1.1 Floating netcage design and materials

1.1.1 Shape and size

Floating netcages vary in shape and size. In Japan, for example, circular and square/rectangular floating netcages are used, whereas in Norway floating netcages are not only circular, square/rectangular, but may also be hexagonally shaped. Rotational netcages that are eitner cylindrical or spherical are used in West Germany.

In Singapore, the farmers use the more conventional square (cuboidal) or rectangular shaped netcages. The former type usually measure 2m × 2m, 3m × 3m or 5m × 5m, with a depth of 2 – 3m; the latter type 6m × 3m, with a depth of 3m. Figures II/1 – 6 show the variety of floating cages that are available.

1.1.2 Design and use

The following should be considered in netcage construction:

the mesnes of the netcage should remain open completely in water to form a diamond-shaped hole so as to allow good water exchange with minimum use of netting material;

the net parels should be cut such that there is minimum wastage of netting material;

the dimensions of the netcage should be slightly smaller than the floating frame on which it is suspended so that the netcage fits well within the frame.

Basically there are 3 types of netcages used in Singapore : hape netcage for stocking of the fish during the early nursery phase (fingerling to about Total Length 10 cm and below), nursery netcage during the later nursery phase (up to 15 cm), and production netcage during the grow-cut phase (to mar steple of 30 cm and beyond). Broadstock require netcages of mesh sizes larger than 50.8 mm (2"). The 3 types of netcages are all box-shaced and are described in (2).

Table II/1 gives the relationship between netcage specifications and fien to be held.

| Netcage | Type | Recommended material and associated rope and twine including specifications | Netcage size ($) | No. netcages from 1 roll | Mesh Size (cm) | Fish size recommended (Total length in cm) | |

| Srouper | Seabass | ||||||

| HAPA | 1 | Material | |||||

| Polyaeide (nylon) 210D/4 ply | 2 × 2 × 2 | approx 10 ) | |||||

| Roll of 45.72a (50yd) (D=Denier) | 3 × 3 × 3 | 4) | - 9(5/16") | 5–10 | 10 and < | ||

