Adrian Whiteman and Ragnar Jonsson1

The Asia–Pacific region accounts for a major share of global forest product production, consumption and trade and continues to be one of the most dynamic and rapidly developing regions in the world. This paper describes recent trends in forest product markets and the outlook for the next 25 years. It also describes some of the driving forces that have shaped these markets and will continue to do so in the future. Finally, the paper discusses some of the implications of the outlook for forest management and future development of the forest processing industry in the region.

Keywords: forest products, econometrics, supply, demand, markets

Introduction

This paper describes recent trends in forest product markets in the Asia–Pacific region and presents a provisional outlook to the year 2030. This outlook is the latest in a long series of global and regional outlook studies that have been produced by the Food and Agriculture Organization of the United Nations (FAO) since the 1950s.

The paper starts by briefly describing the methodology used to analyse historical trends in forest product markets and to produce the projections of future forest product production and consumption. It then illustrates trends in production and consumption since 1980, including an analysis of the consumption of wood and fibre used to produce forest products in the region (the wood raw material balance). Subsequently, the same information is presented for the outlook to the year 2030. Finally, the paper discusses the implications of the outlook for forests and the forest industry in the region and presents some conclusions.

Methodology

The projections of future forest product supply and demand presented here have been based on a statistical analysis of historical data about forest product production and consumption. The analytical approach chosen for this study was to divide consumption and production into several market segments (such as domestic demand, import demand, export demand) and construct separate models to explain the historical trends in each of these market segments as functions of economic variables such as gross domestic product (GDP) and product prices. For countries with significant levels of production, these models were created for each of the main forest product categories and each market segment in each individual country. For smaller countries, cross-sectional analysis was used (i.e. the models were constructed using data from groups of countries and, sometimes, using more aggregated products, for example total sawnwood rather than coniferous and non-coniferous sawnwood separately). Multiple linear regression analysis was used to test and estimate the model parameters that were used to produce the forecasts. A more detailed description of the modeling methodology used here can be found in Kangas and Baudin (2003).

The approach was used mainly for modeling supply and demand of processed forest products (i.e. sawnwood, wood-based panels, wood and non-wood pulp, paper and paperboard). In addition, the production and consumption of wood and fibre inputs (i.e. industrial roundwood, recovered paper and wood residues) were analysed using product conversion factors (i.e. how much wood or fibre is required to manufacture one unit of processed product) and with reference to estimates of current and future potential wood and fibre supply using a raw material balance analysis (for further explanation, see UN 2005).

It should be noted that the projections presented here are provisional. This analysis is part of a global analysis of forest product markets that FAO is currently completing. As the Asia–Pacific region is closely integrated into global forest product markets, the finalization of the global outlook may result in some changes to the projections presented here. In addition, the analysis of future potential wood and fibre supply is based on statistics collected by FAO in the 2000 Global Forest Resource Assessment (FRA). The 2005 FRA is now available (FAO 2006) and FAO is currently analysing these more recent forest resource statistics. The results of the analysis may present a different picture of future wood availability compared to that given here.

Historical trends in forest product markets

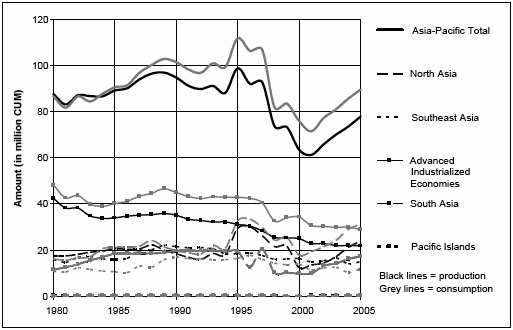

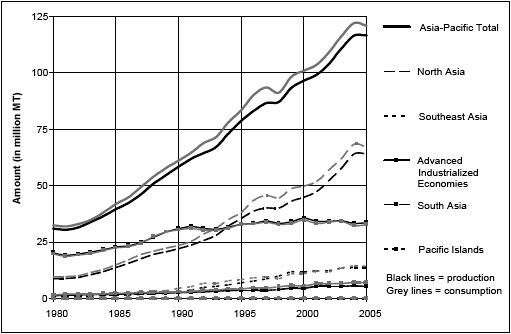

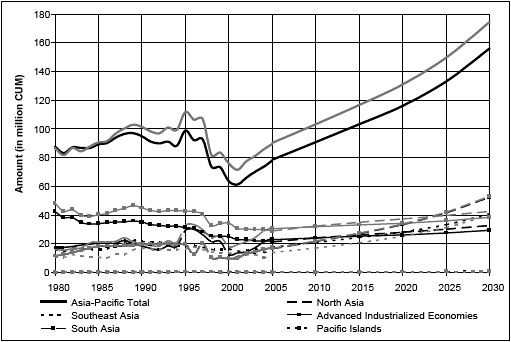

Figure 1 shows the historical trend in sawnwood production and consumption in the Asia– Pacific region from 1980 to 2005. Overall, consumption in 2005 was about the same as in 1980 — 90 million m3 — with production of just under 80 million m3. The trend shows some growth in production and consumption up until 1995, then a sharp decline to 2001, and more rapid growth thereafter. Also noticeable is the growing gap between production and consumption over the period, which has led to net imports of slightly more than 10 million m3 (or just over 10 percent of total consumption) by 2005.

The two largest subregions (in terms of the size of their economies) account for most of these trends. Production and consumption in China (in North Asia) increased rapidly in the mid1990s, possibly in anticipation of the ban on harvesting in natural forests implemented there. It then declined from 1996 to 2000, as domestic roundwood harvesting switched entirely to planted trees. This period also coincided with a reduction in the economic growth rate in China (and the recession in several other nearby countries due to the Asian financial crisis in the late 1990s). From 2000 onwards, domestic production and consumption increased again rapidly and will soon pass the peak reached in 1996.

The trend for the advanced industrialized economies (AIEs — Australia, Japan and New Zealand) shows a gradual decline in both production and consumption throughout the period. This is due to a combination of low economic growth in Japan over much of the period combined with gradual substitution of wood-based panels (and, more recently, engineered wood products) for sawnwood in major end uses such as construction.

Figure 1. Trends in sawnwood production and consumption, 1980–2005

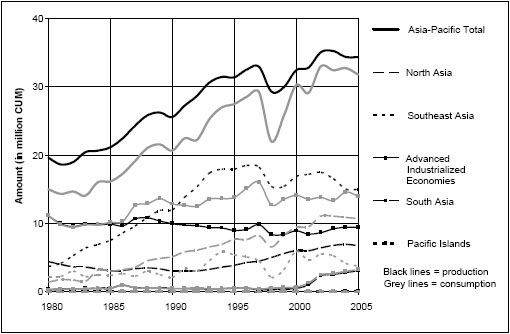

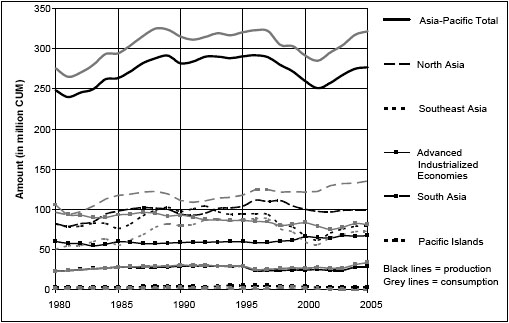

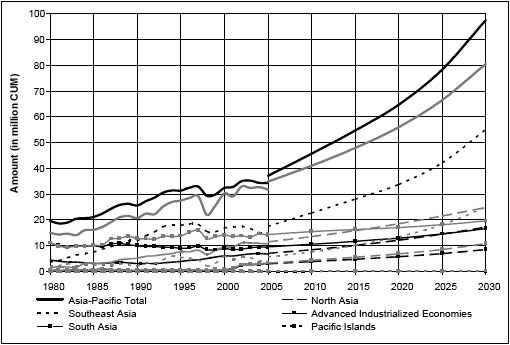

Figure 2. Trends in wood-based panel production and consumption, 1980– 2005

Trends in wood-based panel production and consumption are shown in Figure 2. These show that both production and consumption have risen quite dramatically over the period, with production increasing from 20 million to 35 million m3 and consumption doubling from 15 million to over 30 million m3. All of the subregions display growth in this sector, with the exception of wood-based panel production in the AIEs. Again, a short downturn in this sector appears at the end of the 1990s due to the Asian financial crisis.

The region as a whole is a net exporter of wood-based panels, although this surplus of production over consumption has declined over the period. North Asia and the AIEs are significant net importers of wood-based panels, but Southeast Asia is an even greater net exporter of these products (particularly Indonesia and Malaysia, which export large volumes of plywood).

