UNDP/FAO PROJECT THA/89/003

FISH NUTRITION AND AQUACULTURE DIETS

by

Ronald W. Hardy, Ph.D.

Northwest Fisheries Center

2725 Montlake Boulevard East

Seattle, Washington 98112 USA

Hyperlinks to non-FAO Internet sites do not imply any official endorsement of or responsibility for the opinions, ideas, data or products presented at these locations, or guarantee the validity of the information provided. The sole purpose of links to non-FAO sites is to indicate further information available on related topics.

This electronic document has been scanned using optical character recognition (OCR) software. FAO declines all responsibility for any discrepancies that may exist between the present document and its original printed version.

TERMS OF REFERENCE

SUMMARY

Amino Acid Analysis by HPLC

Ascorbic Acid Analysis by HPCL

Gas Chromatography (GC) Operation

Computer Formulation of Feeds

Fish Nutrition Short Course at NIFI

Evaluation of Equipment and Facilities at NIFI

Future Fish Nutrition Research at NIFI

General Nutrition Consultancy

Recommendations THAI/89/003 Project

General Recommendations FAO/UNDP Nutrition Projects

Personnel Contacted

Annex A. Partial list of local protein sources obtained for

amino acid analysis

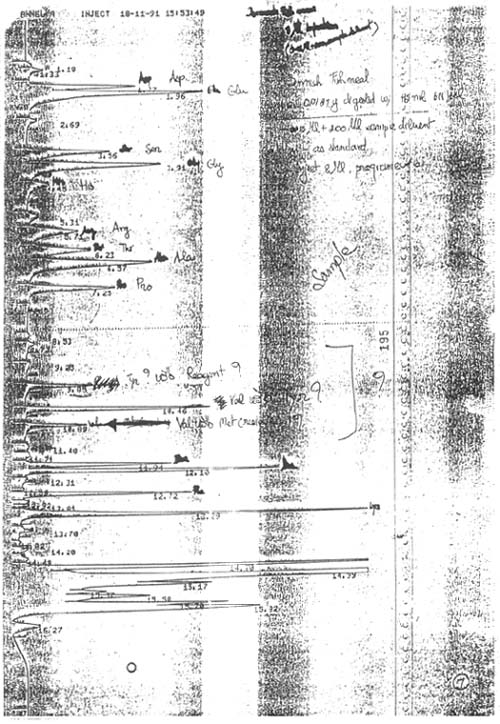

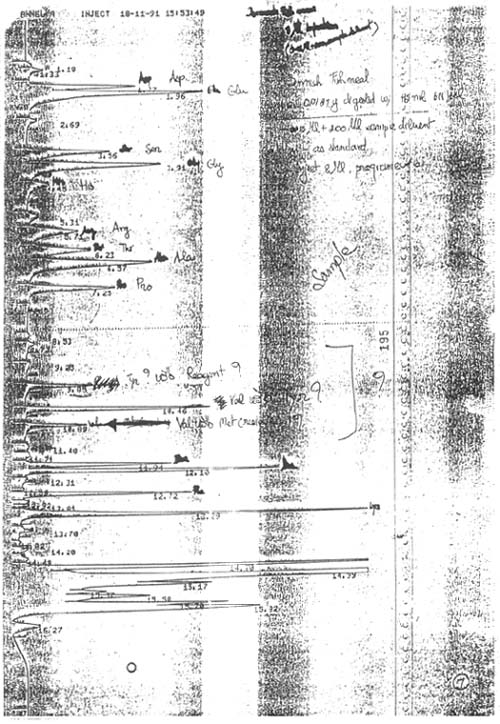

Annex B. Example of chromatography result of amino acid analysis

of feed sample

Annex C. Results of fatty acid analysis of local lipid sources

suitable as feed ingredients

Annex D. Modified procedure for hydrolyzing feed ingredient and

feed samples for amino acid analysis

Annex E. Procedure for analysis of ascorbic acid forms

Annex F. Lecture schedule for fish nutrition short course taught

at NIFI during consultancy

Description of Duties :

Formulate and initiate a research programme to develop optimum dietary feeds for freshwater prawns and marine shrimp including the following:

demonstration of lipid and amino acid analysis techniques for feeds and fish tissue samples

designing of nutritional experiments for juvenile, grow-outs and broodstock fish and crustaceans

advise on feed formulation for freshwater prawn and marine fish.

