IDENTITY

Biological features

Cylindrical body with skin lacking in scales; spots on the sides. Soft fin rays with exception of dorsal and pectoral fins which have spines. Adipose fin present. Barbels located below and at the corners of the mouth, with two barbels on the dorsal surface of the head anterior of the eyes and posterior of the snout. Deeply forked caudal fin and curved anal fin with 24-29 rays.

Images gallery

Catfish pond

|

Catfish fry

|

Catfish raceway

|

Wood spawning container

|

Hatching catfish

|

13-inch catfish (courtesy www.combat-fishing.com)

|

PROFILE

Historical background

Interest in channel catfish began when the United States Fish and Fisheries Commission began stocking fish collected from the wild in the 1870s. Channel catfish were native primarily to the Mississippi River Valley but were widely introduced throughout the nation by the Commission. Spawning was first achieved in 1890 in aquaria, at which time it was learned that the male guards the eggs during incubation. Pond spawning was first observed in 1914 at a government hatchery. Spawning nests (nail kegs) were first used in 1916 and the numbers of fingerlings produced per stocked female increased. Indoor hatching of channel catfish eggs in troughs equipped with paddlewheels to move the water in a manner that simulates the fanning of the eggs by the male fish was first accomplished in 1929.

Commercial aquaculture was first considered to be economically practical in the late 1950s. Catfish farming developed rapidly during the 1960s and 1970s as improvements in pond management, disease identification and control, and prepared feeds were developed and adopted by farmers. The commercial industry developed in the southern United States within the original range of the species. At least 90 percent of the farmed fish are produced in the Mississippi River Valley region.

Commercial aquaculture was first considered to be economically practical in the late 1950s. Catfish farming developed rapidly during the 1960s and 1970s as improvements in pond management, disease identification and control, and prepared feeds were developed and adopted by farmers. The commercial industry developed in the southern United States within the original range of the species. At least 90 percent of the farmed fish are produced in the Mississippi River Valley region.

Main producer countries

Channel catfish have been introduced into Europe, Russian Federation, Cuba and portions of Latin America. The primary interest in many countries appears to be recreational fishing.

Main producer countries of Ictalurus punctatus (FAO Fishery statistics, 2006)

Habitat and biology

Channel catfish are native to flowing waters in temperate environments within North America, including southern Canada and northern Mexico. Adults first spawn at two or three years of age. Spawning in nature occurs in the spring, beginning in about March in the southern part of the range and later as latitude increases. Eggs are often deposited under fallen logs or in some type of natural depression. The eggs are laid in an adhesive mass. Females of 0.5-1.8 kg produce an average of 8 800 eggs/kg of body weight, with larger females producing an average of 6 600 eggs/kg. Once egg laying and fertilization are complete, the male will chase the female from the nesting area and tend to the eggs by fanning the mass with his fins to keep oxygenated water moving over them. Depending on temperature, the eggs will hatch within 5-10 days and the male will continue to guard the sac fry for several days until the yolk sacs are absorbed and the fry are able to swim about in search of food. Channel catfish are known as opportunistic omnivores in that they will feed upon a wide variety of plant and animal matter; that is, virtually anything that is available.