Most of the growth in this sector during the 1980s occurred in the plywood subsector, when Indonesia and Malaysia rapidly developed export-orientated plywood industries. China has also, more recently, developed a significant plywood industry (although production is mostly used domestically). In addition, other types of wood-based panel have gradually replaced sawnwood in some end uses, particularly in the AIEs.

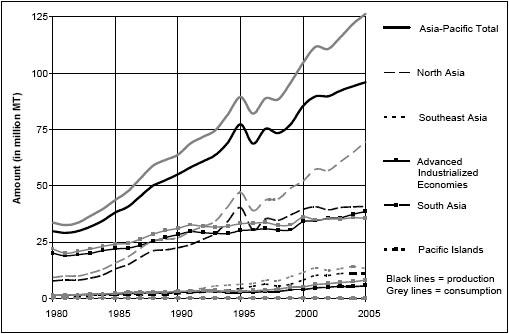

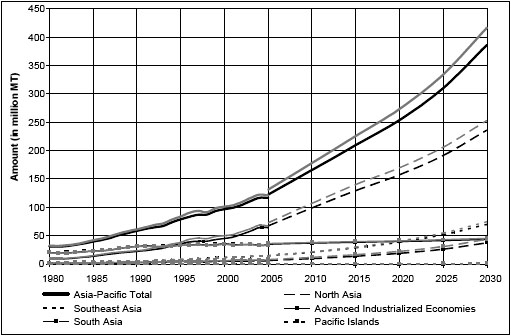

Figure 3. Trends in fibre furnish production and consumption, 1980–2005

Fibre furnish includes the three main types of wood pulp (mechanical, chemical and semi-chemical), plus other fibre pulp and recovered paper (wastepaper); the trends in fibre furnish production and consumption are shown in Figure 3.

As in most other regions and the world as a whole, historical growth in pulp and paper production and consumption has been far higher than in other product sectors. In the Asia–Pacific region, consumption has increased fourfold since 1980 from 35 million to 130 million tonnes in 2005. Production has increased by almost as much, from 30 million to 95 million tonnes over the same period.

Much of the growth in this sector has occurred in North Asia, although growth in South and Southeast Asia has also started to increase over the last decade. In contrast, growth in the AIEs has been relatively slow since 1990. With the exception of the AIEs since 2000, all of the subregions have consistently consumed more fibre furnish than they have produced and the level of net imports has increased since 1995, particularly in North Asia.

Most of the fibre furnish produced and consumed in the region is chemical pulp and recovered paper. Chemical pulp consumption has increased threefold from 13 million to 36 million tonnes over the period, while recovered paper consumption has increased almost fivefold from 12 million to 53 million tonnes.

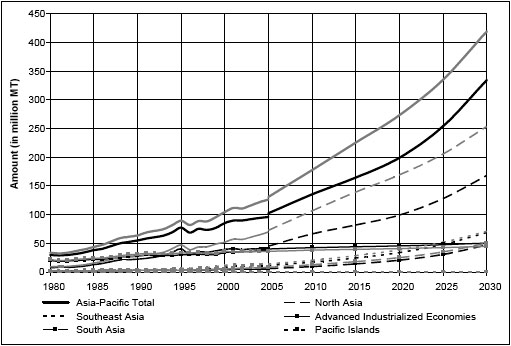

Figure 4. Trends in paper and paperboard production and consumption, 1980–2005

Figure 4 shows similar trends for paper and paperboard production and consumption in the region since 1980. Again, the region is a net importer of paper and paperboard, but this is mostly restricted to North and South Asia and production and consumption levels are very close in the other subregions.

Of the three main paper types, newsprint accounts for a very small share of total production and consumption (around 10 percent) and has grown very slowly since 1980. With the expansion of other types of media (e.g. television and the Internet), growth in newsprint consumption has slowed dramatically in the more developed countries in the region. Printing and writing paper is the second largest part of this market, with production and consumption in 2005 of around 30 million tonnes (equal to about 25 percent of total paper and paperboard). Other paper and paperboard account for the remaining 65 percent of the market, with production and consumption of 75 million and 80 million tonnes respectively in 2005. Production and consumption of both of these paper types has increased almost fourfold since 1980.

Historical trends in wood and fibre production and consumption

The two main sources of wood and fibre raw materials used to produce forest products are industrial roundwood and recovered paper. In addition, trade in wood pulp (a partly processed source of fibre) can add or subtract from the supply of raw materials to the industry (i.e. as imports or exports) and processing residues from the sawmilling and plywood industry may add to wood and fibre supply (although data about this resource are quite poor).

Figure 5. Trends in industrial roundwood production and consumption, 1980–2005

Figure 5 shows the historical trends in industrial roundwood production and consumption since 1980. Overall, production and consumption have not increased by very much over the period. Production increased by about 10 percent, from 250 million m3 in 1980 to 275 million m3 in 2005. Consumption increased by slightly more than this, from 275 million to 325 million m3.

At the subregional level, the trends since 1980 are quite different. Production and consumption in South Asia and the Pacific Islands are roughly the same and have not changed by very much over the period. Southeast Asia is the one subregion that is a net exporter of industrial roundwood, but net exports have declined over the period. North Asia and the AIEs are the two large net importers in the region, but the trends in these subregions are the opposite of each other. Net imports into the AIEs have declined significantly over the period while net imports into North Asia declined very slightly over the start of the period, but increased rapidly in the last decade.

In very simple terms, four main factors have probably contributed most to the complex pattern of trends in industrial roundwood production and consumption seen in the region since 1980: (1) In Southeast Asia, log export bans and the development of domestic processing industries in the early part of the period are the main reasons for the decline in net exports from the subregion; (2) in the AIEs, slow growth in the production of finished products in Japan combined with greater use of recovered paper has resulted in declining wood consumption and net imports (the trends in this subregion are entirely due to trends in Japan, which accounts for most of the production and consumption in this subregion); (3) in North Asia, the decline in production and increased imports over the last few years is due to the harvesting ban implemented in China’s natural forests combined with rapid growth in the forest processing industry there; (4) in Southeast Asia in the last decade, the Asian financial crisis resulted in falling production and consumption from 1995 to 2000, but both are starting to increase again.

Although these complex trends cannot easily be linked to changes in the availability of wood resources (except in the case of China’s harvesting ban), a decline in production from natural forests is undoubtedly occurring along with a gradual replacement of this source of wood supply by industrial roundwood from forest plantations. Countries in the region have had mixed results with the establishment of forest plantations, but it seems likely that almost all of the major producers will increasingly rely on these forests for future wood supply.

This information shows significant growth in the production and consumption of most finished wood products in the region since 1980 while, at the same time, production and consumption of industrial roundwood has grown very slowly. This has been possible due to the structure of growth in the sector and the different demands that are placed on wood and fibre supplies. In particular, most growth has occurred in the pulp and paper industry (which can use a variety of wood and fibre sources) and this growth has occurred alongside rapid increases in wastepaper recovery and utilization in many countries.

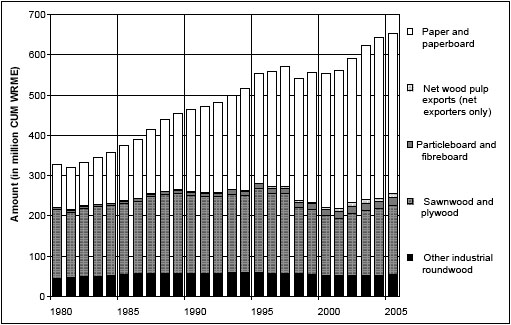

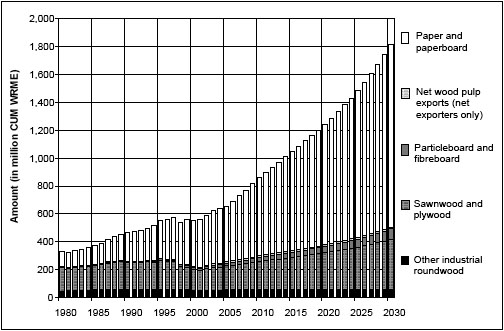

Figure 6 shows the trend in the derived demand for wood and fibre raw materials by the forest processing industry in the region since 1980. This has been calculated by converting the trends in the production of finished products to the amounts of wood and fibre raw materials that would be required to manufacture each of those products (including wood pulp, in the case of countries that are net exporters of wood pulp).

Figure 6. Trends in subsector wood and fibre raw material demand from 1980 to 2005

The results are expressed in terms of cubic metres of wood raw material equivalent (m3 WRME). Thus, for example, approximately 170 million m3 of industrial roundwood were required to produce 100 million m3 of sawnwood and plywood in 2005, with an average conversion factor of around 1.70: 1.00. (Individual conversion factors were applied to each product in each country for this calculation, but these conversion factors were not varied from year to year.)

