G.P. Horgan

Gerard Horgan is a consultant with APR Consultants, New Zealand.

Subsidies and incentives are often needed to make the use of woodfuels attractive – yet in some situations the use of wood energy can be an economic choice.

A basic tenet of economics is that resources are always in limited or scarce supply. This scarcity makes it necessary to choose among alternative uses for resources and imposes limits to both the quantity and types of goods that can be produced. The challenge of selecting a mix of resource uses that maximizes some measure of well-being is usually referred to as the basic economic problem.

There are diverse technical, environmental, social, cultural and economic reasons for choosing woodfuel as a source of energy. These factors make woodfuel use a site- and situation-specific energy option. This article examines the economics of the choice to use woodfuels for the different contexts of developing and developed countries.

Dependence on woodfuels and the mix of fuel types varies from region to region. There are diverse reasons for choosing wood as a source of energy. For many users the choice depends on the availability and affordability of other energy options.

A large and significant group of users remains outside, or at best only on the periphery of, the money economy. Some 2.8 billion people, for example, earn less than US$2 per day, and low daily income is strongly correlated with use of biomass for energy (see Figure). Most users of this type live in developing countries, where woodfuels are a vital component of the primary energy supply (IEA, 2002a). A large part of these users have relatively limited access to alternative fuels for cooking or home heating. For many of them, fuel options are currently confined to locally available energy that can be gathered for the cost of the time and physical exertion (“sweat equity”) involved in its collection.

Development, and with it greater involvement in the monetary economy, increased value assigned to the individual’s time and a wider choice of fuels, is likely to reduce the use of woodfuels by this group. However, at present the basic energy options of this group are limited. A significant amount of research has therefore been targeted at improving the efficiency of cheap stoves and increasing the supply (production) of woodfuel to improve the welfare of these users.

A second group of wood energy users takes part in the monetary economy but is almost as limited in its options as the first. This group comprises commercial enterprises such as food processing industries that depend on woodfuels for baking, brewing, smoking and curing.

A third group consists of industries (e.g. sawmills, power utilities) which use woodfuels for energy production. Users of black liquor, a by-product of pulp and paper making which is burnt to provide energy for the pulping process, fall into this category, as do users of wood residues (including sawdust) for combined heat and power production in forest industries such as sawmilling and particle board industries.

Where energy is produced as an essential part of the process of manufacturing another wood-based product, the energy so produced is in economic terms essentially “free”. Failing to make use of it – opting instead to purchase energy for manufacturing from other sources – makes no economic sense, particularly if the energy is already in the form required by the process. Should the energy production exceed the requirements of the process, selling the excess energy is also likely to make good economic sense for the manufacturer, as long as the sales price more than covers the cost of producing this energy.

In contrast with these groups of producers and users, which are essentially locked into producing and using wood energy, other fuelwood users have choices. Their decision to use wood to provide for their energy needs is not based on necessity, but on the relationship between the costs of achieving the desired results (a warm house, a digestible meal, boiled water, a salable product) with wood or a wood-based fuel and the costs of achieving the same result with some other fuel. Typically the reference will be a fossil fuel (oil, gas, coal), but it can also be another renewable energy source or technology. However, fossil fuels are expected to continue to dominate the primary energy supply for at least the next 20 years (IEA, 2000).

The type of analysis used to determine whether wood is economically the most appropriate fuel may range from an extremely simple accounting, where current and/or projected market prices of the various fuels are used to estimate the cost of meeting a stated goal with each fuel, to highly sophisticated economic analysis. If the relative cost of the various fuels is expected to remain reasonably constant, and if the cost and expected life of the equipment required for the use of each fuel are reasonably comparable, rankings provided by the very simplest of analyses are likely to be quite accurate. However, if the capital cost or the expected economic life of the equipment required by different fuels varies significantly, if relative fuel prices are expected to change, or if taxes on fuels per unit of effective energy differ and do not reflect the externalities imposed by different fuels, the results of a simple analysis can be quite misleading and more sophisticated analysis is required. The analysis may have to take into account specific attributes of each fuel – not just the obvious macro ones of whether the fuel is a solid, liquid or a gas, but possibly more subtle ones concerning chemical composition and related suitability in terms of equipment and operation. A consumer contemplating switching fuels may need to factor in the possible impacts on existing equipment and may have to assign economic values to known or perceived externalities (such as air and water pollution resulting from burning of fuel) which may differ with the energy or fuel source.

