When a variety of different sized cartons are packed at the same time, using boxes in standard sizes can greatly ease future handling. When handling boxes that are non-uniform, stacks can be unstable or heavier cartons can crush lighter ones. An unstable load is likely to fall over during transport or to collapse during storage.

Recommended container sizes are shown below. These containers are part of the MUM program (Modularization, Unitization and Metrication) advocated by the USDA. They can all be stacked in a variety of patterns, depending upon their size, yet still form a stable load on a single pallet of 1000 x 1200 mm (40 x 48 inches).

MUM containers for horticultural crops:

|

Outside Dimensions |

Number Per Layer |

Pallet Surface Area Utilized |

mm |

Inches |

|

Percentage |

600 x 500 |

(23.62 x 19.69) |

4 |

100 |

500 x 400 |

(19.68 x 15.75) |

6 |

100 |

600 x 400 |

(23.62 x 15.75) |

5 |

100 |

500 x 333 |

(19.68 x 13.11) |

7 |

97 |

600 x 333 |

(23.62 x 13.11) |

6 |

99 |

500 x 300 |

(19.68 x 11.81) |

8 |

100 |

475 x 250 |

(18.70 x 9.84) |

10 |

99 |

400 x 300 |

(15.75 x 11.81) |

10 |

100 |

433 x 333 |

(17.01 x 13.11) |

8 |

96 |

400 x 250 |

(15.74 x 9.84) |

12 |

100 |

An example of a pallet load of MUM containers:

Source: Ashby, B.H. et al. 1987. Protecting Perishable Foods During Transport by Truck. Washington , D.C. : USDA, Office of Transportation, Agricultural Handbook No. 669.

The following illustrations show the arrangement of the most popular MUM containers on a standard pallet (1000 x 1200 mm or 40 x 48 inches). Using MUM containers can save space during transport and storage, since pallet utilization is close to 100%.

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Outside dimensions: |

|

Source: McGregor, B. 1989. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

Within a consumer package: If commodity and film permeability characteristics are properly matched, an appropriate atmosphere can evolve passively through consumption of CO2 and production of CO2 during respiration (Kader, 2002). Some rigid plastic consumer packages are designed with a gas diffusion window.

Fresh-cut or lightly processed lettuce (shredded or chopped) can be packaged in 5-mil plastic bags. After a partial vacuum is created, a gas mixture of 30 to 50% CO2 and 4 to 6% CO2 is introduced into the bag, which is then sealed.

SEALED PLASTIC BAG

Within a shipping container: Polyethylene liners are added to shipping containers in cherry boxes, and polyethylene bags are used for bananas destined for distant markets.

Polyethylene liner:

Within a pallet: A single pallet load of produce such as strawberries can be sealed within a shroud of 5 mil polyethylene bag and a plastic sheet on the pallet base using wide tape. A slight vacuum can be introduced and 15% CO2 added to the air introduced via a small hose.

Many plastic films are available for packaging, but very few have gas permeabilities that make them suitable for MAP. Low density polyethylene and polyvinyl chloride are the main films used in packaging fresh fruits and vegetables. Saran and polyester have such low gas permeabilities that they are suitable only for commodities with very low respiration rates. The following table provides the permeabilities of the films currently available for packaging fresh produce (Kader, 2002).

Film type |

Permeabilities (cc/m2/mil/day at 1 atm) |

CO2:O2 Ratio |

|

CO2 |

O2 |

||

Polyethylene: low density |

7,700-77,000 |

3,900-13,000 |

2.0-5.9 |

Polyvinyl chloride |

4,263-8,138 |

620-2,248 |

3.6-6.9 |

Polypropylene |

7,700-21,000 |

1,300-6,400 |

3.3-5.9 |

Polystyrene |

10,000-26,000 |

2,600-7,700 |

3.4-3.8 |

Saran |

52-150 |

8-26 |

5.8-6.5 |

Polyester |

180-390 |

52-130 |

3.0-3.5 |

Many shippers and receivers prefer to handle unit loads of produce pallets rather than handling individual shipping containers. The switch to unit loads has reduced handling, causes less damage to the containers and produce inside, and allows faster loading/ unloading of transportation vehicles. If small scale handlers wish to use unit loads for shipping produce, either wooden pallets or slip sheets can serve as the base of the load. Using guides for aligning the boxes (such as placing the pallet to be loaded against the corner of a room, or building a set of "bounce boards" if the pallet is loaded outside) will stabilize the load. Wooden pallets must be made perfectly square for the pallet load to be as stable as possible.

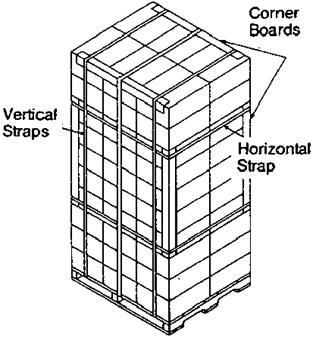

Using fiberboard, plastic or wooden containers with vertical interlocking tabs can also help improve the unit load's stability. Containers must have holes for ventilation which align when stacked squarely on top of one another. Glue can be used between layers of containers to reduce slipping, and plastic netting or plastic or metal straps should be added to secure the load. Corner-boards made from fiberboard, plastic or metal help to provide for a stable unit load.

Strapping and corner-boards on a unit load:

Sources: McGregor, B. 1989. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

Ashby, B.H., et al., 1987. Protecting Perishable Foods During Transport by Truck. USDA, Office of Transportation, Agricultural Handbook Number 669.