As indicated, the sources of fruits that can be made into juices are nearly limitless in plants and the plant parts appropriate for juice. However, the fruit producer and juice processor must adhere to some very important guidelines in fruit selection and juice manufacture.

Human selection of plants for their more desirable features has been practiced for thousands of years, initially by trial and error, more recently by scientific knowledge applied to plant genetics and molecular biology. Thus even within a given fruit there are numerous varieties available including some derived from the wild, others specifically developed by breeders and combinations of both. Recent advances in understanding the molecular basis of plant genetics and how the genes and growing environment influence traits, promises to revolutionize agriculture, once the politics and emotions are resolved.

Fruits originating in the wild have evolved to be reasonably robust and resistant to natural environmental stresses, diseases, insects and other predators. These traits, however, do not necessarily favour concentrated production systems or edibility. The exception is if consumption by wildlife promotes pollination or seed dispersal. Human population pressures further impact upon native plant species, therefore except for exotic plants remote from civilization, most fruits are substantially removed from their origin in time, genetics and location.

Special cultivars, developed with criteria such as yield, location adaptability, resistance to disease, insects, drought tolerance, harvest period, ease of cultivation and harvest, handling and storage durability, processing characteristics and sensory appeal (colour, taste, aroma, texture) are characteristics now determined by commercial breeding practices (Table 5.1). Juice quality considerations are also important in many fruits such as citrus, grape, apple, pineapple and others. Specific cultivars dominate the juice trade, while others are preferred for the fresh market. Some cultivar end uses are dictated by fruit supply, condition and economics and varies by season, location and market depending upon fruit quality.

Nevertheless, all fruit species include cultivars that are highly inappropriate for juice (or consumption for that matter) such as bitter, intensely sour orange rootstock. Bitter watermelon contains cucurbitacum, a very bitter compound. (The selective planting of bitter melons that have no different appearance to normal melons in a commercial field can discourage watermelon theft.). Mango trees are usually grafted and chance seedlings range from those with deliciously sweet, smooth textured flesh to fibrous harsh terpeney fruit. Some fruit species are even toxic and avoided by experience. It is conceivable, even probable, that such inedible or toxic fruits may possess unrecognized nutraceutical value, but safety and palatability are the present criteria.

Table 5.1: Fruit breeding criteria.

Trait |

Rationale |

Plant hardiness |

Survival, resistance to drought, cold, heat, etc |

Disease resistance |

Plant/fruit survival, reduced pesticide use |

Plant morphology |

Ease of cultivation/harvest |

Fruit morphology |

Ease of harvest/processing, high yield |

Composition |

Quality, economic/nutritive value |

Seasonality |

Availability, market demand/price |

Fruit durability |

Marketing/handling/processing |

Yield |

Economic value |

Flavour |

Quality, value |

Colour |

Appeal, value, by-product potential |

Texture |

Appeal, durability |

Nutrients/phytochemicals |

Value, appeal, by-product |

The condition of a fruit tree or plant throughout the season from flowering to fruit maturation can dramatically influence juice quality. Practically all cultivation parameters can influence quality and composition (Table 5.2). Season, location, fertilizer application, form and timing, irrigation, amount of precipitation, temperature, sun exposure, plant spacing and pruning, disease, insect and predator stress influence fruit quality and yield. In the interest of quality, uniformity and yield, horticulturists constantly strive to overcome unfavourable conditions that may be a fresh, unexpected challenge each year. For the commercial grower there is never an "average" season or crop; quality, prices and supply vary accordingly.

Unforeseen, variations in weather can have a significant effect upon fruit quality, quantity and juice characteristics. Unseasonable freezes or hail can decimate a crop or send fruit destined for the fresh market immediately to the juice processor. Insect and disease damage also affects the fresh marketability of fruits and excess or inadequate rainfall influence juice solids, flavour and composition. In contrast to whole fruit quality, juice variability can be somewhat overcome by blending of juice stocks or amelioration, if permitted.

Cultivation practices also affect regulatory matters and labelling. For example, to label the product "organic" certain very specific criteria must be met, some based on perception more than scientific reality, but extremely important to proponents. As with juice purity regulations, organic standards must be rigorously adhered to as a matter of principle. Thus the use of fertilizer, pesticides, and all agricultural inputs, even timing and location relative to standard agricultural enterprises are carefully proscribed (Organic Trade Assoc., 1999; USDA, 2000c).

Table 5.2: Cultivation factors influencing quality.

