Over the past few years, food safety has become and continues to be the number one concern of the fresh produce industry. A “Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables,” was published by the U.S. Food and Drug Administration in October 1998. This guide is based on the following principles:

(1) Prevention of microbial contamination of fresh produce is favored over reliance on corrective actions once contamination has occurred;

(2) In order to minimize microbial food safety hazards in fresh produce, growers, packers, or shippers should use good agricultural and management practices in those areas over which they have control;

(3) Fresh produce can become microbiologically contaminated at any point along the farm-to-table food chain. Human and/or animal faeces are the source of microbial contamination of fresh produce;

(4) Whenever water comes in contact with produce, its quality dictates the potential for contamination. The potential of microbial contamination from water used with fresh fruits and vegetables must be minimized;

(5) The use of animal manure or municipal biosolid wastes as fertilizers should be closely managed in order to minimize the potential for microbial contamination of fresh produce; and

(6) Worker hygiene and sanitation practices during production, harvest, sorting, packing, and transport play a critical role in minimizing the potential for microbial contamination of fresh produce.”

A training manual for trainers, entitled “Improving the Safety and Quality of Fresh Fruits and Vegetables,” was published by the United States Food and Drug Administration (USFDA) in November 2002, with the objective of providing uniform, broad-based scientific and practical information on the safe production, handling, storage, and transport of fresh produce.

Figure 11: Washing Bananas

Clean water containing an appropriate concentration of sanitizers is required in order to minimize the potential transmission of pathogens from water to produce, from healthy to infected produce within a single lot, and from one lot of produce to another, over time. Waterborne microorganisms, including post-harvest plant pathogens and agents of human illness, can be rapidly acquired and taken up on plant surfaces. Natural plant surface contours, natural openings, harvest and trimming wounds and scuffing can provide points of entry as well as safe harbor for microbes. When located in these protected sites, microbes are largely unaffected by common or permitted doses of post-harvest water sanitizing treatments (Table 4). It is therefore essential that the sanitizer concentration is sufficient to kill microbes before they attach or become internalized in produce. The concentration of sanitizer is important in some pre-harvest water uses (such as spraying pesticides or growth regulators) and in all post-harvest procedures involving water, including washing, cooling, water-mediated transport (flumes), and post-harvest drenching with calcium chloride or other chemicals.

Figure 12: Washing potatoes

Transpiration, or evaporation of water from the plant tissues, is one of the major causes of deterioration in fresh horticultural crops after harvest. Water loss through transpiration not only results in direct quantitative losses (loss of saleable weight), but also causes losses in appearance (wilting, shriveling), textural quality (softening, flaccidity, limpness, loss of crispness and juiciness), and nutritional quality. Transpiration can be controlled either through the direct application of post-harvest treatments to the produce (surface coatings and other moisture barriers) or through manipulation of the environment (maintenance of high relative humidity).

Treatments that can be applied to minimize water loss in fruits and vegetables include:

a. Curing of certain root vegetables, such as garlic, onion, potato, and sweet potato.

b. Waxing and the use of other surface coatings on commodities, such as apple, citrus fruits, nectarine, peach, plum, pomegranate, and tomato.

c. Packaging in polymeric films that act as moisture barriers.

d. Careful handling to avoid physical injuries, which increase water loss from produce.

e. Addition of water to those commodities that tolerate misting with water, such as leafy vegetables.

|

Sanitizing chemicals |

Advantages |

Disadvantages |

|

Chlorine compounds

|

Low cost |

Corrosive, irritating, |

|

Iodine compounds |

Low cost, non irritating |

Slightly corrosive, staining |

|

Ozone |

Faster action on |

Higher cost than chlorine |

|

Peroxyacetic acid |

More effective in |

Higher cost than chlorine |

Table 4: Sanitizing chemicals used in produce handling

The promotion of senescence in harvested horticultural crops by ethylene (1 ppm or higher) results in acceleration of deterioration and reduced post-harvest life. Ethylene accelerates chlorophyll degradation and induces yellowing of green tissues, thus reducing the quality of leafy, floral, and immature fruit-vegetables and foliage ornamentals. Ethylene induces abscission of leaves and flowers, softening of fruits, and several physiological disorders. Ethylene may increase decay development of some fruits by accelerating their senescence and softening and by inhibiting the formation of antifungal compounds in the host tissue. In some cases, ethylene may stimulate the growth of fungi, such as Botrytis cineria on strawberries and Penicillium italicum on oranges.