Figure 6 shows that total wood and fibre raw material demand has roughly doubled over the period from 330 million to 650 million m3WRME. However, demand for other industrial roundwood, sawnwood and plywood production has remained approximately constant and almost all of this growth has occurred in the paper and paperboard industry. Thus, the demand for raw materials that must come from trees and forests has not increased by very much at all. Growth in the production of reconstituted panels and paper and paperboard still places some demand on forest and tree resources for wood and fibre raw materials, but these subsectors can also use alternative types of wood and fibre, such as recovered paper and wood residues from the sawnwood and plywood industries.

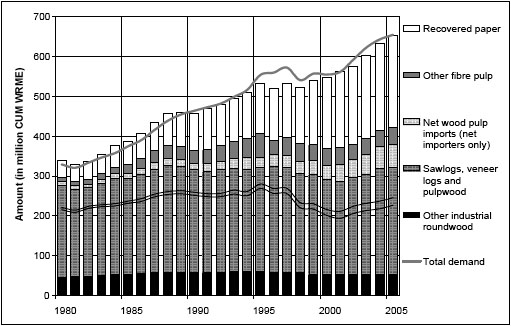

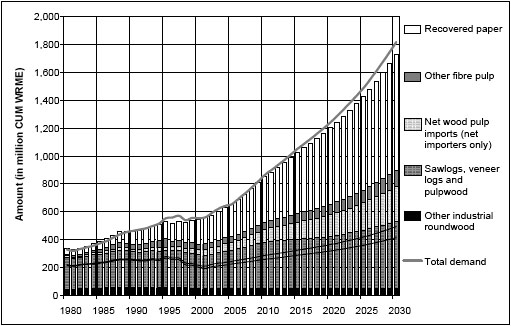

Figure 7. Trends in wood and fibre raw material consumption by type, 1980–2005

Figure 7 shows how this demand has been met by consumption of the different types of wood and fibre raw materials since 1980. For comparability, these figures have also been converted to m3WRME (i.e. in the cases of pulp and recovered paper). The top line shows the total demand (from Figure 6) and each bar shows consumption of each type of wood and fibre raw material. Gaps between the line and the tops of each bar can be attributed to consumption of other wood and fibre raw materials that are not reliably reported across the region (for example wood residues from the processing industry and recovered/recycled wood products). Comparisons between the bars and the line also highlight some uncertainties about the conversion factors used in these calculations and the reliability of the underlying statistics (for example where the bars are higher than the lines, suggesting that more wood and fibre raw materials were consumed than were needed in a year). For additional information, the two thin lines represent the total demand for other industrial roundwood, sawnwood and plywood production (the lower line) plus demand for reconstituted panel production (the higher line).

The figure shows that approximately two-thirds of the industrial roundwood consumed in the region is used to produce other industrial roundwood, sawnwood and plywood, while the remaining one-third is used to produce reconstituted panels, paper and paperboard. This distribution of consumption across the industries has not changed very much at all since 1980.

However, in comparison, the huge growth in wood and fibre raw material consumption by the paper and paperboard industry has been achieved by dramatic changes in the sources and types of fibre used by that industry. In 1980, pulpwood accounted for about half of the wood and fibre used by the paper and paperboard industry in the region, recovered paper accounted for about a quarter of consumption and other fibre pulp and net pulp imports accounted for the remainder. By 2005, recovered paper accounted for over half of all wood and fibre raw material consumption, pulpwood accounted for about a quarter and the other two sources accounted for the remainder. Thus, the relative importance of industrial roundwood in this subsector declined significantly over the period, to be replaced by much higher levels of wastepaper utilization.

Other comments on these historical trends

The above analysis has presented and explained some of the main changes that have occurred in forest product markets in the Asia–Pacific region since 1980. In addition, it is useful to compare these trends with previous projections for the region (Broadhead 2007) and with trends in other regions and at the global level. Some of the main results of this comparison are presented hereunder.

Growth in production and consumption of the different types of forest products over the last decade has varied from what was projected in the last Outlook Study. The reconstituted panels and pulp and paper sectors have grown at a higher rate than was expected while, conversely, the sawnwood and plywood sectors have not grown by as much. To some extent, the latter observation reflects more rapid substitution of reconstituted panels for other solid wood products than was expected. However, the main reason for higher than expected growth in the other sectors is likely to be a higher than expected increase in production and consumption in response to increased incomes (higher income elasticity).

At the subregional level, production and consumption in North Asia has grown much faster than expected while, conversely, production and consumption in the AIEs has grown much more slowly. These changes are largely due to economic growth rates in China and Japan that were higher/lower than expected and they have more or less balanced each other. In addition, the impact of the Asian financial crisis was more severe than expected, to the extent that production and consumption in several Southeast Asian countries is still below what was projected.

International trade has generally grown more rapidly than was expected both within and between countries in the region and at the global level as a whole. In addition, the region now accounts for a greater share of global trade in forest products than was expected (mostly due to the rapid expansion of trade with China in recent years). This increased “globalization” affected many economies and different sectors and was due to numerous socio-economic events in the early 1990s that were not well understood and would anyway have been very difficult to forecast.

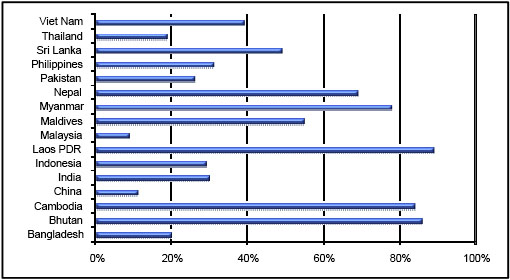

Although the region has achieved great gains in efficiency (in terms of increasing the production of forest products without major increases in the consumption of industrial roundwood), there remains considerable scope for future improvements. For example, wastepaper recovery and utilization is still very low in many countries, substitution of reconstituted panels for sawnwood and plywood is still relatively low and the use of wood residues is not well developed. As the production and consumption of finished products continues to grow rapidly in the future and the production of industrial roundwood gradually moves towards more production from planted forests, it can be expected that improvements in efficiency will become more important to the sector.

The outlook for forest product markets

Figure 8 shows projections to 2030 for sawnwood production and consumption in the region along with the trends shown previously. For the region as a whole, production and consumption are expected to double from 2005 to 2030. Net imports are expected to remain roughly the same at about 20 million m3, with net imports of roughly 10 million m3 each in North Asia and the AIEs and balanced supply and demand in the other subregions.

Figure 8. Trends and projections for sawnwood production and consumption

Modest growth in production and consumption is expected in North Asia and the AIEs. The two subregions with the highest projected growth are Southeast and South Asia, with a doubling of production and consumption in Southeast Asia and a projected increase of around 150 percent in South Asia from now to 2030. The latter projection for South Asia seems optimistic considering the restricted availability of wood supplies there and it may be revised downwards when the global market forecasts and analysis of future industrial roundwood supply and demand are completed. It does, however, indicate that there is significant demand for sawnwood in this subregion, which is currently limited by the availability of raw materials.

Figure 9 shows the trends and projections of wood-based panel production and consumption in the region. The small differences between the trend figure for 2005 (actual production and consumption) and projection for 2005 are because the projections start from the mid-point of the period 2000 to 2005 and are based on a three-year average around that point (to reduce the effect of annual fluctuations).

The projections show that production and consumption are expected to continue to grow rapidly, with an increase of roughly 250 percent by 2030. Net exports from the region are also projected to increase to around 15 million m3with rapid growth in production, particularly from 2020.

Figure 9. Trends and projections for wood-based panel production and consumption

At the subregional level, a low level of growth is expected in the AIEs and the Pacific Islands (which are very small producers and consumers of wood-based panels). In addition, net imports into the AIEs are expected to decline by about half (from the current level of around 5 million m3per year). Production and consumption are expected to double both in North and South Asia by 2030, with a slight increase in net imports into these two subregions.

Production and consumption in Southeast Asia are expected to account for most of the growth of this sector in the region, with a threefold increase by 2030. This subregion is a major net exporter of wood-based panels, because it has developed a significant competitive advantage in this sector (particularly in Indonesia and Malaysia). Although, historically, the plywood industry has been the major component of this sector in the subregion, rapid growth in production and consumption is projected across all types of wood-based panels. However, as with the case of sawnwood in South Asia, these projected levels of growth may be constrained by future wood and fibre availability and this will have to be explored further.