PRODUCTION

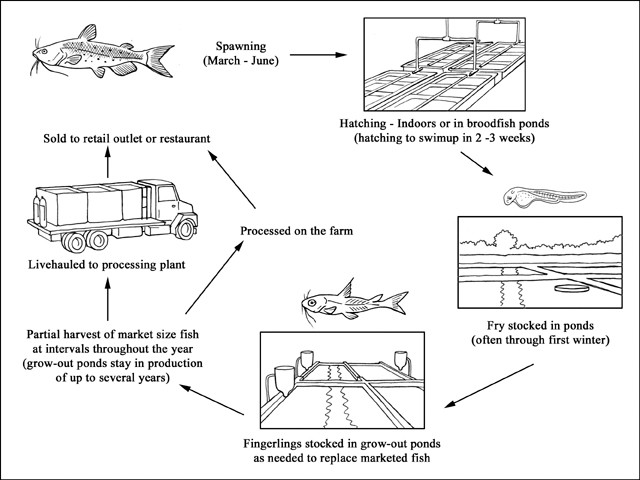

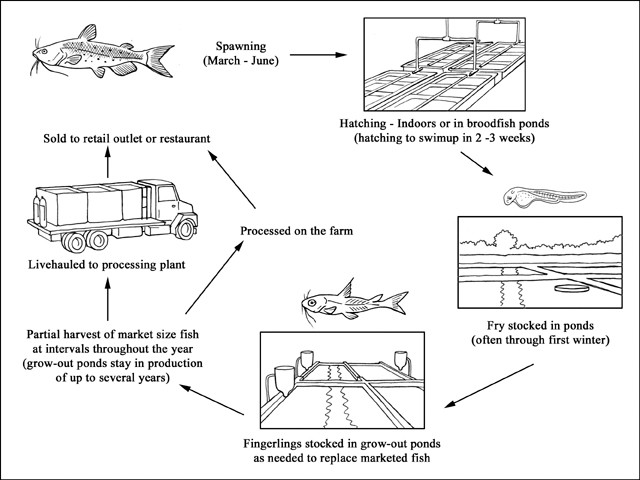

Production cycle

Production cycle of Ictalurus punctatus

Production systems

Channel catfish are reared in ponds, cages, and circular tanks or linear raceways in both the United States and China. Monoculture dominates in the U.S., while both monoculture and polyculture with traditional species such as carp occurs in China. Formulated feeds are employed in both nations. The details presented below refer to channel catfish culture in the United States of America.

Seed supply

The majority of channel catfish are grown in ponds. Spawning occurs in the spring and may be conducted in open ponds where adults are stocked at a density ranging from 60-325/ha in ratios ranging from 1:1 to 1:4 (male:female) and allowed to select their own mates. Alternatively, adults may be paired in pens within a spawning pond. In both instances nests comprised of metal cans, drain tiles, wooden boxes or other types of enclosures of appropriate size are utilized. Eggs may be allowed to hatch within the spawning pond. In that case, after the spawning season the adults are typically removed to another pond. More commonly, the nests are inspected at three or four day intervals and any egg masses found are collected and taken to a hatchery, where the eggs are incubated in troughs or raceways and the fry are maintained until they swim to the water surface in search of food. Fry are often fed finely ground prepared feed for several days prior to being stocked in fingerling ponds where they are reared for several months (often throughout the first year of life).

Some farmers specialize in selling fry or fingerlings to producers of market-sized fish, while others purchase fingerlings for grow-out; however, many farmers operate their own hatcheries and grow-out operations.

Some farmers specialize in selling fry or fingerlings to producers of market-sized fish, while others purchase fingerlings for grow-out; however, many farmers operate their own hatcheries and grow-out operations.

Ongrowing techniques

Ponds

Once the fingerlings are several centimetres long, they can be stocked into grow-out ponds. The traditional approach was to stock a given number of fish per hectare, grow them until the autumn of the second year of life, drain the pond, and harvest the fish for marketing. Since nearly all the fish produced under that system reached the market over a limited period of time, the flow of product to the market was not conducive to having fresh product available year round. Also, glutting of the market during the fall led to depressed prices to producers.

Today, an intermittent harvesting approach is employed. Ponds are partially harvested every several weeks to a few months and marketable fish are removed. The appropriate number of fingerlings is then stocked to replace the fish removed. Thus, various fish sizes are in the pond at the same time. The process can be maintained for several years, during which time the ponds are not drained. Fingerling ponds are often fertilized, usually with inorganic fertilizer, in advance of stocking to induce the development of plankton blooms. Prepared feed fines, and later crumbles, then standard feed pellets (about 6 mm diameter) are provided. The feeding rate may be as high as 50 percent of estimated fish body weight daily at first feeding but is gradually reduced as the fish grow. Once the fish are a few centimetres long they are fed at 3-4 percent of body weight daily during the growing season. The feeding level is reduced and feed may even be withheld completely during winter months.

Water quality management is critical to pond catfish production. High stocking densities, particularly during summer, can lead to stress, disease, and mortality due to deterioration in water quality, particularly low dissolved oxygen. During critical periods ponds are monitored and emergency aeration is provided when necessary to maintain dissolved oxygen levels within an acceptable range (typically >3.0 mg/litre).

Tanks and raceways

Channel catfish are sometimes reared in flow-through tanks or raceways, indoors or outdoors. Recirculating system culture has been attempted over the years but few, if any, economically successful farms have been developed. Flow-through raceway and tank culture depends upon a suitable supply of water of the proper temperature (ideally 26-30 °C) for grow-out. Such water temperatures can be obtained from surface waters in the southern United States, from geothermal waters in various parts of the nation, and from co-generation or electric power generating plants. Production of catfish in such systems represents a small fraction of the annual total. The other aspects of tank and raceway culture are similar to those associated with pond culture with the exception that much less land is required, though water quantities (and thus costs) incurred may be far in excess of those associated with pond culture.

