The forest harvesting system commonly applied in Timber Permits in Papua New Guinea is based on a general forest inventory for the entire project area and a preharvest survey (mapping and pre-logging inventory) of each cutting unit, which is referred to as a "set-up". Data from the survey enable the TP holder and/or the logging contractor to plan harvesting operations and also permit the Papua New Guinea Forest Authority (PNGFA) to monitor harvesting activities. Planning is done at three levels: the Five-Year Plan, the Annual Logging Plan, and the Set-up Plan.

In recognising the PNG Forest Authority Mission Statement "to promote the management and wise utilisation of the forest resources of Papua New Guinea as a renewable asset for the well-being of present and future generations" (PNGFA 1996b), one of the main responsibilities of the PNGFA is to monitor and control logging operations in the field. As outlined in PNGFA (1995b), monitoring and control are undertaken in particular in order to:

· Ensure that logging proceeds in an orderly manner, and in accordance with the terms and conditions specified in the Timber Permit (and associated Project Agreement where this exists);

· Ensure that environmentally and socially sensitive areas are excluded from logging; and

· Ensure that logging takes place in accordance with sound silvicultural and environmental principles, thus ensuring sustainable wood production and the future of the industry.

All harvesting operations undertaken are to be guided by the consideration that unless the forest is left in a condition that will permit the attainment of a desired future condition, sustainability cannot be assured. To meet the requirements of environmentally sound forest harvesting, all harvesting operations must be well-planned. Therefore, short-term planning, often called tactical planning, has to be based on a strategic plan (Dykstra & Heinrich 1996).

The strategic harvest plan is a long-term plan that mainly answers the questions where and when harvesting should be done for the Timber Permit area as a whole. These questions will be addressed in the feasibility study which is conducted by the selected project proponent, the potential "developer," prior to the execution of the project agreement by the Board and the granting of the timber permit by the Minister.

Whereas the development options study is more related to the general fact-finding process on potential future land uses in the project area, the feasibility study addresses questions related to forest production and downstream processing. The former identifies feasible options for the project area and investigates means of landowner participation in such development, environmental and social impacts of such development, and the feasibility of local processing and marketing prospects generally of any forest products (PNGFA 1993). The latter comprises a management-level forest inventory, forest development plan, industrial development plan, implementation strategies, financial prospections and proposed corporate arrangements (Neville 1993).

For new timber projects which are designed to comply with the requirements of the National Forest Policy for sustainable wood production (PNGFA 1995b), the total project's production forest area is split into thirty-five more or less equal portions based on a 35-year cutting cycle. The Five-Year Plan identifies five of the 35 compartments to be harvested during the planning period.

A map of the entire project area at a scale of 1:50,000 demarcates non-harvest areas, namely major preservation areas and deforested areas, from the production forest area and divides the latter into annual logging areas, normally referred to as "annual coupes" or simply "coupes" (Dykstra & Heinrich 1996). The map shows the areas already harvested with the year of harvest, indicates the areas to be harvested during the next five years, and identifies the existing and proposed transportation systems.

The strategic plan itself is part of the forest management plan and both are based on a comprehensive land-use plan which identifies the permanent forest estate, areas of forest plantations, and land to be cleared for other purposes such as agriculture.

The tactical plan, in PNG referred to as the Annual Logging Plan, provides details on operations that are to be carried out during a period of one year. This annual operating area in a particular year will be more or less one-fifth of the total area approved for harvesting in the Five-Year Plan (PNGFA 1995b). The annual coupe is not necessarily a single, contiguous block but instead the area to be harvested within one year is dispersed throughout several separate parts of the area covered by the Five-Year Plan.

The Annual Logging Plan, at a scale of 1:25,000, splits the annual coupe into individual cutting units of up to 150 ha, referred to as "set-ups" in PNG, and indicates the proposed order of harvesting. The sizes of the annual coupes for year 2000 of the two timber projects in this study were 11,384 ha (SBLC 2000) and 22,208 ha (VFP 2000). These areas were divided respectively into 76 set-ups for SBLC (of which 11 were carried over from previous years), and 167 set-ups for VFP.

One of the intended features of the projects is year-round timber harvesting to provide stable, continuous employment. Therefore, the PMCP provides for additional set-ups to be specified by the permit holder or its logging contractor and held in reserve for periods of wet weather.

The individual set-up is the focus for monitoring and control of harvesting operations in the field, and in particular assessing compliance by the permit holder or its logging contractor with the Key Standards for Selection Logging in PNG (PNGFA 1995b).

After pre-logging inventory and terrain reconnaissance have been carried out, each set-up is mapped individually. Harvesting planning of set-ups should be done on the basis of a detailed topographic map (1:10,000). Where a topographic map is not available, the operator's planning staff is required to produce a 1:5,000 sketch map (PNGFA 1995b) showing boundaries of the set-up and all features that may influence harvest planning (water courses, swampy areas, slopes, or other problem sites) within the set-up.

The information obtained from terrain reconnaissance will be used for the layout of temporary forest roads, skidtrails, and landings, all of which will be drawn on the map and also marked in the field. When the pre-logging inventory is carried out in a systematic manner, it will indicate areas of lower and higher volumes and, therefore, should enable a more efficient layout of the transportation system. Combining the set-up map prepared after thorough terrain reconnaissance and the results of a systematic pre-logging inventory would enable preparation of a highly accurate set-up plan for the individual set-up. However, this is not commonly done and layout of skidtrails is guided by relevant terrain features mainly. Planned locations of skidtrails are generally indicated only approximately on the maps (see Figures 3 and 4).