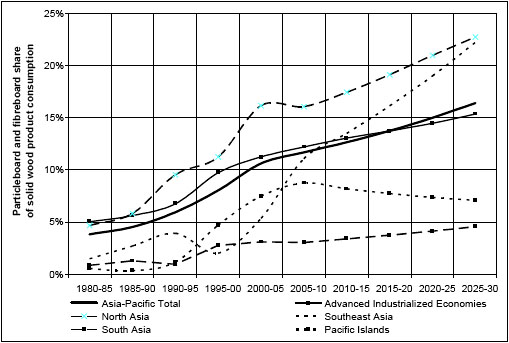

Figure 10. Trends and projections for market penetration of reconstituted panels

The production and use of reconstituted panels has advantages in terms of wood and fibre supply because these products can be manufactured from smaller-sized wood, wood with lower strength properties (for example from fast-growing planted forests), wood residues and recovered wood products. Consequently, significant growth in production of these products in Europe and North America has been partly driven by changes in wood supply.

The projections show that market penetration in the Asia–Pacific region is improving, but it is slightly behind the current levels of market penetration in North America and a long way behind the situation in Europe. Future changes in wood and fibre quality and availability may encourage a more rapid expansion of this subsector than the projections suggest. The extent to which this may occur will depend on future changes in raw material supply, along with the ability of producers in the region to develop the skills, technology and industrial capacity to manufacture these types of products.

Figure 11 shows the trends and projections for fibre furnish production and consumption to 2030. Over the next 25 years, production and consumption in the region are expected to grow by slightly more than 300 percent to reach a production level of 340 million tonnes and consumption of 420 million tonnes in 2030. Net imports will increase from 35 million tonnes at present to around 70 million tonnes in 2020 and remain at this level until 2030. The difference between production and consumption is not expected to increase beyond 2020 due to gradually increasing rates of wastepaper recovery, which will rise from 45 percent in 2005 to about 52 percent in 2030.

Figure 11. Trends and projections for fibre furnish production and consumption

Figure 12. Trends and projections for paper production and consumption

At the subregional level, production and consumption in the AIEs will remain in balance and should continue to grow only slowly, resulting in a very slight increase by 2030. In contrast, production and consumption in North Asia will grow by slightly more than 300 percent and will increase fivefold in South and Southeast Asia (although from much lower levels of current production and consumption). All three of these subregions are net importers of fibre furnish and will remain so in the future. In the case of North Asia, these net imports are significant and are expected to increase to 2020 and then remain about the same (due to the projected increase in wastepaper recovery noted above). It is also worth noting that these three subregions will equal or exceed the AIEs in terms of total production and consumption by 2030.

Figure 12 presents the trends and projections for paper and paperboard production and consumption, which are very similar to those described above for fibre furnish. The main difference is that net imports of these products into the region are much smaller, although they are expected to increase slightly over the next 25 years.

Outlook for wood and fibre production and consumption

The trends and projections for wood and fibre raw material demand in the Asia–Pacific region are shown in Figure 13. As before, they have been calculated from the projections of finished product production, multiplied by conversion factors to arrive at required inputs measured in cubic metres of wood raw material equivalent.

Figure 13. Trends and projections for raw material demand by subsectors

Overall, raw material demand is expected to increase almost threefold by 2030 from 650 million m3WRME at present to slightly more than 1 800 million m3WRME in 2030. The projection of rapid growth in pulp and paper production accounts for the majority of this increase (from around 400 million m3WRME at present to 1 300 million m3WRME in 2030). However, demand for industrial roundwood to manufacture sawnwood and plywood is also projected to double, from around 200 million to 400 million m3WRME over the period.

Figure 14 presents the same information, but with the demand by subsector translated into projected consumption by the different types of wood and fibre. In this case, recovered paper is expected to continue increasing in importance as a source of fibre for paper manufacturing. However, this will not meet all of the growth in future fibre demand and net pulp imports are, therefore, also expected to increase significantly from around 60 million m3WRME at present to 250 million m3WRME in 2030 (the latter figure is equal to about 80 to 100 million tonnes of net pulp imports, depending on the proportions of chemical and mechanical pulp that are imported). Other fibre pulp consumption may also increase, although only by a small amount.

Industrial roundwood consumption is also expected to increase from 325 million to 525 million m3 over the period. Most of this increase in consumption will be to meet the growing demand for sawnwood and wood-based panel production. Pulpwood consumption (currently about one-third of all industrial roundwood consumption) may remain at about 100 million m3 until 2010, and then decline as recovered paper and net pulp imports increase in importance as sources of fibre raw materials for the paper industry. However, this projection for pulpwood consumption depends on the future availability of pulpwood from forests and the extent to which imported pulp is required to meet the expected growth in demand.

Figure 14. Trends and projections for raw material consumption by type

It is also expected that the recovery and use of wood residues from sawnwood and plywood production will increase slightly in the future and start to contribute more to wood supply for reconstituted panel, pulp and paper manufacturing. This is shown in Figure 14 by the slight but expanding gap shown between the total raw material demand (the grey line) and consumption of the major wood and fibre types (the top of each bar).

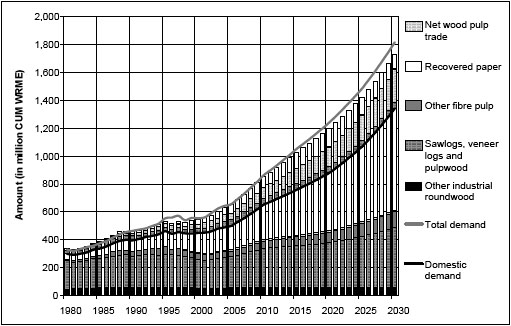

Figure 15 attempts to present the same information as Figure 14, but with the types of wood and fibre also divided into domestic demand (i.e. wood and fibre produced and consumed locally and shown by the bars under the solid black line) and import demand (the bars between the black and grey lines). As before, the gap between the top of each bar and the grey line represents the use of wood residues. International trade in residues is negligible, so it is reasonable to assume that almost all would continue to contribute to domestic demand.

Until the complete global supply and demand model is completed, these projections are provisional, but they are presented here to give a general indication of where future wood and fibre demands may be met in terms of local production and imports.

Net imports of wood and fibre raw materials currently amount to around 150 million m3WRME and account for slightly less than 25 percent of total raw material consumption. In terms of WRME, these net imports are split approximately equally between imports of industrial roundwood, wood pulp and recovered paper.

Figure 15. Trends and projections for raw material consumption by type and source

By 2030, these imports are expected to increase to almost 400 million m3WRME. Net imports of industrial roundwood will remain the same at around 50 million m3, net imports of recovered paper will grow slightly to around 100 million m3WRME and net pulp imports will expand significantly to about 250 million m3WRME. Furthermore, net imports of recovered paper are expected to increase at first — reaching about 135 million m3WRME in 2020 — and subsequently start to decline. This increase followed by some contraction is due to some countries reaching the technical limits on the utilization of recovered paper in paper manufacturing at about this time (which will start to constrain the total demand for recovered paper from 2020) combined with the expected continuation of growth in the wastepaper recovery rate (which will continue to increase domestic supply of wastepaper).

Implications of the market outlook for forests in the region

The projections presented suggest that there will be rapid growth in production and consumption across a broad range of forest products in the Asia–Pacific region. This is to be expected in the world’s most populous region and considering that the region includes many large and rapidly developing economies (for example China, India, Indonesia). In addition, the structure of growth across product sectors (comparatively high for wood-based panels and even more so in the case of pulp and paper) is a continuation of recent historical trends and is quite similar to projections for other regions and the world as whole. The one exception is the projection of rapid growth in sawnwood production and consumption, which is higher than the long-term historical trend (although it is similar to the trend in the last few years) and is quite high compared with projections for other more developed regions.

There are three major areas where these trends have interesting implications for the future of forests in the region. The first is the demands that these growing markets will place on the domestic forest resource — in terms of its ability to supply the required roundwood (potential roundwood supply) — and, as a consequence, the implications that this will have for forest management in the region. The second is the implications of these projections for trade with other regions and, related to this, the impact these demands may have on forest management outside the region. The third is the potential to meet some of these demands through increases and improvements in efficiency.

Table 1 shows the projected domestic demand for sawlogs and pulpwood and assesses how this demand may be satisfied by production from natural forests and forest plantations in the region. It also compares this with the last projections of potential roundwood production from forest plantation produced by FAO (Brown 2000).

Row 1 shows that sawlog demand will double over the next 25 years, from 172 million to 361 million m3. Due to the use of alternative fibre supplies (i.e. recovered paper and imported pulp), demand for pulpwood is much lower and will not grow by nearly as much.

Rows 2 and 3 show how this demand may be divided between production from natural forests and production from forest plantations. Statistics about current production are not divided in this way, but it is possible to make some reasonable assumptions about this based on the levels of total production in each country and their areas of natural forests and forest plantations. Thus, the majority of sawlogs used in the region probably come from natural forests and, conversely, natural forests are probably not a major component of pulpwood supply.

