Clarias farming in Thailand is characterised by some of the highest recorded stocking densities in pond type aquaculture anywhere in the world. When such large quantities of stock are dependent on the pond environment it becomes particularly important to understand and control the processes taking place throughout the production cycle.

One of the most critical components of the clarias farm is the water supply, and it is the use of this together with well controlled feeding, ans possibly regular harvesting, which determines the success of the crop.

Sites and Water Supply

Water service arrangements are relatively simple - water is either introduced and drained by a simple channel and weir, or is pumped in and out by long-tail pumps. Three basic layouts of water supply systems occur, as illustrated in Fig. 16. In favourable areas, with adjacent irrigation canals, water supplies may be drawn in parallel from the main source, which ideally should not receive discharges from other clarias farms. In other areas water is drawn from and discharged into klongs thus receiving as well as contributing clarias wastes. This is dangerous as a source of infections for the fish, especially if several farms are close together on the water source.

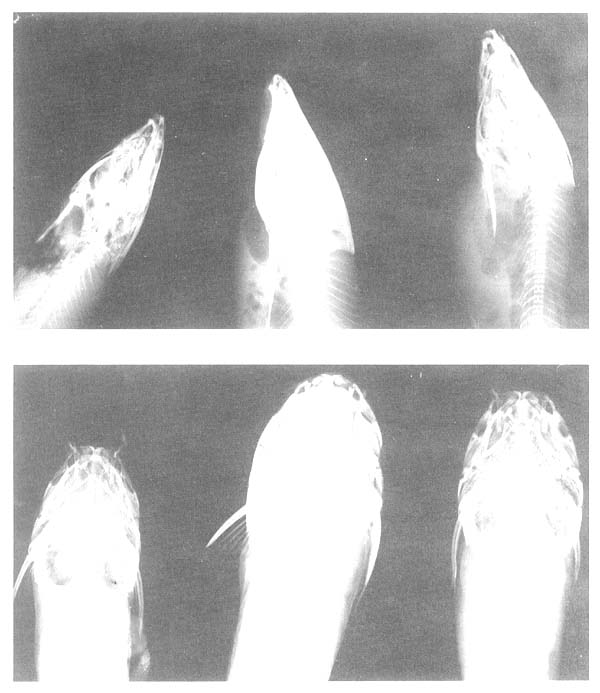

Fig. 14 a & b X-ray photographs of clarias with crackhead. In both figures the fish in the middle are normal, whereas the others show reduction in ossification and X-ray opacity.

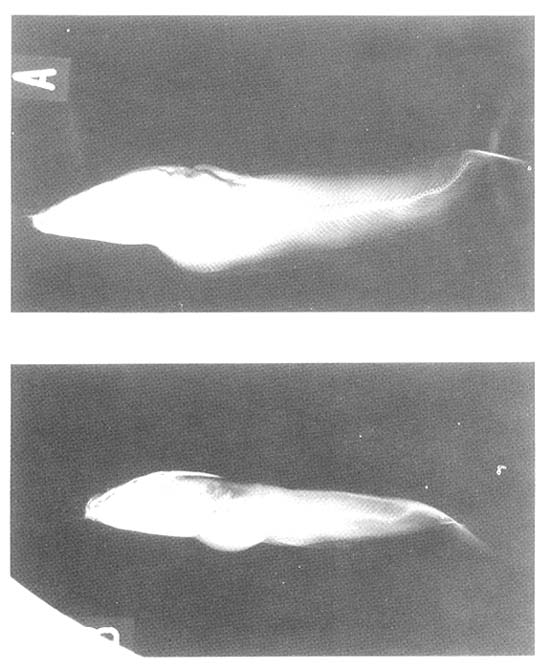

Fig. 15. X-ray of fish in Fig. 18a. showing vertebral collapse, and severe spinal deformation.

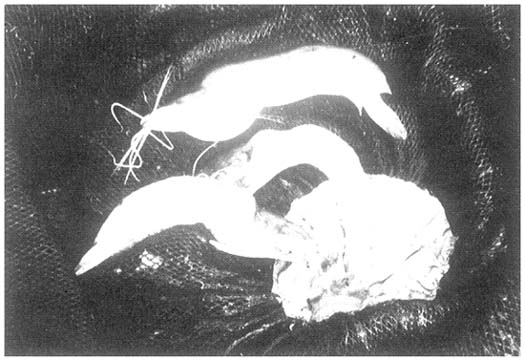

Fig. 15 a. Spinal deformation associated with rarefaction deformity showing the considerable physical malformation exhibited by affected fish.

