Throughout the entire handling system, packaging can be both an aid and a hindrance to obtaining maximum storage life and quality. Packages need to be vented yet be sturdy enough to prevent collapse. If produce is packed for ease of handling, waxed cartons, wooden crates or rigid plastic containers are preferable to bags or open baskets, since bags and baskets provide no protection to the produce when stacked. Sometimes locally constructed containers can be strengthened or lined to provide added protection to produce. Waxed cartons, wooden crates and plastic containers, while more expensive, are cost effective when used for the domestic market. These containers are reusable and can stand up well to the high relative humidity found in the storage environment. Adding a simple cardboard liner to a crate will make it less likely to cause abrasion to produce.

Containers should not be filled either too loosely or too tightly for best results. Loose products may vibrate against others and cause bruising, while over-packing results in compression bruising. Shredded newspaper is inexpensive and a lightweight filler for shipping containers (Harvey et al, 1990).

For small-scale handlers interested in constructing their own cartons from corrugated fiberboard, Broustead and New (1986) provide detailed information. Many types of agricultural fibers are suitable for paper making (Hunsigi, 1989), and handlers may find it economically sensible to include these operations in their postharvest system. Corrugated fiberboard is manufactured in four flute types—type B (1/8 inch in height, 47 to 53 flutes per inch; with a basis weight of 26 lb per 1,000 ft 2) is the most commonly used for handling perishables (Thompson in Kader, 2002).

Whenever packages are handled in a high humidity environment, much of their strength is lost. Collapsed packages provide little or no protection, requiring the commodity inside to support all of the weight of the overhead load. Packing is meant to protect the commodity by immobilizing and cushioning it, but temperature management can be made more difficult if packing materials block ventilation holes. Packing materials can act as vapor barriers and can help maintain higher relative humidity within the package. In addition to protection, packaging allows quick handling throughout distribution and marketing and can minimize impacts of rough handling.

Produce can be hand-packed to create an attractive pack, often using a fixed count of uniformly sized units. Packaging materials such as trays, cups, wraps, liners and pads may be added to help immobilize the produce. Simple mechanical packing systems often use the volume-fill method or tight-fill method, in which sorted produce is delivered into boxes, then vibration settled. Most volume-fillers are designed to use weight as an estimate of volume, and final adjustments are done by hand (Mitchell in Kader, 2002).

Ethylene absorber sachets placed into containers with ethylene sensitive produce can reduce the rate of ripening of fruits, de-greening of vegetables or floral wilting.

Packaging in plastic films can modify the atmosphere surrounding the produce (modified atmosphere packaging or MAP). MAP generally restricts air movement, allowing the product's normal respiration processes to reduce oxygen content and increase carbon dioxide content of the air inside the package. An additional major benefit to the use of plastic films is the reduction of water loss.

MAP can be used within a shipping container and within consumer units. Atmospheric modification can be actively generated by creating a slight vacuum in a vapor sealed package (such as an un-vented polyethylene bag), and then replacing the package atmosphere with the desired gas mixture. In general, lowering oxygen and increasing carbon dioxide concentrations will be beneficial for most commodities (see the tables of recommended gas mixtures for C.A. and M.A. storage and transport of various crops, Chapter 7). Selection of the best polymeric film for each commodity/package size combination depends upon film permeability and the respiration rate of the commodity under the expected time/temperature conditions during handling. Absorbers of oxygen, carbon dioxide and/or ethylene can be used within packages or containers to help maintain the desired atmospheric composition.

Modified atmosphere packaging should always be considered as a supplement to proper temperature and relative humidity management. The differences between beneficial and harmful concentrations of oxygen and carbon dioxide for each kind of produce are relatively small, so great care must be taken when using these technologies.

The packing stand illustrated in the diagram below can be bolted to a second stand of the same construction if more space is required for packing produce. When trimming is necessary, add a loose board, thick enough to reach above the height of the front rail. The front rail should be smooth and rounded.

Source: Grierson, W. 1987. Postharvest Handling Manual: Commercialization of Alternative Crops Project Belize Agribusiness Co./Chemonics International Consulting Division/USAID.

A simple field packing station can be constructed from wooden poles and a sheet of polyethylene. Thatch over the roof will provide shade and keep the station cool. The structure should be oriented so that the roof overhang keeps out the majority of the sun's rays.

Source: Grierson, W. 1987 Postharvest Handling Manual: Commercialization of Alternative Crops Project. Belize Agribusiness Co./ Chemonics International Consulting Division/USAID.

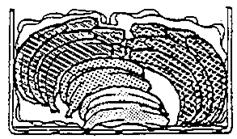

Hands of bananas, after undergoing washing to remove latex and perhaps spraying with fungicides, are typically packed into cardboard containers lined with polyethylene. The following illustrations depict one method of filling a container with the fruit in order to ensure less damage during transport. Note that the polyethylene liner is folded up over the bananas before closing the box.