Provide in-service training of national staff with special reference to lipids and amino acids.

Advise on appropriate equipment and supplies needed for studies on lipids and amino acids.

Submit a technical report at the completion of consultancy assignment.

The terms of reference were discussed with the Government Project Officer (GPC) on arrival and it was decided that the most pressing needs were to provide in service training for government scientists on the methods used to quantify the levels of lipids, amino acids and vitamin C in fish feeds and fish tissues. As mentioned in my 1990 FAO Final Report on the project, this was made more critical by the assignment in August, 1990, of Nanthiya Unprasert to Mississippi State University, where she is pursuing a Ph.D. in fish nutrition and will be occupied until 1993, at least. Until 1990, prior to my consultancy, Ms. Unprasert was the only government scientist in the Fish Nutrition Project at NIFI who had sufficient training to operate the High-Performance Liquid Chromatograph (HPLC) for analyzing amino acids and vitamins, or the Gas Chromatograph (GC) for analyzing fatty acid methyl esters. Therefore, the progress of research at NIFI was slowed after Ms. Unprasert's assignment to Mississippi State University by the lack of trained staff to conduct the required analytical determinations needed to complement the planned feeding trials central to the mission of NIFI and the FAO/UNDP project. Training was therefore provided in 1990 to Dr. Wimol, Mr. Pairat Kosutarak, and Ms. Amornrat Sermwatanakul to establish familiarity with HPLC equipment, especially which elements of HPLC operation were most critical with regard to safety and equipment integrity. In 1991, Dr. Wimol was much more confident on HPLC operation, and no additional training on basic HPLC operation was required other than a brief review of procedures. Mr. Pairat had been sent to Kagoshima University in Japan to study for a MS Degree with Dr. Kanazawa, while Ms. Amornrat was in Vancouver, Canada, studying for a Ph.D. Degree with Professor March. Dr. Supis Thongrod had returned from Tokyo University of Fisheries, where she received a Ph.D. Degree in Fish Nutrition with Dr. Watanabe, and was a new trainee in 1991. Dr. Supis is currently assigned to the Brackish Water Division but may be reassigned to NIFI in the near future. Mrs. Pisamai Somsueb had also returned from a short period of training at Auburn University in the USA.

Upon arrival, HPLC analysis of vitamin C standards and vitamin C in feeds was immediately initiated using two Nova-Pak HPLC columns run in series, which were appropriate for resolving the C1 form of ascorbic acid but not for resolving phosphate derivatives of ascorbic acid. While waiting for replacement HPLC columns to continue work with other forms of vitamin C used in commercial feeds in Thailand, the direction of the laboratory efforts was switched to amino acid analysis. After verification of the HPLC operation by use of amino acid standards, common protein ingredients used in Thailand feeds were analyzed for amino acid content. Concurrent with this effort, the (GC), used for determination of the fatty acid composition of lipid sources, feeds, and fish, was operated to analyze common lipid sources in Thailand. Fatty acid standards were brought and/or send from the Northwest Fisheries Center, Seattle, Washington, to enable identification of individual fatty acid peaks on the chromatograms based on retention times and to verify resolution efficiency. The GC column present in Thailand was a 3 meter packed column, while in modern laboratories, a 30 meter capillary column is used. Despite the differences in resolution capability resulting from differences in columns between Thailand and Seattle, fatty acid peaks of nutritional significance (over 1% of total fatty acids) were resolved within 5–10% accuracy, with most peaks resolved within <5% difference. This degree of resolution is more than sufficient for diet formulation purposes, but is marginally sufficient for biochemical nutrition studies, where differences in fish tissues or lipid fractions may be relatively slight.

