Fig. 4 shows a layout plan as proposed by the writer. It incorporates two nursery and two fingerling/holding ponds for nursery rearing of finfishes. Two nursery ponds for stocking with shrimp post-larvae have been included, both having the common feature of being adjacent to the grow-out ponds they will serve. The rest are grow-out ponds with one or two sluices, the latter for effecting better water exchange.

To ensure water adequacy after closure, bottom elevations of grow-out, fingerling/holding and nursery ponds are recommended at general levels corresponding to 2.4, 2.6 and 2.8 m tides (Kilindi reference station) respectively, or to 1.15, 1.31 and 1.55 m, Ngomeni readings as shown in Fig. 5. Sections through four different planes (A-A1; B-B1; C-C1, and D-D1) as indicated in the sketch and shown in Figs. 6 and 7 represent and typify elevation patterns for ponds to be used for the same purpose.

The even slope of the pond bottom towards the internal canal (net more than 15 cm difference in depth regardless of the length and breadth of the pond) will facilitate easy drainage and harvesting operations as well as culture of benthic and filamentous algae as natural food.

Sluices for each particular type of pond should be standardized with openings and side grooves of equal dimensions to allow interchange of screens and flash-board. The only variation should be in depth and number of openings needed to satisfy filling requirements. As these gates will be opened and closed frequently, gate width should not be more than 1.2 m, so that operations will be easy. The most convenient, however, will be from 0.95 to 1.0 m with second class wood flash-boards 2.5 to 3.0 cm thick and 30 cm wide. These could be raised or set back by only one man even under high water pressure. A 0.5 to 1.0 cm play at both ends should prevent stuck-ups and cartwheeling as they are raised or dropped from the top.

Concrete and semi-concrete sluices should be constructed according to correct engineering specification-reinforcements, mixture ratios, plasticity of mixed material, etc., and design to ensure both durability and workability.

It might be wise to try wooden sluices also. These can be prefabricated, brought to the gate site in pieces and assembled on top of the dike. Installation should not take more than a day. Their durability will depend on the kind of wood used, painting with proper preservatives (coal tar in two or three coatings is suggested), and replacement of boards, studs and posts as they deteriorate. From experience with sea water and tropical conditions, these gates, properly constructed and maintained, should last a minimum of four years, but may be up to eight years.

The existing concrete main gate will need much thicker flash boards, and two men working together to raise or lower them. Otherwise, it should be provided with a capstan pulley to raise these boards evenly and without much effort. A very coarse screen of wooden or bamboo lattice strips at the outside end will prevent debris from coming in.

A V-trap of bamboo gratings set in the supply canal, some 50 m from the main gate, will eliminate a bag net screen during normal filling. At harvest time this length of the canal can be used to hold live fish or shrimps, provided appropriate screens at the inner end of the main gate are set to hold them in the area.

The main concern of the project is to complete Phase I as soon as possible, even if it involves raising the dikes of the supply canals to the same level as the perimeter dikes, in order to be able to develop and operate this section freely. Dike materials should not be any problem, considering the volume of soil that has to be excavated from the ponds.

To speed up construction work, a change in policy whereby the labourers can be allowed to work for longer hours than now, and paid on piece work basis, appears necessary. This would not be very difficult to implement, as gathered in talks with the Director of the Fisheries Department in Nairobi. While it may entail more work on the part of the administration, completion time can be cut by almost 50 percent. Otherwise hiring of more daily wage workers becomes a necessity.

Wheelbarrows can be dispensed with and digging blades (Fig. 8) specially constructed for earth work in mangrove areas can be more efficient than the round shovels presently used, if the relay system of soil movement is adapted. The system calls for a team of up to seven members. The team would normally consist of one or two diggers, 3 or 4 runners and a piler. The diggers cut soil cubes, hand them over to the runners who pass these cubes on to the piler at the dike site. The cubes are dropped from waist high (for compaction) neatly on a brickwork pattern. Little training and practice is needed for attaining proficiency; however, supervisors should check piling from time to time to ensure that the soil blocks are well laid.

