Although forest harvesting is machine-intensive, labour remains the most critical element (Dykstra & Heinrich 1996) if harvesting is to be conducted efficiently and in an environmentally sound way. Only workers who are healthy, competent to fulfil their jobs, and motivated to work properly and efficiently, can be expected to contribute effectively to achieve the goals of environmentally sound forest harvesting.

Timber project agreements normally place a high priority of landowners' participation in resource development and give employment preference to landowners. For Vanimo Forest Products, for example, Sandaun Province has been the company's priority recruiting area. When local skills and capabilities can be matched with company needs, the company has availed itself of the opportunity (VFP 1990a) and local recruits have been hired to fill positions through the entire range from unskilled workers to middle and senior management.

However, minimum requirements such as physical condition, skills, and personal interest of workers have to be taken into account when selecting them for work in forest harvesting. Since the health of workers is not only based on physical conditions, special attention must be paid to safety, adequate standards of comfort, sanitation, food, and welfare by the company. Adequate training as appropriate for job requirements and satisfactory working conditions should be viewed by companies as effective motivators since they not only contribute to improved safety but also to improved efficiency.

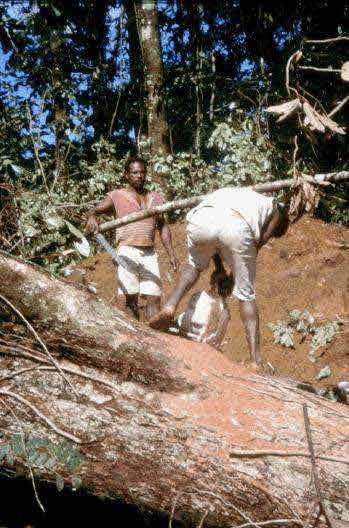

Photo 19. Safety gear is still considered "exotic"-not even shoes or helmets seem to be considered essential by these chainsaw operators.

In the companies visited for this study, the only training that is carried out on a regular basis is for inventory crews. This is done when the harvesting frontier moves to the next customary ownership parcel and new landowners have to be recruited in compliance with the agreements. Inventory training includes at least the following:

· Identification of commercial tree species

· Measurement of trees

· Quality criteria for harvestable trees

· Field organisation for the pre-logging inventory

As mentioned in Section 3.3, the basic knowledge available in felling, acquired by doing rather than by following a training programme, is passed on from chainsaw operators to assistants who are then most likely to become the next generation of chainsaw operators. Although in some cases this will result in highly competent operators, it is more common that assistants acquire the same bad habits as the chainsaw operators from whom they learn. Training programmes for felling crews should include the following:

· Felling safety

· Proper cutting and directional felling techniques

· Maintenance of chainsaw and chain sharpening

· Field organisation of felling activity

· Use of tree location/felling maps

· Criteria for deciding whether or not to fell a marked tree

Practical training for extraction crews should include the following:

· Field considerations for reducing the damage to the remaining forest stand

· Field organisation of the extraction activities

· Use of tree location/extraction maps

Labour cost data summarised in Table 7 are based on information provided by VFP (1990b). Although undoubtedly out of date, the information should provide a reasonable understanding of the relative compensation levels for different positions of responsibility. Information from SBLC and gathered during discussions with workers in the field suggest that salaries in general are about 10% higher than in 1990. Extreme caution should be exercised when using the labour cost information in Table 7 for analysis due to the considerable inflation rates of PNG's currency over the last few years.

Table 7. Forest employee salaries (Source: VFP 1990b).

Operation and job title |

Monthly salary |

Operation and job title |

Monthly salary |

Management |

|

Forest inventory |

|

Production manager |

K 1,850 |

Survey manager |

K 1,050 |

Logging manager |

K 1,500 |

Survey supervisor |

K 800 |

Roading manager |

K 1,500 |

Survey crew |

K 225 |

Logging supervisor |

K 1,050 |

Logging |

|

Roading supervisor |

K 1,050 |

Skidding crew |

K 225 |

Log grader |

K 850 |

Miscellaneous |

|

Forester |

K 600 |

General workers |

K 225 |

The effective work-time is eight hours per day. If the work-time exceeds 8 hours an extra 50% of the hourly rate has to be paid. In addition, there is a daily "camping" and "food" allowance when staying in the bush camps. According to the information provided by VFP (1990b), the monthly salaries of truck drivers, machine operators (skidder, crawler and loader operator; 100%) and their assistants, are more or less the same. However, the logging contractor of SBLC distinguishes between different occupations and responsibilities between and within the crews. For the inventory crew, the hourly salaries range from crew leader (100%) and compass man (92%) to the other crew members such as chain men and brushers (83%).

For comparison, in a forest estate in the Amazon region of Brazil where a company applies environmentally sound harvesting in tropical forest, wages differ according to job description (Winkler 1997) and range from truck driver (100%), crew leader (72%), machine operator (skidder, crawler and loader operator; 71%) and chainsaw operator (64%) to assistant (34%). This shows the different importance attributed to certain occupations in "traditional logging" versus "environmentally sound forest harvesting" as applied by the company in Brazil where a trained harvesting workforce is among the company's priorities.