Before the end of the consultancy period, the twin Bonda-pak columns were installed, and used to determine the levels of ascorbic acid and ascorbic acid-phosphate in standards and feed samples. In addition, the use of the HPLC for quantification of carotenoid pigments found in shrimp tissues and feeds was demonstrated using standards brought from the consultants laboratory in Seattle, Washington, USA.

The capability of formulating and balancing feeds by computer using feed ingredients available in Thailand was further developed, using data on ingredient proximate and amino acid composition determined at NIFI during this consultancy, and the government staff was trained in the use of the computer software. A review of supplies needed for analyzing samples for amino acids, lipids, and vitamin C was completed for six months of operation, and a list of needs was developed and submitted to UNDP as justification for spending a portion of the remaining budget that had been intended as support for a consultancy in larval feeds. Short-term and long-term planning and prioritizing with regard to feeding trials designed to determine the nutritional requirements of important farmed fish and crustacean species for essential amino acids, fatty acids, and key essential vitamins was completed, and an outline of experiments was developed for future planning needs.

A four-day intensive training course in fish nutrition and feeding was conducted for Government fisheries biologists at NIFI. Each day consisted of lectures and demonstrations of principles of nutrition, and application of these principles in practical feed manufacture, storage, and use.

The terms of reference for this consultancy were for a two month consultancy, although the elapsed time between the starting date and the completion date was greater than two months. Despite this apparent discrepancy, this consultancy did not exceed 60 days. During the consultancy, the consultant was required to return to the USA to fulfill the requirements of his employer, and the dates absent from Bangkok were subtracted from the total period of the consultancy, in accordance with verbal approval from FAO Headquarters in Rome. The costs associated with returning to the USA were not charged to the FAO/UNDP project, and the visit to the USA was used to the project's benefit, because the consultant was able to obtain supplies, information, and standards needed to complete his assignment. These items were either not available in Bangkok, or could not be obtained in a timely manner.

1.1 Amino acid analysis by HPLC of protein sources and finished feeds was identified as the most important need of NIFI for future development of the aquaculture industry in Thailand. There are a number of promising protein sources available for use in fish feeds in Thailand, but there is very little knowledge of the amino acid composition of these ingredients, a critical impediment to the use of these protein sources in practical fish feeds. A list of these protein sources is presented in Annex A.

1.2 Amino acid analysis using the Water's HPLC purchased for NIFI on this project uses a system called the “Pico-tag” system. This system, as the name implies, uses extremely small samples for analysis. The system, and sample preparation and derivatization, is designed to analyze purified proteins, as encountered in medical science and biochemistry, for example. Feed ingredients and pelleted feeds are complex mixtures, and sample preparation requires two elements not practiced at NIFI. They are extreme cleanliness in sample preparation, due to the possibility of contamination of the extremely small (picogram) quantities of samples actually analyzed, and a much larger sample size than the pico-tag system, as described by the manufacturer, generally uses. Therefore, efforts were made to improve the cleanliness of the sample preparation area, which is not vermin or insect proof but should be, and to develop a procedure for sample preparation appropriate for feed ingredients and feeds that used a larger initial sample, using equipment available at NIFI.

1.3 A method of sample preparation appropriate for feed ingredients and feeds was developed. Basically, this involved using other glassware appropriate for exposure to heated, 6N HCI, and working out the proper proportions of sample and acid, using a sample size of 300–500 mg (Details are given in Annex D). Using digestion tubes borrowed from the consultant's home laboratory, a system for preparing hydrolysates was developed and appropriate glassware was ordered for NIFI. The need to defat samples of protein sources containing a high percentage of lipid was investigated, and found to be unnecessary.

1.4 While the hydrolysis procedures were being worked out, amino acid standards were derivatized and analyzed on the HPLC. These analyses were useful training on the various steps of derivatization, analysis, and interpreting the results. Several problems were encountered, and systematically solved, resulting in Dr. Wimol becoming both confident and competent in this area prior to analysis of actual feed ingredient samples.

1.5 Of the feed ingredients listed in Annex A, a total of 10 were analyzed prior to the end of this consultancy (see Annex B for typical result). The remaining samples will be analyzed by the NIFI staff. After actual samples were analyzed for amino acid composition by HPLC, methods of converting the raw data to amino acid concentrations in the sample (expressed as percent or mg/g) were reviewed, and the trainees then did the calculations successfully.

