A pilot scheme for the collection of fresh fish from Lake Kainji and distribution of iced chilled fish is envisaged initially to Ilorin.

At two or three larger landing centres a good insulated box sufficiently large to hold 300 kg of fish on ice for a period of 24 hours would be required.

A boat with an insulated fish hold would make daily trips calling at these landings to collect the fish that has been bought during the previous day and that has been chilled in ice delivered daily by the collection vessel.

The fish, after landing in Kainji or another centre, would have to be stored in a refrigerated store until further despatch to larger consuming centres such as Ilorin. Prom here the Kwara State Cooperative could be the appropriate trading channel. The shelf life of the chilled fish is expected to exceed at least one week.

Ice plant (2 tons/24 hours) and chill store (10tons) are both estimated at N 10 000 (US $ 16 578). The transport boat of approximately 10 m length with insulated hold and inboard diesel engine of 30 hp, travelling speed 6 knots, is estimated at N 6 500 (US $ 10 790).

| Costs of transport boat per trip of 60 miles: | ||

| Fuel 70 1 at 10 kobo/litre (16.6 cts US) | 1N 7.00 | (US $ 11.60) |

| Depreciation 15 % -500 N in 200 trips approx. | 5.00 | ( 8.30) |

| Maintenance (5 %) | 1.70 | ( 2.80) |

| Insurance (5%) | 1.70 | ( 2.80} |

| Crew (pilot + assistant) | 4.00 | ( 6.60) |

| Ice (1/2 ton at N 15 per ton) (US $24.90) | 7.50 | ( 12.45) |

| N 26.90 | (US $ 44.55) |

If one ton of fish could be collected per trip, collection costs would amount to 2.7 kobo (US $ 0 045) per kg which seems easily recoverable when judging the price differences for fresh fish at isolated fishing villages and a population centre like New Bussa. The costs of cold storage are estimated at less than 0.5 kobo per kg per day (US $ 0 008).

The ice plant should at the electricity rates in Nigeria, be able to produce ice at a cost price of N 10, (US $16.60), which would be sold to the pilot scheme at N 15 (US $ 25) per ton. The over capacity in ice production could be Bold to the Kwara State Cooperative or private enterprise in New Bussa at N 15 per ton (US $25).

Electricity rates for small commercial use (N.E.P.A.)

| Power demand charge | ||

| First 5 kVA of demand or less | no charge | |

| Next 5 kVA | N 3, per kVA (US $ 5) | |

| All additional kVA at | N 2.25 per kVA (US $ 3.36) | |

| Energy demand charges | ||

| First 20 kWh | N 2 | (US $3.30) each |

| Next 180 " | N 0.055 | ( " 0.091) " |

| " 300 " | N 0.05 | ( " 0.83) " |

| " 2 000 " | N 0.04 | ( " 0.66) " |

| All over 2 500 kWh | N 0.03 | ( " 0.05) " |

Kwara State Cooperative

This cooperative presently sends an 8 ton insulated refrigerated truck to Awuru and Faku, twice weekly. Pish is bought at an average of 60 kobo/kg (US $ 1) and sold in Ilorin at an average of 75 kobo/kg (US $ 2.24) (in fact cutlets are sold at 35 kobo/lb (US $ 0.60) and heads are sold separately at 20 kobo/lb (US $ 0.33). Due to the limited amounts of fish obtained at Awuru and Faku, on average some 200 kg per trip, the cooperative must presently be running this operation at substantial losses.

| Class batch of fish lbs | Distribution % | Mean weight batch fresh fish (lbs) | Mean weight batch smoked fish (lbs) | Difference | Prices (sh/lb) | Differences | ||||

| lbs | % | fresh fish | smoked fish | values % | ||||||

| A | Under 20 lbs | 40 | 36.54 | 14.96 | -21.58 | -59.05 | O.566 | 1.517 | +0.951 | +168.5 |

| B | 20–50 lbs | 30.77 | 61 | 27.85 | -33.15 | -54.34 | 0.635 | 1.508 | +0.873 | +137.5 |

| C | 80–110 lbs | 15.38 | 89 | 40.35 | -48.65 | -54.66 | 0.657 | 1.574 | +0.840 | +139.5 |

| D | Over 110 lbs | 13.85 | 194.22 | 88.33 | -105.89 | -54.52 | 0.468 | 1.308 | +0.840 | +179.5 |

| All | 100 | 73.97 | 32.98 | -40.99 | -55.41 | O.565 | 1.449 | +0.884 | +156.6 | |

Table from Anthonio etal.

| Consultant's note Class A | 36.54 lbs at 0.566 sh/lb | value fresh fish | 20.68 sh |

| 14.96 lbs at 1.517 sh/lb | value dry fish | 22.49 ah | |

| difference | 1.81sh =+ 9% |

The profit on the smoking/drying operation after deduction of costs and labour seems to be very small.

