Comparing the practices and farming methods used in the Philippines and other developing countries in the ASEAN region with those found in Japan or the Republic of Korea, it is readily seen that there is great potential for improvement and development. This could be accomplished by undertaking certain changes.

In general, oyster and mussel farms are located in very shallow coastal waters with in 1–2 meters depth. These are often within paddling distance from the shoreline.

In Japan, oyster farming evolved from these stages: (a) traditional stone-spreading technique; (b) standing-pole culture; (c) standing pole followed by bottom spreading; (d) standing fence culture; (e) simple hanging type; (f) raft-type hanging; and (g) longline hanging type. The hanging type is employed in waters from 5 to more than 10 m deep. The simple hang-ing technique was the basis for the large-scale oyster farming development in Japan.

Although the hanging method is used in the Philippines, the farm sites are still limited to very shallow tidal areas.

The advantages gained in using deeper waters are:

Growth and fattening characteristics of the oysters are improved.

The three-dimensional use of the surface water is effected, hence, less area is required for an equivalent amount of production.

Culture operation could be conducted regardless of sea bed quality.

Unused deeper water areas could be used for culture purposes.

Work could be performed regardless of tide condition.

Predator organisms are avoided.

It will be noted that the Japanese oyster farming had shifted from the shallow tidal oyster farm sites to the deeper water areas as illustrated in Figure 12.

Farming management techniques have to take into account the growth pattern of the oyster since it remains stationary for the rest of its life. It therefore cannot search for a better environment. The farmer, there-fore, has to move the oysters to grounds which can provide the best conditions possible to meet its biological and physiological requirements at each stage of growth period. A good choice of farm sites, timing and combination of their uses spells the difference in oyster farming management.

Water temperature and salinity are the most important growth factors governing the life of the oyster. In temperate countries like Japan and Korea, the most productive period for spawning of oysters is during summer (June–August) when temperature increases to 24°C–25°C. Egg release and fertilization are triggered by a rapid rise in temperature or a sudden decline in salinity.

In the Philippines and other ASEAN countries, water temperature is ideal all year round and oysters become marketable within 4–6 months. Rainfall, although seasonal, is adequate to maintain the flow of streams and rivers to provide suitable salinity levels for growth as well as for spawning. Reproduction of oysters is found excellent in many areas of the country. Setting continuous throughout the year with peaks during March–May and September–November. This situation makes it possible to collect spats at least twice a year. A system of spat collection should be developed other than what is traditionally practiced to insure a year round production and supply of oysters or mussels.

Figure 12. Diagram of the historical development of oyster farming in japan

(Source: Yamaha Fishery Journal No. 28, Jan. 1989)

From the experience of Japan, oyster farming also started in very traditional practices which dates back about 400 years ago. Shallow tidal areas were also used until they found out that oyster larvae could also be collected in deeper waters. From the simple hanging method, the large-scale hanging type developed (Figure 13).

Spat collection is used to be done in shallow tidal areas. However, in Japan, spats are being collected offshore since the 1960s. This practice was influenced by the loss of natural shallow tidal spawning grounds as a consequence of industrial and agricultural reclamation works and more significantly, due to improvements in oyster culture technology. Research work was steadily continued which determined oyster spat resources and their distribution. This led to a reliable method of predicting spat falls and gathering grounds. Hence, under Japanese conditions, the routine process of culturing oysters had been established. The management schedule of oyster farmers are easily programmed as shown in Figure 14.

In the Philippines and other ASEAN countries, oyster spats are collected mainly in shallow tidal areas where growout plots are also located. Information in the Philippines on spat resources and their distribution are hardly known other than what is only traditionally known by local farmers.

Figure 13. Evolution of the simple small-scale hanging type to large-scale hanging method (Source: Yamaha Fishery Journal No. 28, 1989)

A mature oyster produce from 50–100 million eggs. After fertilization the eggs and larvae undergo a random dispersion and distribution depending on tide, wave motion and edding currents. Portion of the eggs are carried offshore. After 2–3 weeks of their drifting stage the larvae settle down. While the distribution of larvae are highly uneven, it is important to know where densest settlement of spats occur. The Japanese found that spat collection is better offshore such that they have established their routine activities of industrial oyster farming operations which include the following steps:

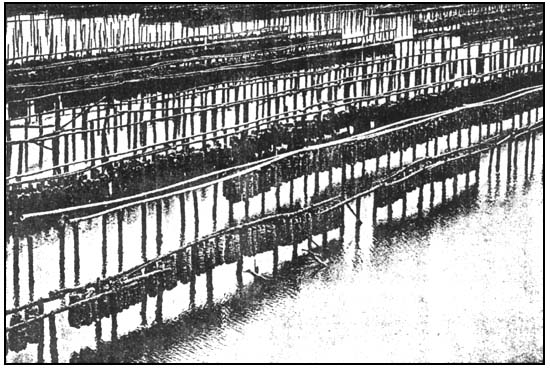

In view of the knowledge about spat resources and their distribution, the Japanese and Korean oyster farmers collect spats off-shore. They use empty scallop shells strung through a wire which are then hung to bamboo rafts which are either movable or fixed (Figure 15). Design and construction is shown in Figure 16.