1.6 The data obtained on amino acid composition of commercially important feed ingredients in Thailand will be entered into two computer programs presented to the NIFI fish nutrition programme last year during Hardy's consultancy. This data will be used initially to formulate feeds for experimental work and for formulation testing, but the data, when complete, will be used to ensure the nutritional adequacy of feed formulations developed by NIFI for Thai aquaculture with respect to essential amino acid requirements of fish of interest.

1.7 By the end of the consultancy, a level of expertise was developed at NIFI sufficient to continue analysis of amino acids in feed ingredients, formulated feeds, and fish tissues. This element was therefore completed successfully, with the high likelihood that effort in this area at NIFI will yield benefits to aquaculture in Thailand, and all of Southeast Asia.

2.1 In contrast to the situation found at the beginning of the FAO consultancy in 1990, when the individual NIFI trainees were unable to even turn on the HPLC equipment, let alone operate it, Dr. Wimol in 1991 was able after a brief review to begin preparing HPLC solvents, operate the equipment, and prepare ascorbic acid standards for analysis.

2.2 Analysis of crystalline ascorbic acid standards using a double C18 column method was demonstrated for the trainees by Drs. Hardy and Halver. The columns obtained by NIFI were “Nova-pak” columns, 15 cm in length. While these columns are satisfactory for identifying ascorbic, acid standards, and will separate ascorbic acid from ascorbate sulfate, they are not appropriate for analyzing ascorbic acid phosphate compounds, due to the acidic nature of the packing material, which removes the phosphate, leading to an underestimation of the level of ascorbate phosphate forms and an overestimation of ascorbic acid in standard mixtures and extracted feed samples. Nevertheless, after suitable retention times and recoveries were obtained with ascorbic acid and ascorbate sulfate standards, actual feed samples, to which a known amount of fat- coated ascorbic acid was added, were examined. Samples after mixing and before pelleting, after pelleting, and after drying were extracted and analyzed. Various methods to extract the fat-coated ascorbic acid were evaluated, and the best method was found. Using this method, recoveries of approximately 70% were obtained in the samples before and after pelleting, but only approximately 40% of the ascorbic acid remained after the pellets had been dried. At this point, the efforts to further develop HPLC assays for ascorbic acid and its various commercial forms was temporarily stopped until delivery of two, 30 cm C18 “Bonda-pak” columns, which are the preferred HPLC column for resolving and quantifying the derivatized forms of ascorbic acid.

2.3 After delivery of the appropriate “Bonda-pak” HPLC columns, and after completion of a sufficient number of samples for amino acid analysis to ensure the expertise of the NIFI personnel, the HPLC effort was switched to ascorbic acid analysis. Procedures sent from the USA by Dr. Halver after completion of his consultancy were adopted, and ascorbic acid standards he sent were used to determine retention times of the new columns for the ascorbic acid forms of interest.

3.1 The presence of Dr. Supis Thongrod provided a well-trained individual in extraction of lipids, methylation, and fatty acid methyl esters analysis using gas chromatography. NIFI did not have any mixed fatty acid standards, however, so I brought several from my laboratory in Seattle. In addition, I had a known sample of fish oil, methyl esters prepared from this fish oil, and a complete fatty acid analysis shipped from Seattle to NIFI. After arrival of these materials, it was possible to identify the fatty acids in lipid sources available in Thailand, using retention times and comparison with standards as a reference.

3.2 Operation of the GC was demonstrated, and methods of program timing to satisfactorily separate fatty acid methyl esters found in fish tissues were reviewed. The trainees (Dr. Supis and Mrs. Pisamai) began by analyzing standards and then conducted analysis of fats from dietary ingredients and from actual samples, including larval fish provided by Ms. Amornrat and artemia-based enriched diets prepared by Dr. Supis. Results of analysis of commercially significant lipid sources in Thailand was completed, with partial results presented in Annex C.

