0093-B1

Alois Skoupý[1]

Power saws require a relatively large amount of oil for their operation, because of the need for idle lubrication of the cutting chain. Oil leakages in the environment can result in soil and water contamination and are known to affect both flora and fauna. Many countries in Europe struggle to minimize the damage by imposing the use of biologically degradable oils for these purposes. This paper presents an assessment of these biologically degradable oils from the viewpoint of their possible occurrence in the environment and from the viewpoint of their technical characteristics, which affect the reliability and economy of work with power saws. Oil dispersion is evaluated, especially from the viewpoint of the concentration of its occurrence on the soil surface after cutting with the power saw. Technical properties evaluated include heat-oxidation stability and pumping properties of oils at low temperatures. Original methods of measurement have been developed for these purposes. The study looks at oils with core technical parameters that are comparable with the mineral oils used so far, but which would represent a lesser burden on the natural environment.

Forest machines use oils both for operational filling of their engines, gearboxes and hydraulic mechanisms, and for a so called idle lubrication of chain cutting parts of power saws and other machines employed in timber felling.

Oil used for idle lubrication gets into forest environment directly and completely. This oil is more or less evenly dispersed and it is oil dispersal that is discussed in the first part of the paper. The second part is devoted to the issue of lubricating capacities of these oils, their applicability at low temperatures and polymerization which is one of frequent reasons of the failure in oil pumps and entire cutting parts of machines.

Use of mineral oils for idle lubrication and as pressure fluids in hydraulic mechanisms was prohibited in the Czech Republic by Forest Law (no. 289/1995 Gaz.).

This was why a number of firms carrying out logging operations in the forests had to face sudden economic and technical problems the solution of which was contributed to by works whose results are summarized in this paper.

The goal was to achieve a condition when the biologically degradable oils have comparable technical parameters at adequate price. The requirement was gradually best complied with by oils based on rape oil with additives ensuring that all studied parameters are comparable with mineral oils and the risk of defects and breakdowns is kept at a low level.

The issue called for detection, verification and development of own original methods enabling a complex technical evaluation of oils.

The issue of harmful impact of oils on natural environment was studied in detail by many authors. Significant in this sense can be considered works dealing with the comparison of mineral and rape oils, possibly of other vegetable oils, and with the testing of their biological degradability and some other technical properties (e.g. Battersby and Morgan 1997; Wightman et al. 1999; Asadauskas, Perez and Duda 1997; Asadauskas and Erhan 1999). Lauhanen et al., (2000) measured possible harmful effects of mineral oils on forest environment in the course of several years and calculated that for a motomanual felling of 200 cubic meters of Derbholz (timber to the top of 7cm over bark) per hectare a power saw will require 20 litres lubricating oil which gets into the forest environment. In their study they focused on the detection of impact of mineral, rape and tall oils on the transplants of forest tree species and on forest soil. They found out that the degradability of tall and rape oils is clearly faster than that of mineral oils both in the laboratory experiments and in the field. Each of oils (mineral and vegetable) applied at a dose of 32 tons per hectare caused growth retardation up to increased mortality in Scotch pine (Pinus sylvestris) and birch (Betula alba) while a dose of 20 litres per hectare did not result in any particular change. A dose over 32 tons oil per hectare resulted in the increased concentration of Fe and Zn in leaves of live transplants.

Oil dispersal in natural environment was studied and testing of oils for wear of cutting part in power saws was made by the Department of Forest and Wood Technology, Mendel University of Agriculture and Forestry (MZLU) in Brno in the period 1988-1997 (e.g. Skoupý 1990; Skoupý, Pøibyl and Ulrich 1992; Skoupý 1995; Skoupý 2000). A total of 33 oils were tested for lubricating properties (of these 4 mineral oils). Results of some oils were verified in pilot operation. The tests revealed that from the viewpoint of operating suitability of vegetable oils it is their heat-oxidation stability parameters that are decisive together with their pumping properties at low temperatures.