For moving soil over longer distances, sealed wooden flatboats (Figs. 9 and 10), 1.2 m wide, 3.65 m long and 0.30 m deep, having 1.27 cm (0.5-in) marine plywood for bottoms and decks are more efficient and would be more economical in the long run than wheelbarrows. At current Mombasa prices, a flatboat is estimated to cost K.Sh. 2 000. Capable of loads up to 700 kg or more (they can be overloaded up to submersion), they can last for more than two years. On the other hand, a wheelbarrow costs K.Sh. 260 and lasts for six months with two repair jobs costing K.Sh. 50 each.

The flatboat will need at least 40 cm of water for better manoeuverability. Completion of pond dikes to be able to hold and maintain working depth is, therefore, required.

It is not necessary to excavate all the surface layers to bring down the ground elevation to the desired pond bottom level. A detailed topographic survey should show how much soil should be removed to obtain the appropriate pond elevations. Digging alternate strips to predetermined depths, then filling them to the desired level with soil from the adjacent untouched ground would preserve as much of the top soil inside the pond and cut down levelling time. The excavated strips properly laid out in advance, could also act as waterways for flatboats.

The necessity for the Ngomeni Fish Farm to use natural food for feeding the stock arises from the fact that artificial feeds are critical items in Kenya. For this, fertilizers are necessary as the lagoon does not get additional nutrients other than from the sea.

Under salinity conditions prevailing in the area, lab-lab would be quite easy to culture, provided adequate fertilizers are used. The southern section of the farm with its silty loam soil appears to be suited for growing lab-lab immediately, needing only liberal amounts of organic and inorganic fertilizers to develop a gelatinous layer best suited for lab-lab growth. The sandy areas, on the other hand, need more organic matter, but where there is heavy peat formation from roots of Rhizophora, special treatment and lime might be necessary for soil stabilization before favourable response to fertilization can be expected.

Measures for hastening mud formation under each possible set of conditions are given in Annex I and for growing lab-lab in Annex II.

Of the three species of penaeid shrimps indigenous to the area (P. monodon, P. indicus and M. monoceros), only P. indicus offers possibilities for commercial production because of its better performance in higher salinities. While P. monodon and M. monoceros grow faster in almost fresh to moderately brackish waters, P. indicus are reported to grow well in waters of about 30‰ salinity. The best part of the year for trying P. indicus culture would be during the long rainy season (April, May and June) when precipitation should bring down salinity in the ponds to this or lower levels.

Juvenile shrimps can be released directly to the grow-out ponds provided the fish components of the catch can be sorted out or eliminated with saponin. These ponds should be free of all fish prior to stocking, as a precautionary measure against predators. On the other hand, the shrimp nursery ponds should be used to hold post larvae for a few weeks, before they are drained slowly to the adjacent grow-out pond intended to receive the stock. The small size of the nursery pond enables it to be prepared and manipulated easily for this purpose.

For shrimp culture at the Ngomeni Fish Farm, saponin should be an indispensable input if only for eliminating any fish mixed with the shrimp fry before stocking. A search for saponin bearing plants, therefore, should be undertaken. In Kenya there should be a few species that have this substance on their bark, sap, leaves or fruit. Reports of plants being used for illegal fishing along the Kenya coast should be verified and the plants tested for saponin content.

There is certainly necessity for considering monoculture of finfish or polyculture with shrimps as an integral part of aquaculture activities at the fish farm. Particularly during the dry period or season of short rains (August to January) when salinity is expected to rise, a shift to fish culture may be necessary to make an all year round production scheme possible.

Pending the location of better stocking material, mullet may be stocked in the grow-out ponds even during the enrichment period after soil stabilization (see step A-7, Annex 1) and thereafter during the second crop season of the year, i.e. August to December. In the latter, culture will need nursery and fingerling-holding ponds and will involve three stages: (i) nursery rearing of late fry to fingerlings in the nursery pond; (ii) growing to post fingerling and holding in the fingerling-holding pond, and (iii) rearing to marketable size in the grow-out ponds. The first will require 1 to 2 months (February to April); the second from 2 to 4 months (April to August); and the last, from 3 to 4 months (September to December). In all these stages, adequate lab-lab should be grown in the pond before stocking operations.