Fig. 16. Typical water supply layouts in Clarias ponds.

Fig. 17. A typical double crop production cycle for clarias

The determination of the quality of the water supply, and the farmer's ability to control the quality of water in the ponds may be particularly difficult, and one of the farmer's greatest problems may be deciding whether to keep a pond's present water or flush it with supplies of possibly poorer quality.

Stocking Rates and Mortalities

One of the most common problems in clarias culture is the overstocking of ponds with fry. While this is understandable on the grounds that the farmers always wishes to have enough fry in the pond to take advantage of the water and feed available, there is ample evidence from other areas of the world, and in Thailand itself, that an individual pond has limits to the number of fish it can carry. Stocking beyond this limit causes mortalities, often by disease, often indirectly by poor environmental conditions, until the stock falls below the limit of capacity. While it is true that the dead fish are not completely wasted, the current cost of fry or fingerlings makes them very expensive feed for the survivors. Worse, if as a result of the high stocking infectious diseases get a chance to become high pathogenic, very large numbers of stock can be lost.

If the pond is stocked at the correct level, however, mortalities are normally kept low, the risk of disease is generally lower, and the total stock costs are considerably reduced. If one considers an average stocking rate of 200–300 fry and fingerlings per metre2, a typical final production rate of 100 tonnes per hectare per annum (tpha) of 120–150 g fish implies the survival of 66–83/m2 or a survival rate of 22–42%. In other words 58–78% of the farmer's initial investment in stock is wasted due to mortalities.

The situation is in fact likely to be more serious than merely a loss of stock. Mortalities are likely to occur at several stages in the production cycle and thus the food given to the fish prior to their death is wasted. Even assuming that the other fish eat these mortalities (which may spread diseases further), the simple budget in Table 1 shows the possible loss of food.

A further point to consider is that excessive stocking densities tend to reduce growth rates, due to parasitism and other factors, as shown in Fig. 18, and therefore the production period may be prolonged. It is notable that farms in Nakon Nayok, using stock densities of 50% of those used in the Suphanburi area, normally manage to produce 3 or 4 crops per year as opposed to 2 in Suphaburi.

On this basis, a stocking rate of perhaps 10–20% greater than the final stock number should be the aim; the lower the better, though there will always be small mortalities during the growing season. In current terms this means a target of about 80–100 fry per square meter at high stock rates, or 25–40 fry per square meter at low stocking rates.

Pond Conditions

The clarias culture system in Thailand is unique in using an anaerobic environment through a major portion of its production cycle. Recent studies at NIFI have shown that in the early stages clarias ponds exhibit conventional patterns of active photosynthesis in aerobic environments with typical diurnal pH, CO2 and oxygen fluctuations and with waste nutrients being taken up in primary production (Fig. 19). The early mortalities observed in clarias culture may be associated with the rapid fluctuations in water quality characteristics in this highly eutrophic system.

Fig. 18. Stocking density, growth, mortality and risk.

Fig. 19. The aerobic system in clarias ponds.

Table 1

FOOD LOST THROUGH MORTALITIES

| Days | 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 |

| No/m2 | 250 | 175 | 175 | 150 | 150 | 125 | 75 | 75 |

| Wt. | 5 | 15 | 40 | 60 | 100 | 120 | 140 | 150 |

| Wt. loss | 10 × 75 750 g | 25 × 50 1250 g | 25 × 110 2750 g | 50 × 130 6500 g | ||||

| Food loss/m2 | 3750 g | 6250 g | 13750 g | 32500 g | ||||

| Loss value of fish | 750 g | 1250 g | 2750 g | 6500 g | ||||

| F.C.R. | 5.0: 1 | |||||||

| Total | ||||||||

| Net loss/m2 | 3000 g | 5000 g | 11000 g | 26000 g | 43000 g | |||

| Net loss/ha | 30 t | 50 t | 110 t | 260 t | 430 t | |||

| Total food used | 75 × 150 × 5 | = | 56,250 g/m2 |

| = | 562 t/ha | ||

| \ Food lost | = | 430/562 × 430 = 43% |

After about 6 to 10 weeks from first stocking the pond system starts to go anaerobic, presumably due to the blocking out of sunlight caused by accumulation of suspended solids. From this point onwards the system appears to remain continously anaerobic, with at the most a very thin aerobic layer at the surface. Although such ponds have not been studied fully, in this condition, it is expected that conventional anaerobic processes will occur, as evidenced by the release of H2S (Fig. 20). Paradoxically by conventional experience, clarias has a tolerance for the chemical characteristics of an anaerobic system, and appears to grow well, at least in the early stages of the anaerobiosis, suggesting the benefit of the greater environmental stability, occuring after the changeover period.

