Small-ScaleDairy Farming Manual |

Volume 1 |

|

|

|

|

|

| Technical

Notes

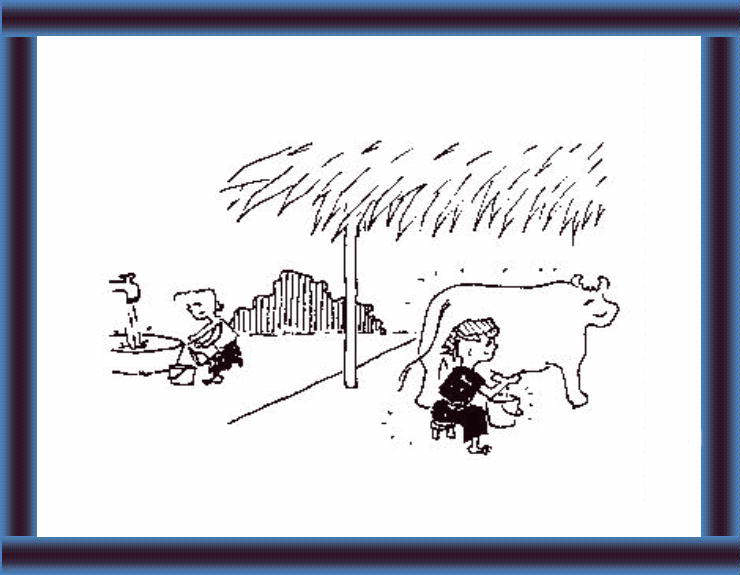

Numbers in brackets refer to illustrations in the Extension materials. Introduction Milk in the udder of healthy animals has very little bacteria. It is only after leaving the udder that the milk can be contaminated with bacteria if proper hygenic handling is not undertaken. Sources of contamination include:

The milker The air The skin of the animal Inflammed udders |

|

|

What should you know about milk quality control ?

|

1 How does the milk collecting centre control

the quality of milk ? (4-6)

They visit your farm and test your milk. |

|

2 What do they test your milk for ? (7-24)

They test for:

|

|

3 How do they test your milk ? (7-24)

They have special equipment for each test. |

How does the milk collecting centres control the quality of milk ?