| 1200 meshes deep. | 5 × 5 × 3 | 2) | |||||

| Rope | |||||||

| Main rope: 05-6aa, Kuralon | |||||||

| (Polyvinyl alcohol) or | |||||||

| polythylene (PE) | |||||||

| Bolch line: 02-3aa, PE | |||||||

| Twine | |||||||

| PE 380D/12 ply | |||||||

| PE 380D/18 ply | |||||||

| NURSERY | 1 | Material | |||||

| Polyethylene, 380D/6 ply | 2 × 2 × 2 | 3 ) | |||||

| Roll of 45.72a (50yd). | 3 × 3 × 3 | 2 ) | - 9.5(3/8") | 10–15 | 10–15 | ||

| 300 reshes deec. | 5 × 5 × 3 | 0.75 ) | |||||

| Rope | |||||||

| Main rope: 09aa, PE | |||||||

| Bolca line: 02aa, PE | |||||||

| Twine | |||||||

| PE 380D/12 ply | |||||||

| PE 380D/18 ply or 21 ply | |||||||

| 2 | Material | ||||||

| Polythylene, 380D/9 or | 2 × 2 × 2 | 4.25 ) | |||||

| 15 ply | 3 × 3 × 3 | 1.8 ) | - 12.7 (1/2") | 10–15 | 10–15 | ||

| Roll of 45.72a (50yd). | 5 × 5 × 3 | 1 ) | |||||

| 300 meshes deep. | |||||||

| Rope | |||||||

| Main rope: 08aa, PE | |||||||

| Bolca line: 02aa PE | |||||||

| Twine | |||||||

| PE 380D/12 ply | |||||||

| PE 380D/21 ply | |||||||

| 3 | Material | ||||||

| Polyethylene, 380D/15 or | 2 × 2 × 2 | 6.3 ) | |||||

| 18 ply | 3 × 3 × 3 | 2.8 ) | - 19.1 (3/4") | 15–30 | 15–20 | ||

| Roll of 45.72a (50yd) | 5 × 5 × 3 | 1.5 ) | |||||

| 300 meshes deep. | |||||||

| Rope | |||||||

| Main ropes 08aa, PE | |||||||

| Bolca line: 02aa PE | |||||||

| Twine | |||||||

| PE 380D ply | |||||||

| PE 380D ply | |||||||

| 4 | Material | ||||||

| Polythenylene, 380D/18 or | 2 × 2 × 2 | 8.9 ) | |||||

| 21 ply | 3 × 3 × 3 | 3.9 ) | 25.4 (1") | 15–40 | 20–30 | ||

| Roll of 45.72m (50yd) | 5 × 5 × 3 | 2 ) | |||||

| 300 meshes deep. | |||||||

| Rope | |||||||

| Main rope : 010aa, PE | |||||||

| Bolch rope: 03aa, PE | |||||||

| Twine | |||||||

| PE 380D/21 ply | |||||||

| PRODUCTION | 1 | Material | |||||

| Polythylene, 380D/21 or 24 ply. | 2 × 2 × 2 | 8.9 ) | |||||

| Roll of 45.72a (50yd) | 3 × 3 × 3 | 3.9 ) | 25.4 (1") | 15 – 40 | >30 | ||

| 300 meshes deep. | 5 × 5 × 5 | 2 ) | |||||

| Rope | |||||||

| Main rope: 010aa, PE | |||||||

| Bolch line: 03-4aa, PE | |||||||

| Twine | |||||||

| PE 380D/21 ply | |||||||

| PE 380D/24 ply | |||||||

| 2 | Material | ||||||

| Polythylene, 380D/27 ply | 2 × 2 × 2 | 12.75 ) | |||||

| Roll of 45.72a (50yd). | 5.5 | 38.1 ) | (1 1/2") | 15–40 | >30 | ||

| 300 meshes deep. | |||||||

| Rope | |||||||

| Main rope: 010aa, PE | |||||||

| Bolch line: 04aa, PE | |||||||

| Twine | |||||||

| PE 380D/21 ply | |||||||

| PE 380D/27 ply | |||||||

| 3 | Material | ||||||

| Polythylene, 380D/30 or 33 ply | 2 × 2 × 2 | 16.9 ) | |||||

| Roll of 45.72a (50 yd) | 3 × 3 × 3 | 7.5 ) | 5.8 (2") | 40–50 | - | ||

| 300 meshes deep. | 5 × 5 × 5 | 4 ) | |||||

| Rope | |||||||

| Main rope: 010aa, PE | |||||||

| Bolch line: 04aa, PE | |||||||

| Twine | |||||||

| PE 380D/21 ply | |||||||

| PE 380D/33 ply | |||||||

1.1.3 Selection of netting material

Most netting materials are made from synthetic fibres which come from simple chemicals like phenol, benzene, acetylene. Synthetic fibres are different from artificial fibres made from natural products like cellulose and natural vegetable fibres like cotton. Netcages made of synthetic fibres are convenient to use as they can be easily folded and are light to handle. They are also easy to install and to remove. It is not surprising that many floating farms use such materials rather than rigid metal cages for rearing the fish.

Synthetic fibres are preferred over artificial or natural fibres because of their durability and strength. Table II/2 below lists the synthetic fibres that are suitable for use as fish netcages.

Polymide/nylon (PA) and polyethylene (PE) netting are readily available locally. Knotless polyamide netting of 210 D/4 ply is popular for making netcages that are to be used for stocking young fish fingerlings and prawns as the material has a smooth surface and there is minimal abrasion on the fish when the netcage is lifted up during net change. PA is however expensive and costs about S$340 per roll of 45.72m (50 yd) length or S$17/kg. However, it has a very high breaking strength and abrasion resistance. Its fibre deteriorates if subjected to prolonged direct sunlight and hence it is classified as having medium durability. The material being soft, can also be gnawed through by crabs and fish with strong dentition and the cultured fish can escape through gaps made in the netcage.

Polythylene netting is generally preferred by netcage operators because it is cheaper and protects better against damage caused by crabs and fish, although large-sized crabs can still bite through the material. It is, in fact, the cheapest of the synthetic netting materials available in Singapore, and, priced at around S$300 – $350 per roll of 45.72 m (50 yd) length or S$7.50–9.00/kg, is less than half the price of PA netting.

PE netting is available in various specifications of Denier and ply and also in knotless and knotted forms. The type that is selected would depend on the species and size of fish stocked (Table II/2). PE has also high breaking strength and abrasion resistance. However, like PA, it is also best that storage is away from direct sunlight, viz. in the shade. When used at the farm, the portion of the netcage above water lasts 3 years, whereas the rest of the netcage which is submerged in the water lasts for 5 or more years. PE netting is usually for making netcages for nursery and grow-out fish.

In the selection of netting material for netcages it is important to bear in mind the following:

that meshes are not so large as to gill the fish stocked;

that the netting yarn will keep its shape. Monofilament netting, for example, although suitable for gill-netting, is not suitable as netcage material because it tangles and folds up easily;

that the material is durable, resistant to aprasion and has high breaking strenght;

that the material is not so heavy as to make handling difficult. For example, thicker netting material may be more durable and resistant to crap bites, but would be heavy at cleaning time especially when it is fouled.

| Type | Breaking strength | Durability | Abresion resistance | Cost |

| PE (Polyethylene) | high | medium | high | cheapest |

| PA (Polyamide) | very high | medium | highest | most expensive |

| PES (Polyester) | high | high | high | most expensive |

| PP (Polyproplynene) | very high | poor | medium | expensive |

| PVC (Polyvinyl chloride) | low | very high | high | expensive |

| PVD (Polyvincylidene) | low | high | high | expensive |

| PVA (polyvinyl alcohol) | medium | high | high | expensive |

Source: Klust, G. 1973. Netting materials for fishing gear. FAO Fishing Manuals, Fishing News (Books) Ltd, London, England, 173 p. 1973.

1.2 Floating netcage construction

1.2.1 Cutting

Synthetic nets are not cut by stretching the material to correspond to the actual cage dimension, but by calculating the meshes required that would give the desired vertical mesh opening or hanging, as described below. Stretching the material will result in uneven measurements and irregular fit.

Essentially, the square/rectangular netcage consists of a square/rectangular bottom net panel and 4 square/rectangular side panels.

