| Ministry of Agriculture and Water Resources: | |

| Salem Bamuflah | Director General of Agriculture Research Centre of the Western Region. |

| Fish Farm Centre Project: | |

| K. Allen | Project Manager |

| S. A. Al-Thobaity | Project Co-Manager |

| M. Arada | Fisheries Biologist |

| Feisal A. Bukhari | Fisheries Biologist |

| Magd Elbawah | Hatcheries Responsible |

| Adel Badawi | General Service Responsible |

| Met also at FFC Project: | |

| Victor C. Salin | Senior Budget and Financial Officer, from FAO, Riyadh, on mission in Jeddah |

| FAO Headquarters, Rome: | |

| Coche, A.G. | Senior Fisheries Resources Office (Aquaculture) |

| Ziesler, R. | Project Operations Officer |

| Padroni, G. | Personnel Officer |

| Padlan, P.G. | Senior Fisheries Officer (Aquaculture) |

| Vincke, M. | Senior Fisheries Officer (Aquaculture) |

| Other persons in the FAO Fisheries Department: | |

| Welcomme, R. L. | |

| Garcia, S. | |

| Kapetsky, J.K. | |

Fig.1: Diagram of the Shoreline Lagoon at the Fish Farming Centre Site, Jeddah

Fig.2: Approximate limit of suitable depth (between 1 and 2 m deep) for fishpen at the Fish Farming Centre shoreline

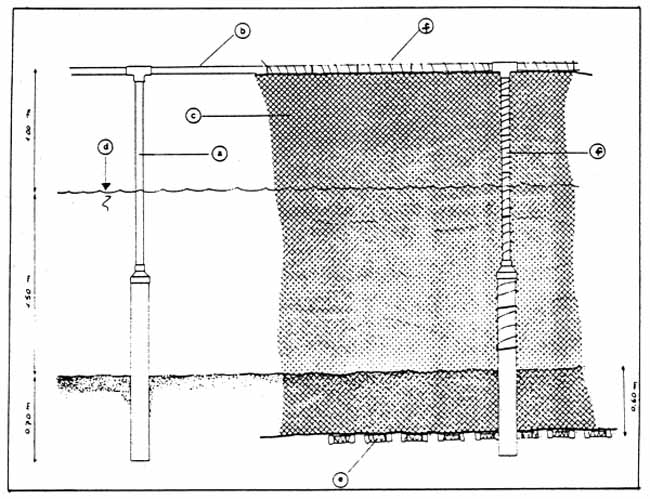

Fig.3 - Detail design for the two demonstration fishpens

| Material and equipment: | |

| - Ready made nets (210/60 – 14 mm) See detail in Fig. 6 | 600 m1 |

| - String 210/60 | 40 bobbins1 |

| - Plastic needle No. 8 (Fig.7) | 301 |

| - Side poles (Fig.4B) | 1701 |

| - Corner poles (Fig.4A) | 10 |

| - Pressure line PVC (diameter 2 in) to join the pole tops (Fig.4a) | 500 m1 |

| - Sinkers (Fig.7) | 1 700 units1 |

1 For all the above, additional quantity included as spares

Fig. 4 - The detail design for the two types of poles

Note: The length of part “c” must be adjusted when all the poles have been installed; it depends on the level of the maximum high tide. For a jumper species such as the mullet, part “c” should be made higher.

Fig. 5 - Steps in constructing a side pole

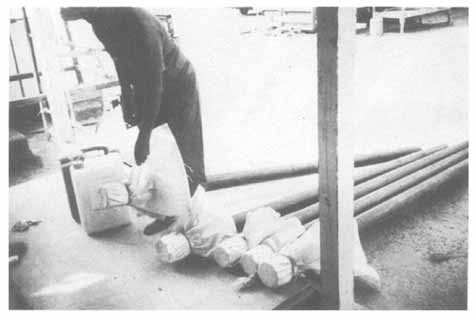

Prepare the bottom part (see Photo No. 1):

jute bag holding the concrete (see Photo No. 1)