As the culture season continues, however, the mortality levels appear to increase, presumably as levels of either NH3, H2S, solids, or some as yet unidentified factor reach the levels of tolerance of the fish, and the anaerobic system reaches the limits of its ability to support the stock. As Fig. 23 shows, the processes involved are unable to remove NH3, H2S, or solids from the environment and at these levels the fish will be sufficiently stressed to allow ready invasion by any opportunist pathogen.

The effect of feeding on the pond conditions may be very marked, as overfeeding, and excess decomposition of food increases levels of NH3, H2S, solid and organic matter. Food is often fed in controlled quantities by moulding the paste into hand-sized lumps which are fed successively until the fish no longer respond to the food. In practice, if hired labour is used there may be little control of the amounts fed, and considerable waste and unncessary fouling of the water may occur if the fish do not feed. As fouling may further reduce the fishes feeding response, this may have severe cumulative effects.

Fig. 20. The anaerobic system in clarias ponds.

Fig. 21. Relationship between actual feeding rate and observed growth rate.

Fig. 21a. Comparison between actual feed rate and ‘idealised’ feed rate.

Fig. 22. Typical feed rate/growth rate/temperature relationship.

Judgement of feeding quantities is not normally standardised, though “rules of thumb” exist, in terms of amounts fed during each month of growth. These are generally based on pond area, and are perhaps influenced by a neighbouring farmer who has already raised clarias. If this practice is followed, it is clear that at the beginning of each month the fish may be overfed, while towards the end of the month the fish become underfed as their weight has increased.

Thus recent studies at NIFI suggested that stocks were considerably underfed at some stages in their growth (Fig. 21), and therefore a size-related feeding curve as shown in the figure needs to be developed (Fig. 22).

Pond Management Procedures

The aim of effective pond management is to manipulate the pond environment and control the food supply to maximise the growth of the fish, minimise mortalities, and reduce the costs of production. The full guidelines to good pond management in clarias farming are yet to be worked out, but a number of sensible procedures can be described. Work at NIFI is currently under way to help to define these more clearly.

(a) Stocking and growth. The earlier section has already referred to the need for reducing the number of fry stocked. Experience in other forms of clarias production suggests a good potential for lower stock rates, higher growth rates and lower proeuction costs; and the farmer would be advised to alter his farming practice on these lines, even by operating a single small pond initially as an experiment.

It is useful to compare stocking practices in Suphanburi and Nakon Nayok farms, as in Table 2.

Although clarias can become disturbed by netting, it is a useful procedure to net out sample batches of fish at periodic intervals (preferably at least every two weeks), either by seining or using a dip net and bait. This allows the operator to determine the average growth rate of his stock, and to estimate the daily quantities of food required. This also allows assessment of overall stock weights and estimation of the daily quantities of food required. The overall stock weights and densities may then be determined to indicate whether the pond is likely to become overloaded.

Table 2

COMPARISON OF CLARIAS CULTURE IN TWO AREAS OF THAILAND

| Suphanburi | Nakon Nayok | |

| Pond size m2 | 400 – 1800 | 400 – 1800 |

| Stock rate fry/m2 | 177 – 300 | 44 – 93 |

| Food input kg/m2 | 23 | 17 |

| Production kg/m2 | 9.6 | 4.0 |

| F.C.R. | 5.35 | 4.26 |

| Fry/kg production | 18.5 | 11 – 23 |

This procedure is likely to become particularly useful once more is known about ideal pond conditions, and it may also be used for multicrop production or grading to other ponds (see later).

Using the regular sample weighings, growth rates can also be calculated. This can serve as a means of assessing the effect of management procedure eg. checking the effects of stocking density feed rates, etc. Growth rate is conventionally expressed as SGR, Specific Growth Rate:

| Wf | = | Final weight |

| Wo | = | Initial weight | |

| _ T | = | Time interval |

Using this figure, expected weight at future time can also be estimated to enable the farmer to match against actual performance and to predict the time of attaining harvest weight.

Another useful measurement is the range of size of the crop (size distribution) as this affects the overall optimum feeding rate, and the percentage of the crop likely to reach the harvest weight at a particular time. This also gives the farmer the potential to use multiple cropping, or grading of stock. It is likely that different pond conditions and stock densities will affect size distribution, and it will be useful for the farmer to find out which conditions have the greatest effect, as this will enable him to control his fish size more accurately.