Factor |

Importance |

Location |

Harvest period, plant survival, market |

Cultivar |

Yield, desirable juice traits, harvest period |

Plant spacing |

Yield, ease of cultivation/harvest |

Plant care |

Yield, ease of harvest, quality |

Pruning |

Yield, maturation, ease of harvest |

Irrigation |

Fruit/juice yield, quality |

Fertilization |

Growth, designation (i.e. organic) |

Pesticide use |

Fruit quality, designation, regulations |

Field protection |

Yield, quality (bird, varmint damage) |

Field sanitation |

Juice safety, quality |

Labour training |

Fruit quality, cultivation/harvest efficiency |

Cultivation also influences food safety, a topic for ongoing emphasis. In the case of fruit production, organic or otherwise, an additional concern is the use of manure as fertilizer. Food poisoning outbreaks involving juices have been traced back to the use of manure. Fruit that has fallen on the ground, becomes contaminated and is later collected and utilized. Even where manure is not used or is properly treated before application, the potential for fruit contamination by insects, wild life or field workers dictates cautious handling and sanitary practices. Good Agricultural Practices (GAPs) are the first line of defense against such dangers (FDA, 1998; FAO, 2000a and c; Rangarajan, et al., 2000).

A further concern may be pesticide residues. A crop can:

Table 5.3 lists some potential safety hazards associated with crop cultivation. There have been food poisoning cases attributed to all. Increasingly, fruit producers who cannot demonstrate GAPs to their buyers will be at a competitive disadvantage nationally and

internationally. Some governments certify only certain

growers to produce crops for export. Implicit throughout the production chain is

the importance of a quality labour force. Without trained, adaptable, motivated

workers, commercial success is unlikely.

Table 5.3: Juice safety hazards from farm to factory.

Hazard |

Effect |

Response |

Wildlife in field |

Contaminated fruit or containers |

Minimize contact (difficult with birds and varmints) |

Insect abundance |

Fruit damage/contamination |

Minimize by integrated pest management |

Mould growth |

Aflatoxin production |

Careful field and factory sorting |

Water quality |

Spray or irrigation contamination |

Monitor/treat water source |

Manure |

Contaminates crop |

Discard/treat manure |

Pesticides |

Unauthorized or over use |

Train applicators, minimize/monitor use |

Harvest |

Poor worker sanitation |

Train/motivate/monitor workers |

Handling |

Unclean containers/equipment |

Sanitation programmme |

Transport |

Unsanitary containers/transporters |

Sanitation programmme |

All of above |

Unsafe fruit |

Rigorous GAPs |

Receiving |

Contamination at factory |

Enforce GMPs |

Processing |

Inadequate procedures |

GMPs plus HACCP |

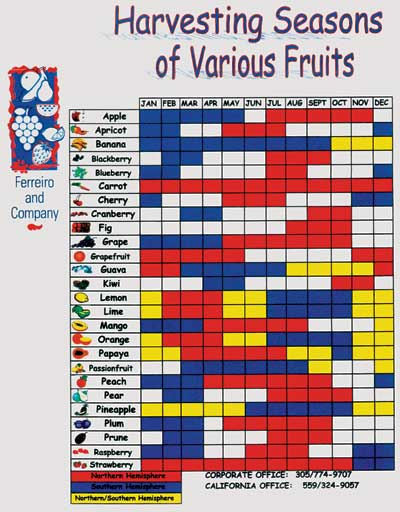

The seasonal availability of fruit is the major determinate for juice manufacturing. Ideally, the maturation of desirable cultivars is either spread over a long period or different fruits can be harvested consecutively so that a juice operation can process for an extended season, if not most of the year. Figure 5.1 indicates the Northern Hemisphere seasons for some major juice crops. Of course, variations in altitude and microclimates can modify or extend the season to some extent. Furthermore, unseasonable and/or variable weather can play havoc with fruit availability and processing schedules. Although the northern and southern hemisphere seasons complement each other (and thus serve global fresh produce demands), the economics of producing juice from ripe fruit precludes such long distance hauling. The operations are best performed reasonably close to production areas. The globalization of the juice trade reflects regional availability.

There is an important distinction between plant maturation and fruit ripening (Kader, 1992). Maturity relates to the full natural development of the plant, whereas, ripeness is the desired stage for consumption or processing. Thus a fruit such as avocado or peach may be mature, fully developed and ready to be harvested, but far from ripe, requiring careful ripening conditions to achieve optimum quality.

Fruit are living structures and undergo complex changes during maturation, ripening and into senescence that influence quality. As fruits mature on the plant or after harvest the composition may change dramatically. Fruits are classified as (1) Climacteric, meaning they have a definite peak in respiratory rate for production of carbon dioxide and ethylene. (2) Nonclimacteric where there is a gradual decrease in respiration and CO2 release (Wills, et al., 1998). Table 5.4 indicates the parameters affecting fruit ripening and Table 5.5 several distinguishing features of ripening.