In addition to set-up mapping after thorough terrain reconnaissance and pre-logging inventory, the PMCP indicates that all trees to be harvested are to be marked in the field prior to approval of the set-up plan by PNGFA. Along with enumeration of trees to be harvested in the individual set-up, the desired felling direction is to be indicated on each tree marked for harvesting. The felling direction chosen by the surveyor should be guided the objective to minimise damage to the remaining stand, namely PCTs and regeneration, and to facilitate efficient and minimum-impact felling and skidding operations. Unless unmarked trees are badly damaged during operations and are found to be of commercial value, logging crews are supposed to remove only marked trees from the set-up.

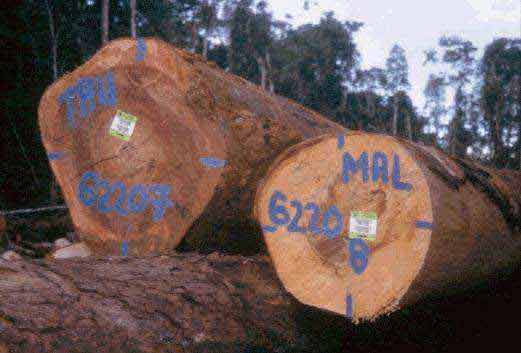

Photo 5. Consistent log tagging permits monitoring and control of logging operations.

Once the logs have arrived at the landing, they are identified, cut to length, and scaled (i.e., measured for volume). It is prohibited for logs to be removed from the landing unless they have been tagged with official PNGFA tags and the scale information has been entered onto the official PNGFA Log Scaling Record Sheet (PNGFA 1996c) for checking by PNGFA officials.

After completion of the harvesting operations and complying with the post-logging requirements as set out in the Key Standards for Selection Logging (PNGFA 1995a) the permit holder or logging contractor may apply for the issuance of a "certificate of satisfactory completion of work" (PNGFA 1995b). This so-called set-up clearance procedure is to ensure:

1) Compliance with the Forestry Act, which requires the issuance of a certificate by the project supervisor before harvesting operations may start in the next set-up;

2) That all post-logging requirements of the PNG Logging Code of Practice have been met;

3) That the set-up is closed to any further logging before the next planned harvest;

4) That the way has been cleared for approval of the next set-up for harvesting.

The granting of a set-up clearance effectively "de-activates" the set-up (PNGFA 1995b) in order to allow the forest to recover until the next planned harvest 35 years later.

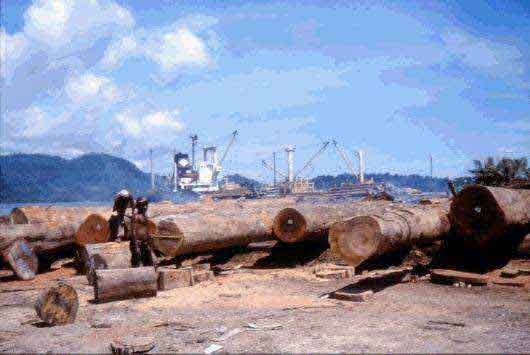

Photo 6. Final grading of logs at the wharf to prepare for export.

Forest roads are unquestionably the most problematic features of timber harvesting operations with regard to environment and landscape (Photo 7). They are complex engineering structures upon which transport efficiency depends and are, nevertheless, essential for providing reliable access to the forest for management and monitoring purposes (Dykstra & Heinrich 1996).

In most timber permits in PNG, furthermore, part of the road network to be established by the timber permit holder is an essential component of the country's development infrastructure and often forms part of the planned network of public roads.

To illustrate the importance of the timber industry as "developer," the area in the northern part of TP 14-52 may serve as an example. The whole area on the north coast is well-served by roads, with the main roads (e.g., Kimbe-Hoskins, Kimbe-Talasea) being sealed (see Photo 2) or in the process of being upgraded. The timber industry, through SBLC, has contributed significantly to the development of the road network on the north coast by the construction of over 60 km of national and 700 km of provincial roads (SBLC 1989) during the implementation of TP 14-31 from which the current project originated.

In contrast, the central part of the island and the south coast had virtually no transport and communications infrastructure in 1989 when the new project agreement was signed between SBLC and the Government of PNG. There was one airstrip in the area, at Fulleborn, where the only large commercial coconut plantation on the south coast is located, and two airstrips nearby at Uvol, about 20 km to the east, and Gasmata, to the west, which were served by regular flights at that time. All other long-distance travel was by village boat or speedboat (SBLC 1989).

Photo 7. Landslide caused by road construction activities.

In addition to roads needed for industrial timber extraction and other forestry activities, SBLC has provided the following infrastructure as outlined in the timber agreement of TP 14-52:

· the Trans-Island road (Ubai Village to Amio, 57 km), connecting the north and the south coasts of the island (not required by the agreement);

· the south coast road (to be constructed over 13 years) from Uvol in ENBP to Gasmata in WNBP (Amio to Gasmata, 55 km; Amio to Uvol, 65 km);

In compliance with the project agreement, SBLC will build a total of 4,288 km of roads over the first 20 years of TP 14-52, of which the above-mentioned 177 km will be roads of provincial importance and the remaining 4,011 km will be forest roads (SBLC 1989).