(b) Feeding: There is already a move in some areas towards the use of pellet foods, which if properly formulated can give good and efficient utilisation, good growth, and a minimum of waste. Whatever type of food is used, records of the amounts and type used, together with fish's growth rate should be kept, to allow the farmer to determine the efficiency of food conversion. As well as indicating the effectiveness of feeding and the overall health and performance of the fish, the food conversion ratio is an important economic indicator, and a means of cost control in production.

There may be some benefit in altering the way in which feed is presented, for example by increasing the number of daily feeds, or by experimenting with feed distribution bags or baskets. The effectiveness of these changes can be measured by the food conversion ratio. Trials with different types of feed can also be done in this way; it will be particularly useful to find alternatives to the present “fattening” diet which is the cause of certain health problems.

It should be noted that any food not converted by the fish is not only wasted, but also contributes to the deterioration of pond water quality. Thus for trash fish feeding, if the minimum possible FCR is 3.5, an FCR of 4.5 implies that 20% of the food given adds directly to the loading in the pond without benefitting fish growth, or put in another way, almost one tonne of expensive additional wastes are produced for every tonne of fish grown. Thus the FCR is a vitally important index of performance.

(c) Pond environment/water chemistry. The critical environmental factors for clarias are discussed in Chapter 1. The complete characteristics of the tolerance of environmental condition by clarias are currently being research in detail at NIFI, though it is probable that the conditions of high ammonia, H2S, and solids levels, together with continued low oxygen levels, contribute jointly to stress conditions where the fish become more susceptible to diseases as described in the earlier chapters. Until more accurate factors are determined, the farmer must aim to keep the pond environment as good as possible within the constraints of his production system, and also avoid sudden changes in conditions; it may be better to maintain uniformly poor conditions, for example, than to stress the fish suddenly by mixing in fresh water of a different temperature.

Oxygen

The oxygen levels in the pond are frequently zero, particularly during the late stages of growth. Oxygen is supplied to the ponds mainly by the photosynthetic actively of the phytoplankton in the pond and is dependent on the type and density of organisms present. During the night-time respiration cycle, oxygen is taken up and CO2 produced. This in turn affects pond pH. The fish consume oxygen to metabolise the food eaten and to provide energy for activity; when it is unavailable in the pond, clarias is able to use aerial respiration.

Ammonia

Ammonia is produced as an end-product of protein metabolism, and is almost directly related to the protein in the food utilised by the fish (a proximately 0.02 – 0.04 times the food fed is excreted as ammonia). This is wasted directly through the gills of the fish. It is possible, though not definitely ascertained, that clarias may discharge urea instead of ammonia when external ammonia concentrations rise excessively in ponds. This however is likely to require more energy, will reduce effective growth, and may stress the fish over long periods of time. Unfortunately, bacterial activity converts the urea to ammonia eventually and so overall ammonia levels are unaffected in the long term.

Nitrite

Nitrite may accumulate in the pond if ammonia is only partly oxidised to nitrate and may cause toxic effects: NH3 NO2 NO3. This is most likely to occur during the transition from aerobic to anaerobic conditions, when normal bacterial processes are interrrupted, or if chemicals are used during the early stages, and may result in sudden toxicity problems.

Carbon Dioxide

Carbon dioxide is produced in the fish's respiratory processes in approximately the same amount as the fish's oxygen consumption. As described earlier, it is also important in the photosynthesis/respiration cycle. Its presence in the water is determined by the pH and the dissolved carbonate and bicarbonate salts.

Hydrogen Sulphide

Hydrogen sulphide and methane are produced by the anaerobic break-down of the organic matter in the uneaten feed and solid wastes. The quantities produced depend on the overall amount of sulphur (normally in proteins and fats) and carbon (in proteins, fats and carbonhydrates) present in the system.

Fig. 23. Inlets and outlets

Suspended Solids

The suspended solids and organic matter in the ponds arise from uneaten food, solid matter, and decaying pond organisms. It appears that at sufficiently high levels a considerable bacterial community builds up, containing large numbers of pathogens. As the organic material breaksdown, further oxygen is required in aerobic system, or digestion proceeds anaerobically. In clarias ponds, although much of this material can settle to the base of ponds, the activity of the fish continually resuspends the solids. The layout of inlets and outlets (Fig. 23) is important in providing for the flushing out of solids where possible. As the solids often contain nitrogen and phosphate nutrients, they are a potentially useful fertiliser, and much may be gained by removing them from the pond.

