Christian Sales is Head of the Forest Products

Programme of the International Cooperation

Centre on Agrarian Research for Development's

Forêt programme (CIRAD-Forêt), and a fellow

of the International Academy of Wood Science.

How will the wood sector respond to competition from other materials? Recent developments and future prospects in wood processing.

Technical innovations in wood processing in the second half of the twentieth century focused on optimizing the utilization of woods from temperate and boreal forests, responding to more sophisticated market segments. In particular, this meant keeping pace with increasing competition from other materials, such as plastics, metals and concrete. As a result, the forest industry is now in a position to supply high-quality products, such as standardized sawnwood of constant, guaranteed quality, composite boards, glued and laminated wood and engineered wood products. In some particularly important sectors of application, such as construction, advances in structural gluing techniques have allowed wood to improve its image to such an extent that it can compete with concrete and steel.

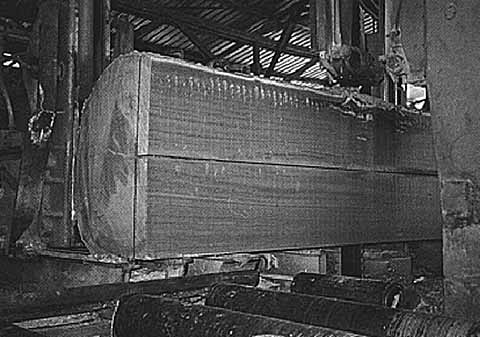

Sawing of a tropical log

- Cirad-Forêt/B. Parant

The development of new technology has often led to a redistribution of market shares within the sector. For example, wood-based panels made from particles or fibres have partly replaced traditional plywood markets as well as solid wood elements in certain furniture sectors. Similarly, medium-density fibreboard (MDF) has replaced the traditional particle board - and indeed solid wood - in many furniture applications. Oriented strand board (OSB) has taken over part of the plywood market for structural uses in construction. Although this is mostly a case of intramaterial redistribution of market segments, it is likely that these innovations have allowed wood to retain parts of the market that it would otherwise probably have lost to competing materials.

This article examines recent innovations that have helped the wood sector retain its share of the market until now, and follows on to predict further technological advances that will help keep wood competitive with other materials in the future.

In this regard, it should also be mentioned that the competitiveness of wood depends on its recognition by the public as a renewable and ecologically acceptable material. It is therefore essential that research be disseminated which demonstrates that if operations are properly conducted, felling to obtain timber is not a factor in deforestation. Such research includes studies on post-logging regeneration, low-impact logging techniques, the role of the growth dynamics of forests in carbon storage and the effect of logging on these dynamics, the life cycle of products and the impact of their lifetime on the carbon cycle.

The most notable recent and expected advances in sawmilling and machining concern productivity gains obtained through mechanization, boosted by the introduction of computer-supported manufacturing processes.

In traditional sawmilling, human judgement was used to obtain the best possible yields from the material. With modern techniques, cutting patterns are optimized on the basis of the qualitative and quantitative collection of data concerning inputs, which is made possible by the development of increasingly refined sensors of form, defects and irregularities. The data are then analysed in terms of the demands to be met, the state of stocks upstream and downstream of the work position, and priorities based on the product's rate of return. Products are produced following specific client orders in a relatively short delivery time, with stocks kept low. The development of these techniques allows considerable improvements in product quality and business competitiveness.

On-line control of sawmilling operations has recently been developed, often using visible, infrared or X-ray imaging techniques. For example, sawmilling machinery is increasingly equipped with sensors, such as lasers, that take account of the tool's behaviour or the blade's passage through the wood in order to assist and optimize manual control. With the recent arrival of new tools resulting from dynamic analysis and acoustic control techniques, the development of very economical sensors can be envisaged for the structural classification of woods, and even for the detection and pinpointing of certain defects or irregularities. Thus it is possible to foresee quality control based on classification by a variety of criteria such as size, the number of acceptable defects, colour, aesthetic properties and dryness. The extent to which these various criteria will be considered depends on the size of the company, the type of raw material and the market sector. Woods with a high level of irregularities (e.g. knots in softwoods) have already benefited from the application of this technology, which is becoming widespread in countries where the softwood industry is predominant. Processing of conventional tropical hardwoods can benefit only marginally from this technology because these woods are not subject to major defects such as knots. However, the technologies could be of great interest in tropical regions for the processing, grading and quality control of timber from plantations, such as eucalypts or tropical pines.

Further developments are expected mainly in the areas of data and information gathering on the milled product in both primary and secondary processing, and in the area of interactive quality control of the process through analysis of the main parameters, such as surface quality or precision of sawing. It will also be possible to reduce significantly the noise pollution produced by saws, while changes in these sounds can be used to determine the condition of the blades and possibly to guide cutting parameters such as feed speed.

In surface machining (planing, moulding, etc.) there is a trend towards very high-speed machining, which can give a surface quality similar to that produced by sanding, while speeding up the work. Until recently, the rotational critical speed, related to the first mode of blade vibration, seemed to be an insurmountable obstacle for turning machinery, but rotation speeds between the first and second critical speeds can now be envisaged, thanks especially to advances in tensioning and computer-run saw-guides.

