is applied. Foreign seaweeds are removed regularly; 5) Harvesting: The first partial harvesting is done after 25–30 days of culture. The rest is retained with density of 500–700 g/m2. Management is continued until next harvest.

| STATUS | SPECIES |

|---|---|

| Gracilaria verrucosa | |

| Source of seed | Wild and artificial |

| Culture method | Pond |

| Yield/ha | 1–2 mt/ha/year (dry wt) |

| Marketing | Export and domestic |

| Production area | 350 ha (10,000 ha: potential area) |

| Level of culture | Developed |

| Major constraints | Limited seed supply; Marketing |