The measurement of ammonia, nitrite, solids, dissolved oxygen and pH can be done quite simply using physical or chemical methods (see appendix) and once we have more definite information on specific lethal levels, the farmer can gain advance notice of probable dangers to his stock. When water quality particularly poor, the farmer normally has the option of changing water, or as a short term measure, reducing the accumulation of wastes. As more information becomes available on the ability of ponds to wastes acceptable.

The chemistry of replenishment water is also important and the same type of measurements may be to use “test fish” such as tilapia, or even other clarias or Ophicephalus, held in a small cage in the water supply area. Care should be taken to avoid sucking out excess solids from the water supply source and so inlet pipes should be held near the surface and disturbance should be minimised.

Improvement of Water Quality

Aeration: This might appear to be the most simple way of maintaining oxygen levels and oxidising waste produces to relatively harmless products. However, it is necessary to consider the amounts of oxygen required and the capacity of the ponds acting as aerobic systems to oxidise the wastes. Typical aerators are shown in Fig. 24.

An estimate of the oxygen required for the clarias can be made from oxygen consumptions of other farmed fish, ie. 0.05 × feed rate dry matter (eg. kg/day). Thus a pond of 0.1 ha with a stock of 5 metric tonnes ( ie. 50 MT/ha) of fish, fed at 3% body weight, will consume approximately 0.05 × 150 kg = 7.5 kg O2/day. The amount of oxygen required in the short term to oxidise the organic wastes can be assessed on the basis of the BOD (biochemical oxygen demand) produced, which could be up to 10 times this figure; UOD (ultimate oxygen demand) is in turn normally greater than BOD, and here a total O2 input of 70–80 kg/day could be required. Preliminary results at NIFI, however, suggested that 10 kg O2/day would be required in total, though this may be because wastes were not being fully oxidised.

Comparison of aerators:

These can be evaluated in terms of

kg O2 added/hour

kg O2 added/Kw power

Factors such as dueability, reliability, damage to fish, mixing effects, etc. must also be considered.

Fig. 24. Typical aerator design.

Reservoirs may be either single-compartment or split into three stages as shown. The three-stage system may allow additional fish production as well as accelerating the improvement of the water. Capacity and operating cycle of the reservoir depends on the stock in the other ponds, and the intensity of feeding.

Fig. 25. Reservoir ponds

On the basis of conventional aeration supplying 10 kg O2/day, inputs of about 5 kw/kg O2 are required for the more efficient units and hence a daily power requirement of 50 kg, which would cost ฿50/day (at 1980 prices) for maintaining a stock of 5 MT. Overall operating costs would be ฿50 × 1120 × 10,000 = ฿0.6/kg, plus approx. ฿0.1/kg capital charges for the aerator, on a 10 MT final crop. If additional O2 is required for BOD removal, the cost will be correspondingly greater and may thus be beyond the means of the average farmer.

For emergency aeration use it could be useful to consider setting up a long-tail pump to return water to the pond via splash some photosynthesis could be encouraged, depending on the levels of solids found to critical. The use of filters, however, would have to be considered carefully in term of:

The available, or expected water source/quality

The amount of use of the filter, and hence the maximum solids load on the filter (the amount possible depends on the void space of the material surrounding the plate) if fine filtration is desired, capacity is less-typical ranges might be 50–500 kg solids/m3 filter volume pumping power required increases as the filter blocks. Filling a 0.1 ha pond with water of initial solids concentration 400 mg/l at a removal rate of 80% would yield 320 kg of solids. If the interval between use is sufficiently large the solids will break down, through endogenous respiration and the filter become more open once again.

Reservoir Ponds: Until a clearer idea of the water quality limitations for clarias is obtained, it is difficult to determine the best way to use a reservoir pond, as the number of water changes required in the culture ponds, the quality of water supplied to the reservoir, and the time the water spends in the reservoir prior to use, will all have some bearing on the design. The operation of the reservoir may be estimated by comparing with conventional waste treatment lagoons or oxidation ditches, where a typical retention period of 5–10 days would be required. As solids would accumulate in the reservoir they would require regular removal. Possible layouts and cycles are shown in Figure 25.

Another way of providing reservoir capacity is to deepen boards or ridged troughs. This would save the additional capital investment required for aerators.

