IDENTITY

Biological features

Habit variable, thallus sometimes tall and loosely branched with few blunt or pointed determinate branchlets, sometimes densely branched with many coarse spinose branchlets. Branchlets irregularly arranged on main indeterminate branches without forming whorls. Cross-section of branch shows medulla consisting of large rounded cells interspersed with small relatively thick walled cells.

PROFILE

Historical background

In the 1960s an American seaweed processing company transferred its procurement of raw materials for the production of carrageenan from Indonesia to the Philippines. During its initial operations the company sourced its supply of raw materials by gathering/collecting the seaweeds from the reefs of islands in the Central Visayas. The unabated gathering of natural stocks resulted to depletion of the stocks towards the later part of the decade. The short supply of dried seaweeds for processing triggered research and development work on the culture of these species, the survey and assessment of coastal areas with potential for seaweed farming, and an inventory of the local varieties of these species for comparative growth studies and assessment of the quality of their colloidal products.

The surveys for potential farming areas centered mainly on Western Mindanao and Central Visayas in the Philippines. Experimental culture was initiated in several sites which included Calatagan, Batangas, Ilin Island in Mindoro and in Danajon Reef, Northern Bohol. In early 1970, these efforts were extended to Sacol Island in the province of Zamboanga and in Tapaan Island lagoon in Siasi province of Sulu. The first commercial farm for Eucheuma/Kappaphycus was established in Tapaan Island in 1972. Meanwhile, test planting in Danajon Reef was also started resulting to the establishment of commercial farms by the Cebu-based seaweed processing companies in the mid 1970s where the two species were utilized as seedstocks. Due to increasing demand for the dried seaweeds in both local and international markets the farming of these seaweeds had expanded to Western Mindanao, Northern, Eastern and Southern Mindanao including the province of Palawan, as well as to Eastern Malaysia (Sabah and Sarawak) and Indonesia.

The surveys for potential farming areas centered mainly on Western Mindanao and Central Visayas in the Philippines. Experimental culture was initiated in several sites which included Calatagan, Batangas, Ilin Island in Mindoro and in Danajon Reef, Northern Bohol. In early 1970, these efforts were extended to Sacol Island in the province of Zamboanga and in Tapaan Island lagoon in Siasi province of Sulu. The first commercial farm for Eucheuma/Kappaphycus was established in Tapaan Island in 1972. Meanwhile, test planting in Danajon Reef was also started resulting to the establishment of commercial farms by the Cebu-based seaweed processing companies in the mid 1970s where the two species were utilized as seedstocks. Due to increasing demand for the dried seaweeds in both local and international markets the farming of these seaweeds had expanded to Western Mindanao, Northern, Eastern and Southern Mindanao including the province of Palawan, as well as to Eastern Malaysia (Sabah and Sarawak) and Indonesia.

Main producer countries

The FAO statistics for these four groups of seaweeds (Kappaphycus alvarezii, Eucheuma cottonii, Eucheuma denticulatum and Eucheuma spp.) are combined within the map shown below. However, this does not present the whole story, since Indonesia, Malaysia, Solomon Islands and Fiji Islands are also producers but do not report them separately.

Main producer countries of Eucheuma spp. (FAO Fishery statistics, 2006)

Habitat and biology

These seaweeds are the most common and fast growing species in the Philippines and are found from just below the low tide mark to the upper subtidal zone of the reef, growing usually on sandy-corally to rocky substrata where water movement is slow to moderate. They grow by means of an apical meristem consisting of a group of actively dividing cells at the tip of the branches. They exhibit a triphasic life cycle, consisting of the gametophyte (n) (dioecious), carposporophyte (2n) and the sporophyte (2n).

The fertilization of the egg in the carpogonium of the female gametophyte by the spermatium results in the production of the zygote, which in turn develops into the microscopic carposporophyte within the fertile structure called cystocarp in the female gametophyte.

The carpospores (2n) produced by the carposporophytes develop into the tetrasporophytes. Meiosis takes place in the tetrasporangia, resulting to the production of tetraspores (n) which in turn develop into the gametophytes.

The gametophyte and the sporophyte are the large phases in the life cycle of this seaweed. The latter, however is the more robust of the two (2n). These seaweeds are characterized by their high vegetative regenerative capacities; these characteristics are used by farmers to their advantage.

