Steel drums can be used to make a simple washing stand. The drums are cut in half, fitted with drain holes, and all the metal edges are covered with split rubber or plastic hose. The drums are then set into a sloped wooden table. The table top is constructed from wooden slats and is used as a drying rack before packing.

Because steel drums are often used to store petroleum and chemical products, they should be thoroughly cleaned before being used as a washing stand.

Source: Grierson, W. 1987. Postharvest Handling Manual. Commercialization of Alternative Crops Project. Belize Agribusiness Company/USAID/Chemonics International Consulting Division.

This tank for washing produce is made from galvanized sheet metal. A baffle made of perforated sheet metal is positioned near the drain pipe and helps to circulate water through the produce. Fresh water is added under pressure through a perforated pipe, which helps move floating produce toward the drain end of the tank for removal after cleaning.

Improvements to the design shown below might include a removable trash screen in front of the baffle, and/or a re-circulating system for the wash water (with the addition of chlorine).

FAO. 1989 . Prevention of Postharvest Food Losses: Fruits Vegetables and Root Crops. A Training Manual. Rome : UNFAO. 157 pp.

Chlorination of wash water is very important. Chlorine can reduce the spread of contamination form one item to another during the washing stage. The pH of the wash water should be maintained at 6.5 to 7.5 for best results.

Typically 1 to 2 mls of chlorine bleach per liter of clean water will provide 100 to 150 ppm total Cl. More chlorine will be required if temperatures are high or if there is a lot of organic matter in the wash water.

The waxing device illustrated here is designed to be used after a series of dry brushes on a conveyor line. Industrial wool felt is used to distribute the liquid wax to the fruits or vegetables from a trough made the same width as the belt. Evaporation of wax from the felt is reduced by covering the felt with a layer of heavy polyethylene sheeting.

Source: Martin, D and Miezitis, E.O. 1964. A wipe-on device for the application of materials to butts. Field Station Record Volume 3 No. 1 CSIRO Tasmanian Regional Laboratory, Hobart , Tasmania .

The table illustrated below is a combination sorting and packing stand. Incoming produce is placed in the sorting bin, sorted by one worker into the packing bin, and finally packed by a second worker. If workers must stand to sort produce, a firm rubber pad for the floor can help reduce fatigue.

Source: FAO. 1986. Improvement of Post-Harvest Fresh Fruits and Vegetables Handling- A Manual. Bangkok : UNFAO Regional Office for Asia and the Pacific.

The surface of the portable sorting table illustrated below is constructed from canvas and has a radius of about 1 meter (about 3 feet). The edges are lined with a thin layer of foam to protect produce from bruising during sorting, and the slope from the center toward the sorter is set at 10 degrees. Produce can be dumped onto the table from a harvesting container, then sorted by size, color and/or grade, and packed directly into shipping containers. Up to 4 sorters/packers can work comfortably side by side.

Source: PHTRC. 1984. A portable sorting table. Appropriate Postharvest Technology 1(1):1-3. (Post-Harvest Training and Research Center , Department of Horticulture, University of the Philippines at Los Banos.)

When sorting for rejects, and removing any product that is too small, decayed or damaged, the height of the sorting table should be set at a level comfortable for sorters. Stools, or a firm rubber pad on which to stand, can be provided to reduce fatigue. Locations of the table and the sorting bins should be chosen to minimize hand movements.

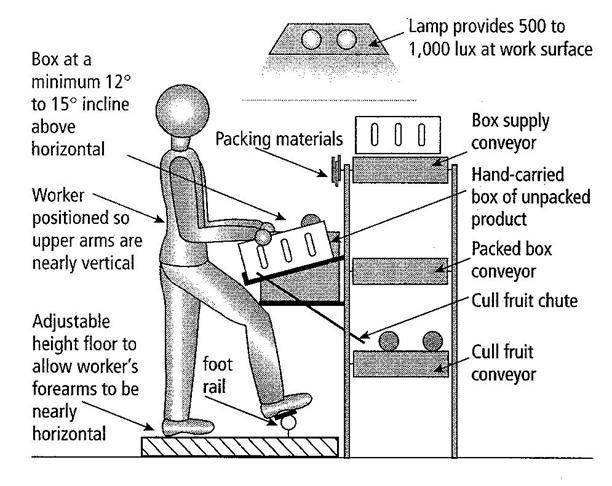

It is recommended that the workers' arms create a 45 degree angle when s/he reaches toward the table, and that the width of the table be less than 0.5 meter to reduce stretching. Good lighting (500 to 1000 lux at work surface) will enhance the ability of the sorter to spot defects, and dark, dull belts or table tops can reduce eye strain.

