In the leather industry the British use the word 'hide' for the skin of full grown large animals and the word 'skin' for that of calves, goats, sheep and pigs. With reference to crocodiles it is customary to use the term 'skin'.

The scale pattern or escalation of a crocodile is shown in Fig. 4. The basic features are common to all crocodiles but species differ in minor details such as presence or absence of post occipital scutes, buttons (osteoderms) in the belly scales, scutes of the nuchal shield, distribution of follicle glands and number of transverse scale rows on the belly.

These variations occur not only between species but within species which have a wide geographical range. For example, the transverse rows of scales on the belly (running across the belly between collar and cloaca) of C. niloticus vary in number from 26 to 32 (King & Brazaitis, 1971). Specimens from the Sudan and Ethiopia usually have the lowest number (and hence biggest scales) while specimens from Madagascar and Mozambique have the higher count and smaller scales. Because the leather trade favours a small scale pattern this makes the southern types of Nile crocodile more valuable.

Belly skins which are free of buttons and can be given a 'classic' finish by the tanner are most valuable and are regarded as an entirely different material to back skins ('hornbacks') and bony belly skins such as those of most caimans. Indeed, only the soft flanks ('sides') of most caiman skins collected by hunters are traded internationally, the rest being not worth transporting.

To keep disturbance and stress to a minimum crocodiles should not be captured and handled needlessly. Experienced operators'can judge commercial skin size by looking at the live animal in the pen. Crocodiles intended for slaughter and skinning are carefully selected by eye before they are captured.

At present most crocodile skins are priced according to belly width. Skins shrink during salting (3.5.1) and belly width can not in any case be measured precisely on the live animal. It varies with the tightness of the tape and the animal's breathing. A captured crocodile may be bellowing, hissing or holding its breath. To demonstrate this point three highly experienced men known to the writer once measured total length and belly width to the nearest centimetre on 49 live crocodiles. There was full agreement on total length but in only six instances did all three get the same belly width.

There is, of course, a relationship between belly width, total length, weight and other measurements but the relationship is not constant. Well-fed young crocodiles in captivity are usually much fatter and heavier than wild ones. For a given length, therefore, they yield a wider belly skin. In the case of New Guinea freshwater crocodiles the difference was found to be considerable. A sample of 132 wild crocodiles were weighed, measured and sorted into 12 size categories. The average length and weight for each category was then compared with the corresponding average from farm reared animals. The results are given in Table 3.

Wild 1/ |

Captive 2/ |

|||

| Total length (mean of n individuals) |

n |

Mean weight |

Mean weight |

% difference |

| 46.6 cm 60.58 68.59 78.38 85.80 89.51 95.16 101.75 106.31 107.00 120.20 123.20 |

11 |

0.23 kg 0.46 0.68 1.14 1.48 1.79 2.25 2.65 3.16 3.74 4.23 5.00 |

0.30 kg 0.76 1.04 1.66 2.25 2.56 2.94 3.77 4.51 4.62 6.85 7.54 |

30 65 53 46 52 43 31 42 43 23 62 51 |

1/ Samaki Swamps. Western Province, Papua New Guinea

2/ Moitaka Farm. Port Moresby, Papua New Guinea

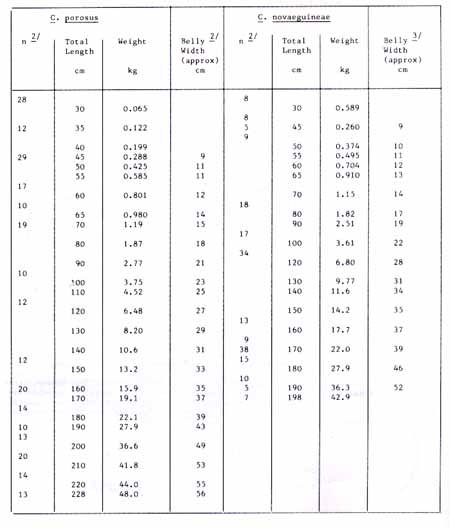

Captive crocodiles also change their proportions as they grow. They become fatter and heavier in proportion to their length. Species differ in this respect. In Papua New Guinea it was found that as the crocodiles approached culling size the freshwater species was usually heavier, for a given length, than C. porosus. This was not the case when the animals were younger (Table4).