The fertilization of the egg in the carpogonium of the female gametophyte by the spermatium results in the production of the zygote, which in turn develops into the microscopic carposporophyte within the fertile structure called cystocarp in the female gametophyte.

The carpospores (2n) produced by the carposporophytes develop into the tetrasporophytes. Meiosis takes place in the tetrasporangia, resulting to the production of tetraspores (n) which in turn develop into the gametophytes.

The gametophyte and the sporophyte are the large phases in the life cycle of this seaweed. The latter, however is the more robust of the two (2n). These seaweeds are characterized by their high vegetative regenerative capacities; these characteristics are used by farmers to their advantage.

PRODUCTION

Twelve varieties of K. alvarezii have been characterized based on their morphology, DNA fingerprints and growth performance during the different cropping seasons. The information derived from these studies is important and very relevant to the cropping management in farms where the farmers use several varieties as seedstocks. The present seedstocks are endemic in the Philippines.

Supplies of seedstock are sourced from the wild and multiplied in a nursery plot. The original seedstock is washed clean of dirt and other contaminants and transported as quickly as possible to the nursery site in Styrofoam boxes with air holes in the top, without exposing it to sun and wind. The nursery-reared cuttings become the seedstock for the first grow-out. Subsequent supplies of seedstock are obtained from the first cropping, and so on.

The most important aspect in developing a potentially productive seaweed farm is site selection. The site must be assessed to conform to the following criteria:

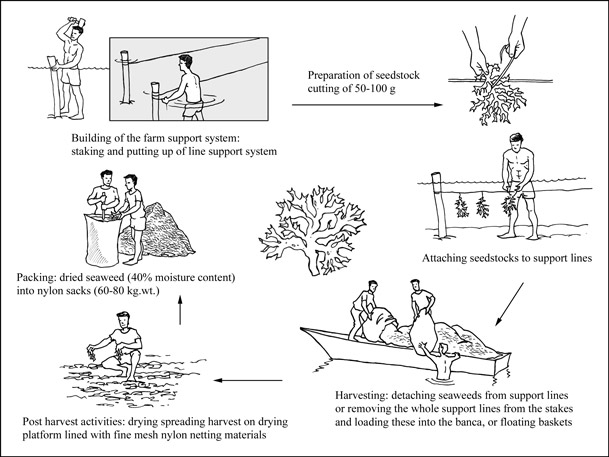

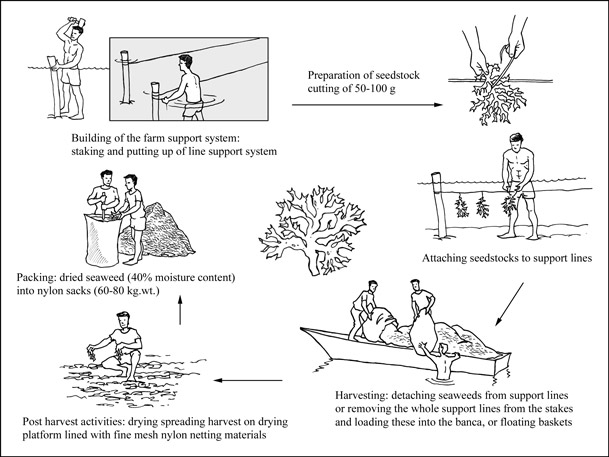

Seedstocks are prepared by tying 50-100 g pieces of cuttings with soft plastic tying materials. The cuttings are tied at 20-25 cm intervals to the monolines in both the bottom monoline and the floating methods.

Two main farming systems are presently used by farmers. These are the fixed off-bottom monoline and the floating methods. In each case farm maintenance consists primarily of weeding out epiphytes associated with the crop, cleaning the seaweed of silt and dirt, harvesting the poorly growing seedstocks and replacing them with fast growing ones, removing other species of seaweeds that grow in close association with the Eucheuma, replacing lost plants, repairing the farm support system and removing benthic grazers. Epiphytes and flotsam compete with seaweed for nutrients and energy from sunlight resulting in slow growth of the crop.