Cages

Historically, there has been some interest in rearing channel catfish in cages placed in streams, lakes or reservoirs. While some facilities of that type could still be in operation, their contribution to total catfish production is insignificant. Other than the type of culture chambers used, cage culture practices would be similar to those used by pond and tank culturists.

Once the fingerlings are several centimetres long, they can be stocked into grow-out ponds. The traditional approach was to stock a given number of fish per hectare, grow them until the autumn of the second year of life, drain the pond, and harvest the fish for marketing. Since nearly all the fish produced under that system reached the market over a limited period of time, the flow of product to the market was not conducive to having fresh product available year round. Also, glutting of the market during the fall led to depressed prices to producers.

Today, an intermittent harvesting approach is employed. Ponds are partially harvested every several weeks to a few months and marketable fish are removed. The appropriate number of fingerlings is then stocked to replace the fish removed. Thus, various fish sizes are in the pond at the same time. The process can be maintained for several years, during which time the ponds are not drained. Fingerling ponds are often fertilized, usually with inorganic fertilizer, in advance of stocking to induce the development of plankton blooms. Prepared feed fines, and later crumbles, then standard feed pellets (about 6 mm diameter) are provided. The feeding rate may be as high as 50 percent of estimated fish body weight daily at first feeding but is gradually reduced as the fish grow. Once the fish are a few centimetres long they are fed at 3-4 percent of body weight daily during the growing season. The feeding level is reduced and feed may even be withheld completely during winter months.

Water quality management is critical to pond catfish production. High stocking densities, particularly during summer, can lead to stress, disease, and mortality due to deterioration in water quality, particularly low dissolved oxygen. During critical periods ponds are monitored and emergency aeration is provided when necessary to maintain dissolved oxygen levels within an acceptable range (typically >3.0 mg/litre).

Tanks and raceways

Channel catfish are sometimes reared in flow-through tanks or raceways, indoors or outdoors. Recirculating system culture has been attempted over the years but few, if any, economically successful farms have been developed. Flow-through raceway and tank culture depends upon a suitable supply of water of the proper temperature (ideally 26-30 °C) for grow-out. Such water temperatures can be obtained from surface waters in the southern United States, from geothermal waters in various parts of the nation, and from co-generation or electric power generating plants. Production of catfish in such systems represents a small fraction of the annual total. The other aspects of tank and raceway culture are similar to those associated with pond culture with the exception that much less land is required, though water quantities (and thus costs) incurred may be far in excess of those associated with pond culture.

Cages

Historically, there has been some interest in rearing channel catfish in cages placed in streams, lakes or reservoirs. While some facilities of that type could still be in operation, their contribution to total catfish production is insignificant. Other than the type of culture chambers used, cage culture practices would be similar to those used by pond and tank culturists.

Feed supply

The prepared feeds referred to above consist of various combinations of such plant proteins such as soybean meal, cottonseed meal, corn meal, peanut (groundnut) meal, and wheat, supplemented with vegetable oil, vitamins, and minerals. Very little, if any animal protein (e.g. fish meal) is currently employed in grow-out feeds for channel catfish. National and international feed companies provide feeds formulated specifically for catfish, as do many local feed mills in regions where catfish culture is concentrated.

The feeds used in tanks and raceways may be supplemented with excess levels of vitamins, since natural foods that can supply those nutrients may not be available, particularly with regard to indoor systems (other than greenhouses).

The feeds used in tanks and raceways may be supplemented with excess levels of vitamins, since natural foods that can supply those nutrients may not be available, particularly with regard to indoor systems (other than greenhouses).

Harvesting techniques

Catfish ponds are partially harvested using seines of sufficiently large mesh size to allow sub-marketable fish to escape.

Handling and processing

Harvested fish are loaded into live-hauling trucks and taken to processing plants in regions where sufficient concentrations of ponds can support year-round operation of such plants. A minority of producers process their own fish. Depending on fish size and market demand, the fish may be steaked; filleted; or sold headed, gutted, and skinned. There is not much value-added processing being undertaken.

Seafood processors are required to develop and follow Hazard Analysis and Critical Control Point (HACCP) programmes, as mandated by the federal government. Inspectors can visit plants at any time to determine that the data required for each HACCP plan are current and complete. At the retail level, grocery stores and restaurants are inspected for maintenance of public health standards.

Seafood processors are required to develop and follow Hazard Analysis and Critical Control Point (HACCP) programmes, as mandated by the federal government. Inspectors can visit plants at any time to determine that the data required for each HACCP plan are current and complete. At the retail level, grocery stores and restaurants are inspected for maintenance of public health standards.