In calculating and measuring net panels, the following points must be remembered :

Mesh size (M.S.) must be noted. M.S. is measured by stretching the two diagonally opposite knots (‘A’ and ‘C’) as in the figures below of a mesh such that the two other opposite knots (‘B’ and ‘D’) are at their closest. AC = mesh size where BD approaches 0. In the case of knotless nets, the joints in the netting yarn are equivalent to the knots. Figure II/7 below illustrates this:

Figure II/7

Illustration of mesh size

Vertical mesh opening or hanging of the netting must be pre-determined. The vertical mesh opening or hanging of the netting is defined as the mesh size of the netting at free hanging to the mesh size of the netting, and is expressed as a percentage.

A vertical mesh opening or hanging of About 70 % is recommended for netcages as the mesh then approaches that of a square as seen in Table II/3 below:

Table II/3

Vertical mesh hanging

| where AD = DE = PC = CA = 1 and AE = BE = CE = DE = 0.71 by (AE)2 = (DE)2 = 1 D (AE)2 = 1 | ||

| AE | = 0.5 | |

| = 0.71 | ||

| AED | = 0.71 × Z = 1.42 | |

| At full stretch, ABC | = ABC = Z | |

.. Hanging (vertical mesh opening) =  | ||

| = | ||

To obtain the net panel measurements, the following calculations are made:

Measure M.S. of the netting material;

ii Use the following formulas shown in Table II/4 below

Table II/4

Formulae for calculating vertical mesh hanging

| (1) | H = (L1 + L2) × 100 | ||

| where H | = | vertical mesh opening or hanging, | |

| L1 | = | intended length (m) of the side of the netcage, | |

| L2 | = | actual length (m) of the side of the netcage to give the required vertical mesh opening or hanging. | |

| (2) | L2 = NM × (M.S. + 1000) | ||

| where NM | = | number of meshes along side of netcage, | |

| M.S. | = | mesh size (mm) of netting. | |

Table II/1 below gives an example of how net panels are measured:

Table II/5

Net panel measurement

Example 1:

If a netcage of 2m × 2m × 2m is to be constructed then each of the net panels (side and bottom) would be 2m × 2m; intended length of the side of the netcage (L1) is therefore 2m;

If vertical mesh opening or hanging (H) of 70 % is selected, then using Formula 1,

70 = (2 + L2) × 100

L2 = 2.86 m

However one cannot just simply measure 2.86 m on a netting material without inadvertently stretching it during measurement. Hence the number of meshes has to be counted instead. This is calculated as follows:

If a netting has a stated specification of PA 210D/4 ply, 8 mm (5/16") M.S., then

| 2.86 | = | NM × (8 - 1000) |

| NM | = | 356 |

| (or 360) |

Hence to obtain a 70 % vertical mesh opening or hanging in a netcage with net panel 2 m length, one should count 360 meshes along that side of the net panel (See Figure II/12 Hapa Netcage Construction.

After the above calculations are made, a plan should be made on how to cut the roll of netting with minimal wastage and so that the 4 side panels are in one continuous piece (See Figure II/12 on Hapa Netcage Construction). This single piece is sewn round the bottom panel which is cut separately. This eliminates unnecessary work in mesh counting which is likely to be tedious and inaccurate.

1.2.2 Joining

Joining net panels (see Figures II/8–10)

The side net panels are joined to the bottom panel by sewing with twine. Sewing is done by passing the twine along the outer edges of the two panels in a 1 mesh side to 1 mesh bottom ratio. For every 5 stitches, an overhand knot is made.

Bolch line

A bolch line is to allow the attachment of the main rope to the netting material. It is passed along the 4 bottom seams of the cage between the side panels and bottom panel (basal bolch) and along the top square of the side panels (top bolch). Threading is done through each mesh, if necessary.

The bolch line is a thin rope whose diameter varies according to the netting material used.

Main rope

The main rope is used for giving the netcage its shape and for suspending the netcages. It is sewn on to the bolch line. It is of a larger diameter than the bolch line and its size, like the bolch line, varies according to the netting material used for the construction of the netcage

The bolch line is fixed to the main rope by starting first with a marlin hitch, followed by ordinary lacing with marlin hitches at every 10 cm interval. Two to three overhand knots could also be used in place of the merlin hitch.

Other joinings

Ropes are usually joined together by en eye-splice while finished twine is joined to a new bank by fisherman knot.

2.1 Hapa netcages

2.1.1 Material

The hapa netcage is usually constructed of knotless material, e.g., PA, so as to avoid any abrasion to the fish fingerlings during hauling of the netcage. Knotted netting should be avoided as far as possible as the abrasions caused to the fingerlings could result in disease, especially bacterial infection. Besides, small-mesh knotted netting materials are also heavy and easily fouled as fouling organisms tend to be congregated to the knots.

2.1.2 Dimensions

The dimensions of the hapa netcage can range from 2m × 2m × 2m to 3m × 3m × 3m to 5m × 5m × 2 - 3m (deep) depending on the scale of stocking. Mesh size can range from 8 mm (5/16") to 9.5 mm (3/8") depending on the initial size of fry/fingerling stocked.

2.1.3 Cost

Costs of various items in a hapa netcage are as follows:

PA netting material of specifications 210D/4 ply, 8 mm (5/16") M.S., 45.72m (50 yd) length, 5670 meshes and 300 meshes deep. It costs S$340 (S$17/kg) and can make 10-2m × 2m × 2m hapas.