Given current policies and the current status of natural forests in the region (for example forest area, condition and stocking), it is reasonable to expect that production from natural forests will not increase in either category and may even decline in the future. The impact of this assumption in later years of the projection is shown by the rapidly increasing demand for sawlogs that will be placed on forest plantations in the region (rising from 45 million m3at present to 233 million m3in 2030).

Table 1. Comparison of projected industrial roundwood demand with potential supply

|

Source and type of roundwood |

Year |

||||||

|

2005 |

2010 |

2015 |

2020 |

2025 |

2030 | ||

|

Sawlog and pulpwood demand |

Sawlogs |

172 |

205 |

235 |

265 |

306 |

361 |

|

Pulpwood |

51 |

79 |

69 |

58 |

64 |

71 | |

|

Total |

223 |

284 |

303 |

323 |

370 |

432 | |

|

Production from natural forests |

Sawlogs |

128 |

128 |

128 |

128 |

128 |

128 |

|

Pulpwood |

10 |

10 |

10 |

10 |

10 |

10 | |

|

Total |

138 |

138 |

138 |

138 |

138 |

138 | |

|

Production from forest plantations |

Sawlogs |

45 |

78 |

107 |

138 |

178 |

233 |

|

Pulpwood |

41 |

69 |

59 |

48 |

54 |

61 | |

|

Total |

86 |

147 |

166 |

186 |

232 |

294 | |

|

Potential plantation supply: Scenario 1 |

Sawlogs |

45 |

58 |

60 |

64 |

64 |

63 |

|

Pulpwood |

134 |

173 |

181 |

193 |

192 |

190 | |

|

Total |

179 |

230 |

241 |

257 |

255 |

254 | |

|

Potential plantation supply: Scenario 2 |

Sawlogs |

46 |

60 |

66 |

72 |

75 |

78 |

|

Pulpwood |

139 |

180 |

198 |

217 |

225 |

234 | |

|

Total |

185 |

240 |

264 |

289 |

301 |

312 | |

|

Potential plantation supply: Scenario 3 |

Sawlogs |

50 |

71 |

89 |

110 |

121 |

133 |

|

Pulpwood |

150 |

214 |

266 |

331 |

364 |

400 | |

|

Total |

200 |

285 |

355 |

441 |

485 |

533 |

Note: All figures are in millions of cubic metres.

Rows 4 to 6 show the projected availability of roundwood (potential roundwood supply) from forest plantations under three different scenarios. Scenario 1 assumes no expansion of forest plantations, Scenario 3 assumes a continuation of new planting at the rates prevailing in 1995 to 2000 followed by a gradual decline in new planting and Scenario 2 assumes rates of new planting somewhere between the other two scenarios (for further details, see Brown 2000).

The table shows that total roundwood demand in the future could be met with a very modest expansion in forest plantation area (slightly less than Scenario 2). However, if the species and management regimes of forest plantations (currently focused on fast growing species managed on short rotations) do not change, this resource will not be able to meet future sawlog demand and will, conversely, result in far more potential pulpwood production than is required. The implications of this are that these management regimes should be re-examined to take into account the structure of industrial roundwood demand in the future. In addition, industrial investment could be considered to utilize this resource for the production of reconstituted panels (which can be substituted for sawnwood in many end uses).

With respect to international trade, the projections do not indicate major changes in net trade of finished products except significant growth in net exports of wood-based panels. In terms of raw material trade, net imports will expand significantly, but imported wood pulp is expected to account for most of this growth. This latter result is interesting because it suggests that, despite the development of fast growing forest plantations in the region, domestic production of wood pulp will not keep up with the projected growth in demand. This result is due to economic factors (as captured in the projection models) rather than resource availability, so it suggests that although the region is developing a resource to supply this industry, it still has some way to go in terms of developing a globally competitive processing sector.

The two most likely sources of wood pulp imports are South America and the Russian Federation. The South American wood pulp industry is largely based on fast-growing forest plantations and Russian wood pulp production is far lower than the potential, given the vast area of underutilized forests. Thus, the current concerns about the impact of rapid development in this region on the rest of the world’s forests are likely to remain focused on a few specific issues in a few selected countries.

The efficiency of resource utilization can be measured in several ways. One indicator is the proportion of forest product production that is manufactured from recycled and recovered wood and fibre compared to the proportion that is produced from industrial roundwood. In Europe, for example, less than half of all production is now manufactured from industrial roundwood and the majority is produced from recovered paper, wood residues and recovered wood products (UN 2005). In the Asia–Pacific region, the use of wood residues is not well recorded but thought to be quite low outside of a few more developed countries and the use of recovered paper is quite low (around 35 percent of all wood and fibre consumption). However, the projections do suggest that this situation will improve considerably and it is expected that recovered paper and wood residues will account for around half of all wood and fibre raw material consumption by 2030.

An alternative measure of efficiency is the amount of wood and fibre used to manufacture one unit of output. Detailed statistics in this respect are not available for all countries and for a long period of time. Consequently, the conversion factors used in this analysis have been estimated from product production and raw material consumption statistics reported to FAO (FAOSTAT) and have been applied to every year in the historical time series and projections. Comparing these data with similar statistics for other regions, the forest processing industry in Asia and the Pacific still has scope to increase conversion efficiency through the introduction of new technology and manufacturing processes.

A similar measure is the efficiency of end uses, particularly with respect to the use of solid wood products. Reconstituted panels require at least 25 percent less wood and fibre per cubic metre of output compared to sawnwood and plywood and, as an additional benefit, can be manufactured from wood residues and recovered wood products. Markets for these products in the Asia– Pacific region have not been fully developed compared with Europe and North America. Considering the gradual change in raw material supply towards forest plantations and the region’s competitive advantage in wood-based panel production generally, there appears to be scope for more rapid development of this subsector.

Bibliography

Broadhead, J. 2007. Asia-Pacific forestry: outlook and realities five years since APFSOS. Asia-Pacific Forestry Sector Outlook Study Working Paper No: APFSOSII/WP/01. Rome, FAO.

Brown, C. 2000. The global outlook for future wood supply from forest plantations. Global Forest Product Outlook Study Working Paper No: GFPOS/WP/03. Rome, FAO.

Food and Agriculture Organization (FAO).2006. Global Forest Resources Assessment 2005: progress towards sustainable forest management. FAO Forestry Paper 147. Rome, FAO.

Kangas, K. & Baudin, A. 2003. Modelling and projections of forest products demand, supply and trade in Europe. Geneva Timber and Forest Discussion Paper ECE/TIM/DP/30. Geneva, UN.

United Nations (UN). 2005. European forest sector outlook study: main report. Geneva Timber and Forest Study Paper ECE/TIM/SP/20. Geneva, UN.

1 Food and Agriculture Organization of the United Nations, Forestry Department, Forest Policy Service, Vialle delle Terme di Caracalla, 00153 Rome, Italy. E-mail: [email protected], [email protected]

B.K. Tiwari,1‹ C. Kumar2 and M.B. Lynser1Œ

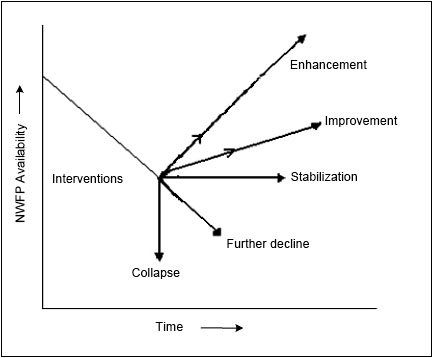

Increasing synchronization of local economies with national and international markets has opened up several opportunities and has introduced unforeseen threats, which can have significant impact on the non-wood forest product (NWFP) sector. This paper analyzes the recent trends in production and trade related to NWFPs from selected sites in South Asia. It then attempts to extrapolate the same trends to predict the future of NWFP production and suggest some strategies for sustainable management of NWFPs in Asia and the Pacific. Experiences from across the region suggest that NWFP domestication is a viable option to address resource supply constraints. Open access forests are prone to unsustainable harvest by collectors for commercial purposes as they are often not concerned about continued supply of the product. The collection of high value NWFPs from open access forests results in overharvesting and severely affects regeneration due to unsustainable and faulty harvesting methods. Hence, increased commercialization is likely to lead to overharvesting, resource depletion, degradation of forests and depletion of biodiversity; it needs stricter enforcement of regulations. On the other hand domestication can reduce the incentives to conserve the ecosystems in which the NWFP species grow naturally. NWFP certification, intensive management, marketing support, popularization of sustainable harvesting techniques and ensuring economic and social equity can assure sustainable production of NWFPs. The review of the NWFP sector across the region suggests that collection of subsistence NWFPs is generally sustainable and does not warrant much concern. Cultivation or enrichment of natural forests with NWFPs (e.g. forest gardens) is generally sustainable. The cultivation of NWFPs on farmlands needs to be promoted to reduce pressure on forests and promote income to people through this sector. However, cultivation of NWFPs on erstwhile forest land or by clearing natural forests is a cause of concern as it depletes biodiversity and affects availability of forest goods and services. In general, the trend of NWFP production is moving away from the forest, except for the clandestine and illegal trade of high value low volume products that continues to deplete the biodiversity and productivity of forests.

