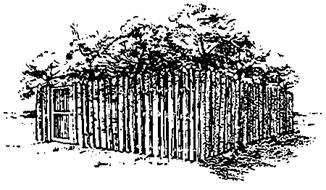

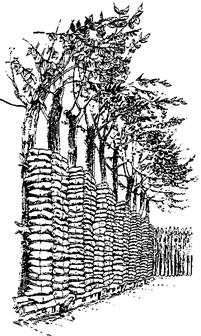

A yam barn is a traditional structure used in West Africa to store yams after curing. Fast-growing, live trees are used to create a rectangular structure, and form the framework of the barn as well as provide shade.

Outside view of barn with 'live' shade

Trunks of fast growing trees planted in situ

Source: Wilson , J. No date. Careful Storage of Yams: Some Basic Principles to Reduce Losses. London , England : Commonwealth Secretariat/International Institute of Tropical Agriculture.

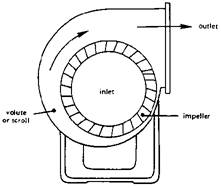

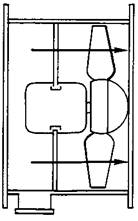

Storage facilities require adequate ventilation in order to help extend shelf life and maintain produce quality. The following are three types of fans found in common use.

Centrifugal:

Axial flow:

Propeller/expeller:

Source: Potato Marketing Board. No date. Control of Environment. Part 2. London : Sutton Bridge Experiment Station, Report No. 6

Ventilation in storage structures is improved if air inlets are located at the bottom of the store, while air outlets are at the top. A simple, light-proof exhaust vent is a pressure-relief flap.

Source: Potato Marketing Board. No date. Control of Environment. Part 2. London : Sutton Bridge Experiment Station, Report No. 6

Any type of building or facility used for storage of horticultural crops should be insulated for maximum effectiveness. A well insulated refrigerated building will require less electricity to keep produce cool. If the structure is to be cooled by evaporative or night air ventilation, a well insulated building will hold the cooled air longer. Insulation R-values are listed below for some common building materials. R refers to resistance, and the higher the R-value, the higher the material's resistance to heat conduction and the better the insulating property of the material.

R – Value

Material |

1 inch thick |

| Batt and Blanket Insulation |

|

Glass wool, mineral wool, or fiberglass |

3.50 |

| Fill-Type Insulation |

|

Cellulose |

3.50 |

Glass or mineral wool |

2.50-3.00 |

Vermiculite |

2.20 |

Wood shavings or sawdust |

2.22 |

Rigid Insulation |

|

Plain expanded extruded polystyrene |

5.00 |

Expanded rubber |

4.55 |

Expanded polystyrene molded beads |

3.57 |

Aged expanded polyurethane |

6.25 |

Glass fiber |

4.00 |

Polyisocyranuate |

8.00 |

Wood or cane fiber board |

2.50 |

Foamed-in-Place Insulation |

|

Sprayed expanded urethane |

6.25 |

Building Materials |

Full thickness of material |

Solid concrete |

0.08 |

8-inch concrete block, open core |

1.11 |

8-inch lightweight concrete block open core |

2.00 |

8-inch concrete block with vermiculite in core |

5.03 |

Lumber, fir or pine |

1.25 |

Metal siding |

<0.01 |

3/8-inch plywood |

1.25 - 0.47 |

1/2-inch plywood |

1.25 - 0.62 |

Masonite particleboard |

1.06 |

25/32-inch insulated sheathing |

2.06 |

1/2-inch Sheetrock |

0.45 |

1/2-inch wood lapsiding |

0.81 |

Reflectix (1/4 inch bubble/aluminum foil sheeting) |

18.00 |

Source: Boyette, M.D. et al. No date. Design of Room Cooling Facilities: Structural and Energy Requirements. North Carolina Agricultural Extension Service.

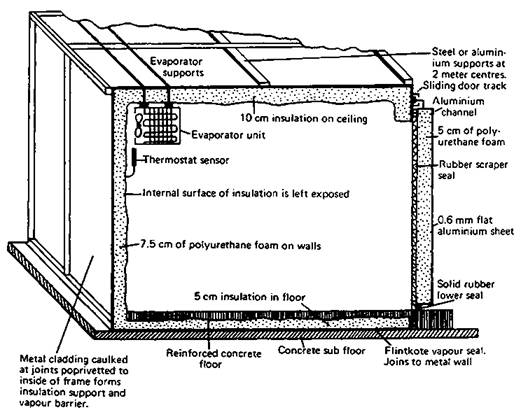

Low cost cold rooms can be constructed using concrete for floors and polyurethane foam as an insulator. Building the storeroom in the shape of a cube will reduce the surface area per unit volume of storage space, thereby reducing construction and refrigeration costs. All joints should be calked and the door should have a rubber seal.