This has been corroborated by Erhan and Asadauskas (2000). These authors make a general statement about lubricants based on vegetable oils being much faster biologically degradable as compared with lubricants made of crude oil; their other technical characteristics are however worse. Most critical appear to be their oxidation stability and difficulties with their pumping at low temperatures. These problems can be only partly mitigated by using lubrication additives.

A radio-indicator method was developed to measure oil dispersal, which makes it possible to do oil dispersion quantification immediately after cutting. There was a total of 42 measurements made on spruce and beech cross-sections of diameters varying from 10 to 30cm with three oils of different viscosities. Measured variables were absolute amount of oil on the soil surface, in sawdust and on worked timber. Formulations were expressed for mutual relations. Oil concentration was measured on the soil surface under the point of cut.

Having had tested and declined the method of KFW (Kuratorium für Waldarbeit und Forsttechnik)-draft standard ISO 3016 for classification of oil flowing property at low temperatures, an own method was developed which makes it possible to classify pumping capacity of oils and to define minimum applicable temperature to accuracy of 1°C. Oil is pumped through a constriction hole at a defined underpressure from a container in which it was temperated with the measured parameter being time required for pumping of 5ml oil.

The KWF method of assessing heat-oxidation degradation (ageing) of oils (draft ISO 3016) was found to be inapplicable, not giving repeatable and interpretable results. Therefore a method was developed in which the to-be-tested oil was applied onto the testing bodies (fitted rollers with inserted pistons, H7/g5) whose contact surface was 10cm². The number of ten testing bodies was then exposed to a temperature of 80°C for a time period of 168 hours with the following procedure being the forcing-out of pistons from the rollers. Magnitude of strength required for the failure of polymerized oil is measured by a strain gauge.

It was found out that oil is captured in sawdust at 55-85% with 3-15% of it remaining on timber surface and 10-35% getting onto the ground. Relative amount of oil on the soil surface decreases with the increasing diameter of cut timber although -as a matter of fact- the absolute values increase (see examples in Graphs 1 and 2).

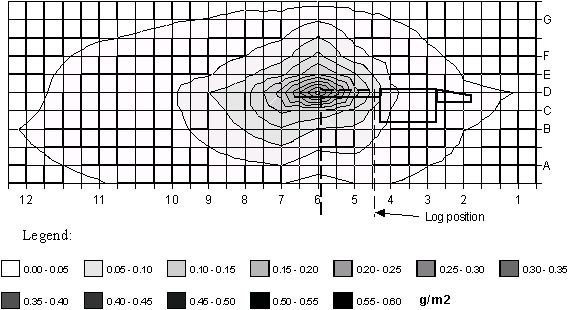

Average oil concentration on the soil surface grows with the increasing log diameter reaching values ranging from 0.01 to 0.1g.m-2. Maximum concentration of oil under the point of cut amounts to 0.05-0.65g.m-2, occurring on a spot whose surface is several tens of square centimeters at maximum. A typical shape of oil stain including measured concentrations is illustrated in Graph 3 with delineated positions of the sawn sample and the power saw. Table 1 preceding Graph 3 presents actual oil concentrations measured on individual measuring points on an area of 1 x 3m.

Figure 1 Dependence of oil weight on the diameter of spruce sample sawn

Figure 2 Relative distribution of OA M6A oil in sawing spruce, oil supply 6ml.min-1

Table I.

|

Species |

Spruce |

Air temperature (c°) |

21 |

|

Diameter (cm) |

29.5 |

Wind velocity (m.s-1) |

0 |

|

Moisture (%) |

41.8 |

Weather |

half covered sky |

|

Oil |

OA M6A |

Time of sawing (s) |

10.2 |

|

Oil pomp set/up |

Stage No. 4 |

Oil total (g) |

0.241 |

Oil concentration g.m-2

Figure 3 Oil concentration on soil surface

Table 2 presents mean and maximum measured oil concentrations on the soil surface by oil types and species with oil supply being adjusted at 2nd degree, i.e. ca. 6ml oil per minute.

