Curing root and tuber crops such as sweetpotatoes, potatoes, cassava and yarns is an important practice if these crops are to be stored for any length of time. Curing is accomplished by holding the produce at high temperature and high relative humidity for several days while harvesting wounds heal and a new, protective layer of cells form. While curing can be initially costly, the long extension of storage life makes the practice economically worthwhile.

The best conditions for curing vary among crops as shown in the following table:

Commodity |

Temperature |

Relative Humidity |

Days |

|

°C |

°F |

(%) |

||

Potato |

15-20 |

59-68 |

90-95 |

5-10 |

Sweetpotato |

30-32 |

86-90 |

85-90 |

4-7 |

Yarns |

32-40 |

90-104 |

90-100 |

1-4 |

Cassava |

30-40 |

86-104 |

90-95 |

2-5 |

Curing, when used for onions, garlic and flowering bulbs refers to the practice directly following harvest, of allowing the external layers of skin and neck tissue to dry out prior to handling and storage. If local weather conditions permit, these crops can be undercut in the field, windrowed and left there to dry for five to ten days. The dried tops of the plants can be arranged to cover and shade the bulbs during the curing process, protecting the produce from excess heat and sunburn. If forced heated air is used for curing onions and other bulbs, one day or less at 35 to 45 °C (95 to 113 °F) and 60 to 75% relative humidity is recommended. The dried layers of 'skin” then protect the produce from further water loss during storage.

Yams and other tropical root and tuber crops can be cured outdoors if piled in a partially shaded area. Cut grasses or straw can be used as insulating materials and the pile should be covered with canvas, burlap or woven grass mats. Curing requires high temperature and high relative humidity, and this covering will trap self-generated heat and moisture. The stack should be left for about four days.

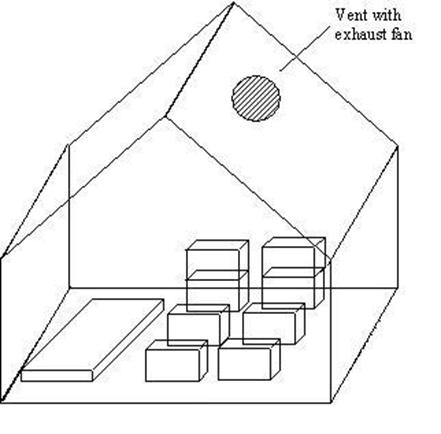

Cut-away view of yam curing

Source: Wilson , J. No date. Careful Storage of Yams: Some Basic Principles to Reduce Losses. London : Commonwealth Secretariat/International Institute of Tropical Agriculture. (IITA, Ibadan , Nigeria .)

Onions and garlic can be cured in the field in regions where harvest coincides with the dry season. The crops can be cured either in windrows or after packing into large fiber or net sacks. The produce can be left in the field for five days, then checked daily until the outer skin and neck tissues are properly dried. Curing may take up to ten days, depending on weather conditions.

Curing can be assisted by the use of ventilated sheds in regions where solar radiation and/or relative humidity is high or natural air movement is low. Produce in sacks can be stacked in the shade on canvas tarpaulins, or placed in an open sided shed under one or more ceiling fans. An exhaust vent in the roof can assist with air circulation.

Curing assisted by shade and ventilation:

Vent with exhaust fan

The most uniform distribution of heat is obtained when heat is introduced near the floor level of a curing structure. Heaters can be placed on the floor near the bins of produce, or heat can be ducted in from outside the curing room. A high relative humidity can be obtained by wetting the floor or by using an evaporative cooler in the room without introducing outside air.

If heaters are located near the ceiling, then ceiling fans can be used to help redistribute the heat down into the room of produce. Bulk bins must be stacked to allow a gap of 10 to 15 cm (4 to 6 inches) between rows for adequate air circulation.

Source: Thompson, J. & Scheuerman, R.W. 1993. Curing and Storing California Sweetpotatoes. Merced County Cooperative Extension, Merced , California

Curing using a bulk system requires a fan, a heating unit and a slatted floor. The illustrations below shows how air can be brought in, heated and distributed through a load of bulk onions in the curing room An exhaust opening near the ceiling re-circulates heated air.

When using heated air it is easy to over-dry the bulbs, leading to loss of external scales and exposure of the fleshy scales underneath. Curing onions should be checked regularly to avoid over-drying.

Source: Davis , H.R et al. No date. Storage Recommendations for Northern Grown Onions. Information Bulletin 148. Ithaca , NY : Cornell University Extension.

If conditions such as rain or flooded fields do not permit field curing and curing facilities are not available, a temporary tent can be used for curing onions. In the example illustrated below, the tent is constructed from large tarps. Heated air is forced into a hollow area (known as a plenum) at the center of the bins of produce. Several fans are used to circulate the warm air through the onions while they are curing.

Source: Davis , H.R. et al. (No date). Storage Recommendations for Northern Grown Onions. Information Bulletin 148, Ithaca , New York Cornell University Extension.