Main rope is made from polyvinyl alcohol (PVA), a synthetic fibre, also known in Japan as "Kuralon". A coil of rope of 5–6 mm diameter and 220 m (241 yd) long costs S$63.00. PE ropes can also be used, and a similar sized rope of the same length costs S$7.50/coil.

Bolch line is usually made of PE material. A coil of 220 m length and 2 – 3 mm diameter costs S$2.50 each.

PA netting twine of 210D/27 ply is used for hitching the bolch line to the main rope, and 210D/18 ply is used for joining the netting material/panels/sections to the bolch line. Both cost S$1.05/coil of 113.6 g (0.25 lb).

2.1.4 Construction

The method of constructing a hapa netcage of 2m × 2m × 2m dimension is covered in Practical II/1.

2.2 Nursery netcage

2.2.1 Material

The netting material used is usually of the knotted type. Polythylene (PE) is usually selected.

2.2.2 Dimension

Like the hapa, the nursery netcage can be of 2m × 2m × 2m, or 3m × 3m × 3m, or 5m × 5m × 2 - 3 m (deep), depending on the scale of stocking. Mesh size can range from 9.5 mm (3/8") to 25.4 mm (1") depending on size and type of fish stocked.

2.2.3 Cost

Costs of various items in a nursery netcage are as follows:

PE material can be of various mesh sizes, namely, 9.5 mm (3/8"), 12.7 mm (1/2"), 19.1 mm (3/4") and 25.4 mm (1"). One type of material that is used locally is PE 380D/6 ply 9.5 mm (3/8"). One such roll costs S$300 and is 45.72 m (50 yd) in length with 4.800 meshes, and 300 meshes deep.

Main rope is PE, and a coil 220 m long and 8 mm diameter costs S$18.00.

Bolch line is also polythylene and a coil of 220 m length, 2mm diameter costs S$1.30.

PE twine of 380D/12 ply is used for joining the netting panels and costs S$0.40/hank (= bundle) of 113.6g (0.25 lb). Twine of 380D/18 or 21 ply is used for joining the bolch line to the main rope. It costs the same. The twine comes in packets of 20 hanks (2.72 kg or 5 lb).

2.1.4 Construction

The method of constructing a 2m × 2m × 2m nursery netcage is covered in Practical II/1.

2.3 Production netcage

2.3.1 Material

Like the nursery netcage, production netcage is also constructed of knotted netting, usually of PE material.

2.3.2 Dimensions

Netcage dimensions are similar to hapa and nursery netcages. Mesh sizes start from 25.4 mm (1") and mesh size to be selected depends on the size of fish stocked. Larger sized fish of 30 cm (12") could be stocked in netcages of mesh size 50.8 mm (2").

2.3.3 Cost

Costs of various items needed for construction of a production netcage are as follows:

Specifications of various PE netting suitable for production netcage construction are detailed in Appendix 2.. One type used commonly is PE 380D/21 ply of 25.4 mm (1") M.S. A roll of 45.72 m (50 yd) length with 1,800 meshes and 300 meshes deep, costs S$340. One roll can make 6-2m × 2m × 2m nets.

The main rope is PE of diameter 10 mm. A coil of 220 m costs S$25.00.

Bolch line, as for nursery netcages, is of PE material and a coil of 3mm diameter and 220 m length costs S$2.50.

Specifications of PE twine are 380D/21 ply and is identical to the netting yarn used. It costs S$0.40/hank of 113.6g (0.25 lb).

2.3.4 Construction

The method of constructing a production netcage of 2m × 2m × 2m is covered in Practical II/3.

3. Table II/6 gives a glossary of terms and Figures 14–23 are accompanying illustrations.

1. Objective:

To construct a hapa netcage of 2m × 2m × 2m.

2. Procedure:

2.1 Cutting net panels (see Figure II/11)

Roll out the nylon netting to extend the material which is 5670 meshes long and 1200 mesh wide.

Count 360 meshes deep from one corner width-wise.

Cut at the 360th mesh lengthwise from one end of the roll to the other to obtain a piece of netting material which is 2630 meshes deep by 5760 meshes long (Panel A).

Starting from the left end of panel A, count 360 meshes lengthwise and cut to obtain Panel B1 which is 360 meshes × 360 meshes. Repeat for 7 more such panels (B2-8, each 360 meshes × 360 meshes and to be saved for other netcages).

2.2 Joining net panels (see Figures II/8–10)

Join the remaining Panel A along its length to the edges of B1 by stitching with nylon twine (210D/18 ply) on all 4 sides of B1. Cut off when one round is complete. The panel (W1) that has now formed the sides of the netcage is about 1440 meshes long and 360 meshes deep. A piece (W2) of about 1350 meshes × 360 meshes from Panel A is left behind. This forms a side panel (W2) for another netcage. Note: It is impractical to cut Panel A into side panels as the counting of meshes is a tedious and inaccurate process, often resulting in ill-fitting pieces.

Join the two widths of W1 vertically from the bottom panel (B1) to the top edge.

2.3 Fixing bolch line and main rope (see Figure II/9,10)

Pass the bolch line through the joining meshes (seem) of the B1 and W1 by threading. Secure the two ends of the bolch line by a short splice.

Mark 2m on the main rope (which is strung horizontally) and at intervals of 11 cm along this length.

Make markings at 20-mesh intervals along the 4 sides of B1 and tie one corner of B1 to the main rope.