|

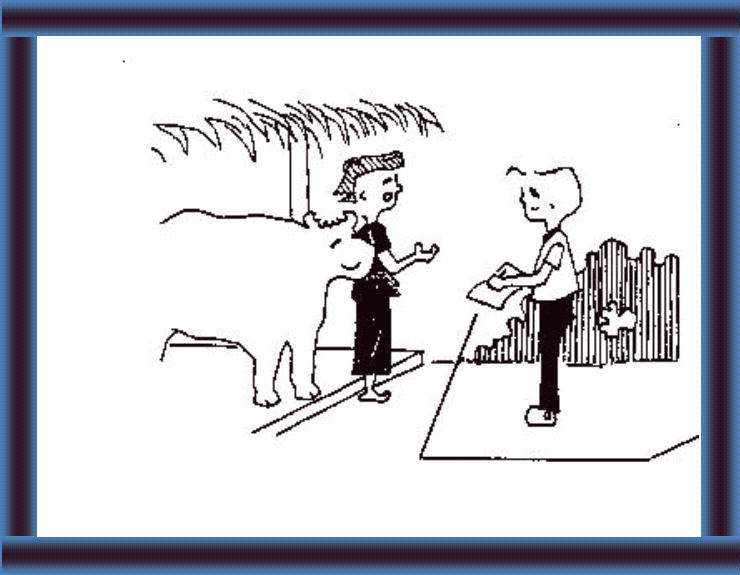

4 Workers from the milk collecting centre visit your farm and keep records. |

|

5 They test your milk on delivery to see if it is suitable for processing. If it is not suitable, they will reject it! |

|

6 The milk collecting centre or factory control the quality of milk to make sure it tastes good and is safe to drink. |

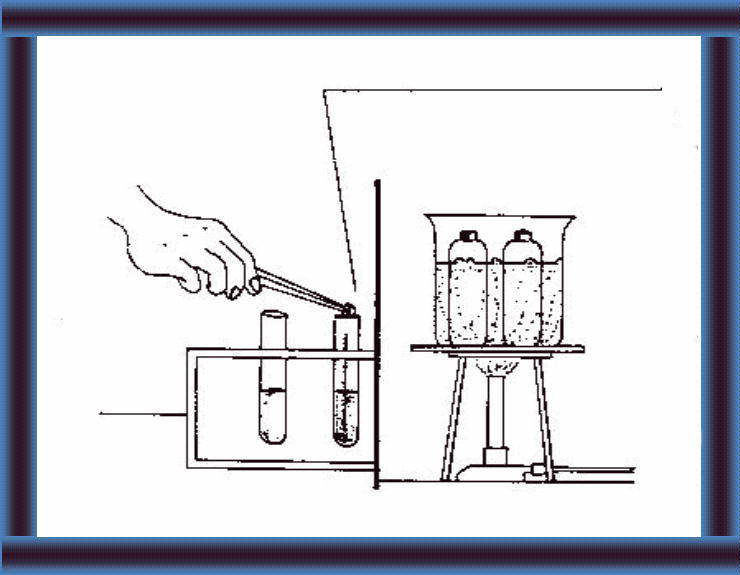

Testing for HygieneThe Sediment Test (8)During the milking and handling of the nilk all kinds of dirt can get into the milk, such as straw, dust, hairs, flies etc. By filtering a representative sample of the milk through a white disc (The Sediment Test) these dirt particles become visible. This test gives a very good indication of the cleanliness of the milk with respect to visible dirt. The test is also useful when training farmers in clean milk production and can also be used for the classification of milk (milk payment). It is obvious that a high amount of visible dirt also indicates high bacteria content. |

page 55

|

7 They visit your farm and look

at your

- buildings - equipment - cows - working methods - and you to make sure you keep everything clean and your cattle are healthy. |

|

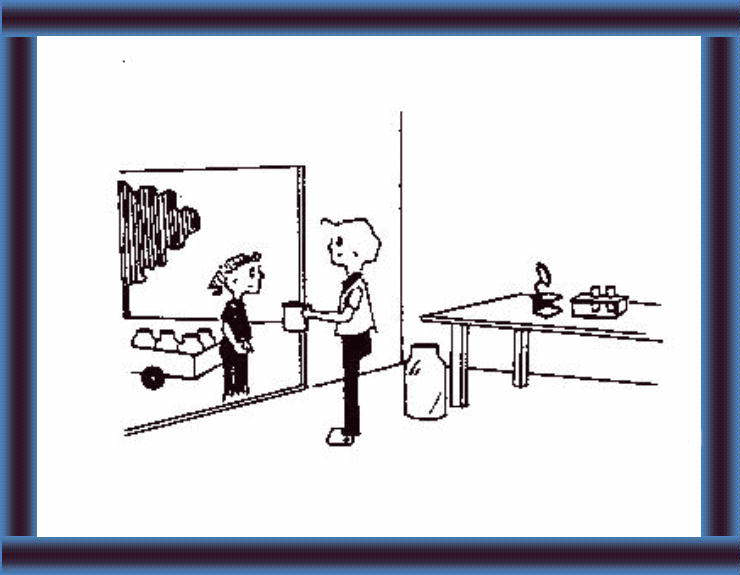

8 On delivery, they check the empty containers and filter your milk to see how much dirt there is. |

|

9 They test one sample of your milk before accepting it to make sure it is suitable for processing and they take other samples for laboratory tests. |

Testing for Physical PropertiesA bad smell or taste in the milk can be caused by bacterial growth, chemical reactions and by flavours being absorbed in the milk.Flavours which are usually absorbed by milk are: feed flavours, medicine flavours, chemical flavours and unclean flavours. Silage flavour is easily absorbed by the milk either directly or indirectly via the cow. However, if the silage is well-preserved and fed in reasonable quantities there will be no problem with silage flavour. Flavours from onions and certain weeds may be absorbed via the cow. Unclean flavours are often due to unclean sheds and animals. Keeping the milk too long in an open container in the milk shed may also cause unclean flavour. Medicine and chemical flavours usually come from medicine used to treat the cows and from detergents and disinfectants which have not been properly rinsed off the milking utensils. (11) |

page 57

How do they test the physical properties of your milk ?