| N | US $ | |

| Gas heated cooking stove | 100 | ( 166 ) |

| Pressure cooker, pots and pans | 100 | ( 166 ) |

| Cutlery, filleting knives | 50 | ( 83 ) |

| Plates | 50 | ( 83 ) |

| Pish boxes, polyethylene, 50 x | 400 | ( 664 ) |

| Plastic buckets, barrels | 150 | ( 249 ) |

| Ice plant (Maja, 600 kg/24 hrs, flake ice) | 3 700 | ( 6 142 ) |

| Refrigerator 1 | 200 | ( 332 ) |

| Freezer cabinet 1 | 200 | ( 332 ) |

| Plastic bag sealer (Audion) | 125 | ( 208 ) |

| Foil wrapping apparatus (Servo-Wrap) | 120 | ( 200 ) |

| Food cutter with meat mincer, 10 1 bowl | 1 250 | ( 2 076 ) |

| Food mixer (Hobart AE-120) | 750 | ( 1 248 ) |

| Scale Sauter Toppan, 6 kg capacity | 700 | ( 1 000 ) |

| Scale up to 100 kg, Bizerba ASE | 1 125 | ( 1 868 ) |

| Hammer mill for samples | 325 | ( 540 ) |

| Drying oven 40–250°C, 30 1 1 | 180 | ( 290 ) |

| Insulated containers, 2 × 350 1 | 400 | ( 664 ) |

| Thermocouple temp. recorder, 6 points Honeywell | 1 100 | ( 1 826 ) |

| Kjeldahl-app. for protein determination, 6 stations | 300 | ( 488 ) |

| Soxhlet fat extraction heater, waterbath, 6 stations | 160 | ( 265 ) |

| Soxhlet fat extraction app., 10 x | 160 | ( 265 ) |

| Bunsen burners for butane | 50 | ( 83 ) |

| Salinometers 6 | 10 | ( 16.6 ) |

| Thermometers 10 | 25 | ( 42 ) |

| Glassware, assorted | 500 | ( 830 ) |

| Water distiller, Manesty, 1.5 l/hr | 200 | ( 332 ) |

| N 12 430 | (US $ 20 458 ) |

1 These items are available in the project already

The necessity of ice plant depends on the ultimate location of a pilot scheme for the collection and distribution of chilled fish.

Borgstrom, G. (Ed.), 1961–5 Fish as food. New York, Academic Press, 4 vols

Burgees, G.H.O., et a1., 1965 Fish handling and processing. Edinburgh, H.M. Stationery Office, 390 p.

Gillies, M.T., 1971 Seafood processing. New Jersey, Noyes Data Corp., Noyes Building, Park Ridge, 260 p.

Kreuzer, R., (Ed.), 1971 Fish inspection and quality control. London, Fishing News (Books) Ltd., 290 p.

Stansby, M.E. Industrial fishery technology. London, Chapman & Hall Ltd.

Anthonio, G.B.O., 1970 Fish marketing survey in the Kainji Lake Basin Yelwa area study. Ibadan, Nigerian Institute of Social and Economic Research, May 1970.

FAO, 1971 Fishery Industries Division, Fishery Products and Marketing Branch, Equipment and methods for improved smoke-drying of fish in the tropics. FAO Tech.Pap., (104):27p.

FAO, 1971a Fishery Industries Division, Fishery Products and Marketing Branch A model fishery products quality control laboratory. FAO Fish.Tech.Pap., (107):22 p.

Ita, E.O., 1972 Approaches to the evaluation and management of the fish stock in Kainji Lake, Nigeria. Paper presented at the CIFA conference, Fort Lamy, Chad, 29 November–6 December, 1972. Rome, FAO, CIFA/72/S.14:18 p.

Jenness, J. 1970 Fishermen of the Kainji Basin. Working paper No. 3. Kainji Lake Research Project. Rome, FAO, FI:3F/NIR 24: 98 P.

FAO/UN 1970 Report to the Government of Nigeria on the fishery investigations on the Niger and Benue Rivers in the Northern Region and development of riverine fishery management and training. Based on the work of M.P. Motwani, Inland Fishery Biologist. Rep.FAO/UNDP(TA). (2771): 196 P.

FAO/UN 1963 Report to the Government of Nigeria on improvement in the bulk smoking of bonga in Western Nigeria. Based on the work of M. Piatek, FAO/TA Fish Processing Expert. Rep.FAO/EPTA. (1756):68 p.

FAO/UN 1969 Report to the Government of Nigeria on fishing technology relating to river and swamp fisheries of Northern Nigeria. Based on the work of W. Reed, FAO/TA Fishery Technologist. Rep.FAO/UNDP(TA). (2711):90 p.

FAO/UN 1970a The fish population of newly impounded Kainji Lake. Report prepared for the Government of Nigeria by FAO of the UN acting as executing agency for UNDP. Based on the work of J.L. Turner, Inland Fishery Biologist. Rome, FAO, Tech.Rep.1 FI:SP/NIR 24: 59 p.

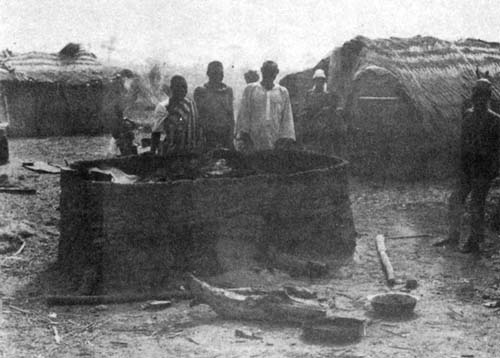

Fig. 1 A TRADITIONAL SMOKING OVEN

Fig. 2. A 3-TRAY MUD SMOKING KILN AT YELWA

Fig. 3 AN HOUR-GLASS SHAPED SMOKING OVEN

Fig. 4 FISH SKEWERED ON A STICK PRICK TO SMOKING

Fig. 5 YELWA MARKET

Fig. 6 PORO FISHING VILLAGE ON LAKE KAINJI