Table 2 Mean and maximum oil concentrations on soil surface in g.cm-2

It was found out by testing the same method of oil dispersal measurement at felling that 75-77% of oil were absorbed by sawdust, 7-13% adhered to the surface of cut timber, and 12-16% got onto the soil surface. Average oil concentration on the soil surface ranged from 0.06 to 0.1g.m-2, maximum soil surface concentration did not reach 0.5g.m-2.

The radioindicator method was tested also at delimbing the trimmed tree. Here it was found out that sawdust can absorb more than 50% oil with about 15% oil remaining on the delimbed stem and 32-35% oil getting onto the soil surface (including slash). It was further found out during the measurement that some 0.5% of total oil gets onto the garments and shoes of the operator: in absolute amount it was 0.1g after debranching a 6m long crown portion of spruce. Of this amount 60% of oil were detected on trousers, 24% on right shoe (up to ankle) and 8% on left glove with the remaining oil being found on other parts of operator's body surface. An amount of 0.001g oil was detected on the respirator; of this amount some could have been inhaled. The amount is 50 ppm of total oil used for delimbing.

Oil was pumped under a pressure of 13kPa. There were 5 series of measurements made for each oil with the temperature of cooled oil gradually increasing. All series had measurements repeated at least ten times within a temperature range from -25°C to +2°C.

The course of time required for oil pumping as depending on oil temperature was fitted with hyperbolic functions of which the following shape complied best with all oils:

Figure 4 Determination of pumping capacity limit in a sample of vegetable oil

Pumping capacity limit for the use of oils at low temperatures was determined so that the pump must suck in at least 5ml oil in 60 seconds under a defined underpressure. The method of evaluation of the measured dependences clearly follows out from Fig. 4 with an example of one of the tested vegetable oils whose limiting temperature for pumping is -15°C. A total number of oils tested was 19, of these two mineral. It was demonstrated that the limiting temperature for pumping all tested oils was below -5°C. Four of these oils can be safely used at temperatures reaching -20°C. Differences between the limiting temperature determined in our experiments and limiting temperature declared by manufacturer were in some cases greater even by 15°C - at all times to the detriment of oil.

There were 10 types of oil (see Fig. 5) of which two were mineral (OA M6A and CHAIN OIL SUMMER), one was a special blend of biodegradable and partly mineral oil (ECOLUBE CUT 80P) and 7 were biologically degradable oils. With respect to friction which can be responsible for a considerable distortion of results, the measurements were at all times made with the fresh oil first and then with the polymerized oil. Results presented are differences between the two measured values. The limiting force required to disengage the testing piston from the cylinder or the magnitude of stress induced by oil polymerization has not been determined so far. To do so, it will be necessary to consult the issue with manufacturers of power saws. The value should be set up in such a way that the oil pump does not suffer any breakdown or another loss of proper functionality in consequence of oil polymerization and this will depend both on the design of the oil pump and on materials used in the gear mechanism to drive the pump.

Figure 5 Results from the measurement of forces required for the failure of polymerized oils

Fig. 5 presents the results of measurements after statistic elimination of gross errors by using the Grubbs test.

It is possible to make a statement that oil concentration on forest soil surface at normal work with the chain power saw in the stand cannot reach values that could have a significant impact on the soil flora and fauna. Neither it is possible to speak of any influence on timber production. Contamination of waters, groundwater in particular comes into consideration at these concentrations only in the case of concentrated oil leakages or spills. More serious contamination of water threatens only in water-logged soils or at cutting timber right above the water surface.

The author assumes however that the use of biodegradable oils such as vegetable oils can be advised for spring areas, spa forests, etc. In all other cases it is logical to require that the technical properties of biodegradable oils are at least on the level of special mineral oils and that it is also their price that could be comparable. Only then the oils can be a real contribution.