Poverty and share of traditional biomass in residential energy consumption |

|

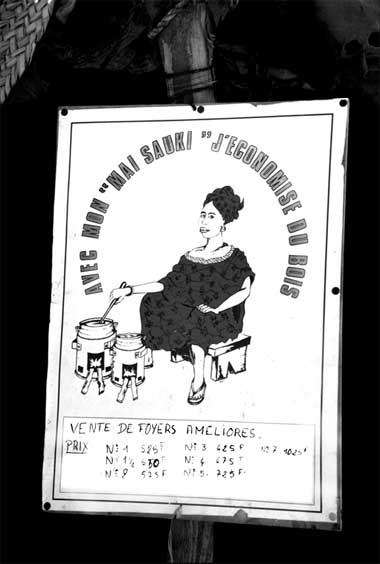

For many fuelwood users in developing countries, energy options are limited; for these users, efforts have been targeted at improving the efficiency of cheap stoves (as promoted in this poster in the Niger) to improve their welfare |

|

FAO FORESTRY DEPARTMENT/FO-1014/S. BRAATZ |

Some commercial enterprises such as food processing industries take part in the monetary economy but are still limited in their energy options (shown, street food preparation in the Sudan) |

|

M.A. TROSSERO |

In techno-economic analysis, energy is often considered a by-product of a process aimed at producing another output, which makes a great deal of difference to the economics, raising issues of how costs should be allocated between various outputs. If demand for some outputs makes prices inelastic, it may be possible to produce cost-competitive energy simply by ensuring that these products carry all or most of the costs of growing, harvesting and processing the wood.

In developed countries, it is apparent that in most cases, based on direct costs, energy from wood is at present more expensive (and in some cases very much more expensive) than the fossil fuel equivalent. Nevertheless, many of these countries provide special subsidies and incentives to encourage the use of woodfuel for various reasons: to ensure national control over at least a portion of the country’s energy resources; to increase familiarity with woodfuel systems in the hope that this will help lower the cost of wood energy; and to help reduce the negative externalities associated with some of the currently used fuels. Woodfuels are seen as a means for conforming with new environmental legislation and with energy policies demanding that by a particular date a set fraction of energy should be supplied from renewable sources. For example, 10 percent of electricity in the United Kingdom should be generated from renewable resources by 2010, and one half of the renewable-resource-based electricity should come from burning biomass.

Government support is not always required to make modern biomass-based energy economically viable, however. In some cases biomass-based fuels are competitive with other energy forms on a pure resource cost basis. This competitiveness is usually due to some specific site or manufacturing process factor, for example when residues are used to produce energy for sawmilling, when black liquor is used in pulp and paper making, or when the site where the energy is needed is remote from both other sources of energy and the rest of the country’s supply infrastructure. These conditions may be more likely to occur in developing countries. However, remoteness and high cost of supply for other forms of energy do not occur only in the developing world.

Biomass is without doubt the most ubiquitously available energy source. However, in comparison with many other energy resources, the energy density of raw wood is relatively low. When newly harvested, wood can be more than 50 percent water by volume. Its low energy density together with the costs of its harvest and transport impose limits on the distance wood for energy can be transported before use. However, many of the modern processes that transform wood into energy exhibit significant economies of scale.

As the production and transport functions tend to favour small-scale operations, while conversion technologies often require large-scale operations to be economic, the challenge for the modern woodfuel industry is to strike the right balance. The current reality is that in many situations the amount of economically available biomass for energy is very much less than the reported physically available amount (East Harbour Management Services, 2002).

Looking to the future for both proven technologies for woodfuel conversion for energy production, such as combustion and gasification, and for other less well-developed technologies, such as pyrolysis, continued research and development continue to hold promise for reducing the cost of producing energy. They can do this by leading to improved efficiency of conversion or by reducing capital cost, in turn reducing the impact of scale economies on the overall economics.

Greater use of residues and wastes is a potential source of relatively cheap biomass for energy. Much of this material is not used, and its cost can be modest when compared with the cost of purpose-produced material. The opportunity cost of large volumes of residue material from conventional forest crops or forest processing is typically in the range of US$1.30 to $3.20 per gigajoule (US$10 to $24 per cubic metre) (Ford-Robertson, Horgan and Wakelin, 1996; Li, Gifford and Hooper, 2000).

On the other hand, the costs of producing significant volumes of purpose-grown fibre for fuel are typically of the order of US$25 to $40 per cubic metre (Graham et al., 1995; Mitchell et al., 1995; Samson and Girouard, 1998; Turhollow, 2000). In the longer term, research, including the development of clones specifically intended to meet the needs of an energy market, might reduce the generic growing and delivery costs by at least 50 percent. Carpentieri, Larson and Wood (1993) estimated that plantations in northeastern Brazil could deliver 13 exajoules (EJ, 1018 joules) per year of biomass at US$1.5 per gigajoule (GJ, 109 joules) (approximately US$12 per cubic metre).