|

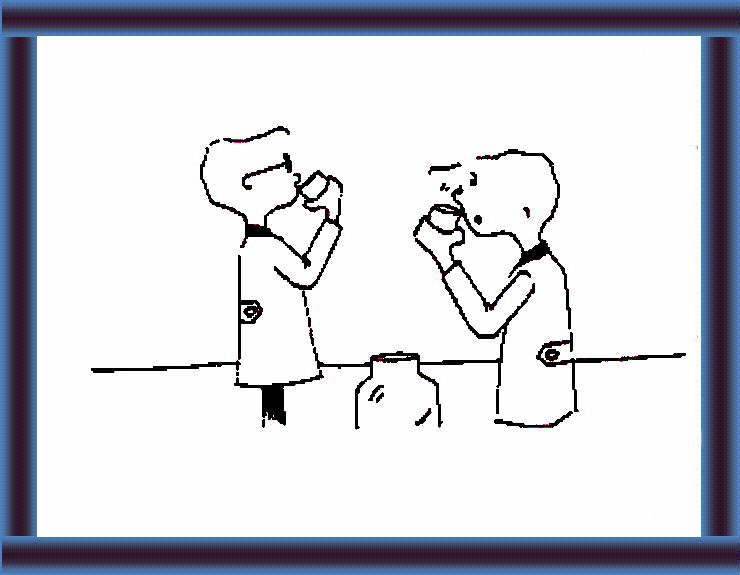

10 They look at your milk to check the colour and make sure that it is not lumpy. |

|

11 They smell your milk and taste it. Bad smell or taste shows low quality of milk. |

|

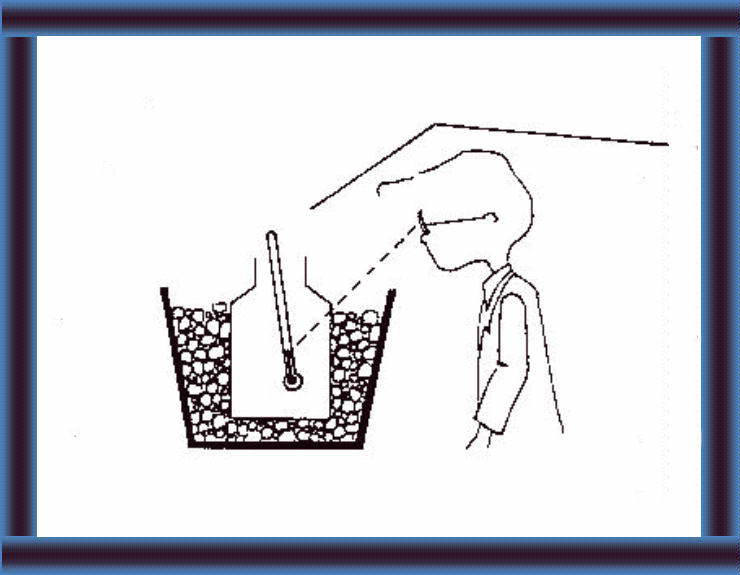

12 They measure the temperature of your milk upon delivery. To store very clean milk for 24 hours, you need a temperature of less than 10 C. Less clean milk needs lower temperatures. |