Production costs

The purchase of land and development of large pond complexes represents the major fixed cost for catfish farmers. The highest variable cost is feed, which typically represents 40-45 percent of the cost of operations. In 1960, channel catfish sold at the farm gate for approximately USD 1.10/kg. That figure changed little over the years, and reached no higher than about USD 1.75/kg by the late 1990s. The price has actually fallen since then, as a result of competition from imports. For example, the price paid to growers averaged USD 1.26 during the first eight months of 2003. A tariff was placed on imported catfish (basa) from Viet Nam during summer 2003, but that action did not translate into higher prices at the farm gate. The production of channel catfish in Viet Nam may eventually be another major source of competition in the United States domestic market.

Diseases and control measures

Channel catfish are subjected to a wide variety of diseases including viruses, bacteria, fungi, helminths, and parasitic copepods. Some of the most important disease organisms are included in the table below.

In some cases antibiotics and other pharmaceuticals have been used in treatment but their inclusion in this table does not imply an FAO recommendation.

Prevention through avoidance of stress on the fish is probably the most effective means of avoiding disease. Chemicals are only used when an epizootic has been detected, and then only for limited periods of time. Prophylactic chemical use is not approved by the United States Food and Drug Administration, which is the agency that approves therapeutic compounds for use on fish.

Suppliers of pathology expertise

There are very few veterinarians in the United States that specialize in or have much knowledge about fish diseases. The majority of the expertise resides in government laboratories and at universities. Examples are the Harry K. Dupree Fish Farming Experimental Station in Stuttgart, Arkansas (U.S. Department of Agriculture); Auburn University, Auburn, Alabama; and Mississippi State University, Mississippi State, Mississippi. The latter three and other universities often have extension agents based in catfish farming areas who can provide diagnostic services and recommend treatments, though faculty on campus may also provide such services.

In some cases antibiotics and other pharmaceuticals have been used in treatment but their inclusion in this table does not imply an FAO recommendation.

| DISEASE | AGENT | TYPE | SYNDROME | MEASURES |

| Channel catfish virus disease | – | Virus | Reduced feeding activity; erratic swimming behaviour, sometimes spiral; alternating hyperactivity and lethargy; swollen abdomen; distended vent area; bulging eyes; haemorrhaging | No treatment; good management practices |

| Enteric septicaemia | Edwardsiella ictaluri | Bacterium | Haemorrhages external on underside and around mouth; white focal lesions on fish back and sides; occasionally grey lesion on top of head that can erupt to an open lesion | Oxytetracycline; sulfamethoxine; ormetoprin |

| Columnaris disease | Flavobacterium columnare | Bacterium | White spots on mouth, edges of scales and fins; cottony growth around mouth; fins disintegrate at edges; 'saddleback' lesion near dorsal fin; fungal invasion of gills and skin | Oxytetracycline; sulfamethoxine; ormetoprin |

| Aeromonas septicaemia | Aeromonas hydrophila; A. sobria | Bacteria | Fraying and reddening of fins; de-pigmentation; ulcers | Oxytetracycline; sulfamethoxine; ormetoprin |

| Water mould | Saprolegnia spp. | Fungi | Grey/white patches on skin or gills resembling cotton-wool, later becoming brown or green; normally small, focal infections spreading rapidly over body or gills | Formalin |

| Gill and/or external parasites | Trichodina sp.; Trichophora sp.; Ambiphrya sp.; Ichthyobodo sp.; Ichthyophthirius multifiliis | Protozoans | Small white spots on skin or gills; irritation, flashing, weakness, loss of appetite, and decreased activity; gills pale and very swollen | Formalin |

| Proliferative gill disease | Aurantiactinomyxon sp.; Dero digitata | Myxozoans | Swelling and red and white mottling of gills gives raw minced meat appearance | Formalin |

| Copepod parasites | Ergasilus sp.; Argulus sp.; Lernaea cyprinacae | Copepods | Visible parasites on gills | Formalin |

| Other parasites | – | Helminths; cestodes; trematodes | – | Formalin |

Prevention through avoidance of stress on the fish is probably the most effective means of avoiding disease. Chemicals are only used when an epizootic has been detected, and then only for limited periods of time. Prophylactic chemical use is not approved by the United States Food and Drug Administration, which is the agency that approves therapeutic compounds for use on fish.