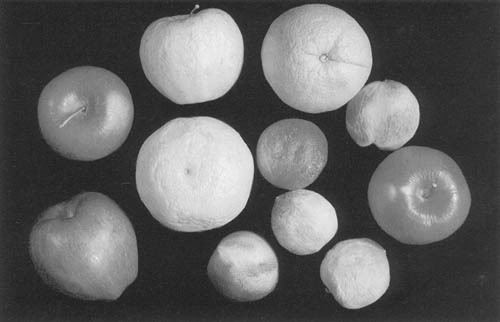

Figure 13: Water loss symptoms on fruits

The incidence and severity of ethylene-induced deterioration symptoms is dependent upon temperature, time of exposure, and ethylene concentration. The yellowing of cucumbers can, for example, result from exposure to either 1 ppm ethylene over 2 days or to 5 ppm ethylene over 1/2 day at 10 °C. Ethylene effects are cumulative throughout the post-harvest life of the commodity.

Treatment of ornamental crops with 1-methylcylopropene (1-MCP), which is an ethylene action inhibitor, provides protection against ethylene damage. The commercial use of this product at concentrations of up to 1 ppm on apples, apricots, avocados, kiwifruit, mangoes, nectarines, papayas, peaches, pears, persimmons, plums, and tomatoes was approved by the United States Environmental Protection Agency. The use of 1-MCP will no doubt be extended to several other fruits and vegetables, and to use in other regions.

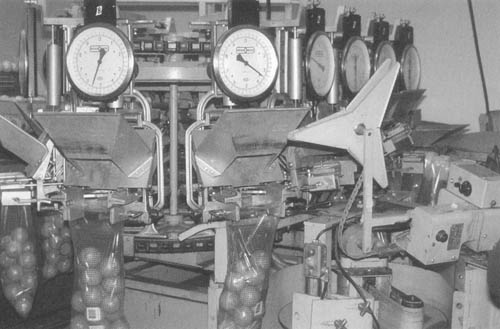

Figure 14: Packaging of oranges

A major cause of losses in perishable crops is the action of a number of microorganisms on the commodity. Fungi and bacteria may infect the plant organ at any time. “Latent” infections, in which fungi invade fruit tissues shortly after flowering, become apparent only at the onset of ripening. Post-harvest rots frequently occur as a result of rough handling during the marketing process and are caused by a wide array of microorganisms. The grey mold Botrytis cineria is a very important cause of loss in many commodities (such as grapes, kiwifruit, pomegranates, raspberries, and strawberries), and is an aggressive pathogen, even at low temperatures. Virus infection frequently lowers the quality of perishable commodities, usually as a result of visual deterioration, although viruses may also affect flavor and composition.

Curing is a post-harvest treatment (Table 5) that facilitates certain anatomical and physiological changes that can prolong the storage life of some root crops. It is one of the most effective and simple means of reducing water loss and decay during subsequent storage of root, tuber, and bulb crops, such as those listed in Table 5.