page 58

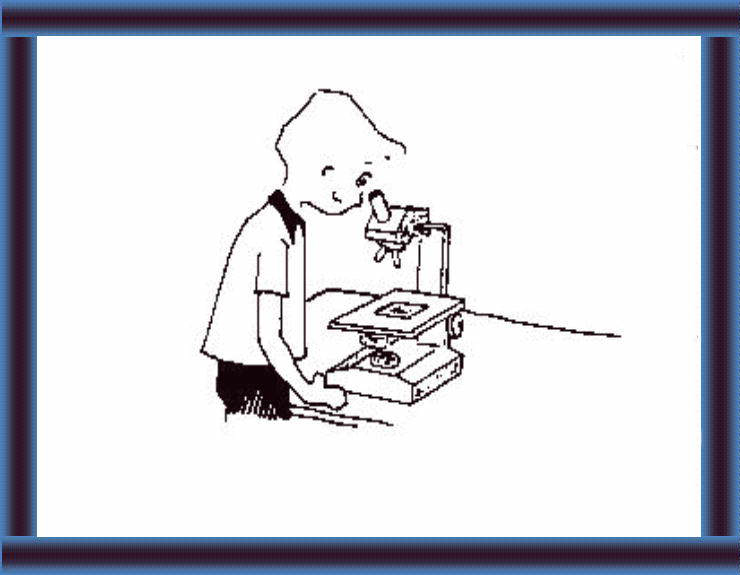

Testing for Healthy AnimalsThe cell count can be undertaken by means of a microscope or automatic cell counter. The cells consist of leucocytes, lymphocytes and epithelium cells. Milk from healthy cows/udders normally contains from 100,000 to 300,000 cells per ml. If an udder is diseased (Mastitis) the number of cells (leucocytes and lymphocytes) will increase. The age of the cow and the stage of lactation will also influence the number of cells. (13)In the case of diseased cows, blood

clots may get into the milk. (14)

Milk containing antibiotic residues cannot be used for dairy products. This is particularly true for products which have to be fermented by lactic acid producing bacteria, as this will be inhibited by the antibiotics. (15) |

How do they test for healthy animals ?