As a general rule, all but village feeder roads should be "decommissioned" after the harvesting operation has been completed (PNGFA 1996a). This means the road will be closed to normal traffic but will be left intact for reopening if required. It is the landowners' prerogative to keep main forest roads open but they must then decide who will maintain the road, including structures such as bridges and culverts. The developer has the obligation to design bridges for a minimum lifetime of 25 years and to maintain the bridges to the standard of construction, in a safe and trafficable condition for the whole period of time they are used for timber hauling (SBLC 1989).

Village access roads of about 41 km and all main forest roads providing access to other infrastructure provided by the developer such as schools, clinics, and government houses will certainly remain open. Although the majority of forest roads will be decommissioned in many timber areas, comprehensive planning (i.e., to ensure proper location, design, construction, and maintenance) is essential to ensure that all roads meet economic objectives with minimal impact on the environment.

The starting point for proper road planning is a good topographic map representing data gathered during the general forest inventory and terrain reconnaissance. In order to open the annual coupes in the most efficient way, the steps in planning the road network are roughly as follows:

· As part of the feasibility study, the permanent transportation system as a whole is designed for the entire timber project area;

· The Five-Year Plan gives the final location of the permanent forest roads, which are generally constructed ahead of the logging operations for medium- or long-term use serving many set-ups;

· Temporary forest roads are constructed where access to individual set-ups is required and their planning is therefore part of the Set-up Plan;

Independent from the planning level there are some guiding principles and factors to be considered which influence road location and layout:

· Delineate areas (such as conservation areas, village reserves, cultural and historic sites, etc.) where roads should not be permitted;

· Consider only areas with sufficient commercial timber and avoid inadequately stocked area to save on costly road construction and maintenance;

· Minimise the total length of roads and skidtrails to keep costs of construction and maintenance low and to reduce environmental impacts while keeping in mind the planned average skidding distance of 500-600 m and the maximum distance of 800 m;

· Avoid difficult terrain and streams, circumvent problem areas such as swamps to minimise environmental problems, and consider the protection of streams in the interest of downstream users;

· Provide year-round access to the forest by means of permanent forest roads with a planned driving speed of about 40 km/h;

· Select landings along the road at intervals of not less than 500 m, providing a minimum storage capacity of 1,500 m³ per landing;

· Utilise stable ridge-top locations for roads wherever feasible;

· Check the projected location of roads and landings in the field and correct the paper plan as appropriate.

The infrastructure densities shown below have been derived from data on planned annual harvest areas and related new road construction in the respective Five-Year Plans for TP14-52 and TP10-8 (SBLC 1999, VFP 1999). These figures may be considered representative for selective harvesting operations in natural forests in PNG since the respective areas cover the whole range of terrain conditions one can expect in PNG.

Type of infrastructure |

Planned density |

Forest roads |

7-8 m/ha |

Main skidtrails |

up to 120 m/ha |

To the degree possible, landings are normally established on both sides of the forest roads. This practice helps to avoid pulling logs across or along roadways thus reducing road maintenance costs and increasing the life of skidding cables.

Since only three landings per set-up are permitted under the Key Standards (PNGFA 1995a), each landing of up to 2,500 m² in size should serve as a collection area for timber harvest from about one-half or one-third of the set-up area. One consequence of this rule is that when the storage capacity of the landings has been reached, logs must be stored along the roadsides.

In order to ensure adequate drainage of water from roads and thus minimise both maintenance problems and environmental impacts, the PNG Logging Code of Practice provides guidance on the maximum average spacing of culverts or cross-drains, based on the following formula (PNGFA 1996a):

![]()

where S = average spacing between culverts or cross-drains, in m

F = a soil factor taken from the table below

G = road gradient, in % of slope

Soil Type |

Soil Factor (F) |

Clay, silt, fine sands |

1000 |

Sand, very fine gravel, pumice |

1500 |

Gravel with some sand |

2000 |

Clean gravel |

2500 |

In addition to soil type and road gradient, another important consideration for culvert spacing is culvert diameter. The maximum spacing for 300 mm culverts is given as 185 m, and that for 375 mm culverts as 325 m (PNGFA 1996a). However, determination of the size and spacing of culverts is to be decided for each site individually according to terrain condition, precipitation, and runoff rates expected. This holds particularly true for TP 14-52 where over most of the area the average annual rainfall is between 3,000 and 4,000 mm, with a narrow band on the south coast receiving more than 5,000 mm annually and having an average rainfall intensity index between 200 and 260, higher than most of PNG (SBLC 1989).

In accordance with the PMCP, any forest clearing for permanent forest road construction taking place ahead of logging operations is also subject to prior approval by PNGFA. The road corridor for permanent forest roads specified in the Annual Logging Plan, must be split into one or more numbered set-ups, so-called "Permanent Roadline Clearing Set-up," and presented for Set-up Plan approval.

Building forest roads in primary tropical rain forests involves clearing vegetation and moving soil in order to create structures capable of supporting heavy vehicles. If a road is important enough to be engineered in survey and design, it is equally important to supervise and oversee the actual construction in order to ensure that the roads will to meet the standard of construction set out in the Annual Logging Plan.