If a conveyor system is in use, the product must not flow too fast for the sorters to do their work. The rotational speed of push-bar or roller conveyors should be adjusted to rotate the product twice within the immediate field of view of the worker. Periodical rotation of worker positions on the line will help to reduce monotony and fatigue. Supervisors should be able to quickly identify under-sorting and over-sorting.

Source: Shewfelt, R.L. and Prussia , S.E. 1993. Postharvest Handling: A Systems Approach. San Diego : Academic Press Inc. 356 pp.

The following illustration shows the key features of a well deisgned sorting/grading station:

Thompson, J,F. et al. 2002. Preparation for Fresh Market. pp. 67-79 IN: Kader, A.A. Postharvest Technology of Horticultural Crops (3rd Edition). UC Publication 3311. University of California, Division of Agriculture and Natural Resources

The following illustrations represent three types of conveyors used to aid sorting of produce. The simplest is a belt conveyor, where the sorter must handle the produce manually in order to see all sides and inspect for damage. A push-bar conveyor causes the produce to rotate forward as it is pushed past the sorters. A roller conveyor rotates the product backwards as it moves past the sorter.

Belt conveyor:

Push-bar conveyor:

Roller conveyor:

Source: Shewfelt, R.L. and Prussia , S.E. 1993. Postharvest Handling: A Systems Approach. San Diego : Academic Press Inc. 356 pp.

Round produce units can be graded by using sizing rings. Rings can be fashioned from wood or purchased ready-made in a wide variety of sizes.

Single size hand held sizing ring:

Multiple size rings:

Source: FAO. 1989. Prevention of Postharvest Food Losses: Fruits, Vegetables and Root Crops. A Training Manual. Rome : UNFAO. 157 pp.

Quality grades and size standards for many horticultural commodities can be found on the USDA website:

http://www.ams.usda.gov/standards/stanfrfv.htm

The onion sizing table illustrated below is one of three (or more) tables used in a stairway fashion. Each table is made of plywood, and has been perforated with holes of a specific size. The uppermost table has the largest size holes, and the lowest table has the smallest holes. A layer of onions is dumped onto the uppermost table. Those that do not pass through are classified as "extra-large'' in size. Those that pass through the holes in the table fall into a mesh bag and roll into a large container. This container of onions is dumped onto the second sizing table. The onions that do not pass through are classified as "large", and so on.

Source: Reyes, M. U. (Ed.) 1988. Design Concept and Operation of ASEAN Packinghouse Equipment for Fruits and Vegetables. Postharvest Horticulture Training and Research Center , University of Los Baños , College of Agriculture , Laguna , Philippines .

The citrus fruit sizer illustrated below is composed of a rectangular chute made of plywood, padded with foam to prevent bruising. The fruit is dumped into the octagonal platform at the top of the chute, then allowed to roll, one by one, down toward a series of constrictions. Large fruits are caught in the first constriction, medium in the second, and small in the last. Undersized fruit passes out the end of the chute directly into a container. Workers must manually remove each fruit and place it into the appropriate size container before the next fruit can pass through the chute. The sizing is fastest when five workers are stationed at the sizer.

Source: Reyes, M. U. (Ed.) 1988. Design Concept and Operation of ASEAN Packinghouse Equipment for Fruits and Vegetables. Postharvest Horticulture Training and Research Center , University of Los Baños , College of Agriculture , Laguna , Philippines .

If a conveyor system is used in the packinghouse, a wide variety of sizing chains and belts are available for sorting produce. Sizing chains can be purchased in many widths and in any size opening.

Square openings are usually used for commodities such as apples, tomatoes and onions, while rectangular openings are used for peaches and peppers. Hexagonal openings are often used for potatoes and onions.

Square:

Rectangular:

Hexagonal:

Source: 2001 Catalog of TEW Manufacturing Corporation, P.O. Box 87 , Penfield , New York 14526 USA

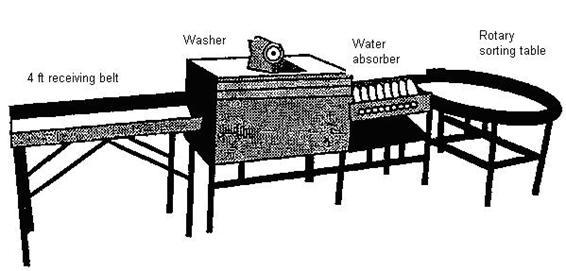

Small scale equipment for packing produce is available from several manufacturers and suppliers. Illustrated below is a fruit packing line, available from TEW Manufacturing Corporation at a cost of US$ 5000 to $6000, depending upon size. This particular model includes a receiving belt, washer, water absorber and sorting table. Optional equipment includes eliminator, dry brusher, waxer, and a variety of sizers, rolling inspection belts, conveyor belts and side tables.

Source: 2001 Catalog of TEW Manufacturing Corporation, P.O. Box 87 , Penfield , NY 14526 USA