|

13 They count the number of cells in your milk and check for blood. |

|

14 Many cells or blood in the milk shows that your cow has mastitis or another disease. |

|

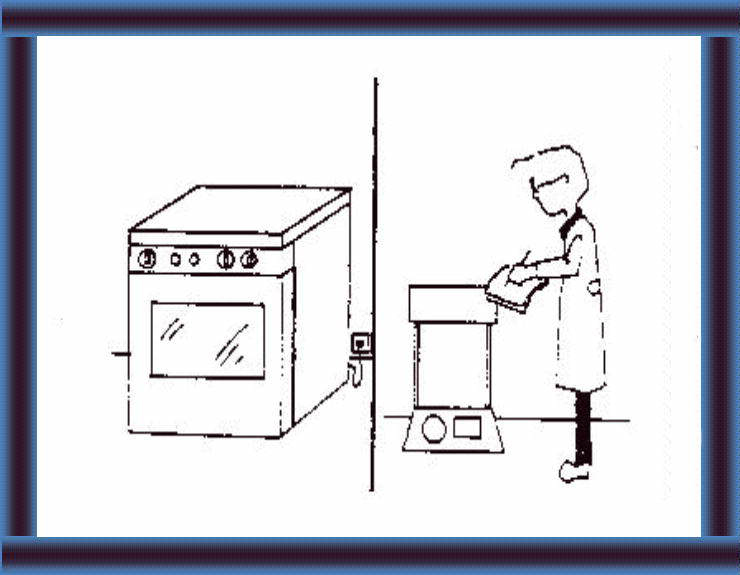

15 They incubate your milk with a special bacteria to check if antibiotics are present. |

page 60

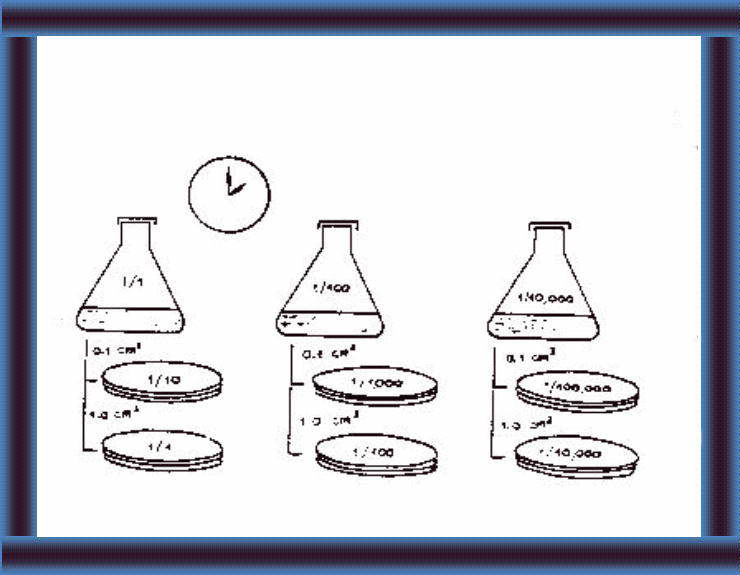

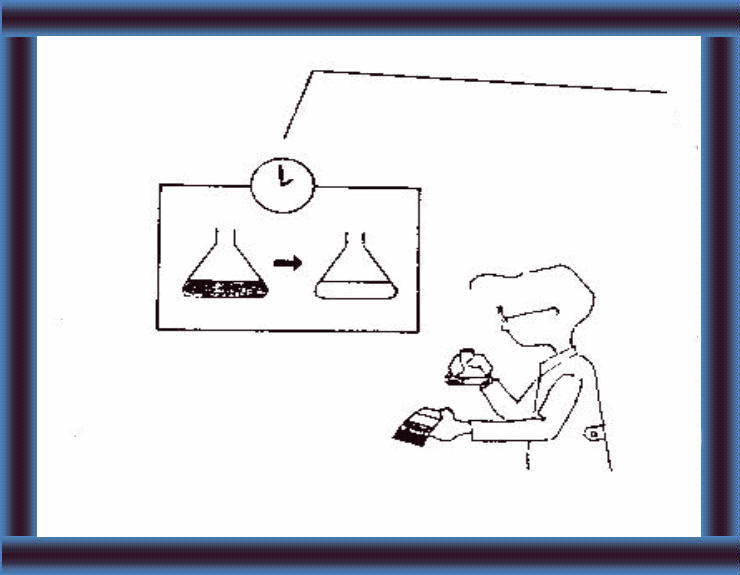

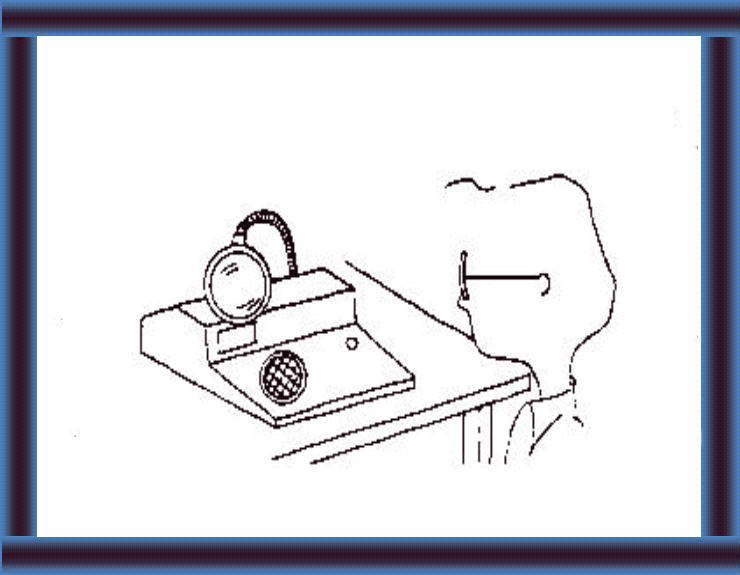

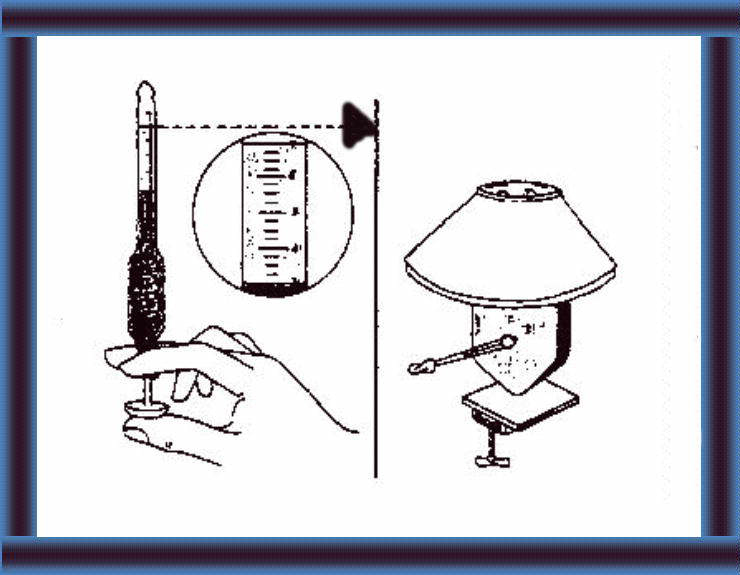

Testing for BacteriaDye Reduction Tests (16-17)The two most common dye reduction tests are the Methylene Blue Test and the Resazurin Test. These dyes will, when added to milk which is incubated at 37 C, be chemically reduced if there is microbial activity in the milk. Generally, the time required to change the colour of the dye is shorter