It is advisable to study in theory a detailed ideal cleaning programme so as to establish a general overview of a cleaning programme.

The programme can be divided into the following subroutines:

Clearance for cleaning

Assembling for cleaning

Removal of solid waste

Prerinsing with water

Application of detergent

Rinsing

Disinfection

Post rinsing

Post treatment

Disassembling after cleaning

This could be a subroutine of the cleaning programme or a subroutine in processing (see process hygiene) and it will be necessary to establish which one it is. If the carcasses and/or meat have not been removed from the processing area as a part of processing, the first part of the clearance must be removal of carcasses/meat for storage.

It is recommended that each person in processing be responsible for clearing the area concerned as this tends to intensify discipline regarding tidiness and hygiene. However, one person must have the main responsibility for clearing.

The purpose of clearance after work is to prepare an easy and quick cleaning procedure.

Clearance implies removal of all items which may retard performance. Items which may be damaged by water should be removed. Nonremovable equipment should be covered to protect against water. Water and electric installations may constitute a safety hazard.

Examples of items which should be removed are:

packaging materials (cardboard, paper, etc.)

items kept by personnel of the area (personal items)

small or mobile equipment (may be removed for central cleaning (see 6.1).

Assembling for cleaning may be a time-consuming subroutine but it is necessary.

Assembling for cleaning consists of preparing solutions of detergents and disinfectants and maintenance and/or preparation of cleaning materials and equipment (pressure cleaners, hoses, etc.). If there is sufficient running water this will not be a problem, but where running water supplies are insufficient, it may be necessary to provide sufficient water in tanks, pails, drums etc.

If there is sufficient running water it is recommended that water taps be placed conveniently for cleaning. If pressure cleaners are used assembling for cleaning will include controlling if there is oil in the pump etc. (ref. instructions concerning the pressure cleaners in question).

The maintenance of couplings, pumps, electrical fittings etc. must be done as a subroutine of assembling for cleaning and according to instructions given by the suppliers of this equipment.

Assembling for cleaning will always depend on local conditions and may be time-consuming but cannot be neglected if the cleaning procedure which follows is to be optimal.

Where there are large amounts of solid waste, it should be removed before water is used in the area. It may not be necessary to remove the solid waste in all places in a slaughterhouse, but it is recommended where the amount of solid waste is large and the water supply is insufficient.

Waste can be collected by a broom or a squeegee and then shoveled into waste containers. Depending on the type of soil the use of a broom will often be the most economical in time.

The purpose of prerinsing is:

to prevent drying of the soil on the surfaces and to moisten the soil and the surfaces

to loosen and collect a small amount of solid waste.

Prerinsing can be carried out with water supplied from a water hose (water tap) or from a low pressure cleaner.

Water temperature should be adjusted to the remaining cleaning programme and the types of soil on the specific areas. Hot water can only be recommended for prerinsing where the dirt types mainly consist of fat (see 4.1.2). Cold water for prerinsing will be sufficient on most surfaces if the remaining cleaning programme is optimal.

If large amounts of solid waste have been collected by prerinsing, it must be removed before application of detergent.

Removal of solid waste and prerinsing

These two subroutines have partly the same purpose - to remove most of the solid waste. A thorough removal of waste will decrease the demand for prerinsing and a thorough prerinsing can increase the effect of a less thorough removal of waste.

The purpose of applying detergent is to decompose and loosen the soil from surfaces and prevent the soil already loosened redepositing. This principle will be the same for all detergents but the systems for application of detergents may differ (see 6.2.2).

The choice of detergent depends on:

type of soil

hardness of water

type of surfaces

system for application of detergent

remaining cleaning programme (water temperature, mechanical force etc.).

Application of detergent as foam may be recommended if the rinsing which follows is carried out by a low pressure system. The low pressure system will add less energy to the cleaning system than high pressure cleaning or manual cleaning. It will therefore be necessary to utilize chemical energy as far as possible.

Warm water will normally be recommended for application of detergents but cold water may be sufficient if the detergents are soluble in cold water. Water anyway reaches the temperature of the environment when applied.

Decomposed and suspended soil and detergent residues should be removed by rinsing with water. Rinsing can be carried out with water under pressure (low or high) or with water and manual force.

The optimal water temperature for rinsing will depend on:

which detergent has been used

which types of soil have to be removed

which surfaces have to be cleaned

which amounts of water are available

which cleaning system (manual/pressure systems) is used.

To prevent deposits of suspended soil warm water is recommended for rinsing. In nearly all cases a temperature of 40°C will be sufficient. However, it is better to have a constant water temperature than very hot water but for special purposes a water temperature above 40°C is recommended. Water temperature should be thermostatically controlled.