Source: Tugwell, B.L. No date. Coolroom construction for the fruit and vegetable grower. Department of Agriculture and Fisheries, South Australia . Special Bulletin 11.75.

Illustrated below is a cross-sectional view of a storehouse for fruits. This system was officially approved as the standard model for farm-level storehouses by the Ministry of Construction ( Korea ) in 1983. Note that air inlets are at the base of the building, and the floor is perforated, allowing free movement of air. The entire building is set below ground level taking advantage of the cooling properties of soil.

Source: Seung Koo Lee, 1994. Assoc. Prof., Postharvest Technology Lab., Department of Horticulture, Seoul National University, Suwon 441-744, Korea.

For storage facilities that are refrigerated, using outside air for ventilation is wasteful of energy. For these systems, a simple recirculation system can be designed by adding a fan below floor level and providing a free space at one end of the storeroom for cool air to return to the inlet vents.

Source: Potato Marketing Board. No date. Control of Environment. Part 2. London : Sutton Bridge Experiment Station, Report No. 6

The proper arrangement of floor vents for air circulation will improve ventilation in the storage house. Lateral ducts should be 2 meters apart when measured from center to center. Air flow velocities from the main duct should be 10 to 13 meters/second.

Source: Potato Marketing Board. No date. Control of Environment. Part 2. London : Sutton Bridge Experiment Station, Report No. 6

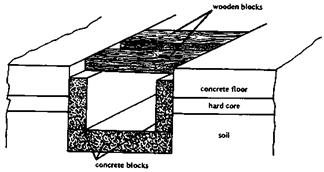

Lateral ducts can be constructed of a variety of materials. Portable vents can be made from wooden slats, in a triangular, square or rectangular design. A round tube of plastic or clay can be used if holes can be drilled without causing structural damage, or permanent ducts can be constructed below ground, using concrete blocks.

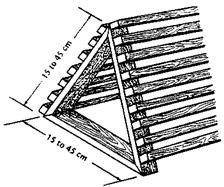

Triangular wooden duct:

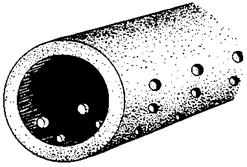

Clay pipe duct:

Sunken concrete duct:

Source: Potato Marketing Board. No date. Control of Environment. Part 2. London : Sutton Bridge Experiment Station, Report No. 6

In cooler regions, suitable storage temperatures can be maintained by bringing outside air into the storage facility. Typical fan installations for a pressurized ventilation system are illustrated below. Overhead distribution of air simplifies the storehouse design. An indoor recirculation inlet can be added if refrigeration is in use. Ducts can be constructed of wood, plastic tubing or any suitable materials.

Overhead ventilation distribution system:

Types of ducts for air inlet fans:

Source: Davis, R. et al. No date. Storage Recommendations for Northern Onion Growers. Cornell University Extension Information Bulletin 148

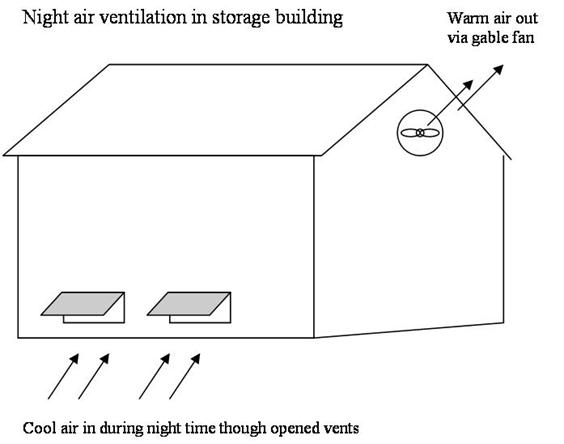

Storage structures can be cooled by ventilating at night when outside air is cool. For best results, air vents should be located at the base of the storage structure. An exhaust fan located at the top of the structure pulls the cool air through the storeroom. Vents should be closed at sunrise, and remain closed during the heat of the day.