Stitch the 20 meshes along one seam of B1 and W1, pushing the netting material to one side along the main rope to fix the 20th mesh to the first 11-cm marking on the main rope and secure by a marlin hitch. This means fitting 15.8 cm (0.8 cm m.s. × 20 meshes) to the 11 cm space along the main rope, and that the meshes are about 70% open.

Repeat the stitching and hitching at intervals of 20 meshes (11 cm on the main rope) through all the sides of B1.

Fix the bolch line along the vertical edges of the W1 panel.

Cut a 4-m length of main rope and eve-solice one end of this to the main rope of one corner of B1 (the bottom corner). Mark 11-cm intervals along this 4-m long main rope for 2m. Hitch the main rope for 2m to the vertical bolch rope at 11-cm intervals (and 20-mesh intervals on W1) as in (10), leaving about 2m of the main rope at the opposite top corner, to be used as a hand-rope.

Repeat the procedure for remaining 3 corners of the netcage.

Fix a bolch line to the top square of the netcage and hitch likewise to a main rope. This completes the netcage.

3. Exercises

3.1 Note the mesh size of the hapa netting.

3.2 Note the number of bottom and wall (side) panels that can be cut from a standard roll of hapa netting of 45.72m (50 yd, 5760 meshes) and 1200 meshes deep, with a hanging of 70%.

3.3 Note the left over panel and consider what you can do with it.

3.4 How many netcages of 3m × 6m × 3m (depth) can be constructed with a roll of netting material of specifications PA 210D/4 ply; m.s. 8 mm; 45.72m (50 yd), 5670 meshes length and 1200 meshes deep with minimal wastage?

1. Objective

To construct a nursery netcage of 2m × 2m × 2m.

2. Procedure

2.1 Cutting net panels (see Figure II/12)

Roll out the polyethylene (PE) netting to extend the material which is 4800 meshes (estimated long and 300 meshes wide.

Count 300 meshes lengthwise from one end.

Cut at the 300th mesh widthwise to obtain Panel B1. Repeat for 2 more such panels (B2–3, each 300 meshes × 300 meshes and to be saved for other netcages).

2.2 Joining net panels (see Figures II/8–10)

Join the remaining Panel A along its length to the edges of B1 by stitching with PE twine (380D/12 ply) on all 4 sides of B1. Use an overhand knot followed by lacing to join the pieces. Cut off when one round is completed. The panel (W1) that has now formed the sides of the netcage is 1200 meshes long and 300 meshes deep. (Remaining panel A 300 meshes wide by 2700 meshes long).

Join the two ends of W1 vertically from the bottom panel (B1) to the top edge.

2.3 Fixing bolch line and main rope (see Figures II/9, 10)

Pass the bolch line through the joining meshes (seam) of the B1 and W1 by threading. Secure the two ends of the bolch line by a short splice.

Mark 2m on the main rope (which is strung horizontally) and at intervals of 10 cm along this length.

Make markings at 15-mesh intervals along 4 sides of B1 and tie one corner of B1 to the main rope.

Stitch the 15 meshes along the seam of B1 and W1, pushing the netting material to one side along the main rope to fix the 15th mesh to the 1st 10-cm marking on the main rope. Secure by a marlin hitch. This means fitting 14.25 cm (0.95 cm m.s. × 15 meshes) to 10 cm space along the main rope, and that the meshes are about 70% open.

Repeat the stitching and hitching at intervals of 15 meshes (10 cm on the main rope) through all the sides of B1.

Fix the bolch line along the vertical edges of the W1 panel.

Cut a 4-m length of main rope and eye-splice one end of this to the main rope of one corner of B1 (the bottom corner). Mark 10-cm intervals along this 4-m long main rope for 2m. Hitch the main rope for 2m to the vertical bolch rope at 10-cm, leaving about 2m of the main rope at the opposite top corner, to be used as a hand-rope.

Repeat the procedure for the remaining 3 corners of the netcage.

Fix a bolch line to the top square of the netcage and hitch likewise to a main rope. This completes the netcage.

3. Exercises

3.1 Note the mesh size of the nursery netting.

3.2 Note the number of bottom and wall (side) panels that can be cut from a standard roll of nursery netting of 45.72 m (50 yd, 4800 meshes) and 300 meshes deep, with a hanging of 70%.

3.3 Note the left over panel and consider what you can do with it.

3.4 How many netcages of 3m × 6m × 3m (depth) can be constructed with a roll of netting material of specifications PE 380D/6 ply; m.s. 9.5 mm; 45.72 m (50 yd), 4800 meshes length and 300 meshes deep with minimal wastage?

1. Objective:

To construct a production netcage of 2m × 2m × 2m.

2. Procedure:

2.1 Cutting net panels (see Figure II/13)

Roll out the polyethylene (PE) netting to extend the material which is 1800 meshes (estimated) long and 300 meshes wide.

Count 110 meshes deep from one corner width-wise.

Cut at the 110th mesh lengthwise from one end of the roll to the other to obtain a piece of netting material which is 110 meshes deep × 1800 meshes long (Panel A).

Starting from the left end of panel A, count 110 meshes lengthwise and cut width-wise to obtain panel B, which is 220 meshes × 110 meshes.

