Fruit and vegetable crops often are susceptible to chilling injury when cooled below 13 to 16 °C (55 to 60 °F). Chilling injury reduces the quality of the product and shortens shelf life. The table below provides some examples of the symptoms of chilling injury in a variety of crops. Symptoms often appear only after the commodity is returned to warmer temperatures, as when marketed.

Fruits and vegetables susceptible to chilling injury when stored at moderately low but nonfreezing temperatures

|

Commodity |

Approximate lowest safe temperature |

Character of injury when stored between 0°C and safe temperature 1 |

|

| °C | °F | ||

|

Apples (Jonathan, McIntosh, Yellow Newton ) |

2-3 |

36-38 |

Internal browning, brown core, soggy breakdown, soft scald |

|

Asparagus |

0-2 |

32-36 |

Dull, gray-green, and limp tips |

|

Avocados |

4.5-13 |

40-55 |

Grayish-brown discoloration of flesh |

|

Bananas, green or ripe |

11.5-13 |

53-56 |

Dull color when ripened |

|

Beans ( lima ) |

1-4.5 |

34-40 |

Rusty brown specks, spots, or areas |

|

Beans (snap) |

7 |

45 |

Pitting and russeting |

|

Cranberries |

2 |

36 |

Rubbery texture, red flesh |

|

Cucumbers |

7 |

45 |

Pitting, water-soaked spots, decay |

|

Eggplants |

7 |

45 |

Surface scald, alternaria rot, blackening of seeds |

|

Guavas |

4.5 |

40 |

Pulp injury, decay |

|

Grapefruit |

10 |

50 |

Scald, pitting, watery breakdown |

|

Jicama |

13-18 |

55-65 |

Surface decay, discoloration |

|

Lemons |

11-13 |

52-55 |

Pitting, membranous staining, red blotch |

|

Limes |

7-9 |

45-48 |

Pitting, turning tan with time |

|

Mangos |

10-13 |

50-55 |

Grayish scald-like discoloration of skin, uneven ripening |

|

Melons Cantaloupe |

2-5 |

36-41 |

Pitting, surface decay |

|

Melons Honey Dew |

7-10 |

45-50 |

Reddish-tan discoloration, pitting, surface decay, failure to ripen |

|

Melons Casaba |

7-10 |

45-50 |

Same as above but no discoloration |

|

Melons Crenshaw and Persian |

7-10 |

45-50 |

Same as above but no discoloration |

|

Watermelons |

4.5 |

40 |

Pitting, objectionable flavor |

|

Okra |

7 |

45 |

Discoloration, water-soaked areas, pitting, decay |

|

Olives, fresh |

7 |

45 |

Internal browning |

|

Oranges , California and Arizona |

3 |

38 |

Pitting, brown stain |

|

Papayas |

7 |

45 |

Pitting, failure to ripen, off flavor, decay |

|

Peppers, sweet |

7 |

45 |

Sheet pitting, alternaria rot on pods and calyxes, darkening of seed |

|

Pineapples |

7-10 |

45-50 |

Dull green when ripened |

|

Pomegranates |

4.5 |

40 |

Pitting, external and internal browning |

|

Potatoes |

3 |

38 |

Mahogany browning (Chippewa and Sebago), sweetening² |

|

Pumpkins and hard-shell squashes |

10 |

50 |

Decay, especially alternaria rot |

|

Sweetpotatoes |

13 |

55 |

Decay, pitting, internal discoloration; hardcore when cooked |

|

Tamarillos |

3-4 |

37-40 |

Surface pitting, discoloration |

|

Tomatoes Ripe |

7-10 |

45-50 |

Water-soaking and softening, decay |

|

Tomatoes Mature-green |

13 |

55 |

Poor color when ripe, alternaria rot |

1 Symptoms often apparent only after removal to warm temperatures, often during marketing.

2 For potatoes that will be processed to chips, French fries or other fried products, the proper storage temperature is 8 to 12 °C (46-54 °F).

Source: Harderburg, R.E., A. E. Watada, and C-Y. Wang 1986. The Commercial Storage of Fruits Vegetables. and Florist and Nursery Stocks. USDA, Agricultural Handbook No. 66.

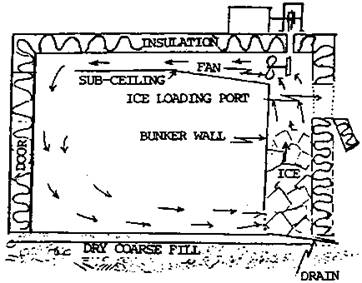

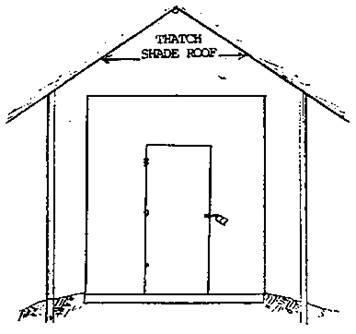

Ice can be used as a bunker source of refrigeration (used by passing air through a bank of ice and then through the commodity) or as top ice (laid directly in contact with the product). Ice can cool a commodity only if it melts, so good ventilation is necessary for effective cooling. A simple bunker is illustrated here (two pages).