if there is high bacterial activity in the milk (many bacteria) and longer if there is low bacterial activity (few bacteria). Dye reduction tests do not indicate anything about the kind of bacteria in the milk, they only indicate the number of bacteria. Plate Count Test (18) The plate count method is used for determining total number of bacterial colonies per ml sample. A measured amount of milk is placed on agar plates and the number of colonies are counted after incubation. Microscope Count Test (18) To obtain the amount of single bacteria present in milk, a direct count must be carried out, using a microscope. |

|

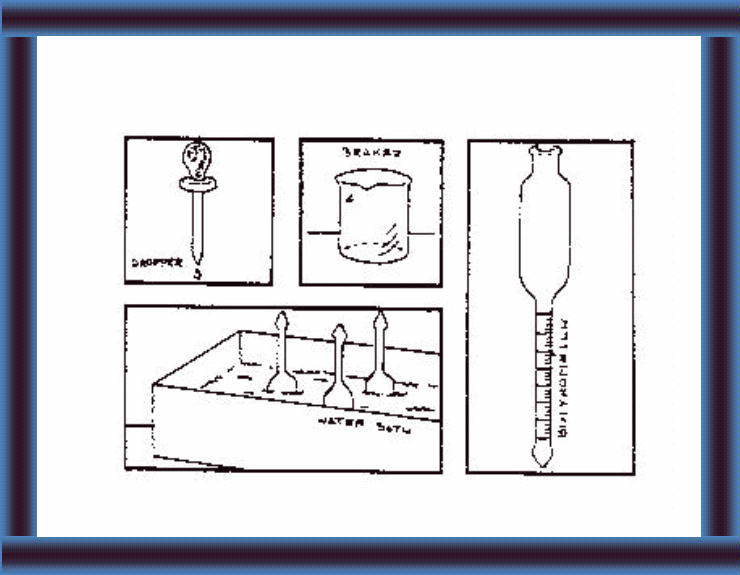

16 For a quick test they add a dye to your milk. |

|

17 Then they check the time for the colour to

disappear. The shorter time, the more bacteria.