3.3 By the end of the consultancy, the trainees were sufficiently proficient in sample extraction, methylation, and analysis procedures that they will be able to continue these analyses without further assistance. While Dr. Supis arrived well-trained, Mrs. Pisamai benefited greatly from the training and will assist Dr. Wimol in this area in the future.

4.1 A computer spreadsheet, designed for use with either Excel or Lotus software by Dr. Hardy, was brought to Thailand and made available to the fish nutrition program at NIFI. This spreadsheet enables the user to develop a feed formulation and obtain instantaneously the proximate composition, amino acid composition, mineral composition, energy content, and price of the feed. It can be used for practical feeds or for experimental feeds, including semi-purified diets.

4.2 The computer file was transferred to the computer in the fish nutrition office at NIFI and instruction was provided for the trainees on how to use it effectively.

4.3 Efforts were begun to modify the data files in the spreadsheet to reflect the proximate and nutrient composition, and price, of feed ingredients available in Thailand. Data generated in the fish nutrition program by Dr. Supis and Dr. Wimol were used wherever possible. The use of this spreadsheet by the trainees will greatly improve the speed and accuracy with which they will be able to develop appropriate feed formulations for farmed fish in Thailand and for experimental purposes at NIFI.

5.1 A one-week intensive short course was presented to extension and field research personnel of the Directorate of Fisheries at NIFI at the request of Mr. Prasert, the Government Program Officer.

5.2 The course was attended by approximately 35 persons, and instruction was given in a range of subjects, with the aim being to emphasize topics of practical significance to the attendees. Instruction was given in the theory and biochemistry of fish nutrition, when this information was necessary to provide a background for practical recommendations and activities. A schedule of lectures is presented in Annex F.

6.1 The analytical laboratory equipment in the fish nutrition section at NIFI is suitable for the goals and objectives of the agency under project THA/89/003. The equipment has all been tested and was in working order appropriate for continued analysis at the end of this consultancy.

6.2 The proximate analysis laboratory equipment is in good working order. The only modification recommended in this laboratory is the installation of a fume hood to remove organic fumes during lipid analysis. A unused hood was located at NIFI, and moved to the laboratory for installation.

6.3 Inventories of expendable supplies used in nutritional analysis were examined, and a list of needed supplies and minor equipment (such as HPLC columns, dry ice storage chest, etc.) was developed by Drs. Halver and Hardy. This list was sent to UNDP as part of a letter of justification for transferring remaining project funds from the consultant section to the supplies section of the proposed budget. It is the opinion of Halver and Hardy that the goals of the FAO/UNDP project would be better met by this change. The list of supplies can be found in Dr. Halver's 1991 Final Report on project THAI/89/003.

7.1 NIFI now possesses the equipment, skills, and trained personnel to make significant contributions to aquaculture in SE Asia by improving the quality and economy of feeds. However, these attributes must be used correctly for the FAO/UNDP investment to reach its ultimate goal. Sensible planning, taking into account the true state of fish nutrition knowledge in the region and the actual needs to advance aquaculture, is a critical component of future success. This section of the final report will present a framework for future efforts by the fish nutrition project at NIFI.

7.2 The main objective of the fish nutrition program at NIFI is to improve the quality of feeds for five key aquatic species (Clarius, P. monodon, Puntius, Pangasius, and Macrobranchium), and to improve the economics of fish production by improving the efficiency of feeds, by lowering the cost of feeds, or both. A number of impediments to achieving this objective remain, but they can be divided into two categories: (1) insufficient knowledge of the nutritional requirements of the key aquatic species, including dietary carbohydrate tolerance; and (2) insufficient knowledge of the nutritional value of major feed ingredients, including nutrient levels, and nutrient availability (digestibility). Also required is information on feed technology, primarily the effects of pelleting on nutrient stability, availability, and pellet stability.

7.3 Secondary objectives of the fish nutrition program at NIFI include extension activities for rural farmers on diet preparation, training programs for Thai government fisheries officers, and those from neighboring countries, analytical services for regulatory agencies having the responsibility to monitor feed quality, and reducing the effects of fish farming on the aquatic environment caused by nutrient enrichment. Of these, the latter two are objectives satisfied in part by the activities of Project THA/89/003, in that the expertise and equipment is now in place at NIFI to service these needs if they become higher priorities than they are now.