If pressure systems are used for rinsing, pressure should not be more than 30 bar. Practical experiments have shown that a pressure of 30 bar and 20 l water per minute will give sufficient cleaning results, both regarding hygiene and economy.

The purpose of disinfection is destruction of microorganisms by the use of chemical or physical agents or processes. The number of microorganisms should be reduced to a level that will not cause the harmful contamination of food.

Choosing the correct disinfectant and method will depend on:

surface materials

type of processing area (heat treated or non-treated products)

remaining cleaning programme (especially the detergent)

disinfection method

The application of disinfectant has to be carried out by low pressure. Sprays (manual sprays or sprays carried on the back, mobile pressure containers etc.) are recommended for disinfection purposes (see 6.2).

Low pressure and high pressure systems may be uneconomical in use because the consumption of water and disinfectant will be larger than when using the previously mentioned sprays. The amount of disinfectant when using the pressure systems may be unnecessarily large. When using the spray system the intensity of disinfection may differ from area to area, depending on the demand for disinfection.

There may be restrictions through legislation on the use of disinfectants and approval may be necessary.

A disinfectant with a broad spectrum is recommended for most purposes. Disinfectants restricted in effect against microorganisms may be used for specific purposes and hypochlorite and peracetic acid can be used for all purposes. Quarternary ammonium compounds and amphoteric compounds may be used on areas where heat treated products are produced.

To avoid residues of disinfectants on surfaces and to counteract corrosion post rinsing after the disinfection procedure may be required. Post rinsing should be carried out using water from a water hose or from a low pressure system.

It is important to assure that surfaces will not be recontaminated by post rinsing, i.e. water must be of potable quality.

It may be necessary to apply oil (edible oil) on surfaces such as cast iron to avoid the corrosive effect of detergents and disinfectants.

Disassembling after cleaning will depend on the equipment and methods used for cleaning, but will always include clearing and cleaning of the equipment used for the cleaning process.

Equipment should be maintained in accordance with instructions from the suppliers and the management of the slaughterhouse.

Cleaning equipment should be stored in a separate room where detergents and disinfectants may also be stored.

Emptying of waste containers and cleaning of these is a part of disassembling as well as switching off the light and closing the doors.

The cleaning programme consists of several subroutines which must be considered as one process. None of the subroutines may be changed without evaluating if the other subroutines should be changed at the same time.

When a cleaning programme has been planned concerning use of detergents, methods and equipment, the working programme has to be planned in detail. How it will be planned may depend on local conditions but it is important to ensure that:

the staff is aware of individual responsibilities for each area

the staff knows who has the responsibility when irregularities occur

everybody works according to the principle: from clean to unclean

the working routines are planned in such a way that clean and unclean procedures are never mixed

As an example it may be mentioned that spraying from unclean areas to clean areas should be avoided.

The management should plan working routines for optimal economy and hygiene.

According to actual conditions a single or more subroutines may be omitted but if this is done the required hygienic level must be assured. A few examples are mentioned in 7.4

The management of the meat plant has to plan how often the cleaning programme must be carried out. A thorough cleaning programme has to be carried out at least once a day and eventually a reduced cleaning programme could be carried out before the type of process is changed during the day.

Cleaning requirements may be reduced if the discipline concerning cleaning during processing is at a high level.

The best hygiene standard will be reached:

if the processing is planned in a way which ensures minimal contamination of animals, meat, surfaces and personnel

if the discipline concerning clearing and hygiene during processing is good

if the cleaning programme is well planned and well done.

The cleaning programme will be set up according to local conditions and a few examples are given below.

Example no. 1

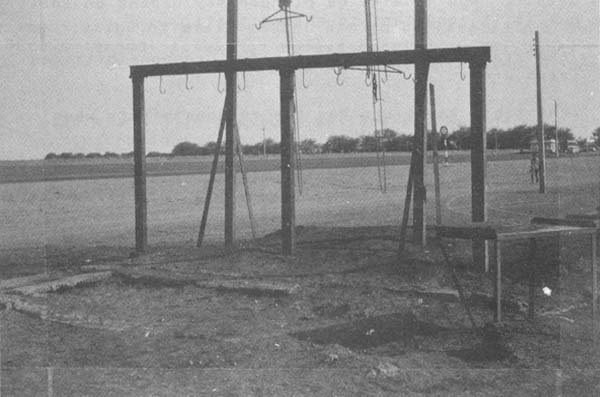

Conditions: Open slaughterplace in a dry and sunny climate. Restricted or no water supplies are available. The surfaces (floors, tables etc.) must be scraped clean for all waste and soil (see Fig. 10).