|

|

18 For an accurate test, they count the number of bacteria in your milk. |

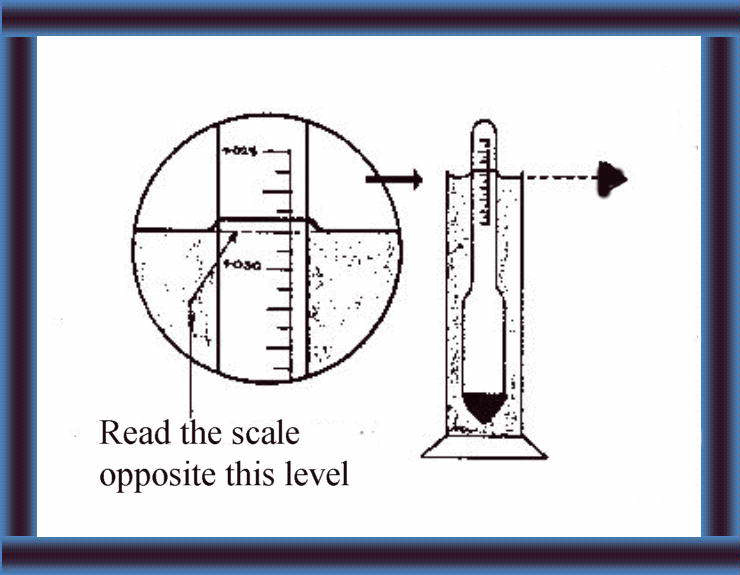

Testing for CompositionMeasuring freezing point (19)The normal freezing point of milk is a little lower than the freezing point of water owing to dissolved components (mainly lactose and salts). The freezing point, being one of the most constant physical characteristics of milk, is used to detect adulteration of milk with water. The freezing point of cows milk varies between -0.53 C and -0.59 C with -0.54 C being the average value. Values below -0.53 C usually indicate extraneous water. A cryoscope is used for determination of the freezing point. Measuring density (20) Another method to detect adulteration with water is by measuring the relative density of the milk. The method is not as reliable as detection by determination of freezing point but is easier to carry out and requires less sophisticated equipment. The density of milk normally varies between 1.028 and 1.034 g per ml at 15oC depending on the composition. The density of water is 1.0 g per ml. A lactodensimeter and glass cylinder are required for the test. Measuring fat content (21) For small to medium scale operations

the Gerber test is used for determination of fat content in the milk. The

test is a volumetric method in which fat is separated from skimmilk by

centrifugal force. Sulphuric acid is used to dissolve the protein that

forms the membrane around the fat (fat globules) and amyl alcohol is added

to improve the separation of fat from protein.

|

|

19 They measure the freezing point, if it is abnormal, your milk may contain excess water, detergents or other substances. |

|

20 They measure the density of your milk with lactometer. If it is abnormal, perhaps:- some one added water or another substance- some one removed the cream- your milk is colostrum. |

|

21 They separate the fat from the skim milk and measure how much fat your milk contains. |

|

22 They may dry the milk and measure the total solids content. |

page 64

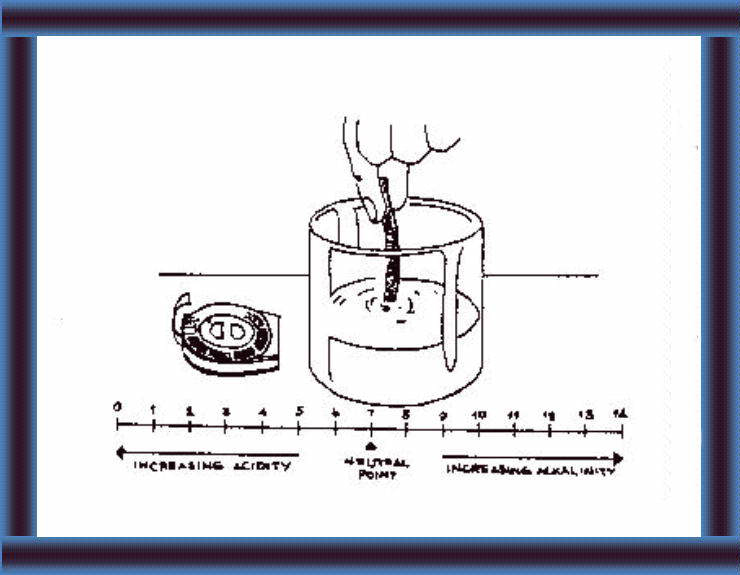

Testing Suitability for ProcessingThe titratable acidity test is carried out in order to check whether milk contains a large amount of lactic acid which will reduce the heat stability and thereby the suitability for processing. The milk will clot when it is heated. Different procedures are employed to test the acidity, however the principle is the same: A dye which changes colour at a specific pH is added to the milk which is then titrated with a base (added little by little) until the colour changes. By recording the volume of base required and the volume of the milk sample, the amount of lactic acid can be calculated. This test is also used for testing fermented products. The lactic acid is produced by bacteria in the milk. The milk becomes sour. |

|

23 They measure the acidity of your milk. If it is abnormal, your milk is low quality. |

|

24 They add alcohol to your

milk. if the mixture curdles, it is not suitable for pasturization.

This may show: - bacteria (acid production) - mastitis - residues (e.g. detergents) - colostrum. |

page 66

|