Road construction machinery is normally owned by the developer and used by logging contractors to construct the roads. The following machines are available for road construction and maintenance from the companies involved in this study:

Activity |

Machine Type |

Equipment |

Clearing / first opening |

Crawler tractor |

Cat D7G Komatsu 83P |

Grading |

Crawler tractor |

Caterpillar D6H |

Construction / loading |

Excavator |

Komatsu PC220-5 |

Loading gravel |

Bucket loader |

Komatsu WA420 |

Transportation of gravel |

Dump truck |

Nissan TZA520 |

Surfacing / shaping / maintenance |

Motor grader |

Caterpillar 140G Caterpillar 12G |

Road compaction |

Roller / Compactor |

Komatsu JV100 |

Contributing to Sustainable Land Management in many rural areas of PNG, forest roads, as essential components of the local development infrastructure, must meet the needs of both the forestry and agriculture sectors while serving other current and anticipated demands.

Forest roads, therefore, often have to provide year-round access to villages, agricultural land, and forest. This necessity must be considered not only during the planning stage, but also in road construction and maintenance. The bearing strength of the roads must be sufficient to meet this type of use and must be surfaced with at least 15 cm of gravel, depending on soil conditions, to form a solid running surface. Adequate compaction of the base layer and running surface is essential but, unfortunately, has not yet become common practice in PNG.

Design road widths are 10 m for two-lane roads and 6 m or one-lane roads (PNGFA 1996a). Daylight clearings are used along roadways to permit the roads to dry out quickly after rain and avoid temporary closures due to wet roads. Typical daylight clearings in the wet tropics are up to twice the road width (Winkler 1997). Although practices will vary in different regions and depend on the specific terrain conditions and precipitation, the maximum clearing width of 40 m specified in the PNG Logging Code of Practice (PNGFA 1996a), seems quite high. One of the principal recommendations from Wells (1999) is that an evaluation of the current road classification, design, and clearing-width standards is needed by the PNGFA.

Whereas roads intended for medium- and long-term use, which are referred to as "permanent forest roads", are constructed well in advance of logging operations, temporary roads and landings are constructed while the harvesting operation is underway. The time required for construction of a single 50 m × 50 m landing with the company's Caterpillar D6H crawler tractor was 2-4 hours.

Like road construction, road maintenance is also done with company-owned machinery. Maintenance activities include necessary repairs such as replacement of ineffective or damaged bridges and culverts, reinforcement of wet stretches of road with gravel, and re-shaping and re-surfacing of permanent roads to allow for the safe and efficient movement of timber and local traffic.

Photo 8. Savings in road maintenance cost do not always pay off-this breakdown occurred after a sharp stone, stuck between the dual tires, seriously damaged the tires under the weight of the loaded truck.

Photo 9. Lack of gravel is a serious problem at many road construction sites in the tropics-gravel obtained from the river bed often is the only economical alternative.

An essential requirement for strategic harvest planning is the development of a comprehensive management plan (Dykstra & Heinrich 1996), which itself should be based on a land-use plan. A written plan should describe in detail what is shown on the planning maps. In PNG, maps with elevation contour lines and drawn to a scale between 1:25,000 and 1:50,000 are to be prepared by the timber permit holder or logging contractor in compliance with the PMCPs. These maps are generally referred to as "forest management maps" in PNG.

The following features are normally included on forest management maps, with minor variations between companies:

Features of maps prepared to accompany: |

Five-Year Plan |

Annual Logging Plan | |||

Scale |

1:50,000 |

1:25,000 | |||

Boundaries (provincial, TP and/or TRP/OGA) |

× |

× | |||

Areas of logged-over forest and year of logging |

× |

× | |||

Water courses |

× |

× | |||

Timber inventory lines |

× |

× | |||

Annual coupes |

× |

||||

Proposed set-ups and alternate set-ups |

× | ||||

Harvestable but reserved forest |

× |

||||

Buffer zones (50 metres wide) along major rivers |

× |

||||

Inaccessible forest areas |

× |

× | |||

Areas excluded from harvesting such as: |

|||||

mountainous terrain with slopes over 30 degrees |

× |

||||

larger swampy areas |

× |

||||

developed / cleared / inhabited areas |

× |

× | |||

village reserves / cultural and historic sites |

× | ||||

Existing roads (by category) and bridges |

× |

× | |||

Proposed roads and bridges: |

|||||

main / branch forest roads / alternative routes |

× |

||||

roads to be retained / decommissioned |

× | ||||

Proposed low-level water crossings: |

|||||

bridge/culvert to be decommissioned |

× | ||||

bridge/culvert to be retained |

× | ||||

Sawmills |

× |

||||

Logging base camps |

× |

||||

Log ponds |

× | ||||

Log landings |

× | ||||

Gravel pits |

× |

The Five-Year Plan will also include a so-called "locality map," typically drawn to a scale of 1:200,000 and showing the following:

· timber permit boundaries and other administrative boundaries

· coupes for the planning period relevant to the project area

· clearance area

· existing base camps

· existing and/or temporary log ponds

· existing gravel/pumice pits

· wharves

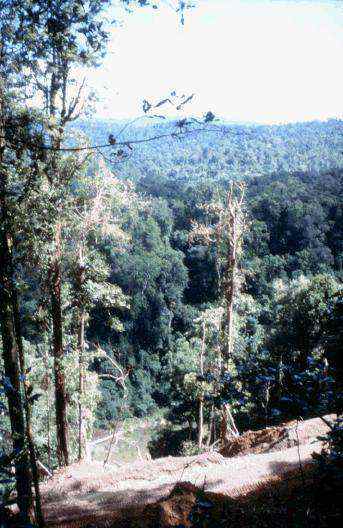

In order to reduce the adverse impact of logging on the forest and the communities living in them, the Department of Environment and Conservation (DEC) and the PNGFA have agreed that selective harvesting in PNG may be practised only in forest areas which are not excluded by the following criteria (PNGFA 1996a):

· slopes steeper than 30 degrees;

· areas of high relief on slopes steeper than an average of 25 degrees;

· permanently inundated land;

· limestone country (karst); and

· mangrove areas

In forest areas that have not been excluded from harvesting because of the above or because they have been legally reserved for other uses (e.g., conservation areas), "buffer zones" are used to reduce environmental impacts. Areas where buffer zones are required as specified under Key Standard 2 (PNGFA 1996a) include the following:

Site |

Width of buffer zone | |

Cultural sites, reserves, conservation and garden areas |

At minimum 100 m, can be increased upon request by local community to the PNGFA project supervisor | |

Village areas |

At minimum 500 m, can be increased upon request by local community to the PNGFA project supervisor | |

Lakes, lagoons, coastal shorelines, swamps |

At minimum 100 m | |

Permanent streams |

At minimum, 50 m from the sides of a class 1 stream (bed width > 5 m) At minimum, 10 m from the sides of a class 2 stream (bed width 1 to 5 m) | |

Streams of any width (either permanent or intermittent) used by a community |

At minimum, 50 m from the sides of the watercourse; but harvesting might also be excluded from the catchment area of the water source | |

Log ponds and wharves |

No buffer, but the maximum shoreline clearance is 100 m |

Set-up mapping and pre-harvest inventory are done consecutively by SBLC's logging contractor and in contrast are carried out simultaneously by VFP, where the inventory crew is split into sub-groups. Independent of the sequence of tasks, the following tasks may be distinguished:

· Establishing set-up boundaries

· Establishing buffer zones

· Marking harvestable trees and cutting climbers if necessary

· Locating and marking landings and skidtrails

In general, the typical inventory crew is 7 or 8 persons. The minimum size is a group of four, the maximum a crew of 10. Typical inventory crews used by the companies are as follows:

SBLC (1989) |

VFP (1990a) |

|||

Crew leader |

1 |

- |

||

Compass man |

1 |

Compass man |

1 | |

Chain man (length measurement) |

2 |

Chain main (length measurement) |

2 | |

- |

Tree taggers |

2 | ||

Brushers |

3 |

Brushers |

3 | |

Total crew |

7 |

Total crew |

8 |

Set-ups are pre-laid on a topographic map preferably with a scale of 1:20,000. The boundary of each individual set-up is then followed on the ground. Boundaries must reflect natural features (PNGFA 1995b), in particular rivers and creeks, to avoid crossing them during extraction operations. A pre-logging inventory with a sampling intensity of at least 10% of the harvestable set-up area has to be carried out in compliance with the PMCP and should give a good indication of the availability of timber in terms of species and volume.

One way of carrying out the pre-harvest inventory is described in VFP (1990a). Base-lines are run parallel to a prominent landmark, such as a river or ridge. Cruise-lines are then run perpendicular to the base-lines (Figure 6). The width of the inventory strip is determined by the distance between cruise-lines and the desired sampling intensity. A 10% sampling when cruise-lines are 50 m apart requires an inventory strip 5 m wide that can be thought of as a continuous line-plot (PNGFA 1995b). All trees within the inventory strip having a dbh of 50 cm or larger are recorded.

Under favourable terrain conditions where the area bordered by rivers and ridges comprises several set-ups, a system combining natural features with a grid can be used to define the individual set-ups. The orientation of the grid is determined by the shape of the catchment area in order to minimise the total length of grid lines to be opened up (to keep costs low), and therefore might differ even for adjacent catchment areas of the same annual coupe.

In flat terrain, a regular grid (north-south/east-west) can be laid out over the entire project area to form administrative blocks (e.g., 4 km × 4 km) that permit all administrative units, both annual coupes and set-ups, to be conveniently referenced on the ground. All main north-south lines of the grid are opened and permanently marked by the inventory crew and are kept open by clearance of undergrowth when necessary.

Figure 6. Map of a set-up showing the inventory striplines (Source: VFP 1990a).

In establishing set-ups and planning the harvesting operations, companies are required to follow a set of "Key Standards." Key Standard 1 defines the watercourse category on which widths of buffer zones have to be decided in the field. Key Standards 2 to 4 deal with all types of buffer zones, location of roads and landings in relation to the buffer zones, and the size and location of landings in general. Key Standard 5 prescribes that climbing vines are to be cut during the marking of harvestable trees in the set-up, normally about one year ahead of harvesting. The climbers, which tend to bridge across adjacent tree crowns, will die and become brittle when cut well in advance of the felling operation, thus reducing the chance that a felled tree will pull over neighbouring trees as it falls.

If it is impossible for logging operators to comply with the Key Standards, they may seek specific approval by the PNGFA project supervisor for departure from the standards. All approved departures from the Key Standards must be noted in the Set-up Monitoring and Control Logbook which will provide important inputs to future reviews of the Key Standards and the Logging Code as a whole.