Fig. 10. Open slaughterhouse. (Photo by S. Gade Christensen)

If no water supplies are available, the surfaces, knives and hand tools will be sundried.

If water supplies are available but restricted, water must be reserved for cleaning of knives and hand tools and for hand washing. The surfaces will be scraped and sundried.

If water supplies are available in amounts allowing rinsing of surfaces these must be scraped, rinsed and sundried. The knives and hand tools must be cleaned with detergent and rinsed.

If water supplies are available in reduced amounts the cleaning programme may consist of:

scraping off solid waste with shovels and/or sweeping with brooms

prerinsing with cold water

manual washing with cold or lukewarm water/detergent

rinsing with cold water

sundrying of surfaces or disinfection with hypochlorite

Example no. 2

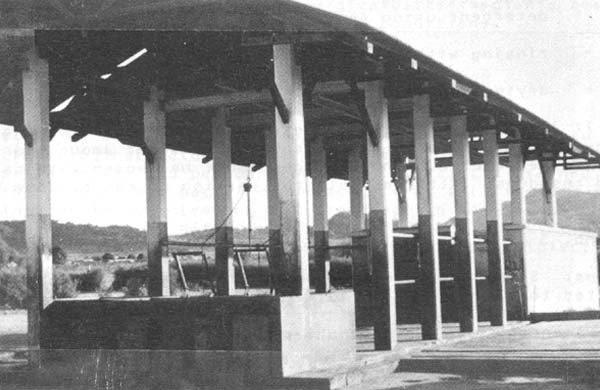

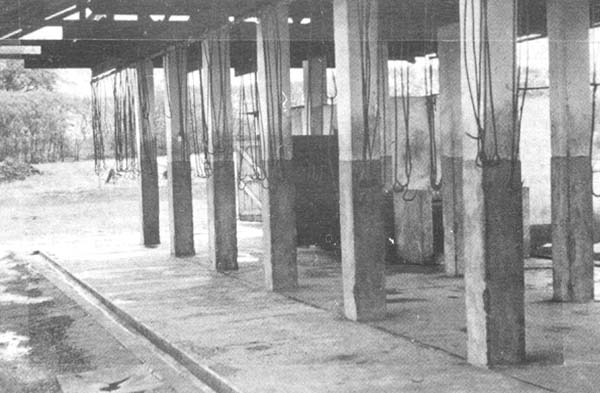

Conditions: Slaughterhouse in a sunny climate. The buildings are open in construction and may or may not be roofed. The supplies of energy and water are restricted. Figs. 11 and 12 show slaughterhouses of open construction.

Fig. 11. Slaughterhouse of open construction, but roofed. (Photo by S. Gade Christensen)

Fig. 12. Slaughterhouse of open construction, showing arrangements for hoisting. (Photo by S. Gade Christensen).

Available water must be reserved for cleaning of knives and hand tools and handwashing.

If more water is available but in a restricted amount, the cleaning programme may consist of:

removing solid waste from surfaces by scraping with shovels and/or sweeping with brooms etc.

manual cleaning (with brushes and cold/lukewarm water/ detergent using the two-pail system)

rinsing with clean water - if possible

drying of surfaces or disinfection with hypochlorite

It is important that the detergents used for cleaning do not leave unwanted residues on surfaces when the water amount for rinsing purposes is restricted. The detergent must be chosen with care to avoid unwanted residues. Alternatively the working up can be done with clean water.

Example no. 3

Conditions: Slaughterhouse in a temperate climate. The buildings are constructed to protect against different climatic conditions.

Sufficient energy and water supplies are available.

The cleaning programme may consist of:

removing solid waste from surfaces using brooms and shovels

prerinsing with cold water using a low pressure cleaner (20 bar)

application of detergent (dosage according to suppliers' instructions) using a low pressure cleaner with an injector for intake of water, detergent and air. Water temperature 55°C. Pressure 5 bar

rinsing with warm water (40°C) using a low pressure cleaner (20–30 bar)

disinfection with 200 ppm chlorine using a garden spray

post rinsing with water of potable quality using a low pressure cleaner

Referring to 7.1 and 7.4 there may be a difference between the ideal and the practical cleaning programme due to actual conditions.

The ideal cleaning programme has evolved in developed countries where water and energy supplies normally are available in sufficient amounts. However, even here, the actual cleaning programme will still differ - often very much - from the ideal cleaning programme, because of:

insufficient management and education concerning cleaning,

a practical programme which may differ from the proposed programme due to local conditions

Practical programmes may be developed for use in developing countries which may differ totally from the ideal cleaning programme. Nevertheless, the practical programme may give better hygienic results than an ideal cleaning programme due to local conditions.