Keywords: non-wood forest products, commercialization, cultivation

Introduction

Non-wood forest products (NWFPs) include all goods of biological origin other than wood derived from forests, other wooded lands and trees outside forests. They are important in day-to-day life, as they are used for food, spices, edible oils and medicines; for fodder, forage, stall bedding and green manure; as construction material and household utensils; as fibre for cloth and rope; for basket and mat-making; and for ornamentation and religious purposes. NWFPs can be put both in subsistence and commercialized contexts; therefore people associate them with enormous value. For the majority of tribal and indigenous people living in regions rich in forest resources, NWFPs constitute a critical component of their food and livelihood security. NWFPs provide supplementary income sources to forest and forest-fringe dwellers. NWFP-based activities including collection, sale of raw materials, simple primary processing and local handicraft production fill seasonal food or income gaps. They also act as a “safety net” in times of hardship or emergency and generally improve household income security (Ruiz Perez and Arnold 1996). During the early years of scientific forestry, NWFPs were considered as minor forest produce and hidden harvest. But about a decade or two ago several studies highlighted the importance of NWFPs for sustainable forest management in general and poverty reduction in particular (Wollenberg and Ingles 1998; Sunderland and Ndoye 2004). Commercialization and expansion of trade in forest products have further enhanced their role by making harvesting and sale of these products important to the rural poor.

In Asia and the Pacific, NWFPs form an important subsistence and livelihood means for the majority of people living near forests. NWFPs like rubber, rattan, bamboo, aromatic oils and medicinal plants are traded or bartered within the Asia–Pacific region and in markets outside the region generating billions of US dollars per year as revenue. Countries like Malaysia, Indonesia, Viet Nam and China generate around US$50 million from rattan alone, thus occupying a lion’s share of the average annual world trade of US$88 million (Iqbal 1993). Growing population, rapid economic growth, reduction in poverty and expanding trade in the region have over the years changed the outlook towards forests and forest products. There is increasing shift from subsistence towards commercialization of these products. Increasing synchronization of local economies with national and international markets has opened up several opportunities and has brought in unforeseen threats, which can have significant impact on the NWFP sector. This paper analyzes the recent trends in production, trade and policies related to NWFPs, attempts to extrapolate the same trends with the objective of predicting the future of NWFP production and suggests the strategies for sustainable management of NWFPs in Asia and the Pacific.

Subsistence and commercial NWFPs

NWFPs can be broadly grouped into subsistence and commercial components. Subsistence NWFPs are collected in small quantities mainly for household use; for example, food (nuts, fruits, animals, insects, vegetables and mushrooms), fodder and roofing material. Commercial NWFPs are those that are collected or produced on a large scale mainly for trade; for example, bamboo, rattan, medicinal plants and spices. Rattan and bamboos, for instance, form important commercial NWFPs in several Asian countries making them the major international traders of these products (FAO 1997). The commercialization of tendu leaves (Diospyros melanoxylonRoxb.) has yielded huge economic benefits to local communities in Central India (Boaz 2004). In many cases, the development of socio-economic networks and infrastructure as well as markets B.K. Tiwari, C. Kumar and M.B. Lynser has led to the conversion of subsistence NWFPs to commercial varieties. Bamboo shoots, medicinal herbs, broom grass and mushrooms are some examples of such a shift. Evidence from many countries shows that extraction of NWFPs for subsistence use is generally sustainable, as it does not lead to depletion of the resource, while extraction of NWFPs from natural ecosystems for trade and commerce is generally not sustainable. Although subsistence NWFPs play a major role in the livelihoods of the forest-dependent poor in the region there is a glaring lack of reliable quantitative data on the subject. One of our recent studies conducted in the forest-rich state of Meghalaya has revealed that as many as 380 NWFPs are collected by the people. Bamboo, cane, broom grass (Thysanolaena maxima), bay leaf (Cinnamomom tamala), bark of Cinnamomum zeylanicum, Emblica officianalis, wild pepper (Piper longum), lichen (Usneasp.) and honey are major commercial NWFPs. Important subsistence NWFPs of the state include Phoenix spp., Luffa spp., cones and seeds of Pinus kesiya, mushrooms, torch wood, nuts of Castanopsis hysterix, fruits of Prunus nepalensis, Myrica nagi, Eleagnus khasianum, Flemengia vestita, Zanthozylum khasianum and ornamentals like orchids and rhododendrons. It is noted that the spectrum of species tapers as we move from household consumption to international trade NWFPs (Table 1). However, there is significant lack of information on quantity and methods used for the collection of these products.

Table 1. Important subsistence and commercial NWFPs of northeastern India

| Subsistence | Commercial | |||||

|---|---|---|---|---|---|---|

| Household consumption | Local markets | National markets | Industrial raw material | International trade | ||

| Bamboo, nuts, fruits, vegetables, medicinal plants, thatch grass, fodder, insects, snails, fish, crab, frogs, reptiles | Bamboo, rattan, bay leaf, wild pepper, medicinal plants | Bamboo, bay leaf, broom grass, wild pepper, medicinal lichen, resin, medicinal plants | Bamboo, broom grass, plants | Medicinal plants and aromatics | ||

Distribution of NWFPs in forests across the management gradient

NWFPs are extracted from natural forests, forest gardens or home gardens and from tree plantations that are subjected to varying degrees of management. Mostly wild edible items like mushrooms, insects, worms, nuts and fruits as well as lianas, bamboo, rattan and medicinal plants are collected from natural forests. Some NWFPs sourced from natural forests have a complex life cycle and population dynamics and cannot be brought under cultivation. Such wild NWFPs are mainly extracted for subsistence use as their availability is limited to geographical distribution and seasonality. However, there are cases where such NWFPs are sought for commercial use and fetch cash income for the collectors or gatherers. An example of a commercialized wild NWFP is wood lichen (Usneasp.), which has a good national market but the harvest is not sustainable. In forest gardens efforts are made to promote and enrich the forests with NWFP species. Such NWFPs can be classed as semi-wild because they are also extracted from the wild. The wild collection is generally done by the landless and poorer sections of the society, while forest gardens are under the control of landowning communities. Examples of semi-wild NWFPs are Thysanolaena maxima (broom grass), Cinnamomom tamala (bay leaf) in Meghalaya, Aleuritesspp. in Mizoram and Livistona jenkinsiana in Arunachal Pradesh (Tiwari 2001). In the high ranges and Nelliampathy Hills in Kerela (India), cardamom is grown in managed forests. Some 90 percent of the households in the area are involved in production or processing of cardamom in some way or other, deriving most of their cash income from it (Nair and Kutty 2004). In Nepal, many medicinal and aromatic plants such as keshar (Crocus sativa), jatamansi (Nardostachys grandiflora), sugandhwal (Valeriana jatamansii), padamchal (Rheum australe), bojho (Acorus calamus), kutki (Neopicrorhiza scrophulariiflora), atis (Delphnium himalayai), chiraito (Swertia chiraita), hatkaudo (Podophyllum hexandrum) and nirbisi (Pernacia nubicola) are being cultivated in community forests (Bhandari et al. 2006). Most NWFPs are collected from natural forests and very few from plantations (Table 2).

Table 2. Important NWFPs found in forests under varying degrees of management

| Natural forests | Forest gardens | Home gardens | Plantations on forest lands |

|---|---|---|---|

| Bamboo, rattan, lichen, wild nuts, fruits, mushroom, vegetables, medicinal plants, insects, fish, snails, crab, frogs, reptiles | Bamboo, rattan, bay leaf, wild pepper, medicinal plants | Bamboo, bay leaf, wild pepper, medicinal plants | Bamboo, broom grass |

Economic, ecological and social values of NWFPs

NWFPs make a substantial contribution to the livelihoods of hundreds of millions of people living in or near forests. Around 200 million people in the Asia–Pacific region are dependent on NWFPs for at least some part of their income. Aside from the millions of people that benefit directly from NWFP-based activities, millions of others consume NWFPs to meet their nutritional requirements. Although NWFPs provide important benefits year-round, it is during periods of scarcity when collection, processing and trade of NWFPs are most critical to family survival; hence they represent an important safety net. The vast majority of upland farmers in the Asia– Pacific region (e.g. shifting cultivators) cannot produce sufficient food to satisfy their annual household nutritional requirements. Hence, they resort to NWFPs to supplement food and income deficiencies. Therefore, NWFPs can be considered to be one of the crucial alternatives available to supplement income and ensure minimal family subsistence needs.