The fixed off-bottom monoline method

Construction of the farm support system starts with knocking holes in the substratum using a pointed iron bar and heavy bull hammer. Pointed wooden stakes are firmly driven into the holes in the substratum using a ball hammer. The stakes are arranged in rows at 1 m intervals, with the distance between rows being 10 m. A loop is made at one end of the monofilament line and is attached to a stake. The line is then stretched tightly and the other end tied to a stake in the next row. The distance of the lines from the ground is adjusted to the depth of the water during low tides so that the plants are not exposed to air and sun. The lines are generally positioned parallel to the direction of the current or waves. An additional support stake may be placed midway between the original rows of stakes to prevent the lines from sagging.

Floating methods

These methods are used in deeper areas as well as in shallow areas that are characterized by weak water movement or where the bottom topography is irregular.

Monolines

In the raft method, the monolines are attached to a wooden or bamboo frame, the size of which varies depending on the available frame materials. The monolines are attached to the frame parallel to the length of the frame at 20-30 cm intervals. A 4 x 5 m raft unit may be planted with 350-400 cuttings. The units are anchored to the substrate from their corners, using nylon ropes. Floatation materials are attached to the corner of the rafts to increase their buoyancy.

Floating longlines

The floating longlines have two major variations – single and multiple. In the single variant, 100 m nylon ropes (3-4 mm diameter) are used as main support lines, both ends of which are anchored to the substratum. The level of the lines in relation to the surface of the water column is determined by adjusting the length of the line of the floatation device. Single floating lines are distanced some 5-8 meters apart to avoid them from becoming entangled.

Multiple long line units consist of 4-5 nylon lines (3-4 mm diameter), each of 20 m length or more. The ends of the lines are attached at 30 cm intervals to the main spacing supports, which consist of 3 to 4 cm thick hardwood. Depending on the length of the lines, one or more wood spacers are attached to the middle of the unit. The corner ends of the units are directly anchored to the substratum or are attached (tied) to the main support anchor line (5-6 mm nylon rope) in series at 2 m intervals.

Seaweed that is grown for less than 10 weeks is immature and contains little carrageenan. For the best quality product, the crop should be harvested 10-12 weeks after planting to allow the crop to mature.

Harvesting simply consists of detaching the stocks from the support line, placing them in a bangka boat (a vessel that looks like a catamaran) and transporting them to the drying area.

Traditionally the harvested seaweed is cleaned, sorted, and freed from dirt and other seaweeds, before being sun-dried on clean drying platforms (usually made of bamboo slats). This method had been slightly modified recently to minimize the loss of materials and facilitate improved drying. The platform is first lined with fine-mesh braided nylon net and the harvest is spread on top of it. The plants are regularly turned over to ensure complete sun-drying. The drying crop must be protected from rain: the crop is piled into a heap by pulling the lining net to one part of the platform which is then covered by a waterproof sheet. During hot, sunny weather, the harvest may be dried in two or three days. The final moisture content of the crop should not be more than be 40 percent. The dried material is tightly packed in plastic sacks and stored in dry areas before shipment to buying centres.

Production cycle

Production cycle of Eucheuma spp.

Production systems

Seed supply

Twelve varieties of K. alvarezii have been characterized based on their morphology, DNA fingerprints and growth performance during the different cropping seasons. The information derived from these studies is important and very relevant to the cropping management in farms where the farmers use several varieties as seedstocks. The present seedstocks are endemic in the Philippines.

Supplies of seedstock are sourced from the wild and multiplied in a nursery plot. The original seedstock is washed clean of dirt and other contaminants and transported as quickly as possible to the nursery site in Styrofoam boxes with air holes in the top, without exposing it to sun and wind. The nursery-reared cuttings become the seedstock for the first grow-out. Subsequent supplies of seedstock are obtained from the first cropping, and so on.

Ongrowing techniques

The most important aspect in developing a potentially productive seaweed farm is site selection. The site must be assessed to conform to the following criteria:

- Moderate water current and wave action to maintain high diffusion pressure which enhances the absorption of nutrients by the seaweed.

- Adequate but not excessive light; irradiance levels of 500-900 μEm-2S-1 are optimum for both photosynthesis and pigment synthesis.

- Sufficient water depth; in shallow areas the seedstocks must not be exposed during low tides. The development of the floating farm support system has made farming in deep areas possible.