7.4 To meet the main objective of the fish nutrition program at NIFI, efforts must be directed towards the following:

7.4.1 Establish the dietary protein and limiting essential amino acid requirements of key aquatic species. This work has already begun.

7.4.2 Establish the dietary energy requirements of key aquatic species. This work has already begun.

7.4.3 Establish the carbohydrate and lipid tolerance of key species. This, especially the carbohydrate tolerance of fish, is highly variable among species and, because carbohydrates are the least expensive and most abundant energy source for feeding fish and animals on the planet, knowledge in this area will be a key element in the development of efficient and economical feed formulations for aquaculture. This work has begun.

7.4.4 Establish the optimum dietary protein/energy ratio for key aquatic species. This work will begin soon.

7.4.5 Determine the proximate and nutrient composition of key feed ingredients available in Thailand and SE Asia. This work is underway.

7.4.6 Measure the apparent digestibility coefficients of dry matter, protein, lipid, and carbohydrate for key aquatic species in key feed ingredients. Measure apparent digestibility coefficients for essential amino acids. Training is these techniques was provided by Mr. Wilson.

7.4.7 Enter all values for feed ingredients into a data base used to formulate feeds by spreadsheet, or enter values into least-cost computer program.

7.4.8 Continue efforts to establish the dietary requirements of key species for micronutrients (vitamins and minerals) and for essential fatty acids. Until this work is completed, use known values for similar species, for example, channel catfish.

7.5 Once the dietary needs of the fish are known, and the chemical and nutrient analysis of the feeds is complete, formulate feeds for key aquatic species for field testing. When testing is complete, the formulations should be published and the information sent to the aquaculture industry via seminars, workshops, extension activities, and other means.

8.1 Two presentations were made at the American Soybean Association-sponsored workshop “Fish Nutrition and Feed Manufacturing Technology,” held at the Imperial Hotel in Bangkok from September 19–21, 1991. The presentations were entitled “Feed Quality Assurance using HACCP Principles” and “Fish Hyrolysates-Manufacture and Use.”

8.2 An informal seminar on fish nutrition arranged by Dr. Mali for the technical staff of Charoen Pokphand Feedmill Co., Ltd. (CP) was held on a Saturday. The subjects discussed by this consultant were “Fish Meal Quality Assessment”, “Proper Methods of Conducting Fish Nutrition Feeding Trials”, and “Fish vs Domestic Animals; Nutritional Considerations.”

8.3. The state of the feed preparation facilities at NIFI was examined and, in general, found sufficiently developed to carry out the mission intended by FAO, namely the preparation of pilot scale-quantities of practical feeds for testing. A problem with the dryer used to dry extruded feeds was identified, and efforts made to correct it. The pelleting machine was not in operation, but, with a little effort, it could be made operational very easily.

8.4 The opening ceremony of the Third Governing Council Meeting of NACA, at FAO Headquarters in Bangkok was attended by Hardy. Informal discussions of the project at NIFI, and of regional needs in fish nutrition and feed technology were held with some of the participants.

9.1 Purchase items on the recommended supply list developed by Drs. Halver and Hardy.

9.2 Improve the sanitation of the analytical laboratory, particularly the section where samples are prepared for analysis. As mentioned in Dr. Halver's report, the area is not insect or vermin proof, a fact witnessed by this consultant on many occasions. Apart from the aesthetic elements of such a state, the analytical efforts, particularly in amino acid analysis, may be seriously compromised by this problem. The problem could be rather simply solved, and the planned move of the fish disease unit to another area at NIFI will free laboratory areas more appropriate for this kind of activity than the present area.

9.3 Develop and follow a long-range plan for fish nutrition research at NIFI.

9.4 Continue to accumulate data on the nutritional composition of Thai feed ingredients, using the analytical laboratory to conduct the analyses. Use the resulting data to replace existing values in the computer data base of feed ingredients.

9.5 Repair the pelleting machine and continue to modify the extruder dryer, which is poorly designed, to achieve operational status.