2.2 Joining net panels (see Figures II/8–10)

Join the remaining Panel A along its length to the edges of B1 by braiding with PE twine (380D/21 ply) on all 4 sides of B1 using an overhand knot followed by lacing. Cut off when one round is completed. The panel (W1) that has now formed the sides of the netcage is 440 meshes long and 110 meshes deep. Remaining Panel A: 1250 meshes long by 110 meshes wide, can be used for 2 more netcages.

Join the two ends of W1 vertically from the bottom panel (B1) to the top edge.

2.3 Fixing bolch line and main rope (see Figures II/9, 10)

Pass the bolch line through the joining meshes (seam) of the B1 and W1 by threading. Secure the two ends of the bolch line by a short solice.

Mark 2m on the main rope (which is strung horizontally) and at intervals of 10 cm along this length.

Make markings at 5 and 6 meshes intervals alternatively along the 4 sides of B1 and tie one corner of B1 to the main rope.

Stitch the 5 and 6 alternating meshes along one seem of B1 and W1, pushing the netting material to one side along the main rope to fix the 5th mesh or 6th mesh to the 10-cm markings on the main rope. Secure by a marlin hitch. This means fitting 12.7 cm (2.54 cm m.s. × 5 meshes) or 15.2 cm (2.54 cm m.s. × 6 meshes) to the 10 cm space along the main rope and that the meshes are about 70% open.

Repeat the stitching and hitching at intervals of 5 or 6 meshes (10 cm on the main rope) through all the sides of B1.

Fix the bolch line along the vertical edges of the W1 panel.

Cut 4-m length main rope and eye-splice one end of this to the main rope of one corner of B1 (the bottom corner). Mark 10-cm intervals along this 4-m long main rope for 2m. Hitch the main rope for 2m to the vertical bolch rope at 10-cm intervals (at alternating 5 and 6-mesh intervals on W1). This leaves about 2m of the main rope at the opposite top corner, to be used as a handrope.

Repeat the procedure for the remaining 3 corners of the netcage.

Fix a bolch line to the top square of the netcage and hitch likewise to a main rope. This completes the netcage.

3. Exercises

3.1 Note the mesh size of the production netting.

3.2 Note the number of bottom and wall (side) panel that can be cut from a standard roll of production netting of 45.72 m (50 yd, 1800 meshes) and 300 meshes deep, with a hanging of 70%.

3.3 Note the left over panel and consider what you can do with it.

3.4 How many netcages of 3m × 6m × 3m (depth) can be constructed with a roll of netting material of specifications 380D/21 ply; m.s. 25.4 mm; 45.72 m (50 yd), 1800 meshes length and 300 meshes deep with minimal wastage?

| Abrasion resistance | Susceptibility to mechanical wear and tear such as rubbing together or with other objects. |

| Ammonia-nitrogen index (pH) | An important parameter for assessing the amount of inorganic nutrient in water. It is used to express the amount of ammonia in terms of nitrogen in water. Ammonia is produced largely by the deamination of organic nitrogen-containing compounds and by the hydrolysis of urea. High ammonia content is harmful to the growth and survival of aquatic organisms. |

| Aquaculture | The growing of aquatic organisms under controlled conditions. |

| Auto-feeders | Automatically controlled feed dispensers. |

| Batch-operation | Production in batches or groups. |

| Biofouling | Organisms which clogs the netcages or any submerged structures in water. |

| Biological feasibilities | Practicality of growing the animal. |

| Biomass | The total weight of fish (or organisms) per unit volume or area. |

| Bolch line | Also called hanging line. The intermediate rope of low breaking strength, fitted between the netting material and main rope, (figure II/14). |

| Braid | Three or more single yarns or strands plaited together form a braid (Figure II/19C). |

| Breaking, strength | Breaking load. The maximum force or load required to break a specimen of twine in a tensile test. |

| Chemical oxygen demand (COD) | An important parameter for assessing the quantity of chemically oxidizable matter mainly organic matter. It is usually used to indicate the organic load in water. |

| Current velocity | A rate of water motion in which direction as well as speed of flow is considered. |

| Denier | When 9000m of single yarn weighs 1g, the single yarn is said to be of 1 Denier. The weight in grammes of 9000 metres of filament or single yarn or ply with the specifications 380D/21 ply is 380g or the single yarn is specified as 380 Denier. For practical purposes, and when the Denier of a single yarn is to be calculated, 450 m of the single yarn is usually weighed and the weight multiplied by 20 to obtain the Denier (Eg. 450 m of the single yarn or ply of netting which is 380D/21 ply would be equal to about 19g. 19 × 20 = 380). |

| Dinoflagellate | One of a class (Dinophyceas) of single-celled microscopic organisms. Dinoflagellates may possess both plant (chlorophyll and cellulose plates) and animal (ingestion of food) characteristics. Dense concentration of dinoflagellate may create discoloration of seawater and cause mass mortality of marine life. |

| Durability (= resistance to weather) | Susceptibility to deterioration effect of various factors like sunlight (ultra-violet radiation), rain wind and immersion in water. Measured by the decrease in breaking strength. |

| Ebb current | The tidal movement associated with the decrease in the height of a tide. Ebb current generally set seaward, or in an opposite direction to the tide progression. |

| Economical feasibilities | Practicality of being financially sound. |

| Eye splice | The loop of rope formed by turning the end of the rope to form a loop, then spliting (joining two ends of a rope by weaving the strands of one into the strands of the other), (Figure II/15). |