Cross section - a gasoline or diesel engine must be mounted outside.

Back of Room - an electric fan motor is commonly mounted inside the cold room, fan capacity should at least equal the empty volume of-the room (i.e. 12x8x8=768 cu ft.; so fan capacity should be 768 cfm at minimum.)

(cfm= cubic feet/min)

(cfm= cubic feet/min)

Front elevation

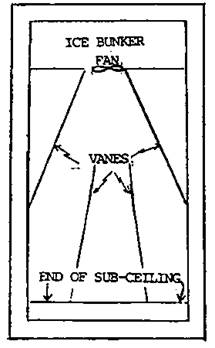

Top view - vanes over the sub-ceiling greatly improve air distribution and hence cooling.

Source: Grierson, W. 1987. Postharvest Handling Manual Commercialization of Alternative Handling Crops Project. The Belize Agribusiness Company/Chenomics International/USAID.

Crushed or flaked ice for package icing can be applied directly or as a slurry in water. The use of ice to cool produce provides a high relative humidity environment around the product. Package ice can be used only with water tolerant, non-chilling sensitive products and with water tolerant packages (waxed fiberboard, plastic or wood).

Top ice is used for certain products during transport to help maintain a high relative humidity. Top ice can be used only with water tolerant, non-chilling sensitive products (such as: carrots, sweet corn, cantaloupes, escarole, lettuce, spinach, radishes, broccoli, green onions), and with water tolerant packages (waxed fiberboard, or wood).

Top-ice on loads should be applied in rows rather than a solid mass. It is important not to block air circulation inside the transport vehicle.

|

Should be Top-iced: |

Can be Top-iced: |

|

beets with tops broccoli carrots with tops corn sweet endive escarole green onions parsley radishes with tops radish greens spinach turnips turnips with tops turnip greens watercress |

artichokes, globe beet greens beets topped brussels sprouts cantaloupes carrots, topped celeriac chard kohlrabi leeks mustard greens parsnips radishes rutabagas |

| Sources: | Thompson, J.F. 2002. Cooling horticultural commodities. pp.97-112. In: Kader, A.A. (ed). Postharvest Technology of Horticultural Crops. Univ. of California , Div. of Agriculture and Natural Resources, Publication 3311. |

| McGregor, B.M. 1989. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668. |

Radiant Cooling

Radiant cooling can be used to lower the air temperature in a storage structure if a solar collector is connected to the ventilation system of the building. By using the solar collector at night, heat will be lost to the environment. Temperatures inside the structure of 4 °C (about 8 °F) less than night temperature can be achieved.

Use of Well Water

Well water is often much cooler than air temperature in most regions of the world. The water temperature of a deep well tends to be in the same range as the average air temperature of the same locality. Well water can be used for hydro-cooling and as a spray or mist to maintain high relative humidity in the storage environment.

High Altitude Storage

Typically air temperatures decrease by 10 °C (18 °F) for every one kilometer increase in altitude. If handlers have an option to pack and/or store commodities at higher altitude, costs could be reduced. Cooling and storage facilities operated at high altitude would require less energy than those at sea level for the same results.

As a rule night ventilation effectively maintains product temperature when the outside air temperature is below the desired product temperature for 5 to 7 hours per night.

Sources: Thompson, J.F. 2002. Cooling horticultural commodities. pp.97-112. In: Kader, A.A. (ed). Postharvest Technology of Horticultural Crops. Univ. of California, Div. of Agriculture and Natural Resources, Publication 3311.

Refrigerated air tends to be lower in relative humidity than is beneficial for storage of most horticultural crops. The simplest method of increasing relative humidity of the storage air is to wet the floor of the room or mist the storage containers with cold water and allow the water to evaporate.

For a more permanent system of high relative humidity in the storage environment, moisture can be added to the refrigerated air. A fan draws air past the refrigerator's evaporator coils (R) then past wet moss or straw (M). The moist air is then pulled into the store-room through a perforated wall (P).

Wet moss as a moisture source inside a refrigerated storeroom:

Source: Lopez, E.G. 1983. Conservación de la Producción Agrícola. Barcelona Editorial Aedos. 188 pp.

Using a polyethylene liner in a fiberboard carton can help protect produce and reduce water loss in commodities such as cherries, nectarines, kiwifruits, bananas and herbs. Water vapor given off by the product is contained within the inner, increasing the RH around the product. The liner can also reduce abrasion damage that results from fruit rubbing against the inside of the box.

Maintaining the Cold Chain for Perishables

|

Harvest |

|

| Cooling |

|

|

| Temporary Storage |

|

|

| Transport to Market |

|

|

| Handling at destination |

|

|

| Handling at home or food service outlet |

|

|