10.1 Coordination among consultants and better matching of consultants skills with project needs would have improved the effectiveness of this FAO/UNDP Nutrition Project.

10.2 Coordination among consultants could be improved by hiring consultants from the same institution, or from the same country. The model of ODA, where an institution is given responsibility for overall project coordination and then selects consultants from its staff or network, results in better definition of consultant's duties and matching individuals to the goals of the project. In many cases, overlapping the periods of consultancy greatly increases the effectiveness of the consultants, and permits the first-arriving consultant to request procedures, supplies, and standards needed for analytical work to be sent or brought by the second-arriving consultant. In the case of Project THA/89/003, overlapping of the three consultancies in 1991 greatly increased the effectiveness of the efforts of the consultants, and contributed greatly to the successful attainment of the goals of the project with respect to in-service training and development of the analytical capabilities of the NIFI staff.

10.3 Matching consultant's skills with a technical project such as THAI/89/003 is very difficult for FAO Personnel, who must deal with a wide range of technical expertise. The needs of this project were three: (1) overall expertise in administration, planning, training, assessment of needs, and, of course, recognized expertise in fish nutrition; (2) expertise in technical laboratory equipment and detailed analytical methods appropriate for assessment of nutrients; and (3) expertise in feed technology, including equipment, ingredients, feed production, and feed formulation, both for practical feeds and for experimental, purified diets. Expertise in laboratory equipment or pelleting is usually possessed by technicians working daily in laboratories, not by the program leader or professor. Recruitment of such individuals, who normally do not possess the international credentials of top scientists, could be best accomplished by recruiting a top scientist and allowing him/her to recommend technical specialists. This approach would provide a project with individuals with complementary skills, greatly increasing the effectiveness of the consultants' activities.

| Mr. Imre Csavas | Regional Aquaculture Officer FAO/RAPA |

| Mr. Prasert Sitasit | Government Project Manager THA/89/003 |

| Mr. Chen Foo Yan | Coordinator, Network of Aquaculture Centers in the Asia and Pacific Region (NACA) |

| Dr. Mali Boonyarapalin | Head, Marine Aquaculture Nutrition Research Group |

| Ms. Luxamee Patboon | Charoen Pokphand Co., Ltd. |

| Dr. Sujint | Charoen Pokphand Co., Ltd. |

| Dr. Lin | Charoen Pokphand Co., Ltd. |

| Dr. John Halver | University of Washington |

| Dr. Dean Akiyama | Amer. Soybean Assn., Singapore |

| Dr. Y Kato | Director, FIO, FAO, Rome |

| Mr. Sompong Hiranwat | Director, NIFI |

| Dr. Ron Roberts | Stirling University, UK |

| Dr. Kamonport Tanguhai | NIFI |

Fatty acid profiles in several sources of oil in Thailand

| Fatty acid | Menhaden* oil | Marine* oil | Fish oil | Palm oil | Soybean oil | Cuttlefish liver oil |