Complex multi-axial machining systems carrying out multiple simultaneous operations, such as the "work centres" available in the furniture industry, are gaining ground, as a result of developments in felling equipment, the widespread use of diamonds and the increased use of ceramics. These new cutting materials make it possible to adapt the tool's wear resistance to the high cutting speeds of such equipment and lengthen the use between sharpenings.

In veneering, automatic log-centring devices allow gains in time and, hence, in material. As in sawing, vibration or sound sensors will allow interactive control of veneering machines based on analysis of their performance. Furthermore, peripheral drive has made it possible to use very small-diameter logs and to reduce peeler cores to a few centimetres. On-line control systems, defect sensors, etc. also allow optimization of certain stages, such as wet clipping while the product and its various components are monitored during manufacture.

The wear resistance of the steel used for blades and pressure bars will be improved by nitriding (the deposition of thin, extremely hard layers, possibly using plasma torches) and associated techniques.

Research on jet cutting techniques (using lasers, water jets, etc.) will very probably remain marginal in the timber sector. The use of lasers is likely to be of interest only in the case of complex forms of machining (cutting rather than planing) or non-edge cutting in thicknesses of less than 40 mm. Conventional machining systems using chip removal methods are still by far the most cost-effective for all straight-edge cutting, and are likely to remain so.

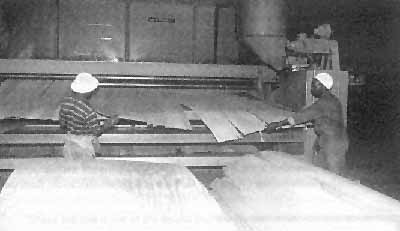

Dry veneers emerging from a roller drier in Zimbabwe; in the future, vibration or sound sensors will allow interactive control of veneering machines

- FAO/20282/G. Diana

At present, the most widely used drying technique is based on temperature and humidity control with forced ventilation. The low-temperature kiln dryer, which saw its hour of glory in the 1970s, has been almost abandoned as being too slow and entailing high risks of deterioration for fragile woods. High-temperature drying (at over 100° C), developed mainly for softwoods and some lighter hardwoods, tends to be unsuitable for solid hardwoods.

The following technologies are now being developed for drying hardwood species that present difficulties and dry particularly slowly:

Advances in modelling will allow the development of more effective and, above all, more reliable control methods. Continuous measurement of changes in the moisture level of wood, above the fibre saturation point, during the drying process is still a difficult technical problem. The absence of a reliable method of measuring high moisture content rates, other than weighing either the wood stacks or test samples, under industrial conditions considerably limits the effectiveness of the most recent generation of monitoring techniques, especially during the first steps of the drying process. Ultrasound and high frequency are among the avenues currently under research.

The environmental impact of existing preservation processes has considerably hampered the development of new chemical approaches. The European directive on the use of biocides will further limit both the number of active substances used in preservation and their fields of application. Over the last decade, many pesticides have been removed from the market, and industrialized countries have banned some well-known families of products such as creosotes and pentachlorophenols.

There is also much debate on aqueous-phase heavy-metal-based products of chrome or copper combined with arsenic or boron, which are used to improve durability. Since there is no real substitute for these products, a definitive ban could put an end to the outdoor use of the species in most common use today.

Solvents used as a medium for active materials have been developed considerably, and emulsion systems have been refined for non-water-soluble substances.

In addition to the development and refinement of preservative products with a low environmental impact, many lines of research on the margins of preservation chemistry are being pursued and are likely to find alternative solutions. These include the following:

The most advanced and probably the most innovative lines of research concern the use of:

The identification of genes responsible for the natural durability of particular species could, in a more distant future, make it possible to modify the intrinsic durability of certain species through genetic modification. Such advances will depend to a large extent on the international debate on genetically modified organisms (GMOs).

The development of chemical products has been affected by the need to take account of the effects of volatile organic compounds on human health and the environment. In the glue sector, the main innovations have concerned the development of low-formol products, in line with changing regulations. The sector now has an extremely wide range of specific products that meet both the technical demands of use conditions and the demands arising from issues of industrial implementation. Available products range from hot-melt to hot-hardening glues, with a whole gamut of intermediate products. New developments include glues for greenwood, glues for rough sawnwood with thick joints, and electromagnetic wave-accelerated polymerization technologies (high-frequency, microwave, etc.).

In finishing, problems arising from the use of organic solvents have been partially solved by the development of products with a high content of dry extracts or by the refinement of water-based systems in the paint and stain sector. Research is also being carried out on products such as radiation-polymerizable products and powdered products that do not use solvents. The lifetime of exterior facing systems has been improved by the addition of anti-ultraviolet (UV) components, improvements in the visco-elastic behaviour of films and slowing in the physicochemical degradation of existing products.