| Fisherman's knot | A half hitch followed by a normal knot, (Figure II/16). Eg. Joining two pieces of twine together. |

| Flood current | The tidal current associated with the increase in the height of a tide. Flood currents generally set toward the shore, or in the direction of the tide progression. |

| Hanging | See vertical mesh opening. |

| Hanging ratio | Ratio of vertical lift (%) to 100% which is the condition of the netting at full stretch. |

| Hatchery-bred | Produced in hatcheries. |

| High market value | High priced with good market demand. |

| High water | The highest limit of the surface water level reached by the rising tide. |

| Hitch | Fastening with a loop of rope. |

| Husbandry | Farm management. |

| Hydrogen ion index (pH) | An index of the nature of a solution with respect to acidity. An increase in hydrogen ion concentration (i.e. in acidity) is accompanied by a decrease in the pH of the solution. A neutral aqueous solution has a pH of 7. The pH is higher than 7 in alkaline solution and lower than 7 in acidic solution. |

| Lacing (=stitching | Simple looping in an over and under manner round two strands by a twine to effect joining. |

| Low water | The lowest limit of the surface water level reached by the falling tide. |

| Main rope | Rope of higher breaking strength to which the bolch line is tied (Figure II/14). |

| Marlin hitch | A simple cross-shaped hitch (Figure II/17). |

| Mesh | One of the spaces bounded by the yarn of a netting material. |

| Mesh size | The dimension of mesh at its full stretch. The measurement is taken from the centre of one knot to the centre of the diagonally opposite knot (Figure II/18). For knotless nets, same measurement is taken. |

| Monofilament | Strictly speaking, a strong single filament strong enough to function alone as a yarn. for example transparent polyamide (nylon) monofilaments are used in gill nets. There are other individual fibres or fine filaments which are single filaments but not strong enough to function as a netting yarn. In practice, it is a general term covering single filaments of diameters of up to 1mm or more. Several monofilaments can be twisted to form a yarn (Figure II/19B). |

| Neap tide | Tide of decreased range which occurs about every two week when the moon is in quadrature, i.e. moon and sun are nearly at a right angle to the earth. |

| Netting twine | Two or more single yarns or monofilaments twisted together make a netting twine, (Figure II/6A-C). For eg. a 15-ply netting twine has 15 yarns to the bundle of twine. If the twine is used for making netting material, it is called the netting yarn. Netting twine can also be used to sew together pieces of netting material, such as for netcages. The netting twines used in netcage construction here are of the twisted type. |

| Netting yarn | The netting material or all textile materials suitable for the manufacture of netting, (Figure II/19A-C). |

| Overhand knot | Thumb knot used for finishing off loose ends or for preventing twine from slipping. A simple loop followed by passing the twine over and under is shown in Figure II/22. |

| Phytoplankton | The plant forms of plankton. They are the basic synthesizers of organic matter by photosynthesis in seawater. |

| Ply | The ply is a single yarn. For eg. a 21-ply netting yarn has 21 plys to the bundle of yarn. A 21-ply twine has 21 plys to one twine. |

| Prerequisite | Preliminary condition or requirement. |

| Pre-selection | Picking of the best. |

| Rope | When a large number of single yarns or monofilaments are twisted or braided together, and several of these bundles (also called strands) are twisted or braided together again, the resultant is a rope (Figure II/20). The main rope of a netcage is the twisted type. |

| Salinity | An important measurement of the quantity of dissolved salts in seawater. It is defined as the total amount of dissolved solids in seawater in parts per thousand (%) by weight when all the carbonate have been converted to oxide, the bromide and iodide to chloride, and all organic matter is completely oxidized. |

| Seed | The young or progeny. |

| Short splice | To weave ends of two ropes to form a strong but thick jointing (Figure II/23). |

| Single yarn filament, thread, strand, ply) | The simplest continuous thread composed of fibres and which is the basic component of netting yarn, (Figure II/19A). The single yarn can be of spun fibres, split fibres, several monofilaments or even a single filament (single fibre or monofilament), (Figure II/19B). The single yarn is called a strand if it is braided with 2 or more single yarns, (Figure II/19C). (Note that “strand” also describes a bundle of single yarn for rope-making). |

| Spring tide | Tide of increased range which occurs about every two weeks when the moon is new or full. |

| Suspended solids | An indicator of the turbidity of water which is caused by the presence of suspended matter. |

| Tidal current | The alternating horizontal movement of water associated with the rise and fall of the tide caused by the astronomical tide-producing forces. |

| Total length | Length of the fish as measured from the snout to the end of the caudal fin. |

| Vertical lift | Difference between mesh size of the netting and mesh size at free hanging to mesh size, expressed as percentage (Figure II/21). |

| Vertical mesh opening (=hanging) | Mesh size at free hanging to mesh size of the netting, expressed as percentage (Figure II/21). |

| Wild-caught | Caught from nature eg., rivers, coastal areas, mangroves, etc. |

Figures II/1–6

Types of netcages used in fish farming

Figure II/1

Cuboidal (box-shaped) floating netcages of 5m × 5m × 3m with cover net. Top view shows a 5m × 5m square at Primary Production Department Fish Farm

Figure II/2

Rectangular (box-shaped) floating netcages of 6m × 6m × 3m at commercial fish farm