| 16:0 | 16.20 | 10.00 | 36.80 | 11.70 | 16.80 | |

| 16:1 | 9.30 | 17.00 | 9.10 | 5.20 | ||

| 16:2n-7 | 2.20 | 2.60 | 1.10 | 0.10 | 1.10 | |

| 18:0 | 4.30 | 2.20 | 2.20 | 3.20 | 3.60 | 2.20 |

| 18:1n-9 | 11.20 | 7.90 | 25.20 | 43.20 | 25.90 | 16.60 |

| 18:2n-6 | 2.40 | 2.90 | 3.10 | 11.10 | 49.70 | 2.20 |

| 18:3n-3 | 1.80 | 1.20 | 1.00 | 0.40 | 6.70 | 2.90 |

| 18:4n-3 | 4.20 | 3.50 | 2.00 | |||

| 20:1n-9 | 1.30 | 4.30 | 11.80 | 0.20 | 0.50 | 0.40 |

| 20:4n-6 | 1.10 | 1.30 | 0.50 | 1.40 | ||

| 20:4n-3 | 1.80 | 0.90 | 0.50 | 0.70 | ||

| 20:5n-3 | 14.40 | 25.00 | 14.00 | 0.10 | 0.40 | 16.50 |

| 22:1n-9 | 0.70 | 0.80 | 0.30 | |||

| 22:4n-6 | 0.30 | |||||

| 22:5n-6 | 0.50 | |||||

| 22:5n-3 | 2.20 | 4.00 | 0.90 | 0.60 | ||

| 22:6n-3 | 18.10 | 20.50 | 11.40 | 19.00 | ||

| Total n-3 | 42.50 | 55.10 | 29.80 | 0.50 | 7.10 | 39.70 |

| Total n-6 | 3.90 | 2.90 | 3.30 | 11.10 | 49.90 | 4.10 |

| n-3 HUFA | 36.50 | 50.40 | 26.80 | 0.10 | 0.40 | 36.80 |

Steps:

To hydrolysate tubes, add 0.5g of finely ground, de-fatted sample.

Add 4 ml of 6N HCl, mix.

Flush with nitrogen gas for 30 seconds, close tube.

Connect to vacuum, remove air for 1–2 minutes, close tube before disconnecting from vacuum.

Repeat steps 3–4.

Place in oven at 105C for 24 hours, sample should be a yellowish liquid, with some but not much dark solids after removing from oven.

Transfer contents to centrifuge tube, spin to settle solids, remove 1ml of supernatant, label, store for later analysis, or proceed to next step, storing remaining material.

Withdraw 10 ul from sample, dry on vacuum system until vacuum gauge reads <50 millitorr.

Add 30 ul of redry solution, vortex, dry again to <50 millitorr. At this stage, sample can be stored under vacuum until derivatized with derivatization reagent according to Waters' procedures.

For analysis of C1 and C2 in feeds and tissues:

Use two Bondapak columns (30cm) hooked in series, with guard column installed upstream of columns.

Equilibrate in mobile phase for one hour before injection of samples.

C1 will elute at 5 minutes.

C2 will elute at 8–10 minutes.

C3 (monophosphate) will co-elute with C1 and resolution is impossible, hence, do not use this system for feed samples containing C3 monophosphate form of ascorbic acid. After analysis is complete, flush with water, store in methanol. Use a lot of water!.

For feed samples (no C3 in tissues) containing C3 monophosphate:

Use two Novapak columns (15 cm) hooked in series, with guard column installed upstream of columns.

Flush with methanol for one hour, then equilibrate in mobile phase for 6 hours.

C1 will elute at 5 minutes.

C2 will elute at 15 minutes.

C3 MP will elute at 17 minutes.

In feed or tissue samples, C1 will be very difficult to resolve with this system, due to interfering peaks eluting at the same time as C1. When analysis is completed, flush with a lot of water, store in methanol. When analysis are going to be done again, it is necessary to re-equilibrate in mobile phase again for six hours.

Monday, November 25:

| 09:00 | Opening Ceremony, Introduction |

| 10:00 | Overview of Nutrients |

| 12:00 | Lunch |

| 13:00 | Proximate and Nutrient Analysis |

| 15:00 | Feed Ingredients and Processing |

Tuesday, November 26:

| 09:00 | Proteins and Amino Acids |

| 10:00 | Protein Sources |

| 11:00 | Dietary Energy |

| 12:00 | Lunch |

| 13:30 | Lipids |

| 14:30 | Fatty Acids, Phospholipids, and Sources |

| 15:00 | Carbohydrates and Carbohydrate Sources |

Wednesday, November 27:

| 09:00 | Vitamins |

| 10:00 | Vitamin Sources and Practical Considerations |

| 11:00 | Essential Minerals and Practical Considerations |

| 12:00 | Lunch |

| 13:30 | Non-nutrients Feed Additives |

| 14:30 | Feed Formulation and Manufacturing |

Thursday, November 28:

| 09:00 | Experimental Design in Nutrition Studies |

| 10:00 | Conducting Feeding Studies |

| 11:00 | Tour of nutrition facilities at NIFI |

| 12:00 | Lunch |

| 13:30 | Question and Answer Session |