On the basis of topographic features relevant for planning, the planner will lay out the harvesting operations by identifying and marking in the field the following (PNGFA 1995b):

1. For permanent Roadline Clearing set-ups:

· The surveyed road alignment, which must reflect relevant road standards

· All water crossings

· Clan boundaries where these cross the planned road alignment so that royalties and levies for harvested logs can be paid to the correct landowners

2. For Selection Logging set-ups:

· Set-up boundaries

· Areas to be excluded from logging such as buffer zones, slopes steeper than 30 degrees, cultural areas, swamps, community water supply sources, etc.

· Clan boundaries where these do not coincide with set-up boundaries so that royalties and levies for harvested logs can be paid to the correct landowners

· Planned temporary forest roads and water crossings

· Planned skidtrails

· Planned log landing locations

All the above-mentioned information is to be marked on the set-up map and also in the field. Different coloured tapes or paint can be used to transfer the information to the ground and the meaning of the different colours used must be passed on to logging supervisors and equipment operators.

A summary of results from the pre-logging inventory for a set-up will accompany the map for that set-up, the "Landowner Cultural Site Identification Form," and a covering letter when submitting the set-up plan for approval (PNGFA 1995b). The information obtained through the planning exercised will be used by PNGFA and the timber company to provide a rough estimate of the species and volumes to be harvested from the set-up.

An obligatory 100% marking of trees to be harvested in the particular set-up finally provides a count of the number of trees to be harvested and a final estimate of the volume to be removed from the set-up. The information obtained serves the PNGFA project supervisor as a rough check that all the trees which should be harvested are removed by the logging operator. One way to approach this task is to tag the trees along the survey lines, at the time of the pre-logging inventory, and to later come back and tag all trees between the tagged inventory lines (PNGFA 1995b).

Based on the topographic map and information to be excluded from harvesting, primary skidtrails are located and marked both on the map and in the field. The planner uses favourable locations for the skidtrails, following ridges with favourable grades wherever possible. However, secondary skidtrails (referred to as "minor skid tracks" in PNG), which are created by the tractor operator rather than being planned in advance, remain a matter of concern.

For each individual set-up, a topographic map with elevation contour lines, drawn to a scale of 1:10,000 or larger, or where topographic maps are not available, a sketch map drawn to a scale of 1:5,000 will show the following features:

Permanent roadline clearing set-up

· Surveyed road alignment, which must reflect the forest road standards set out in the Annual Logging Plan

· All water courses to be crossed, with the class of watercourse indicated

· All water crossings, with the type of crossing marked on each

· Clan boundaries where these cross the planned road alignment so that royalties and levies for harvested logs can be paid to the correct land owners

Selection logging set-up

· Topographic features and water courses, including the class of watercourse

· Set-up boundaries, which must tie in with the boundaries of adjacent set-ups

· Clan boundaries where these do not coincide with the set-up boundary

· Areas to be excluded from logging and all access by road and logging machinery

· Planned forest roads, with all water crossings sequentially numbered

· Planned skid tracks, and all water crossings

· Planned log landing location

Based on data provided for M38/SBLC and BL14/VFP by SBLC's logging contractor and by VFP respectively, and general information from the survey managers with the respective companies, the following performance can be expected for individual activities in field surveying and tree mapping:

Production rates [worker-days/ha] | |||

Activity |

Flat terrain |

BL14/VFP |

M38/SBLC |

Establishing of set-up boundaries |

No data |

0.16 |

No data |

Establishing of buffer zones |

0.28 |

0.03 |

0.42 |

Marking of harvestable trees |

0.35 |

0.17 |

1.68 |

Location of landings and skidtrails |

0.07 |

0.05 |

0.14 |

Felling, which is among the most hazardous of all industrial occupations (Dykstra & Heinrich 1996), should be carried out by well-trained personnel outfitted with appropriate safety gear and using equipment suitable for the work. The Key Standards relevant for felling operations, namely Key Standards 5, 15, 16 and 17 (PNGFA 1995a), can be summarised as follows:

Measures |

Objectives | |

Vine/climber cutting during set-up marking (Key Standard 5) |

· Minimise size of felling gaps · Minimise damage to residual trees, especially PCTs · Reduce safety hazards of felling operations | |

Directional felling into canopy gaps (Key Standard 15) |

· Minimise size of gaps in the forest canopy · Minimise damage to residual trees, especially PCTs · Facilitate efficient extraction (aligning logs in a "herringbone" pattern relative to the skidtrail) | |

Keep stump heights low, make cut level and complete back cuts to reduce pulled wood (Key Standard 16) |

· Avoid wood waste (maximise the volume of wood utilised from each felled tree) | |

No felling into buffer zones or excluded areas (Key Standard 17) |

· Keep buffer zones and excluded areas intact |

Regardless of the degree of sophistication used in planning, the final decision on the felling direction of each tree must be made in the field by the leader of the felling crew. Ideally, the felling direction should be based on a tree location map and the planned skidtrail network, taking account of the field situation as regards the distribution of future crop trees, existing regeneration, previously felled trees, and safety issues that may be evident.

