Labour-saving technologies and practices: manually operated strippers and shellers

The following provides information on the features of manually operated groundnut strippers and maize shellers. The former separates the pods from the plant whereas the latter removes the kernels from the cob. Advantages and disadvantages of these practices are also provided in terms of labour saving, livelihood resilience strengthening, livelihood diversification, equipment, cost, risk, skills and infrastructure.

Description

Groundnuts are usually removed from the plant by hand. Maize is commonly shelled by hand or by placing the cobs in jute bags and beating them with stocks to separate the kernels from the cob. Any kernels left on the cob after the beatings are removed by hand.

1. Features of manually operated strippers and shellers

1.1 Groundnut strippers separate the pods from the plant

- A rectangular frame is created on legs onto which vertical pegs are attached, such as nails partly hammered into the frame.

- The groundnuts are dragged through the pegs, separating them from the plant

- An old steel drum is cut in half and plants are banged against the edge of the drum until the pods fall into the drum.

- Groundnut shellers or decorticators are made of a curved screen in the base of an open tank mounted on a frame, with a rasp bar operated in a reciprocating semi-circular motion.

- The rasp bar scrapes the groundnuts against the screen, breaking the shells and allowing the nuts and shells to fall through the screen, after which they are winnowed.

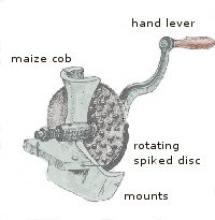

1.2 Maize shellers remove the kernels from the cob

- A cylinder with rows of internal teeth is used.

- The cob is inserted into the cylinder which is rotated with a handle (very simple).

- A cast iron rotating disk with protrusions on it is used where cobs are pushed against the disk and the kernels are knocked off (more common).

- Medium sized maize shellers have an output ranging from 30 kg per hour to 120 kg per hour when operated manually.

- Up to 800 kg per hour when powered by a small 0.5 kW electric motor.

Figure 1. Maize sheller

©FAO/TECA

2. Advantages

2.1 Labour saving

- These practices lead to higher work rates compared to manual harvesting.

- Drudgery is diminished and time requirements are lower.

2.2 Livelihood resilience strengthening

- The practices are suitable for small farmers and small plots.

- They are able to increase the quality and value of the processed crop.

2.3 Livelihood diversification

- The practices provide an opportunity to offer farm power hiring services to others.

2.4 Equipment

- Most mowers and reapers are based on power tiller units, which make them very versatile implements when all the attachments are available.

3. Disadvantages

3.1 Equipment

- The equipment is relatively complex.

3.2 Cost and risk

- There is a high cost of purchasing and running machinery compared to manual harvesting tools, and risk associated with financial investment.

3.3 Skills

- Skills are required for efficient and safe operation of machinery.

3.4 Risk

- There is potential failure of use of the practices if hiring services are introduced into an area where there is insufficient demand to pay for contractual services.

3.5 Infrastructure

- Considerable infrastructure support is required for their efficient operation.

4. Agro-ecological zones

- Tropics, warm.

5. Related/associated technologies

6. Objectives fulfilled by the project

6.1 Labour saving technology (LST)

The technology allows for higher work rates and lower time requirements.

6.2 Resource use efficiency

The technology increases crop quality and value.

6.3 Pro-poor technology

The technology provides opportunity for farm power hiring services. Better quality and value crops means also additional income generation.