Figure II/3

Rectangular (box-shaped) floating netcages for salmonid culture in Norway

Figure II/4

Circular floating netcages for salmonid culture in Norway. Note float rings (Helgeland Plast, Norway)

Figure II/5

Globe cages (“Kiel Raft”) in West Germany (Aquakulturgesellschaft “Ostseeforelle” GbR)

Figure II/6

Cylindrical and rotational cages (Samsoe Laks) for trout culture in Denmark

[Note: Figure II/7 found in para 1.2.1.c (i)]

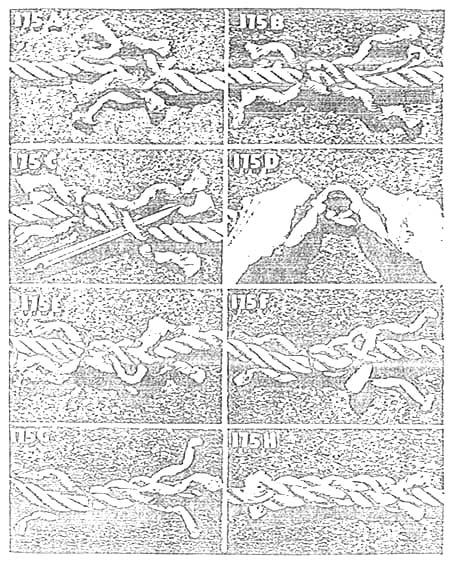

Figures II/8–10

Illustrations on joining of net panels

| Figure II/8 Joining bottom net panel (B1) to wall panel (W1) and fitting the basal bolch line. |

| Figure II/9 Fixing the bolch line and net panel to the main rope. |

| Figure II/10 Fixing the vertical bolch line and main rope. |

Figure II/11

Hapa netcage construction

Cutting a roll of hapa netting material (PA 2100/4 ply, Sea (5/16') M.S. × 45.72 a (50 yd) at 5670 meshes length × 1200 meshes (width)±1 to make about 10 (2m × 2m × 2m) netcages.

| 360 | 360 | 360 | 360 | 360 | 360 | 360 | 360 | 1440 | 1350 | ||

| 360 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | W1 | W2 | } Panel A } (5670 × 360 m) |

| 360 | W3 1440 | W4 1440 | W5 1440 | W6 1350 | |||||||

| 360 | W7 | W8 | W9 | W10 | |||||||

| 120 | Panel C (reenant) | ||||||||||

| 5670 | |||||||||||

| Scales lee to 25 reshes | All figures in meshes |

Ropes and twine

| Main rope | : | 05-6aa of Kuralon (PVA) ±2 or PE±2 |

| Bolch rope | : | 02-aa, PE |

| Twine, PA | : | 2100/27 ply for hitching bolch to main ropes; 2100/18 ply for stitching net panels to bolch rope. |

±1 PA = Polyanice nylon; D = Denter; M.S. = mesh size

±2 PVA = Polyvinyl alcohol; PE = Polyethylene

Figure II/12

Nursery net construction

Cutting a roll of nursery netting material (PE±1 3802/6 ply, 9.5 aa (3/8') M.S. × 45.72 aa (50 yd) at 4800 meshes length × 300 meshes width) to make 3 (2a × 2a × 2a) netcages.

| 300 | 300 | 300 | 1200 | 1200 | 1200 | ||

| 300 | B1 | B2 | B3 | W1 | W2 | W3 | } Panel A } (equivalent } to the roll) |

| Scale: 1 aa to 25 meshes | All figures in meshes |

Ropes and twine

| Main rope | : 08aa, PE |

| Bolch rope | : 02aa, PE |

| Twine, PE | : 380D/12 ply for hitching bolch to main rope 380D/18 ply for stitching net panels to bolch rope |

Figure II/13

Production netcage construction

Cutting a roll of production netting material (PE 380D/21 ply 25.4 aa (1') M.S. × 45.7 a (50 yd) at 1800 meshes length × 300 meshes width) to make about 6 (2m × 2m × 2m) netcages.

| 110 | 440 | 110 | 440 | 110 | 440 | ||

| 110 | B1 | W1 | B2 | W2 | B3 | W3 | } Panel A } (110 meshes X } 1800 meshes) |

| 110 | B4 | W4 | B5 | W5 | B6 | W6 | |

| 80 | |||||||

| 1800 | |||||||

| Scale: 1aa to 10 meshes | All figures in meshes |

Ropes and twine

Main rope : 010aa, PE

Bolch rope : 03aa, PE

Twine, PE : 380D/21 ply

D47

naca-2

Figures II/14–23

Figures illustrating terms in glossary (Table II/6)

| Figure II/14 Bolch line and main rope |

| Figure II/15 Eye splice. 1–3 = strands |

| Figure II/16 Fisherman knot |

| Figure II/17 Marlin hitch |

| Figure II/18 Mesh size (M.S.) |

Figure 6 (A-C)

Illustrations of netting twine/yarn.

Figure II/19 A-C

Illustrations of netting twine/yarn.

Figure II/20

Ropes, twisted from twisted or braided strands

Figure II/21

Vertical mesh opening (hanging) and hanging ratio

Figure II/22

Overhand knot.

Figure II/23

Short splice (Taken from Pg. 147. Day 1964)