(a) Wide, flat medium-to-small hand in middle of compartment

(b) Medium-length, wide hand on top, crown not touching fruit below

(c) Medium-to-short length, wide hand, crown not touching fruit below

(d) One large hand, or two clusters with long fingers

Source: FAO. 1989 . Prevention of Postharvest Food Losses: Fruits. Vegetables and Root Crops. A Training Manual. Rome : UNFAO. 157 PP.

A circular rotating table can be used to pack a variety of crops. The produce is fed in along a conveyor or if no conveyor is in use, simply put onto the table, where packers select the produce and fill cartons at their stations. In the illustration below, a discard belt has been added below the supply belt, allowing easy disposal of culls.

Each packer can work independently, trimming as needed and check weighing cartons on occasion.

Source: National Institute of Agricultural Engineering. 1979. Preparing vegetables for supermarkets. Field Vegetable Department, Silsoe, Bedford : NIAE

Sacks are often used to package produce, since they tend to be inexpensive and readily available. The following table provides some information regarding the characteristics of different kinds of materials used to make sacks. None of the types of sacks available are good for protecting fresh produce, and they should be avoided whenever possible.

Characteristics of sacks as packaging units

| Sack types |

Tearing and snagging |

Impact |

Protection against |

Contamination |

Notes |

|

|

Moisture absorption |

Insect invasion |

|||||

|

Jute |

Good |

Good |

None |

None |

Poor, also cause contamination by sack fibers |

Bio-deterioration. |

|

Cotton |

Fair |

Fair |

None |

None

|

Fair |

High re-use value. |

|

Woven plastics |

Fair-Good |

Good |

None |

Some protection (if closely woven) |

Fair |

Badly affected by ultra-violet light. Difficult to stitch. |

|

Paper |

Poor |

Fair-Poor |

Good - WFP multi-wall sacks have plastic liners. |

Some protection, better if treated. |

Good |

Consistent quality. Good print. |

Source: Walker, D.J. (Ed) 1992. World Food Programme Food Storage Manual. Chatham , UK : Natural Resources Institute

The table below provides examples of some types of typical mechanical damage and their effect on packaging containers.

|

Type of damage |

Container |

Result |

Important factors |

|

Impact damage through dropping |

Sacks - woven and paper |

Splitting of seams and material causing leaking and spillage loss.

|

Seam strength |

|

Fiberboard boxes |

Splitting of seams, opening of flaps causing loss of containment function. Distortion of shape reducing stacking ability. |

Bursting strength Closure method |

|

|

Wooden cases |

Fracture of joints, loss of containment function. |

Fastenings |

|

|

Cans and drums |

Denting, rim damage. Splitting of seams and closures causing loss of containment and spoilage of contents.

|

|

|

|

Plastic bottles |

Splitting or shattering causes loss of contents.

|

Material grade |

|

|

Compression damage through high stacking |

Fiberboard boxes |

Distortion of shape, seam splitting causing loss of containment and splitting of inner cartons, bags, and foil wrappings. |

Box compression strength |

|

Plastic bottles |

Distortion, collapse and sometimes splitting, causing loss of contents.

|

Design, material, wall thickness |

|

|

Vibration |

Corrugated fiberboard cases |

Become compressed and lose their cushioning qualities. Contents more prone to impact damage.

|

Box compression strength |

|

Snagging, tearing, hook damage |

Sacks - woven and paper |

Loss of containment function - spillage (more severe with paper sacks).

|

Tear strength |

|

Tins |

Punctured, loss of contents.

|

Metal thickness |

Source: Walker, D.J. (Ed.) 1992. World Food Programme Food Storage Manual. Chatham , UK : Natural Resources Institute

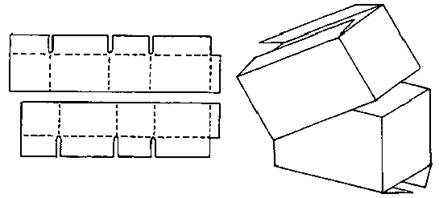

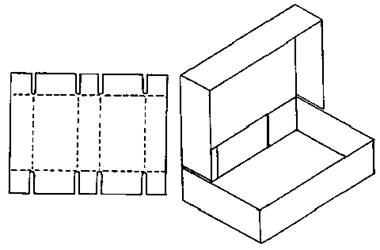

The diagrams below are for a variety of commonly used fiberboard containers. Final dimensions can be altered to suit the needs of the handler, and all containers should have adequate vents. Cartons can be glued, taped or stapled as desired during construction at the packinghouse.

One piece box:

Two-piece box with cover:

Source: McGregor, B. 1987. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

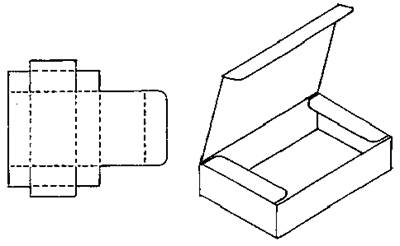

The diagrams below are for a variety of commonly used fiberboard containers. Final dimensions can be altered to suit the needs of the handler, and all containers should have adequate vents.