Suppliers of pathology expertise

There are very few veterinarians in the United States that specialize in or have much knowledge about fish diseases. The majority of the expertise resides in government laboratories and at universities. Examples are the Harry K. Dupree Fish Farming Experimental Station in Stuttgart, Arkansas (U.S. Department of Agriculture); Auburn University, Auburn, Alabama; and Mississippi State University, Mississippi State, Mississippi. The latter three and other universities often have extension agents based in catfish farming areas who can provide diagnostic services and recommend treatments, though faculty on campus may also provide such services.

STATISTICS

Production statistics

Global aquaculture production of Ictalurus punctatus (FAO Fishery statistics)  |

Market and trade

The market has been impacted by an influx of unrelated species of catfish from Viet Nam in recent years. This has led to intense competition with domestic channel catfish in the marketplace to the extent that prices paid to many producers do not offset production costs. Predictions are that some producers may be forced out of catfish farming, though legislation to require country of origin branding may provide some relief. Country of origin labelling may aid in moving retail grocery stores and restaurants towards a preference for domestic catfish. There is also a movement by the catfish farmers to encourage legislation that would place a tariff on imported catfish. Prices in the marketplace are fairly stable.

STATUS AND TRENDS

While the catfish industry is quite mature, research continues on disease control, nutrition, genetic improvement, and other aspects associated with the farming of the species. Research is also being conducted to reduce the level of nutrients in pond effluents by developing diets that are better utilized by the fish.

The future of the catfish industry in the United States is unclear. Until the situation with respect to imported exotic catfishes is resolved, it is difficult to determine whether the industry will grow in the future, remain at its current level, or decline.

The market for channel catfish in the United States is well developed. Once considered a product of interest only in the southern states, catfish can now be found in restaurants and on menus in grocery stores throughout the nation. It is seen by consumers as being a healthy choice food. Market expansion may be possible through development of new product forms and value added processing.

The future of the catfish industry in the United States is unclear. Until the situation with respect to imported exotic catfishes is resolved, it is difficult to determine whether the industry will grow in the future, remain at its current level, or decline.

The market for channel catfish in the United States is well developed. Once considered a product of interest only in the southern states, catfish can now be found in restaurants and on menus in grocery stores throughout the nation. It is seen by consumers as being a healthy choice food. Market expansion may be possible through development of new product forms and value added processing.

MAIN ISSUES

Since channel catfish are produced almost exclusively on private land there are few environmental issues associated with production of the species. In cases where ponds or intensive culture facility effluents enter public waters, there is an issue of eutrophication which is being addressed, in part, through development of feeds that are better utilized by the fish. The issue of potential eutrophication also exists with respect to cage culture.

Responsible aquaculture practices

In general, channel catfish culture is conducted responsibly. The industry is regulated by the appropriate agency in the U.S. states where it is practiced. Federal agencies may be asked to comment on state aquaculture permits in situations where navigable waters are involved and where effluents enter public waters. Catfish farmers in the United States adhere to the tenets of the FAO Code of Conduct for Responsible Fisheries and the FAO Technical Guidelines for Responsible Fisheries (Aquaculture Development).

REFERENCES

Bibliography

| Baisre, J.A. & Castell, J.D. 1991. Aquaculture in Cuba. World Aquaculture, 22(4):28-35. |

| Esquivel, R.R., Gomes, S.Z., Esquivel, B.M. & Schlindwein, A.P. 1998. Growth of channel catfish, Ictalurus punctatus, in southern Brazil. Journal of Applied Aquaculture, 8: 71-78. |

| Melotti, P., Gennari, L. & Roncarati, A. 1993. Ictalurus and other introduced species: Possibilities and prospects in Europe. Paper presented at Workshop on Aquaculture of Freshwater Species (except Salmonids). World Aquaculture '93, Torremolinos, Spain, 24-27 May. World Aquaculture Society, Baton Rouge, Louisiana, USA. |

| Stickney, R.R. 1994. Principles of Aquaculture. John Wiley & Sons, New York, New York USA. 502 pp. |

| Stickney, R.R. 1996. History of Aquaculture in the United States. John Wiley & Sons, New York, New York USA. 372 pp. |

| Stickney, R.R. 2000. Encyclopedia of Aquaculture. John Wiley & Sons, New York, New York USA. 1063 pp. |

| Tucker, C. 2003. Channel catfish. In Lucas, J.S. & Southgate, P.C. (eds.), Aquaculture: Farming Aquatic Animals and Plants, pp. 346-363. Blackwell Publishing, Oxford, England |

| U.S. Department of Commerce. 2003. Fisheries of the United States, 2002. U.S. Department of Commerce, Washington DC, USA. 126 pp |