Formalised training of felling crews is almost unknown in the companies visited for this study. As with most places in the tropics, fellers at these companies pass their knowledge on to their assistants who often become the next generation of chainsaw operators with the companies. As a result, knowledge of proper felling techniques, skills, and performance vary considerably. However, at the M38/SBLC site, one operator having about seven years' experience reported having participated in a two-day training programme organised by the company about six years ago. Another chainsaw operator with about eight years' experience indicated that he had undergone a two-month training course before joining SBLC five years ago.

The Harvesting Training Unit, located at the Timber Industry Training College in Lae, provides training in a variety of skills, including felling. One of the fellers observed during the work and time studies at the BL14/VFP site, who had became a chainsaw operator about seven months previous to the study, reported having participated in a half-day training exercise conducted by the Unit. However, the other two fellers at the BL14/VFP site, each with about one year's experience in felling, had never received any training.

Photo 10. Climber cutting must be done well in advance of felling so that climbers die and become brittle, thus reducing the chance of a felled tree pulling over neighbouring trees as it falls.

During the study some of the fellers used wedges in an effort to direct the fall of the tree. This indicates a basic knowledge of felling principles. However, in general the skills observed were far from sufficient to permit the competent use of directional felling.

As mentioned earlier, all harvestable trees are marked by the inventory crew and the desired felling direction is indicated on the bole of each tree. However, the fellers were not provided with tree location maps. In combination with their limited level of training, this meant that the actual felling direction often differed substantially from the desired felling direction indicated by the inventory crew. The actual felling direction also differed in many cases from the intended felling direction as indicated by the chainsaw operator prior to felling.

An important requirement of most timber permit agreements is that landowners will be given preference for employment. This means that when the harvesting frontier moves to another area that is owned by another clan, the move will be accompanied by a change in workforce. This constant changing of the workforce, particularly in jobs such as chainsaw operator, seems likely to hamper the implementation of measures set out in the Key Standards.

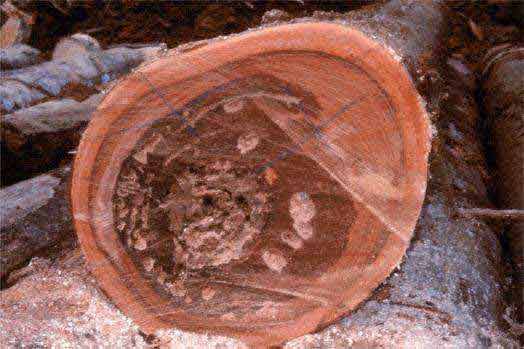

Photo 11. Use of proper felling techniques is uncommon in the timber permits, as this stump testifies.

An additional problem stemming from the employment of landowners in felling crews became apparent at the study sites, both in New Britain with SBLC and in Sandaun Province with VFP. Since employed clan members not only receive a salary for felling but also benefit from royalties paid by the companies to the landowners for each tree harvested, they did not always respect the dbh limit for commercial species, nor were they always willing to observe the prohibition on felling trees into or within buffer zones. Neither the fact of being observed during the time study where all details on operations at the felling site were measured and recorded, nor the presence of a senior official of the PNGFA prevented them from cutting unmarked trees.

On this study both a bulldozer (Caterpillar D6D) and a tracked skidder (Caterpillar 527) were used for skidding. Each machine operator had one assistant and the crew was provided with a Stihl 07 chainsaw. The extraction of logs began with the opening of the main skidtrail. In most cases the machine operator did not open the skidtrail right through to the end but only far enough to reach the first felled tree. After the logs from that tree had been skidded to the landing, the operator then opened the skidtrail to the next tree, continuing in this manner until the skidtrail had been opened in its entirety.

In Subplot BL14/VFP, only one main skidtrail was laid out for the entire subplot area (see Figures 5 and 8). Whenever logs or canopy openings were discovered, the operator created secondary skidtrails by driving the tractor into the stand to each felled tree in order to attach the skidding cable to the log and deliver it to the landing.

Photo 12. Skidding of logs-trees next to the road should be retained as "bumper trees" and cut only after skidding operations are finished.

Photo 13. Buttresses not removed prior to skidding can hamper extraction and may damage residual trees and cause excessive soil disturbance.

In general, extraction of logs during the study was carried out in the haphazard way common in many parts of the tropics (see the network of skidtrails in Figure 9). The fellers briefed the operator on areas where they thought most trees had been felled. Based on this information, the tractor operator searched for logs by driving the crawler tractor into the stand towards canopy openings. The operator drove to each log in order to attach the winch line directly around the log. Because the operator was not provided with a map of tree locations, some secondary skidtrails were opened by accident that led to natural canopy gaps in which no tree had been felled.

Due to the hilly terrain in the area studied for this report, the tractor operator had to use favourable terrain features such as ridges and therefore extraction of logs to the landing was generally carried out by retracing the path used to arrive at the log. As a result, the density of secondary skidtrails on the operating area was kept to a reasonable level (see Section 6.4) as compared to conventional logging operations in flat, easy terrain.

Because the trees were not directionally felled in alignment with skidtrails, there was often a need for the crawler tractor to reposition logs for skidding by using the dozer blade. These tractor manoeuvrings at the felling site to align the heavy logs are one of the most devastating activities associated with "conventional" logging. They not only cause damage to residual trees and regeneration but also increase the size of the canopy gap by pushing over additional trees, either accidentally or to gain operating room. Such procedures are not consistent with the concept of reduced-impact logging or with the principles of the PNG Logging Code of Practice.