Bliss-style box:

Full telescoping box:

Source: McGregor, B. 1987. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

The diagrams below are for a variety of commonly used fiberboard containers. Final dimensions can be altered to suit the needs of the handler, and all containers should have adequate vents.

One-piece telescoping box:

One-piece tuck-in cover box:

Source: McGregor, B. 1987: Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

The diagrams below are for a variety of commonly used fiberboard containers. Final dimensions can be altered to suit the needs of the handler, and all containers should have adequate vents.

Self-locking tray:

Interlocking box:

Source: McGregor, B. 1987. Tropical Products Transport Handbook. USDA, Office of Transportation, Agricultural Handbook Number 668.

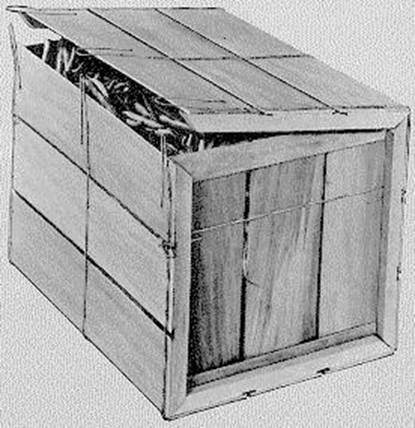

Containers can be constructed from wood and wire, using the general diagrams provided below. A special closing tool makes bending the wire loops on the crate's lid easier for packers to do. Wire-bound crates are used for many commodities including melons, beans, eggplant, greens, peppers, squash and citrus fruits. Package Research Laboratory ( 41 Pine Street , Rockaway , New Jersey 07866 ) can provide a list of suppliers in your area.

Here is a simple illustration of the parts of a wooden crate.

Ends:

Blank for body:

Source: Peleg, K. 1985. Produce Handling Packaging and Distribution. Westport , Conn. : AVI publishing Co., Inc.

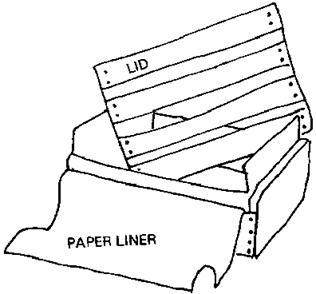

A wooden lug is the typical packing container for table grapes. This container is very sturdy and maintains its stacking strength over long periods of time at high relative humidity. Rigid plastic containers are also widely used.

Often, a paper liner is folded over the grapes before the top is nailed closed. The liner protects the produce from dust and water condensation. If a pad containing sulfur dioxide can be enclosed with the grapes within a plastic liner as a treatment to control decay. Most commodities other than table grapes can be damaged (bleached) by sulfur dioxide treatments.

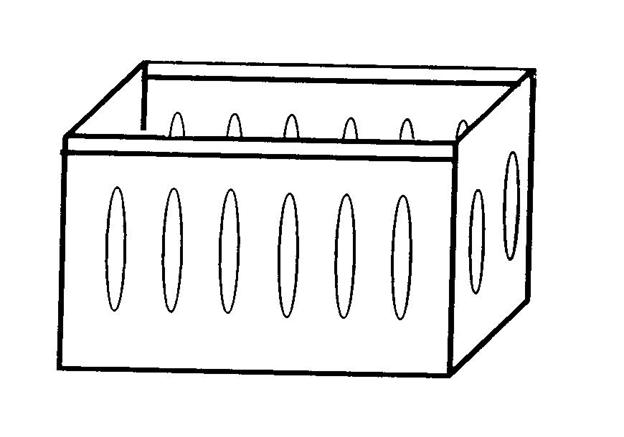

Rigid plastic or wooden containers are also used extensively for asparagus. The trimmed spears are packed upright in containers that provide for a large amount of ventilation.

For domestic marketing, plastic crates provide excellent protection for produce and adequate ventilation during handling, cooling, transport and storage. Some plastic crates are collapsible or can be nested when stacked for easier handling when empty. Crates should be cleaned on a regular basis with chlorinated water and detergent to reduce the chances of spreading decay from one load to the next.

Containers for cut flowers are often long and narrow, of full telescopic design with vents at both ends to facilitate forced-air cooling. The total vent area should be 5% of the total box surface area. A closable flap can help maintain cool temperatures if boxes are temporarily delayed in transport or storage in an uncontrolled temperature environment.

Source: Rij, R. et al. 1979. Handling, precooling and temperature management of cut flower crops for truck transportation. USDA Science and Education Administration, AAT-W-5, 26 pp (Issued jointly as University of California Division of Agricultural Sciences Leaflet 21058).

A simple wooden tray with raised corners is stackable and allows plenty of ventilation for fragile crops such as ripe tomatoes.

Source: FAO. 1985. Prevention of Post-Harvest Food Losses: A Training Manual. Rome : UNFAO. 120pp