- When farming shallow areas the substratum must be dark, consisting of coarse sand to rocky-corally materials; substrata consisting of white fine sand must be avoided.

- Minimal presence of grazers, microorganisms, silt epiphytes and flotsam.

- Optimum temperature range 27-30 ºC.

- Salinity level of 30-35‰; brackish water areas should be avoided.

Seedstocks are prepared by tying 50-100 g pieces of cuttings with soft plastic tying materials. The cuttings are tied at 20-25 cm intervals to the monolines in both the bottom monoline and the floating methods.

Two main farming systems are presently used by farmers. These are the fixed off-bottom monoline and the floating methods. In each case farm maintenance consists primarily of weeding out epiphytes associated with the crop, cleaning the seaweed of silt and dirt, harvesting the poorly growing seedstocks and replacing them with fast growing ones, removing other species of seaweeds that grow in close association with the Eucheuma, replacing lost plants, repairing the farm support system and removing benthic grazers. Epiphytes and flotsam compete with seaweed for nutrients and energy from sunlight resulting in slow growth of the crop.

The fixed off-bottom monoline method

Construction of the farm support system starts with knocking holes in the substratum using a pointed iron bar and heavy bull hammer. Pointed wooden stakes are firmly driven into the holes in the substratum using a ball hammer. The stakes are arranged in rows at 1 m intervals, with the distance between rows being 10 m. A loop is made at one end of the monofilament line and is attached to a stake. The line is then stretched tightly and the other end tied to a stake in the next row. The distance of the lines from the ground is adjusted to the depth of the water during low tides so that the plants are not exposed to air and sun. The lines are generally positioned parallel to the direction of the current or waves. An additional support stake may be placed midway between the original rows of stakes to prevent the lines from sagging.

Floating methods

These methods are used in deeper areas as well as in shallow areas that are characterized by weak water movement or where the bottom topography is irregular.

Monolines

In the raft method, the monolines are attached to a wooden or bamboo frame, the size of which varies depending on the available frame materials. The monolines are attached to the frame parallel to the length of the frame at 20-30 cm intervals. A 4 x 5 m raft unit may be planted with 350-400 cuttings. The units are anchored to the substrate from their corners, using nylon ropes. Floatation materials are attached to the corner of the rafts to increase their buoyancy.

Floating longlines

The floating longlines have two major variations – single and multiple. In the single variant, 100 m nylon ropes (3-4 mm diameter) are used as main support lines, both ends of which are anchored to the substratum. The level of the lines in relation to the surface of the water column is determined by adjusting the length of the line of the floatation device. Single floating lines are distanced some 5-8 meters apart to avoid them from becoming entangled.

Multiple long line units consist of 4-5 nylon lines (3-4 mm diameter), each of 20 m length or more. The ends of the lines are attached at 30 cm intervals to the main spacing supports, which consist of 3 to 4 cm thick hardwood. Depending on the length of the lines, one or more wood spacers are attached to the middle of the unit. The corner ends of the units are directly anchored to the substratum or are attached (tied) to the main support anchor line (5-6 mm nylon rope) in series at 2 m intervals.

Harvesting techniques

Seaweed that is grown for less than 10 weeks is immature and contains little carrageenan. For the best quality product, the crop should be harvested 10-12 weeks after planting to allow the crop to mature.

Handling and processing

Harvesting simply consists of detaching the stocks from the support line, placing them in a bangka boat (a vessel that looks like a catamaran) and transporting them to the drying area.

Traditionally the harvested seaweed is cleaned, sorted, and freed from dirt and other seaweeds, before being sun-dried on clean drying platforms (usually made of bamboo slats). This method had been slightly modified recently to minimize the loss of materials and facilitate improved drying. The platform is first lined with fine-mesh braided nylon net and the harvest is spread on top of it. The plants are regularly turned over to ensure complete sun-drying. The drying crop must be protected from rain: the crop is piled into a heap by pulling the lining net to one part of the platform which is then covered by a waterproof sheet. During hot, sunny weather, the harvest may be dried in two or three days. The final moisture content of the crop should not be more than be 40 percent. The dried material is tightly packed in plastic sacks and stored in dry areas before shipment to buying centres.