1/ All records from fish-fed crocodiles at Moitaka Farm, Port Moresby.

2/ Number of individuals from which actual means were obtained at points shown, values in

between interpolated.

3/ Measured with live animal exhaled.

When crocodiles are being captured they may bellow and will struggle and splash if they are not promptly restrained. If capture operations cause a daily commotion it can unsettle the remaining crocodiles so much that they stop feeding and may refuse to feed for several days after the disturbances have ceased.

If all crocodiles in a pen are being slaughtered over a period of a few days then this is of no consequence. But if crocodiles are being selected from a pen and there are frequent disturbances over a period of weeks then the effect on the remaining crocodiles is worth considering. The number that can be killed in any day is limited by the labour available for skinning.

A small annex to a pen (Part 1. 8.8) can be useful for separating a few individuals from the main stock. Alternatively, if a large proportion of the stock in a pen is to be slaughtered the pools can be drained and the selection made in a single day. The culled animals are moved to a separate pen until they can be slaughtered. The remainder can then be left undisturbed.

In Papua New Guinea labourers capture crocodiles on land by throwing a wet jute sack (gunny bag) over the animal's head. It is a two-man job. One grips the head through the sack while the other straddles the tail and grips the hind limbs. The jaws are held together, carefully uncovered and bound with string or a rubber band cut from an old inner tube.

On land, crocodiles which are cornered will gape defiantly and this habit makes them easier to capture with a noose on a pole. Slipped over the upper jaw it will catch in the teeth and can be pulled tight. With large, powerful animals a second noose can then be run down the rope so that it encircles both jaws - forcing them to close when pulled tight. It needs two persons to pull and keep the nooses tight while a third binds the jaws.

In pools which can not be drained each crocodile has to be located and partially lifted with long poles so that a noose (also on a pole) can be slipped over the jaws. Experienced labourers in Papua New Guinea are scornful of this technique. They wade into the pools and, working in pairs, locate the crocodiles underwater by hand. one man then siezes the snout while the other grabs the hind limbs. The writer has seen many crocodiles caught this way without accident but can not recommend the method.

All the above operations capture the crocodile uninjured. It must then be killed humanely with a 22 bullet or captive bolt placed well behind the eyes at the centre of the bony platform. The brain is very small. A more crude method is to flex the animals, neck over a log and sever the spinal cord between the skull and the first vertebra.

It is, of course, quite possible to shoot crocodiles in the pen with a minimum of disturbance provided it is done with extreme accuracy, usually at very close range, to make a clean kill. At night crocodiles can be approached very closely with a torch and killed easily but skinning must not be long delayed.

Skinning (flaying) should be done out of the sun in reasonable comfort for it is tedious work and Must be done carefully. If the meat is to be used for human consumption the skinning and possibly slaughter will have to be done in compliance with local health regulations.

The dead crocodile should not be dragged along the ground with a risk of scratching the belly skin. Nor should it be left lying in the hot sun - in any position. A skin can be ruined in a short time by overheating on the dead animal. If the crocodile has been killed with a knife it is advisable to allow it to bleed near a drain and to hose it clean. It should in any case be left until all muscle spasms have ceased before any skinning cuts are made.

It is assumed that, as a rule, the requirement will be for belly skins. The opening cuts are best described with reference to Fig. 5. With the crocodile on its belly a convenient sequence of cutting is as follows:

- cut across the back of the head platform to the lower jawbone on each side.

- from the head cut down the midline of the neck, through the nuchal shield and stop.

- move out one row of scutes from the midline on each side and continue the back cuts down

to the base of the tail. (This will leave a strip two scutes wide down the middle of the

back).

- pass the blade through the tail, under the skin, and slice the top (dorsal) skin off all

the way to the tail tip.

- cut along the back of each hindlimb from the foot to meet the tail cut on each side.

Make encircling cuts around the 'ankle'.