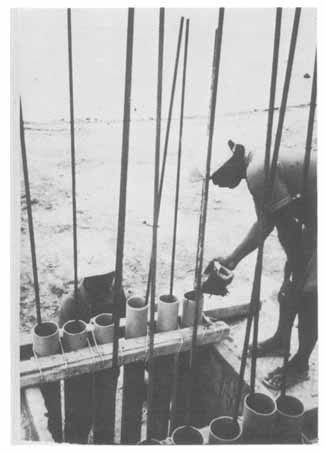

Prepare the top part (see Photo No. 2):

reducer (ordinary PVC) 4 to 2 in

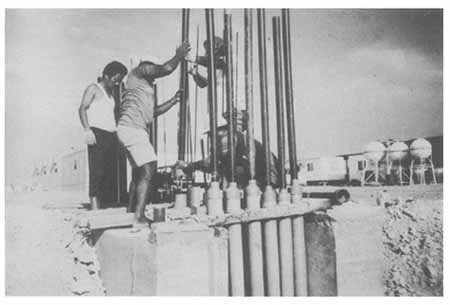

Fill up the bottom part with concrete which needs to be well packed by stirring the iron rod and by slightly hammering the PVC (see Photo No. 3 and 4)

Join the top and the bottom parts (see Photo No. 5)

Fill up the top part

Pole is ready after 24 to 48 hours

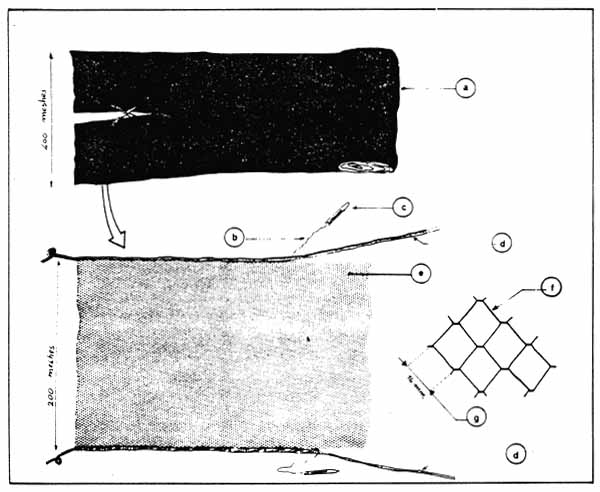

Fig. 6 - Details of netting

Net 210/60 – 14 mm, delivered from factory by sheet of 400 meshes (about 7 m wide and 40 m long), Half of the sheet with (200 meshes) will be used as net side barrier after being attached with a 10 mm diameter rope.

String 210/60

Special plastic needle

10 mm diameter rope

Net 210/60 – 14 mm

Mesh size: 210/60

14 mm is the distance between two knots

Fig. 7 - Sinkers (see Photos 6, 7 and 8)

Sinkers are made with ordinary PVC (diameter 2 in and 20 cm long).

The diameter of the two extremes are slightly extended by heating.

Fill up the sinkers with concrete.

Diagram of a sinker.

The sinkers are strongly attached on the bottom side of the net with string 210/60 (f).

Fig. 8 - Net installation

1. Water pressure from a 2 HP water pump.

2. Furrow dug by water pressure.

3. & 4. Sinkers and net are carefully laid into the furrow.

5. Bottom furrow closing.

6. Digging direction.

7. Hose (diameter 2 in) used to orient the water pressure.

Fig. 9 - Diagram of installed net

-side pole

-top edge of the fishpen

-net 210/60 – 14 mm

-water level

-sinker

-side of net needs to be tied to the side pole up to the top edge of the fishpen and to the pipes connecting the side poles.

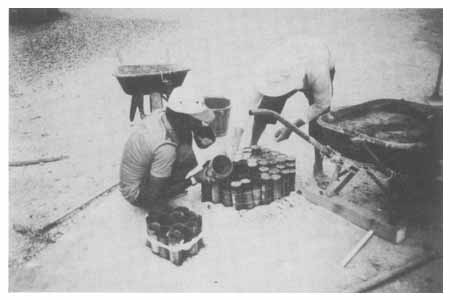

Photo No. 1 - Preparation of the bottom part of the pole.

Photo No. 2 - Preparation of the top part of the pole.

Photo No. 3 - Filling pole with concrete.

Photo No. 4 - Filling pole with concrete

Photo No. 5 - Joining the top and the bottom parts of the pole.

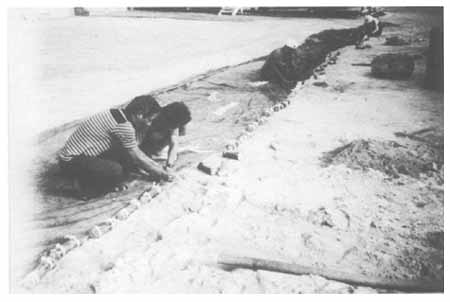

Photo No. 6 - Fabrication of sinkers.

Photo No. 7 - Attaching sinkers to the bottom of the net.

Photo No. 8 - Attaching sinkers.