Figure 5.1:

Harvest season of various fruits, Northern Hemisphere.

Courtesy Ferreiro

and Co. (Brandon and Ferreiro, 1998)

Table 5.4: Factors influencing postharvest fruit ripening.

|

Factor |

Result |

|

Cultivar |

Cultivar-specific response to holding conditions |

|

High temperature |

Accelerates ripening and microbial growth |

|

Low temperature |

Retards ripening, chill injury in some fruits |

|

High oxygen (~21%) |

Increased respiration and ripening rates |

|

Low oxygen (<3%) |

Promotes anaerobic respiration |

|

High CO2 |

Promotes anaerobic respiration |

|

Ethylene |

Accelerates ripening of climacteric fruit |

|

Moisture (Rel. Humidity %) |

>90%, microbial growth; < ~80%, wilting |

|

Contamination |

Losses during ripening |

|

Physical damage |

Speeds up ripening, decay |

Whether these changes occur on the plant or post-harvest, it is important to understand and control them in order to optimize fruit and juice quality. For example, cold storage extends the shelf life of many fruits, such as apples and oranges, so the colder the better (avoiding freezing). In contrast, tomatoes and banana require storage temperatures above 7ºC. Excessive holding at lower temperatures cause irreversible damage referred to as chill injury (higher temperatures are also detrimental). There are well-understood fruit and cultivar-specific holding and ripening regimens for all major fruit cultivars. With minor or exotic fruits, local knowledge and experience is the best guide; there is continual need for focused cultivar and location-specific ripening/holding research (Mitra, 1997).

In general, fruit destined for juicing should be of good edible quality, full flavoured and substantially more mature than fresh market fruit. This favours softer tissues (more amenable to juice extraction and higher yield), higher sugar content, deeper colour and a lesser amount of acid. However, overripe fruit quality is inappropriate as the flavour and acidity may suffer. Also, the fruit's defence mechanisms are diminishing, so incipient spoilage and microbial loads are apt to be higher. One of the major quality deficiencies in small juice operations is due to the use of under or over mature fruit, a propensity to use drops, culls and salvaged pieces.

At this stage the fruit have reached maturity and subject to a finite "harvest window" during which picking must take place. Cultivation and cultivar, as well as climate and weather affect this window. Heavy rains or extremes in temperature hasten or delay harvest and influence fruit quality. Harvest aids, machines and hand-pickers function better in moderate weather, but this isn't always possible. Delays and improper conditions extract a quality, yield and expense toll. Maturity standards as they influence colour, sugars, acid, fruit damage, etc., may be the basis of payment and dictate the end use, i.e. the fresh market, whole processing, juice, by-products, animal feed, or destruction (at supplier's expense).

Even given an acceptable, gentle, timely harvest, attention must be paid to field handling and transportation. Worker's judgement is critical in optimizing picked fruit quality as determined by size, shape, maturity and free from defects. Improper packing into field containers, rough terrain in transport and delays in transit can equally damage delicate or rugged fruit. A further consideration is the danger of contamination by field workers, containers and equipment. The inclusion of plant debris, mud, dust or soil contacting fruit can greatly complicate subsequent cleaning operations.

The major harvesting and handling factors affecting fruit quality are outlined in Table 5.5. A basic tenant of GAPs is that it is easier and more efficient to prevent field, harvest and handling damage and contamination than it is to correct or decontaminate improperly treated produce later in the production chain.

After cultivation there are many parameters impacting fruit and juice quality and safety. Some of these parameters are obvious, others are subtle while there can be complex interactions between several factors. Under most circumstances a fine balance must be achieved between these factors. It is worth emphasizing that extremes in any parameter are to be avoided. The proverbial "happy medium" is an attainable compromise, albeit species, cultivar, fruit condition and process specific (Table 5.5).

Table 5.5: Influence of fruit harvesting and handling on juice quality.

Procedure |

Error |

Result |

Harvest timing |

Too early |

Inadequate flavour and colour development, low yield |

Harvest timing |

Too late |

Incipient spoilage, low quality |

Rough harvest |

Fruit damaged, soiled |

Incipient spoilage, contamination |

Improper packing |

Unsanitary container |

Fruit contamination |

Transportation |

Delayed/hot fruit |

Fruit deterioration |

Rough transportation |

Unprotected fruit |

Damaged fruit |

Temperature abuse |

Too high or low |

Rapid quality deterioration |

Lengthy holding |

Fruit unprotected |

Rapid quality deterioration |

Rough unloading/conveying |

Fruit damaged |

Rapid quality deterioration |