- cut along the front of each forelimb from the foot to meet the neck cut on each side.

Make encircling cuts at the 'wrist'.

- roll the crocodile on to its back and continue the cuts from the lower jaw along each

lower jawbone to meet at the chin. (This final stage can be left until the crocodile is

rolled over to remove the belly skin).

With the crocodile on its belly the skin must be cut away from the underlying tissue with a skinning (flaying) knife. No quicker way has been demonstrated. Special care is needed in the groins and armpits where the skin is thin and wrinkled.

Eventually the skin will be free from the back, sides and limbs except for the narrow strip left on the back. This strip is excluded from the skin in order to reduce weight and freight cost. It might possibly be used locally to make scute - studded belts. The crocodile is now rolled over for removal of the belly skin.

To separate the belly skin first cut it free from throat and neck with the knife then pull it backwards as far as the cloaca. It should tear cleanly away from the belly without any need for cutting.

Use the knife very carefully around the cloaca where the skin is thin and easily snicked. Once the skin is free from the cloaca continue tugging the skin free to the end of the tail.

Skilled skinners will leave a minimum of muscle or other tissue attached to the skin because all such tissue must now be scraped off.

Scraping (fleshing) is best done on a smooth table with the skin lying flat. The tool can be a blunt knife, fish scaler or anything with an edge that will remove meat and fat without cutting the skin. This process is important because the underside of the skin must be cleanly exposed to the salt. High pressure waterjets (as used for cleaning masonry) are used in Australia but jet shape and pressure are critical.

It is during this process that any buttons in the belly skin will be noticed. They can be seen and felt from the flesh side.

Salting is done twice. The initial salting draws water from the skin and the second salting further preserves it until it reaches the tannery.

The quality of the salt used in the first salting is not critical but it should be clean and fine enough to dissolve evenly over the surface of the skin. To help this process the skin should be washed clean and salt rubbed very thoroughly into the surface.

There should be no delay between the scraping and the salting because a partially dried skin will not absorb the salt. After salt has been rubbed in more salt is spread over the surface in a thick layer. As a rough guide the amount of salt used should weigh at least half as much as the skin. This is more than will dissolve but the surplus can be used again for the first salting of other skins.

After the initial salting the skins must be left where they can drain freely for at least forty-eight hours. Ideally they should be in a well-ventilated shed with a concrete floor and drainage to carry the salty water away or lead it to a sump.

The skins should be stacked, salt-side up on slatted wooden benches, preferably with a slope so that no pockets of liquid can form within the stack. There must be no rusty metal in contact with the skins as it may cause stains which will not come out. Even water dripping from a rusty metal roof can be troublesome. A roof of corrugated fibre-cement or fibreglass is better than metal. Without good ventilation the air will become very hot and humid but the ventilators should not allow the sun to reach the skins. They must be kept shaded and as cool as possible.

After at least forty eight hours the skins will have lost most of their water. The surplus salt can then be shaken off and the skins placed, flesh side down, on a flat table for measuring and grading.

There will have been some shrinkage during the first salting. Shrinkage of up to 15% occurred in one batch of 30 skins measured in Papua New Guinea. Measurements taken after the first salting should not change significantly before the damp skins reach the tannery - even if this takes several weeks.

With the skin laid flat but not stretched belly width is measured across the smooth belly scales between the horny scutes of the flanks. In the standards laid down by the Japanese Reptile (leather) Association (Appendix 2) the measurement is taken at a point one third of the distance from the neck collar to the cloaca. The width being the distance between the innermost edges of the horny scutes.

In Papua New Guinea the law states precisely which horny scutes the measurer must refer to. Counting downwards (from head to tail) the measurement is taken between those scutes nearest the belly which lie on the third row across (transverse row) behind the nuchal shield. This appears to be very far forward; across the 'chest' rather than the belly. But in practice it gives the same belly width as that obtained by measuring across the smooth belly scales at the wider part.

Measurements are made in centimetres, fractions of a centimetre being rounded downwards. At present the price paid for skins is based entirely upon belly width, regardless of length. American alligator skins are an exception in that they are sold (at auction) by length in feet regardless of belly width.