In general, the purpose of planning and marking skidtrails in advance is to create an extraction network that will allow the crawler tractor to remain on designated skidtrails at all times. The operator's assistant would then pull out the winch line and attach it to a choker cable that had been pre-set around the log to be skidded. However, a prerequisite for such a system to be workable is that a tree location map showing the skidtrail layout must be provided to the felling crew, which would then use directional felling techniques to direct the fall of the trees so that they were aligned with the skidtrails in order to facilitate skidding. This coordination between skidtrail location and felling would minimise the need to manoeuvre the tractor at the felling site in order to reposition logs for skidding. The extraction crew would also use the tree maps to locate the logs for skidding.

Photo 14. Log handling at the landing and loading of logs onto timber lorries is normally done by means of wheeled front-end loaders.

Landings are collection areas to which logs are delivered during the extraction process and prepared for transport to the processing facility or other final destination. Representing the interface between extraction and transport (Dykstra & Heinrich 1996), the landings are located and designed during set-up planning, at the same time that the primary skidtrails and temporary forest roads are located. Generally speaking, each landing is intended to serve an individual set-up only.

Loading of logs onto trucks is mechanised in both of the timber permits that were involved in this study, with wheeled front-end loaders being used (Photo 14). Similar equipment is also used to unload and sort logs at transit landings and at the log ponds.

At the landings within the set-up, logs are temporarily stored for the following reasons:

· To permit the logs to be cut to length, identified and scaled

· Delays in extraction when loading activities are carried out simultaneously

· Delays in log transport due to closure of temporary roads during periods of heavy rain

· Loss of log weight during storage facilitates handling and transport

At the transit landings the logs are temporarily stored for the following reasons:

· To build up a buffer to ensure a continuous supply of timber to the sawmill

· To sort logs by tree species, utilisation groups, or export classes

Photo 15. Log grading at the landing is carried out by log graders in accordance with PNG rules and regulations.

After logs have been cut to length, each log must be tagged at one end with an official PNGFA log tag (Photo 5). This is normally done when logs are scaling at the set-up landing (PNGFA 1996c). In general, no cross-cutting is done outside of the landings except that the unmerchantable portion of the felled tree is removed before being skidded to the landing.

Photo 16. The defective part of the log should have been removed at the felling site.

The responsibility for log scaling lies with the timber permit holder, who may pass it on to the logging contractor or employ independent, licensed log-scaling contractors. However, only log scalers licensed by the PNGFA may scale logs, fill in and sign the Log Scaling Record Sheets which facilitate:

· Charging and collecting royalty payments, and any other volume- and/or species-based payments which may be due

· Control of log production levels agreed from the individual TPs

· Provision of rough forest yield data to be used to estimate potential yield from other similar areas of forest

· Provision of production statistics at project, regional and national level

In PNG timber permits, the transport of logs from the forest to the processing facility or other final destination is generally carried out by company-owned logging trucks. At both study sites, trucks used were Nissan TZA 520 "Jinkers" or the equivalent, equipped with pole trailers and capable of transporting an average load of 25 m³.

From Block 5 where the VFP study site was located, log transport was carried out in two phases. From the landings within the set-ups, sometimes referred to as "bush landings," logs were transported to a "transit landing" at the base camp in Pual. At the two transit landings (at Kilipau and Pual, both in Block 6) logs harvested from Blocks 1, 2, 4, and 5 are stockpiled during the dry season and subsequently transported to Vanimo Log Pond during the wet season on the all-weather main roads established by the developer as part of the project agreement.

The cost of unloading and reloading logs at the transit landing seems to pay off because it provides a year-round, steady supply of logs and full use of machinery such as trucks and loaders while providing more year-round employment opportunities for local people.

Due to the cost of transportation, average transport distance is an important economic factor. The average distance from the transit landing at the base camp in Pual to the company's log pond at Vanimo is about 24 kilometres. The overall average hauling distance for the five-year planning period was estimated to be about 45 kilometres. In order to establish data on travel velocities and truck loads, log hauling from the transit landing at Pual to the Vanimo log pond was observed.

Photo 17. Forest roads of lower standard are used only during dry weather to transport logs from the "bush landing" within the set-up to a "transit landing" located at the base camp.

Five round trips with three different, randomly chosen trucks and drivers were observed by work and time studies. The average transport time per trip was about two and a half hours over an average transport distance of 24 km. The time distribution among the work elements observed was as follows:

Work element |

Time |

Time share |

Travel unloaded |

39 min |

26% |

Loading operation |

12 min |

8% |

Load control and fixing load |

1 min |

1% |

Travel loaded |

50 min |

33% |

Unloading |

8 min |

5% |

Waiting to be loaded or unloaded |

41 min |

27% |

Total time |

2 h 31 min |

100% |

Travel time unloaded was about three-quarters of the travel time when loaded. The average travel velocity unloaded was about 40 km/h against 30 km/h for loaded trucks. The average travel velocity was calculated from the known distance and measured travel time for each round trip. However, the highest average travel velocity when unloaded, 43.6 km/h, gives an indication of the practical speed limits on these roads. The highest speedometer reading while travelling in this quite new Jinker was near the 50 km/h mark.

Photo 18. Risk of bridge failure sometimes forces unconventional solutions-here a timber lorry is pulled through a stream by a bulldozer.