Even with cheap feedstock and a technically efficient conversion process, stand-alone commercial viability is and is likely to remain dependent on site-specific factors, which are often coupled with significant levels of public financial support. Such support sometimes even ensures commercial viability for systems that do not enjoy any specific site advantages. The impetus for this support ranges from the desire to demonstrate the effectiveness of a particular process to universal concerns about climate change, the security of energy supplies or overdependence on other countries for domestic primary energy supplies. While the concerns may be general, however, the value placed on wood energy as a means of addressing them is site and situation specific.

When the site where energy is needed is remote from other sources of energy, woodfuel can be competitive with other energy forms – shown, brickmaking (above) and cement production (below) using wood energy in Brazil |

|

M.A. TROSSERO |

|

M.A. TROSSERO |

Growing awareness of woodfuels as a potentially environmentally friendly source of energy is currently leading to a renewed interest in wood energy and an increasing number of initiatives and projects in this field. In general, the direct cost of energy from wood is greater, and in some cases substantially greater, than the direct cost of energy from conventional fossil-fuel-based systems. Based on projected international trends of the pre-tax cost of oil and other fossil fuels, it appears probable that this will remain the case for some time unless an unexpected breakthrough can produce an immediate and substantial reduction in the cost of biofuels. Accordingly agencies such as IEA (2002b) have projected relatively modest growth for non-hydro renewables, at least over the next five to ten years. This conclusion may seem to be at odds with the upsurge in development of woodfuel systems, yet in fact it serves to highlight the site- and situation-specific nature of many of the economic conclusions concerning wood energy.

The present interest in woodfuels does not simply reflect a focus on the direct cost of producing energy from wood. It also reflects an appreciation of the externalities associated with the use of wood as a fuel relative to those associated with other fuels. Although some externalities, notably those related to climate change induced by fossil fuel use, may apply to all fuels, there is as yet no universal agreement on the costs. The values applied for greenhouse gas emission reductions are therefore at present site, country or region specific. Externalities related to national security clearly depend on the particular circumstances of the region or country. As a result, the inclusion of externalities in the analysis generally reinforces the site- and situation-specific nature of the economics of wood energy systems, rather than narrowing the differences.

Bibliography

Bibliography

Carpentieri, A.E., Larson, E.D. & Wood, J. 1993. Future biomass-based electricity supply in Northeast Brazil. Biomass and Bioenergy, 4: 149-174.

East Harbour Management Services. 2002. Availabilities and cost of renewable sources of energy for generating electricity and heat: a report to the Ministry of Economic Development. Wellington, New Zealand. Available on the Internet: www.med.govt.nz

Ford-Robertson, J.B., Horgan, G.P. & Wakelin, S. 1996. Biomass site scoping study: a report for the Electricity Corporation of New Zealand. Rotorua, New Zealand, New Zealand Forest Research Institute.

Graham, R.L., Lichtenberg, E., Roningen, V.O., Shapouri, H. & Walsh, M.E. 1995. The economics of biomass production in the United States. Oak Ridge, Tennessee, USA, Oak Ridge National Laboratory.

International Energy Agency (IEA). 2000. World Energy Outlook 2000. Paris, France.

IEA. 2002a. Energy and poverty. In World Energy Outlook 2002, p. 365-406. Paris, France. Available on the Internet: www.iea.org

IEA. 2002b. Key World Energy Statistics 2002. Paris, France. Available on the Internet: www.iea.org

Li, J., Gifford, G. & Hooper, G. 2000. Reconstituted solid fuels from wood wastes. Presented at WasteMINZ 12th Annual Conference, Auckland New Zealand, 1-3 November.

Mitchell, C.P., Bridgwater, A.V., Stevens, D.J., Toft, A.J. & Watters, M.P. 1995. Technoeconomic assessment of biomass to energy. Biomass and Bioenergy, 9(1-5): 205-226.

Samson, R. & Girouard, P. 1998. Bioenergy opportunities from agriculture. Presented at the 24th Annual Conference of the Solar Energy Society of Canada, “Renewable Energy Technologies in Cold Climates” Montreal, Canada, 4-6 May.

Turhollow, A. 2000. Costs of producing biomass from riparian buffer strips. ORNL/TM-1999/146. Oak Ridge, Tennessee, USA, Oak Ridge National Laboratory.