Three grades,are recognized. Most dealers are willing to pay 75% of full price for a second grade skin and 50% of full price for a third grade skin. Skins considered to be inferior to grade 3 will not be purchased by reputable tanneries as they are not worth the expensive process of tanning. Obviously, it is well worth taking the trouble to produce top quality, first grade skins.

Skins may be downgraded if they show signs of putrefaction, blemishes, stains, cuts,

holes or buttons (osteoderms). For the purpose of grading there is an area on each skin

which is considered to be of prime importance. It is known as the pattern area. In general

any fault within the pattern will result in downgrading but some faults outside the

pattern can be accepted.

The pattern as defined by the Japanese Reptile Association includes not only the belly but

about half the length of the tail and the neck as far forward as the throat (Appendix 2).

French tanners are less demanding in that the pattern ends at the front of the cloaca and

does not include any of the tail. The neck collar row is also excluded. This does not mean

that French tanners are less strict about quality. Leading tanners maintain a very high

level of quality control but grading is done on the basis of experience without written

rules. To a large extent this must also be true of Japanese tanners because terms such as

'fresh and well preserved' are not precise and must be Interpreted by the grader.

The Japanese rules are probably best regarded as a guide for the new producer and a useful frame of reference for discussion between producer and buyer.

Accidental cuts may sometimes occur even with careful skinning and are most easily seen by holding the skin up to the light. Natural 'faults' such as buttons or large belly scales are unavoidable but downgrading because of signs of putrefaction or staining can certainly be prevented by careful preparation and good management. Common signs of putrefaction are described in the next section.

The first salting will have drawn most of the water from the skin. The second salting is intended to preserve (cure) the skin during storage. For this purpose only clean, fine grade salt must be used. Spent salt, shaken off skins at the end of the first salting, should only be used for subsequent first saltings.

Salt alone, no matter how good the quality, will not prevent putrefaction because some bacteria are salt-tolerant. Some other preservative must also be used and a convenient method of application is to mix it with the salt. Preservatives are discussed later (3.5.4).

Assuming that the preservative is mixed with the salt the procedure for the second salting is no different from the first. Simply shake and brush the skin clean (do not beat it) and rub in the new preserving salt, finally applying it as a layer over the entire surface as before.

When this has been done the side portions of the skin (limbs and flanks) are folded in towards the middle and the skin is rolled from the head end to make a compact bundle. If skins are to be kept for weeks or months before despatch to a tannery they should be kept in the coolest place available but not frozen.

In a wooden storage box the rolled skins can be stacked and more salt/preservative packed between and over them.

Transport to the tannery will usually be by air and for this the surplus salt mix is shaken off and a fresh thin layer applied. The skins are then rolled as before and packed into a strong jute sack with an outer jute sack which is stitched up and labelled. There should be minimum delay in despatching the skins once they are packed.

Putrefaction, because of inadequate curing or storage, can be detected before the skin becomes worthless. Common signs include the following:

Smell

There is a stale smell quite distinct from the smell of a freshly salted skin. As deterioration advances the smell of decay becomes obvious.

Feel

Experienced operators can distinguish the feel of a well-cured skin from one which is deteriorating. Skins which have been allowed to become too dry are easily identified by feel.

Scale-slip

This is the equivalent of hair slip on mammal skins. The scales will slough off when rubbed with the fingers. Scale-slip usually begins in small patches and can be arrested if found in time.

Red heat

Red or orange patches on the flesh side of the skin are caused by salt-tolerant (halophilic) bacteria. Areas of red heat are often found beneath areas of scale-slip. As with scale-slip, damaged areas can not be restored but the spread of deterioration can be stopped by thorough application of salt/preservative.

There is no universally accepted preservative for crocodile skins and , in general, the tanneries prefer to have the minimum chemical interference with wet salted skins.

The addition of 1% boric acid and 1% naphthalene (by weight) to the preserving salt has been used for more than twenty years for the preservation of skins and hides of domestic stock in New Zealand.