Detritus which mullet can utilize with efficiency should also be tried, using deeper waters if attainable and regular applications of organic and inorganic fertilizers in appropriate quantities that would produce sufficient food without resulting in lethal O2 deficiency.

Besides mullets, siganids (rabbit fishes) hold possibilities for culture if seeds are available. A concerted effort to locate fry grounds should now be the main activity of the prawn and fish seed survey team. If this is successful the techniques for commercial farming of this group in shallow water ponds under Ngomeni conditions and based on natural food can be evolved.

Another species that may be cultured is Tilapia (T. mossambica or T. Spilurus). Both grow well in sea water. T. spilurus is indigenous in Kenya.

Farm construction makes up the major bulk of the work at the Ngomeni Fish Farm now and a lot has yet to be accomplished in this regard. As aquaculture activities can only commence when ponds are completed, and as satisfactory results are possible only when conditions have developed to the extent that positive response to standard care is easily achieved, completion of the ponds in as short a term as possible should be the immediate concern of the project.

The assignment of an expatriate expert with broad experience in pond construction, soil stabilization and brackishwater pond management for shrimp and fish culture should help the team leader in planning and executing the work programme designed to achieve the objectives of the project.

The appointment of a counterpart Farm Manager who should take responsibility on all internal administrative functions connected with the construction and operations, and at the same time acquire the technical training required to run the farm after withdrawal of FAO, is deemed an immediate necessity.

It is further recommended that local staff members directly engaged in field work at the Fish Farm be based at Ngomeni to be able to supervise and/or undertake specific tasks as may be required for effective programme implementations.

Fig. 1 Aerial photograph of Ngomeni showing location of the Pilot Brackishwater Fish Farm.

Fig. 2 - Planned layout of Phase I, Ngomeni Pilot Brackishwater Fish Farm as of August 1981.

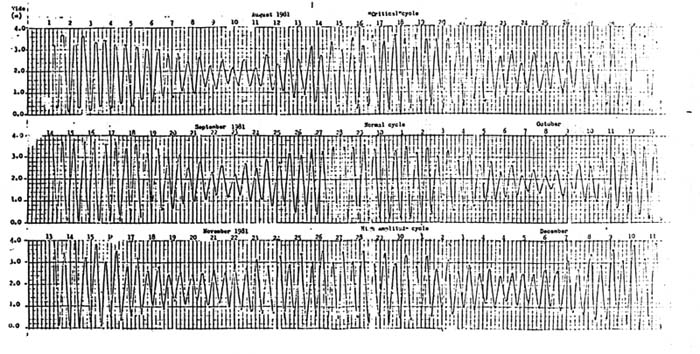

Fig. 3 - Predicted tide curves for Malindi (Kilindini, Mombasa Reference Station) showing patterns for “critical”, normal and high amplitude cycles.

Fig. 4 - Proposed layout plan for Ngomeni Brackishwater Fish Farm.

Scale = 1:5000

Fig. 5 - Relationship between tide levels, standard part in Kilindini and gauge site in Ngomeni.

Fig. 6 - Specifications, Sections A, B and C in proposed layout plan.

Fig. 7 - Specifications, Section D in proposed layout plan.

Scale - 1:100

Note: Elevations are based on Ngomeni water levels shown in subsequent chart, Fig. 7.

Fig. 8 - Digging blades suitable for soil work at Ngomeni Pilot Brackishwater Fish Farm.

Note: A - of ordinary block iron

B - of discarded steel leaf spring

Fig. 9 - Sketch of flat-boat for pond construction

(From “Engineering Aspects of Brackish Water Aquaculture

in the South China Sea Region” by Jamandre and Rabanal

Working Paper No. SCS/75/WP/16)

Fig. 10 - Details of flat-boat for fishpond construction, (From “Engineering Aspects of Brackish Water Aquaculture in the South China Sea Region” by Jamandre and Rabanal, Working Paper No. SCS/75/WP/16)

Fig. 11 - Leveling by “stripping” (From “Engineering Aspects of Brackish Water Aquaculture in the South China Sea Region” by Jamandre and Rabanal, Working Paper SCS/75/WP/16)