The main handicap in the exterior use of wood, however, is that the physical appearance still deteriorates too quickly. Research has shown the primary role played by the species selected in the lifetime of a finishing system; this lifetime can be doubled by the use of certain species. Research is focusing increasingly on this subject and investigating the performance of species-product combinations. Other work suggests that, in due course, it will be possible to coat wood-based materials with metallic materials such as copper, aluminium and zinc, or with carbon-based "diamond" coating.

The main developments in the future could concern improvements in the productivity of finishing procedures through the development of single-coat products to replace the classic system of three successive coats. Regarding associated technologies, haze application systems that make it possible to obtain thin and very homogeneous coatings could come to the fore. Flat composites could see the development of powder finishing techniques. The use of electromagnetic wave devices could be expanded to speed up the drying of finishes in secondary processing industries, especially the furniture sector.

The past 30 years have seen the development of many types of board in response to two main demands on the part of the furniture and construction sectors - for thin flat materials and for large areas of board. Plywood was the first response to these requirements, but its manufacture required the use of high-quality wood (well-formed, cylindrical logs, straight trunks, etc.). Fibreboard and particle board produced from defibrated or fragmented wood do not require these qualities, and allow an optimal use of forest subproducts such as timber from coppicing or from thinnings, or residues from the processing of solid wood. Variations in the type of glue used, and in the size, shape and orientation of the particles, allow the production of board with a wide range of different properties to meet the technical and economic requirements of any application.

Research is likely to develop in two main directions:

Plastic-wood composites should also see interesting developments. These allow the recovery of fine residues such as sawdust. Sawdust, when mixed with plastic in a proportion of up to 50 percent, produces materials that are mechanically more resistant than basic plastics, as well as being partially biodegradable.

The normal techniques used in manufacturing reconstituted elements from offcuts or small-sized pieces continue to be developed, particularly in relatively unindustrialized countries, as alternatives to the use of waste in situations where fibre or particle composites are not a valid option.

Heavy demand for wood as construction material will contribute to the growth of specific needs for technological innovation in certain tropical regions - here, a wood-shingle house in Iles du Salut, French Guyana

- Cirad-Forêt/E. Loffeier

For most of the twentieth century, research and the resulting technological innovations were mainly in the hands of temperate industrialized countries. Seldom have innovations first developed specifically for tropical woods been transferred to temperate or cold-climate woods. One case that comes to mind is stellite tipping, a technique developed for metal machining and adapted by the International Cooperation Centre on Agrarian Research for Development's Forêt programme (CIRAD-Forêt), the French forest research and development organization for tropical regions. The technique has now been extended to all sawing operations and is used as widely for temperate as for tropical woods.

Tropical countries are increasingly in a position to benefit from the technological developments already introduced in the North, adapted to their needs if necessary. The emergence of a strong demand for wood as a construction material and a source of energy in certain tropical regions where there are highly industrialized wood sectors, such as Southeast Asia, has transformed the trade structures inherited from the twentieth century and will contribute to the increase of specific needs for technological innovation. The role of the emerging countries of the South will be vital in preventing the widening of the technological gap between the wood sectors of the South and the North.

As with all processing industries, the wood sector has experienced major technological upheavals over the past decades. It may seem that there has been far too little innovation in some fields, where wood has lost considerable market shares (industrial joinery, tool handles, everyday office items, etc.). For example, in joinery (windows), wood supplied more than 80 percent of the European market 20 years ago. This proportion has now been reduced to 30 percent as wood has been replaced by plastics and aluminium. On the other hand, wood has gained a new place in certain traditional sectors thanks to good industrialization of products, the adaptation of fitting techniques to reduce the length of building processes, a good quality-to-price ratio, and recognized quality and effectiveness (parquet and other floor coverings, panelling, exterior furnishings, etc.). In addition, wood is increasingly being used in the manufacture of new composites that have become available on the market within the past 20 years: medium-density fibreboard, oriented strand board and laminated veneer lumber, as well as their various derivatives. Wood has become less visible and its presence more difficult to identify in such products. For example, most drivers are unaware that the interior trim of a number of cars is made of wood-based composite board.

Technological developments must be adapted and further developed to comply with the increasingly demanding consumer sectors of construction, furniture and packaging. Industrialization of manufacturing processes requires a regular supply of raw material of constant, controlled and guaranteed quality (not necessarily very high quality). Cloning and genetic selection will allow a partial response to these requirements. The demand for plantation wood is likely to rise considerably. Research into genetic determinism and the properties of different woods is still in its infancy, but will be a major focus in the next ten years. After the genes responsible for certain essential characteristics such as mechanical resistance or natural durability have been identified, forest sciences may also have to face ethical questions concerned with the use of genetically modified seedlings in plantations and future reforestation plans.

In the shorter term, the sector must become much more effective in supplying users with specially tailored, high-quality, reliable and highly competitive products. There is no market sector where wood is safe from substitution by competing materials - which are, moreover, produced by more powerful or better-organized industrial sectors. Researchers must be increasingly attentive to the demands of the sector and to market shifts, and must be ready to assist professionals throughout the innovation process, involving themselves in the transfer of technology, technical support and training.