There is a growing interest in NWFPs for their enormous economic value. A number of NWFPs contribute to the creation of economic benefits and cash income at the local and community level, e.g. forest foods and medicines sold in village markets. NWFPs generate local, national and international trade revenues that are worth billions of dollars annually.

NWFPs provide subsistence income and livelihood security to forest and forest-fringe dwellers, encouraging local communities to conserve the forests. Large tracts of community forests of northeastern India maintained for day-to-day NWFP requirements also conserve natural resources like soil, water and biodiversity and thus ensure ecological security. Tiwari (2005) found that medicinal aromatic plants contribute towards the conservation of biodiversity and save a fragile ecosystem from degradation. Hence, managing forests for their NWFP values helps in meeting the complex demands of both conservation and development.

One of the key characteristics of NWFP trade is that it provides employment to women who harvest, process and sell NWFPs. This has helped to improve their economic and political status in many cases. For example, collection and processing of lichen in Meghalaya is mainly done by women. Similarly, the mat-making industry of Tangmang village of Meghalaya is entirely in the hands of women. In Manipur State of India about 250 000 women are involved in collecting forest products (FAO 1992).

For forest-dwelling ethnic groups in Asia and the Pacific, forests are integral to culture and a source of physical, spiritual and psychological sustenance. One can see that cultural identity and traditional knowledge systems are intertwined with the forests mainly due to the use of NWFPs in various cultural activities and rituals. Thus, numerous NWFP species and forest habitats are valued as components of cultural identity and religious rituals for which they are mostly conserved. Many indigenous traditional knowledge (ITK) systems have evolved in relation to the dependence of remote traditional populations on forest resources to secure reliable and sustainable livelihoods.

Opportunities in the NWFP sector

Commercialization and domestication of any NWFP species is motivated by high market demand, adequate product availability and advantageous pricing, which generally provide the strongest incentives for harvesters, buyers and processors. Increasing commercialization of a particular NWFP may be attributed to: (1) the preferences of the consumers; and (2) easy and cheap access to harvest the product by the producers.

Many NWFPs that were harvested only for subsistence use some years ago have now been commercialized on a large scale (e.g. bamboo shoots in China). NWFP commercialization has been promoted by development programmes and driven by market forces or both have acted synergetically. Some scholars have argued that in tropical rain forest areas, NWFP commercialization is an effective way to simultaneously solve the problem of achieving species and ecosystem conservation and improving local livelihoods (Ruiz Perez and Arnold 1996; Wollenberg and Ingles 1998). But others challenge this view and have raised serious doubts about achieving the objective of conservation through commercialization of NWFPs (Belcher and Schreckenberg 2007).

The commercial success of any NWFP at a global scale has the potential to result in such high demand that this cannot be assured from supplies of natural NWFP stocks as the quantities available have already declined with continuous harvesting in many cases. However, this decline more often than not creates strong incentives for domestication and cultivation of NWFP species and can be an effective alternative for conserving biodiversity as well as generating income. Some examples of NWFP domestication are: the mulberry plant (Broussonetia papyrifera) in Sayaboury Province, Lao PDR; Moso bamboo (Phyllostachys heterocyclavar. pubescens) in Anji County, China; rattan (Calamus tetradactylus) in the buffer zone of Ke Go Natural Reserve Area, Cam Xuyen District, Viet Nam; and broom grass (Thysanoleama maxima) in Meghalaya, India.

Factors affecting the NWFP sector

Availability: For successful and sustainable development of commercial NWFPs the most important factor is resource availability. Many forest species that yield commercial NWFPs are usually remotely located and found in small volume. In the long run, these species are unlikely to remain important suppliers of commercially large quantities, as they can be quickly overharvested. For example, high market demand of rattan has caused serious depletion of the product in the forests of Arunachal Pradesh (India), so much so that now rattan is available only in inaccessible areas. This is also the case for lichens in Meghalaya.

Market and demand: NWFP exploitation is usually the first and easiest step taken when supply constraints appear due to high market demands generated by commercialization. Domesticating NWFP species is ultimately the most viable option to address resource supply constraints when trade demands occur. A case study in Paklay District of Sayaboury Province, Lao PDR, shows a steady increase in areas planted with paper mulberry as well as production between 1990 and 1999 under the influence of a strong Thai market demand (Aubertin 2004). The value of the products multiplies as they move away from the site of production. A good example of this is the marketing of broom grass in Meghalaya. There is a vast difference between the prices of raw broom grass in the local markets in the interior areas compared to the retail price in the regional markets. The main reason is there are a few traders who are organized in small groups and hence they monopolize the business (Tiwari et al. 1995).

Key stakeholders in the market chain, whether producers, traders, consumers or governments, have decisive roles to play. Traders can influence the output of raw materials by increasing prices paid to producers and they also control and decide the fate of a product. When NWFP profit margins decline, they often shift their investments to other products with better margins. Consumers influence markets by their preferences for products or processes (e.g. organic products or fair trade), while producers can expand or improve their gathering intensity or change their production systems in response to demand. For low value products, e.g. leafy vegetables, tubers and wild fruits where demand is likely to decline with economic prosperity, domestication and cultivation is unlikely to occur. A common picture in the northeastern region of India is that the major portion of the NWFP market is dominated by traders and intermediaries who earn most of the benefits while the participation of the local producer/collector is limited only to the collection and disposal to the intermediary forces (Tiwari 2000).

Pricing: A stable and/or growing demand with fair prices offered to producers gives strong incentives to private investors at all levels to increase commercialization and cultivation of NWFPs. The supply of traded NWFPs depends directly on the prices offered to gatherers or cultivators. For the NWFPs gathered from the forests, the price is often determined by the time spent in collection and not by the actual value of the NWFP. The women collectors of lichen in the Jaintia Hills of Meghalaya, India are paid Rs20–35 (<US$1) for a kilogram of lichen that after some processing is sold to the consumers at a price of more than Rs200 (US$5) per kilogram. The collector and the communities owning the NWFPs have very little or no say in this regard. The intermediaries, traders and larger processors benefit because they usually control the price of the product. A village survey in Pynursla community development block of Meghlaya revealed that in the absence of organized marketing, the price of broom grass had slumped from Rs1 700 (~US$41) for 100 kilograms in 1996 to Rs700 (~US$16) per 100 kilograms in 2000, causing significant loss to the growers and gatherers of this NWFP.

Certain policies can also negatively affect prices paid to producers; for instance in Indonesia, the restrictive trading policies on raw rattan depressed the domestic prices of rattan, which in turn had an adverse impact on the income of rattan farmers and collectors (FAO 1997). Prices also tend to be cyclical, as they depend more on economic, social or climatic factors outside the producers’ region or on the price fluctuations of their competing substitute(s).

High value NWFPs are more likely to be cultivated rather than their low value counterparts as they result in more economic benefits. High value NWFPs, even though traded in small quantities, generate higher returns generally. When higher prices are offered, producers intensify or expand their gathering or cultivating efforts over larger areas as appropriate to their means. When prices are down, they even forsake gathering or cultivating, as it may not compensate their time investment vis-à-vis other income-earning options. For example in Meghalaya, NWFPs such as broom grass, wild pepper and lichen (the rate exceeds Rs10/kg) are preferred to low value products like thatch grass, bay leaf and bamboo.

Extraction: Extraction of NWFPs for both subsistence and commercial uses is often done by children, herders and women. Generally, children are involved in collecting nuts, fruits and birds while the women collect inter alia tubers, leafy vegetables and fuelwood. The herders mostly collect wild animals, insects, vegetables and fish that are usually meant for consumption. NWFPs that are collected for commercial use are mostly seasonal. Hence, they generate seasonal income and employment involving villagers from all ages and gender groups. The mode of collection varies from place to place and time to time. In the commercial exploitation of NWFPs, most methods employed for collection from open access forests are not sustainable and the collectors are not concerned about their continued supply either.

Medicinal plants are collected by both common villagers and traditional herbal practitioners. Globally, the trade in medicinal plants is increasing at a very fast rate; it is mainly characterized by supply of products from poor countries to economically growing countries as well as developed countries. This has a positive income transfer effect. China and India are the two leading countries in the trade. Increasing global interest in medicinal plants has created a sustained demand, but at the same time increased illegal trade in plant materials resulting in indiscriminate harvest of wild varieties and serious damage to biodiversity. The overexploitation of several of these plant species and resultant decline in availability has led to their cultivation under field conditions. In many cases, medicinal and aromatic crops have better economic opportunities as opposed to traditional field crops. The price of these crops as raw material to pharmaceutical industries has increased substantially, fetching higher prices for the cultivators and collectors.