Encouraging Photosynthesis: The possibility of maintaining photosynthetic activity, by reducing shading or preventing dominance by anaerobic species, might have some prospects, as only supplementary aeration may be required. Recent work in Ictalurus culture has shown that good mixing of pond waters during the day can eliminate many of the problems of night-time respiration by ensuring that oxygen-saturated water is moved to all strata during the day, and so overall energy requirements for oxygenation could be considerably less.

It would be useful therefore to monitor more closely the occurrence and distribution of planktonic species and water quality during the period of transition between aerobic and anaerobic activity. Thus toxic effects, for example, or the stimulation of organisms by nutrient composition could be identified and possibly corrected. A trial using aeration at this stage to attempt to continue the period of aerobic activity would also be useful.

| Calculation of water required: | 1) Area = 0.1 ha. depth = 1.5 m, V = 1,500 m3 |

| 2) Food input relative to M, stock wt. a) 1 t, early stage 60 kg/day b) 5 t. ongrowing 150 kg/day c) 10 t, harvest 200 kg/day |

| Water exchange

1 change/day = 1,500 m3/day = 0.017 m3/sec |

3) Using ammonia level as the limit: Ammonia production = 0.03 × food input |

4 changes/day = 6,000 m3/day = 0.068 m3/sec. etc. | 4)Concentration = = 1.2 mg/l. early stages = 3.0 mg/l. ongrowing = 4.0 mg/l. at harvest |

Fig. 26. Use of flowing water

Filtration/Water Treatment: The concept of filtering replacement water or holding waste water, treating it, then returning it to the clarias pond could be quite useful, though the main effect will be to remove solids from the water, NH3, and BOD being relatively unaffected, as there is in most cases insufficient oxygen for the filters to act in the conventional biological manner. The removal of solids, and the BOD associated with them, would of course improve the conditions in the pond, and if shading is a cause of difficulty the ponds. Provided the water is well mixed this should improve the overall ability of the pond to maintain water quality. Thus, a pond with depth of 2.5 m has a 66% increase in critical capacity over a 1.5 m pond.

Flowing Water: In areas where an irrigation water supply is available, the provision of flowing water of good quality can improve conditions considerably and wherever possible its use could be encouraged. The relationship between inflow and pond water quality is shown in Fig. 26. If water has to be pumped, however, continuous operation may be too costly; at, eg. 1 meter head, changing the water daily in a 0.1 ha pond, 1 meter deep, would require a power consumption of 250 to 500 w depending on pump efficiency, or 6 to 12 per day at ฿1/kwh, which amounts to ฿720 to 1440 per crop (120 days) or 0.07 to 0.14/kg of fish on the basis of a 10 MT crop, plus capital costs of the pumps. Costs could be correspondingly more if water exchange was increased, as determined by inflow water quality and desired pond water quality.

Production Planning: In the longer term, it may be possible to reduce the overall environmental stress on the fish by managing the ponds to produce the same overall quality of fish but with less stock held at any time, by the use of sequential cropping. This makes the most efficient use of the pond, and ensures that the pond is never overstocked. Suggested methods are shown in Figs. 27 and 28. It must be noted, however, that satisfactory methods of part-cropping must be developed to avoid damaging the stock.

Thus, by introducing 100,000 fish in April, and by removing the larger fish according to the size distribution, a total production of 12–15 tonnes can be obtained from a 0.1 ha pond with a capacity of 10 tonnes. This same system can be used to reduced stress by limiting capacity to 6–8 tonnes (ie. reducing typical stocking densities to 60–80%), with the yield same as at present, 10 tonnes.

The method of planning relies on the size distribution, as above, and the maximum stock limits, thus:

| Month | Time | Wt. | Size Class | Maximum stock No. permissible |

| April | 1 | 10 | A | 1,000,000 |

| May | 2 | 33 | B | 300,000 |

| June | 3 | 66 | C | 150,000 |

| July | 4 | 100 | D | 100,000 |

| August | 5 | 150 | E | 66,700 |

Fig. 27. Production planning in a single pond

By moving fish at specified internals, considerable gains can be made using as before 0.1 ha ponds, with capacity.

In this example

Fry are brought in from March - May

Harvest from early June - mid August

A planning table can be drawn up, as follows. Stock in each

pond at a particular month are coded as: number, previous pond,

(if different), and size class.

| H = Harvest, T = Transfer | |

| 150,000 fish, from pond 1 size class B (10–33 g) |

Thus, in this cases, 150 tonnes of fish are produced from a capacity of 60 tonnes.

Fig. 28. Production planning - using a system of ponds.