Vivian (1969) conducted extensive tests on the preservation of cow hides which involved shipping them from New Zealand to England and back. The addition of 1% boric acid and 1% naphthalene was compared with six other bactericide treatments (including sodium pentachlorphenate and other chlorinated phenols). He concluded that "one percent naphthalene plus one percent boric acid produced the best cured stock. These hides were free of defects after ten months". He also -,tressed the importance of good quality, fine-grade salt; a point also emphasized by ,Tuchs (1975).

Boric acid and naphthalene are not expensive and are widely available. Boric (boracic) acid is a white powder that dissolves in water. Naphthalene occurs as small, flaky crystals. It is a coal tar derivative which is very slightly soluble in water though possibly some will dissolve in the skin's natural oils. The addition of only one percent to the salt imparts a soft, dry feel which seems to make the salt easier to spread evenly. It slowly evaporates from the salt.

One percent each of these ingredients is such a small proportion that the mixing must be very thorough. If it has to be done by hand it is probably best done on a concrete floor where, say, 100 kg of clean, dry salt can be spread out and 1 kg each of boric acid and naphthalene sprinkled evenly over it before mixing with a shovel.

This boric acid/naphthalene treatment is used for crocodile skins in Zimbabwe (Van Jaarsveldt, 1982a) and was tested by the writer in a small trial in Papua New Guinea. In this test it was compared with two brand name preservatives. After six months of storage under very adverse conditions the test samples (48 strips of skin in 3 batches of 16) were sent to a Paris tannery for comment. All three batches were considered to be equally well-reserved. A control batch treated with pure salt went putrid in less than six months.

An experiment with alligator skins led to another conclusion. David,(1985) compared the boric acid/naphthalene application with a treatment which involved dipping the skins in a 0.5% sodium pentachlorphenate dip. He found the dip to be more effective in suppressing red heat and scale slip in skins which were subsequently stored in a salt box. He also found that storing skins in brine (i.e. completely immersed in a saturated salt solution) after treatment produced equally good results from both treatments with no scale slip or red heat after a year of storage.

Phenol dips cannot be recommended with confidence. Not only are the substances toxic but they might possibly harm the skins-especially if concentrations are not very carefully controlled. Vivian (1969) found that the chlorinated phenols accentuated the vein pattern in cowhides. While this may not be relevant to crocodile skins it does demonstrate that skin tissues can react to these chemicals.

If skins are kept in a salt solution instead of a wooden box it is essential that the brine is kept up to full strength (i.e. as much salt as can be dissolved at the storage temperature) and that the solution is not contaminated with blood, debris from the skins or other impurities. A fresh solution should be made up for each new batch of skins if the previous batch had been stored for a long period. As with other storage methods, tropical temperatures greatly increase the risk of deterioration.

If proprietary skin preservatives are considered the active ingredients should be determined and chlorinated phenols should be avoided, at least until more is known about their suitability for crocodile skins. Some products such as Dermacon 11 are claimed by the manufacturers to be neither toxic nor chemically reactive but, to the writer's knowledge, they are largely untried in the crocodile skin industry. Dermacon can be sprayed on to the skins, used as a dip or mixed with the salt.

The safest course when trying a new preservative is to treat a small batch of skins and ask for a report from the tanner to whom they are consigned.

The flaying procedure for a hornback skin involves cutting through the belly skin which, in the species most likely to be farmed, is the most valuable part. There may be occasions, however, when a hornback is needed for a special request or when a crocodile has such a badly scarred belly skin that a hornback flay would be more profitable. The procedure for obtaining a hornback skin is as follows:

- With the crocodile on its back make a single opening cut from the point of the chin down the mid-ventral (belly) line to the tip of the tail

- From the mid-ventral line cut at right angles down the centre (underside) of each

limb to the foot. Make encircling cuts at the 'ankle' and 'wrist'.

- From the point of the chin cut along each lower jawbone to the angle of each jaw. From

the angle of the jaw cut over the top of the head to meet the angle of the jaw at the

other side. This cut must be against the back of the bony platform so that the full length

of skin in front of the nuchal shield is,obtained (Fig. 6). Preservation of hornback skins

is the same as for belly skins.