Overhanging roof extensions on storage structures are very helpful in shading the walls and ventilation openings from the sun's rays, and in providing protection from rain. An overhang of at least 1 meter (3 feet) is recommended.

Source: Walker, D.J. 1992. World Food Programme Food Storage Manual. Chatham , UK : Natural Resources Institute.

Where electricity is not available, wind-powered turbines can help keep storerooms cool by pulling air up through the building. Vents at the floor level are especially useful for cooling via night air ventilation.

The turbine illustrated below can be constructed of sheet metal that is twisted to catch the wind, and attached to a central pole that acts as the axis of rotation. Warm air in the storage room rises, causing the turbine to rotate, expelling the air and initiating an upward flow of warm air. The turbine should be placed on the peak of the roof of a storage structure.

Protected surface storage is a simple method for storing small quantities of produce. The examples illustrated below are especially good for storage when night temperatures are lower than that desired for proper storage. Insulating materials such as straw can be used and protective covers can be constructed from wooden planks, plastic sheeting or layers of compacted soil.

Cone-shaped pit storage:

Mound storage:

Source: McKay, S. 1992. Home Storage of Fruits and Vegetables. Northeast Regional Agricultural Engineering Service Publication No. 7

Trench storage:

Source: McKay, S. 1992. Home Storage of Fruits and Vegetables. Northeast Regional Agricultural Engineering Service Publication No. 7

One of the simplest methods for storing small quantities of produce is to use any available container, and create a cool environment for storage by burying the container using insulating materials and soil. The example provided here employs a wooden barrel and straw for insulation.

Storage barrel:

Source: Bubel, M. and Bubel, N. 1979. Root Cellaring: The Simple. No-Processing Way to Store Fruits and Vegetables. Emmaus , PA : Rodale Press. 297 pp.

A root cellar can be constructed by digging out a pit to a depth of about 2 meters (7 to 8 feet) and framing the sides with wooden planks or cinder blocks. The example illustrated here is about 3 by 4 meters (12 by 15 feet) in size, with a 35 cm square (one foot square) wooden chute as a roof vent Cover the roofing materials with roofing tar, and cover cinderblocks with cement plaster before covering the cellar with a thick layer (2 feet) of soil.

Ideally, the root cellar should be located on a sloping site. Avoid low-lying areas or the cellar may become water-logged. Stay away from trees, since the roots will eventually invade the cellar walls. Costs for a root cellar constructed using new materials may run to $1200 or more, and it will have a useful life of at least 20 years. To cut costs, consider building with used cinderblocks, recycled wood or using sand to fill the cavities of the blocks instead of purchasing new insulation materials.

Sources: Bubel, M. and Bubel, N. 1979. Root Cellaring: The Simple. No-Processing Way to Store Fruits and Vegetables. Emmaus , PA : Rodale Press. 297 pp.

Hobson, Phyllis. 1981. Build your own underground root cellar. Storey Communications, Inc. 32 pp.

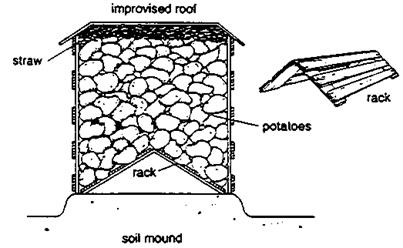

An outdoor storage bin can serve as a place to keep small quantities of potatoes in a region with a cool but not freezing climate. A wooden rack provides an air space for ventilation and straw provides insulation. The best location for such a structure would be in a shady spot.

Storage bin:

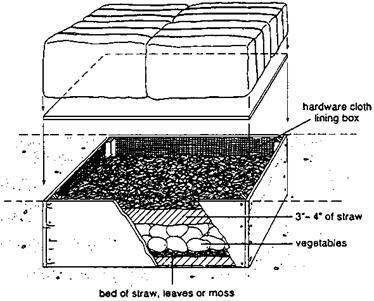

A root box, lined with hardware cloth and straw, buried to the top edge in soil will keep potatoes cool wile providing protection from freezing. The wooden lid can be lifted for easy access to produce, and straw bales on top provide more insulation.

Root box:

Source: Bubel, M. and Bubel, N. 1979. Root Cellaring: The Simple No-Processing Way to Store Fruits and Vegetables. Emmaus , PA : Rodale Press. 297 pp.