The methods of measuring applicability (pumping capacity) of oils at low temperatures and their thermal-oxidation stability based on the comparison of mechanical variables give a very good repeatability of results which are well interpretable. The provided information is therefore fitted for direct practical use and is considered more suitable than other methods proposed for the international standard.

The radioisotope method is applicable in practical use, fast and relatively low-cost. It can be recommended at all places where accurate values of oil distribution in the environment and oil concentration on the soil surface are required. After a relatively extensive verification of the method it is possible to claim that oil concentration on the soil surface resulting from oil dispersal from the cutting part of power saw is 0.5g per m2 at maximum. Sawdust absorbs 75-77% oil, 7-13% oil remains on the surface of cut timber, and 12-16% oil gets onto the soil surface.

As to the classification of applicability of oils at low temperatures and evaluation of their thermal-oxidation stability the author claims that the procedures contained in the draft ISO standard do not give applicable results. The method for determination of pumping capacity of oils has been widely tested and provides statistically significant results which are well applicable in practical use.

The method for evaluation of thermal-oxidation changes of oils is promising; nevertheless, it is to be further perfected and tested.

The paper was prepared within the Research Project of the Faculty of Forestry and Wood Technology, Mendel University of Agriculture and Forestry, No.: MSM434100005 „Sustainable Forest Management. From the Concept to the Implementation."

Asadauskas, S. and Erhan, S. Z., 1999. Depression of Pour Points of Vegetable Oils by Blending with Diluents Used for Biodegradable Lubricants. Journal of the American Oil Chemists Society. 76, (3), p. 313-316.

Asadauskas, S., Perez, J. M. and Duda, J. L., 1997. Lubrication Properties of Castor Oil Potential Basestock for Biodegradable Lubricants. Lubrication Engineering, 53, (12), p. 35-41.

Battersby, N. S. and Morgan, P., 1997. A Note on the Use of the CEC L-33-A-93 Test to Predict the Potential Biodegradation of Mineral Oil Based Lubricants in Soil. Chemosphere, 35 (8), p. 1773-1779.

Erhan, S. Z. and Asadauskas, S., 2000. Lubricant Basestocks from Vegetable Oils. Industrial crops and products. 11, (2-3), p. 277-282.

Lauhanen, R., Kolppanen, R., Takalo, S., Kuokkanen, T., KolaA, H. and Valimaki, I., 2000. Effects of Biodegradable Oils on Forest Machines and Forest Environment. In: Forest and Wood Technology vs. Environment. Brno, p. 203-207.

Skoupý, A., 1990. The Wear Patterns of the Cutting Parts of Chain Saws Lubricated with Rapeseed Oil, Compared with the OA M6A Oil. Lesnictví, 36, (11), p. 959-968.

Skoupý, A,. 1995. Evaluation of Biodegradable Oils for the Lubrication of Power Saw Chains. IUFRO XX World Congress, Tampere, 12 p.

Skoupý, A., 2000. Biodegradable Oils in the Operation of Forest Machines. In: IUFRO XXI World Congress, Abstracts of Group Discussions, vol. 2, Kuala Lumpur, p. 84-85.

Skoupý, A., Pøibyl, F. and Ulrich, R., 1992. Comparison of Lubricating Properties of Some Mineral and Vegetable Oils Used to Lubricate Chains of Chainsaws. Scientia Agriculturae Bohemoslovaca, 24 (XLI), (4), p. 361-371.

Wightman, P., Eavis, R., Batchelor, S., Walker, K., Bennett, R., Carruthers, P. and Tranter, R., 1999. Comparison of Rapeseed and Mineral Oils Using Life-Cycle Assessment and Cost-Benefit Analysis. OCL-Oleagineux Corps Gras Lipides 6, (5), p. 384-388.

| [1] Mendel University of Agriculture

and Forestry Brno, Zemìdìlská 3, CZ-613 00 Brno, Czech

Republic. Tel: + 420-5-45134103; Fax: + 420-5-45211422; Email: [email protected];

Website: www.mendelu.cz |