Figure 14. Routine oyster farming management technique in Japan

(Source: Yamaha Fishery Journal No. 28, 1989)

|  |

Figure 15. Cultch collectors and spat holding rafts

(Source: Yamaha Fishery Journal No. 28, 1989)

|  |

Figure 16. Design and construction of oyster raft and longline hanging method of oyster culture (see photographs 1 and 2) (Source: Yamaha Fishery Journal No. 28, 1989)

In the case of the Pacific oyster (Crassostrea gigas), the water layer in which it could settle or adhere to is from the high tide to 1 and 2 m below the ebb tide line. It was reported (Park, et. al., 1988) that in this range, the middle layer of water provides the best opportunity for settlement of the oyster (Figure 17). The nature of settlement and adherance vary according to depth of water and collecting method.

In shallow areas the fixed collecting method is used as the range of vertical adherance is narrow. Conversely, this becomes wider in deeper waters and in this case the hanging method is used (Figure 18). Spat setting is highly affected by water current. Settlement does not occur where water flow is more than 5–7 cm/sec. The density of larvae during the planktonic stage indicates the degree of settlement levels that could take place. It is estimated that oyster spats developed per million eggs is about 1 percent (Park, et. al., 1988).

Figure 17. Depth range where natural setting of the Pacific oyster occurs (Source: Park, Byung Ha, et al., 1988)

Figure 18. Distribution of oyster larvae by water depth (Source: Park, Byung Ha, et. al., 1988)

Photograph 1. Oyster raft for hanging method of oyster culture

(Courtesy of Mr. Alessandro Lovatelli, RAS/86/024)

Photograph 2. Longline hanging method of oyster culture

(Courtesy of Mr. Alessandro Lovatelli, RAS/86/024)

After the oyster spats have settled on the cultch collectors, these are transferred to hardening racks located in shallow tidal areas as shown in Figure 19. This area is the highest portion of the tidal zone which becomes exposed during low tide.

The hardening process undergoes a gradual period of increased exposure each day to encourage optimal growth of oysters. Exposure to air eliminates the weak individuals and ensures the survivors to mature properly by hardening their shells. This makes them endure environmental changes; mortality is reduced as the oysters become more resistant; growth is rapid and none gets lost in harvesting and handling. The period of hardening lasts from 6–8 months which coincides with the decline of temperature beginning October up to the end of spring in May. In the ASEAN countries where there is no pronounced change in temperature except slightly during the months of December to January, such hardening process will not take that long. However, naturally grown spats from the time of settling could be hardened by intermit-tent exposure before they are transplanted to deeper areas and proceed to growout. Most oyster farmers do not practice the hardening process as the oyster plots are periodically exposed at low tide. Other considerations such as water quality and elimination or control of predators could increase production.

The hardening effect under tropical conditions could take place as well by exposure of the spats during low tide if spat collection is done in deeper areas where no such expo-sure is possible. More refinement of rearing techniques is necessary to improve the present traditional methods.

Transplantation of the spats to the grow-out rafts in deeper areas are carried out. This is done by re-stringing the hardened seed oysters on a 9-m long wire for hanging on the growout rafts (Figure 20).

Usually, the spat collector strings contain 60–100 shells. These are restrung into 30–50 shells per growout string and are hung at 40–50 cm apart along the bamboo poles of the raft. A raft of 10 m × 20 m will contain from 500–600 strings of oysters containing from 20 000–30 000 shells with oyster spats.

Figure 19. Hardening racks of oyster seeds

(Source: Yamaha Fishery Journal No. 28, 1989)

|  |

| Shells with spats are restrung for growout in offshore rafts or longline | Real long-term hanging method in Japan |

Figure 20. Preparation of seed oysters for hanging in growout

(Source: Yamaha Fishery Journal No. 28, 1989)

This is carried out for 1–2 months prior to harvesting. This entails the transfer of the oyster strings to the higher or shallower strata of the water to take advantage of better nutrition and abundant food.

In Japan, the rational for lowering the oyster strings to deeper water during part of the growing period is to avoid high temperatures near the surface water and avoid attachment of barnacles and ascidians on the oyster.

With the above routine, a single oyster raft of 10 m × 20 m produce 2–4 tons of shucked oysters.

The Philippines would do well in oyster and mussel production if farming sites are shifted from heavily polluted shallow coastal areas to deeper and cleaner waters and farming management techniques improved from the traditional methods. Government research institutions must undertake a thorough study of the spat resources, their distribution and grounds for development of oyster farming to provide alter-native economic activity of small-scale fishermen. Besides mollusc farming, the fishermen could still engage in part-time fishing in the vicinity of the oyster or mussel rafts. Certain fishes would also be attracted below the rafts to feed on epiphytic organisms which grow below the rafts or the oyster shells. This aspect needs to be looked into.