Ownership rights: For the domestication of NWFPs, individual ownership is more effective than community ownership. For instance, in 1983, the shift from commune-based management to individual management after the introduction of the Household Responsibility System (HRS) in Anji County in China generated more intensive cultivation of bamboo by the farmers. Since then, most bamboo cultivation has been contracted to individual farmers who currently manage 96 percent of the total bamboo area. The introduction of the HRS brought dynamism to a stagnant sector, greatly increasing culm and shoot production (Maoyi and Xiaosheng 2004). Similarly, in Meghalaya, tenurial security has promoted cultivation of broom grass on forest lands previously subject to shifting cultivation.

Issues relating to NWFP commercialization

Economic benefits: Commercialization and domestication of NWFPs has improved the economic conditions of poor forest dwellers by increasing their household incomes. For example, the rattan sector in the Philippines is generating significant amounts of foreign exchange and rural employment and constitutes up to 60 percent to a household’s cash income among the Batak tribal groups (Palis 2004). While subsistence NWFPs benefit the poorest of the poor, commercial NWFPs generate employment and supplement income for many people involved at various levels in the NWFP value chain, for example collection, production, harvesting, processing, value addition and sale of such products. In India, about 50 percent of 68 million tribal populations are dependent on NWFPs for their livelihood requirements. Tendu leaf (Diospyros melanoxylon), for instance, forms an important NWFP with an annual production of 350 000 tonnes (US$2 000 million) and employs about 30 to 40 million people in both collection and local cigarette making (Bhattacharya 2007). NWFPs also provide substantial income to households during seasons when other income is low. The people of Tangmang village, Meghalaya, are involved in making bamboo items like mats and baskets during slack seasons when there is little or no agricultural work. They sell these goods in the market, earning some income to meet household needs.

Domestication of commercial NWFPs: Domestication of commercial NWFPs can result in better-quality products, more control over the timing and quantity of production and higher efficiencies in producers’ time and resource inputs, while reducing production costs. Harvest can be facilitated by the proximity of planted stocks to settlements and product quality can be improved by using genetically superior planting material. The higher returns to labour from cultivated NWFPs tend to discourage forest collection, therefore possibly allowing natural stocks to regenerate. Cultivating an NWFP species can also significantly diversify areas of production compared to the limited occurrences of the same species in its natural habitat. If demand levels and prices remain stable over time, rewards for intensifying management will increase. For instance, broom grass has a high benefit–cost ratio and a very good market. As a result, broom grass cultivation is expanding rapidly and the farmers are obtaining good returns while the traders are assured a steady supply. In villages where farmers cultivated this crop, within ten to 15 years it had almost completely occupied all the lands previously used for shifting cultivation (Tiwari et al. 1995).

Policy initiatives: Governments in Nepal, Indonesia and the Philippines, among others, are attempting to revise forestry policies to support national sustainable management and conservation goals. Recently enacted laws and newly revisited legal interpretations in these countries now support the provision of resource rights to local forest communities (Republic of Philippines 1992). Policies related to collection of NWFPs are becoming more pro-poor in India. Section 14 of the Scheduled Tribes and other Traditional Forest Dwellers (Recognition of Forest Rights) Act, 2006 (2 of 2007) of India states that the access, collection, use and disposal of all holders of forest rights shall be free of royalty. In about 100 000 Joint Forest Management villages of India, the forest dwellers have the right to collect NWFPs from government-controlled forests. Such policy initiatives are helping the rural poor who are dependent on the collection of NWFPs for their livelihoods.

The popular trends of the past two decades have been greater decentralization and devolution, privatization and the delegation of many social service/welfare functions from the state to civil society and NGOs. This has begun to influence forestry policy and practices also. Involvement of local communities in forest management and NWFP harvest and sale by scrapping restrictive policies can create strong incentives for local people to actively implement sustainable forest management (Ruiz Perez and Arnold 1996). This will directly benefit people by providing alternative livelihoods which in turn reduces pressures on the forest.

Weakening of traditional/customary management systems: In many countries, customary law and traditional management arrangements predominated long before forest resources came under the ownership, administration and/or regulation of governments. However, increased commercialization of NWFPs in response to growing market demand has weakened customary tenure and increased private property. As a result, many traditional arrangements and systems are under pressure and on the verge of breaking down. They either need to be strengthened or replaced with systems that can cope with the changes induced by markets and privatization of common resources.

Decline in traditional sustainable harvest practices: Decline in product availability due to commercialization has led to many traditional sustainable harvest practices being abandoned in favour of more destructive methods, even among some indigenous forest groups. Increase in demand and hence price of certain NWFPs has attracted outsiders to hitherto less valuable resources. This has often resulted in overharvesting or unsustainable and improper harvesting methods. Many NWFP collectors, mostly outsiders, have generally caused negative impacts on forest resources, fuelled escalating social tensions and prompted local collectors to “get what they can, while they can.” In India this has happened to Embilica officinalis (amla) fruit in Madhya Pradesh and Litsea citrata and Cinnamomum zeylanicum bark in Meghalaya. Commercial exploitation of NWFPs often leads to supply constraints because the resource is being harvested in uncontrolled and unlimited quantities and in an unsustainable manner. Such cases are usually in the context of free access systems where the resource is not subjected to any control. An example is the medicinal plant, Taxus baccata, in Meghalaya, where commercialization drastically reduced the availability of the species until it was depleted to the extent that the government was forced to impose a ban on the trade of the plant.

Decline in importance of wild products: Commercialization of NWFPs will favour only some products and make them more important while other products will remain important only in economic or ecological niches and are likely to be abandoned as better opportunities arise. Take for example the rattan species Calamus tetradactylus Hance (locally known as may) in Viet Nam. The farmers living in the buffer zone of Ke Go Natural Reserve Area in Cam Xuyen District previously harvested this rattan species from the wild. However, as availability of wild may has been decreasing owing to overharvesting, it is being replaced by a domesticated variety to meet commercial demands (Quang 2004). Similarly, domesticated NWFPs, like nuts and fruit species, will often be larger and of better quality. As a result, they can be supplied with more regularity. In combination, these “domesticated” attributes of NWFPs can result in their forest cousins completely losing their marketability. A number of fruits (Calamus, Myrica, Castonopsis, Prunussp.) collected from the forest have very high nutritive value yet they are not able to compete with the fruits available in the market. Also, in some cultures, fruit and vegetables collected from forests are considered to be inferior to those bought from the market (Tiwari and Rani 2004).

Socio-economic disparity: From the socio-economic point of view, an important long-term implication of promoting domestication is that it will benefit the farmers more than the gatherers and may even result in forest clearing to grow NWFPs. The promoters of NWFP commercialization often tend to ignore that many forest products are important because they are available to poor people. Development and conservation projects that make forests inaccessible — economically or legally — to poor people can have severe economic and social consequences, especially in times of financial distress. Unabated, these trends will lead to the demise of natural NWFP supplies, to the loss of critical livelihoods for forest-dependent people and to the further degradation of forest resources and ecosystems. Several examples have shown that NWFP commercialization has resulted in extremely low returns for women in comparison to the amount of work they have done. This is seen in Sarawak, eastern Malaysia, where women are involved in labour-intensive production of fine woven rattan mats and baskets for very low returns (Brosius 1995). The women collectors of lichen and mat weavers in Meghalaya also receive very low remuneration for their labour as reported by Tiwari (2000).

Ecological effects: Increased commercialization will lead to overharvesting, resource depletion, degradation of forest and depletion of biodiversity while domestication of NWFPs can reduce incentives to conserve the ecosystems in which the NWFP species grow naturally. Increasing demand for Thysanolaena maxima inflorescence for the production of broom in Meghalaya has resulted in large-scale conversion of erstwhile forest lands into pure plantations of the species, resulting in loss of ecological services provided by the forests in the mountainous regions (like water and soil conservation). Gathering NWFPs in forests is felt by some environmental conservation organizations to be more compatible with biodiversity conservation than timber extraction (Kuster et al. 2006). However, this very much depends on the type and way in which the product is harvested. Low density NWFP extraction from natural forests, as occurs for some fruits, leaves or nuts, can have minimal impact on local biodiversity at landscape and species levels. But as harvesting intensity increases, techniques become more destructive, such as uprooting or clear felling to harvest products. Hence, the exploitation of NWFPs can become as harmful to the long-term survival of a species and its related ecosystem as timber extraction. Intensively managed NWFP production systems can even completely displace natural vegetation, as in the case of bamboo shoot production in China.

Assuring sustainable production of NWFPs