Figure 15: Symptoms of decay (caused by various fungi)

Sanitation practices include treatment to reduce populations of microorganisms on equipment, on the commodity, and in the wash water used to clean it. Water washes alone are effective in removing nutrients that allow microorganisms to grow on the surfaces of produce as well as in removing inoculum of post-harvest pathogens. The addition of sanitizers (Section 4.1) to water dumps and spray or dip washes, reduces inoculum levels of decay-causing organisms from fruit surfaces, inactivates spores brought into solution from fruit or soil and prevents the secondary spread of inoculum in water. Treatments for decay control include: (1) heat treatments, such as dipping mangoes in water at a temperature of 50 °C, for 5 minutes in order to reduce subsequent development of anthracnose; (2) use of post-harvest fungicides, such as imazalil and/or thiabendazole on citrus fruits; (3) use of biological control agents, such as “Bio-Save” (Pseudomonas syringae) and “Aspire” (Candida oleophila) alone or in combination with fungicides at lower concentrations on citrus fruits; (4) use of growth regulators such as gibberellic acid or 2, 4-D to delay senescence of citrus fruits; (5) use of 15-20 percent CO2 in air or 5 percent O2 on strawberries, cane berries, figs, and pomegranates; and (6) use of SO2 fumigation (100 ppm for one hour) on grapes.

|

Crops |

Temperature |

Relative humidity |

Duration |

|

Cassava root |

30-40 |

90-95 |

2-5 |

|

Onion and garlic bulbs |

30-45 |

60-75 |

1-4 |

|

Potato tubers |

15-20 |

85-90 |

5-10 |

|

Sweet Potato roots |

30-32 |

85-90 |

4-7 |

|

Yam tubers |

32-40 |

90-100 |

1-4 |

Table 5: Conditions for curing root, tuber, and bulb crops

Fresh fruits, vegetables and flowers may harbor a large number of insects during post-harvest handling. Many of these insect species, in particular fruit flies of the family Tephritidae (e.g. Mediterranean fruit fly, Oriental fruit fly, Mexican fruit fly, Caribbean fruit fly), can seriously disrupt trade among countries. The identification and application of acceptable disinfestation treatments including irradiation will greatly facilitate globalization of trade in fresh produce. Criteria for the selection of the most appropriate disinfestation treatment for a specific commodity include cost, the efficacy of that treatment against insects of concern, safety of the treatment as well as the ability of that treatment to preserve and maintain produce quality. Currently approved quarantine treatments, other than irradiation, include certification of insect-free areas, use of chemicals (e.g. methyl bromide, phosphine, hydrogen cyanide), cold treatments, heat treatments, and combinations of these treatments, such as methyl bromide fumigation in conjunction with cold treatment. The use of alternative treatments, such as fumigants (carbonyl sulphide, methyl iodide, sulphuryl fluoride) and insecticidal atmospheres (oxygen concentrations of less than 0.5 percent and/or carbon dioxide concentrations ranging between 40 and 60 percent) alone or in combination with heat treatments, and ultraviolet radiation, are currently under investigation. These treatments are not, however, broad-spectrum treatments and are potentially phytotoxic when applied to some commodities.

Most insects become sterile when subjected to irradiation doses ranging between 50 and 750 Gy. The actual dosage required to produce sterility in insects varies in accordance with the species concerned and its stage of development. An irradiation dose of 250 Gy was approved by the United States quarantine authorities for application to fresh commodities, such as lychees, mangoes, and papayas in light of the efficacy of that dose in preventing the reproduction of tropical fruit flies. Irradiation doses of 250 Gy can be tolerated by most fresh fruits and vegetables with minimal detrimental effects on quality. Doses ranging between 250 and 1000 Gy (the maximum irradiation dose allowed as of 2002), can, however, be damaging to some commodities. Fruits, in general, are more tolerant to the expected dose range (250 to 500 Gy absorbed by fruits on the inside vs. those on the outside of the pallet) than non-fruit vegetables and cut flowers. Detrimental effects of irradiation on fresh produce may include loss of green color (yellowing), abscission of leaves and petals, tissue discoloration, and uneven ripening. These detrimental effects may not become visible until after the commodity reaches the market. The effects of irradiation must therefore be tested on individual commodities, prior to large-scale commercialization of the irradiation treatment.