Thierry Facon1

Summary

The vast and expanding body of literature on the performance of irrigation systems reflects the expanding circle of specialists, disciplines and stakeholders interested in evaluating the performance of irrigation systems. The selection of a particular set of performance indicators reflects a particular perspective and has a significant influence on the specific objectives of system management and improvement. It also has a significant influence on the details of interventions and the changes considered.

Efforts to improve irrigation performance in Asia have to a large extent concentrated on “irrigation efficiency” and on-farm water management and, more recently, on governance and institutional issues, mostly to improve cost recovery. Aspects related to design and operation of irrigation systems and service delivery have been neglected and this neglect is also reflected in many irrigation development and rehabilitation programmes. As a result, farmers often have not seen much improvement in the water delivery service provided by the systems and results in terms of agricultural and economic performance and irrigation efficiency have been disappointing.

The selection by FAO of the rapid appraisal process (RAP), developed by the Irrigation Training and Research Centre of California Polytechnic University, and its further development for FAO and the World Bank, as a methodology for appraisal of conditions and performance of irrigation systems, have been consistent with the promotion of irrigation modernization understood as “a process of technical and managerial upgrading (as opposed to mere rehabilitation) of irrigation schemes with the objective to improve resource utilization (labour, water, economic resources, environmental resources) and water delivery service to farms” and the promotion of a service orientation in the irrigation sector.

A recent series of appraisals of large and medium-scale irrigation systems by FAO and partner national irrigation agencies in eight countries in Asia by trainees of national workshops organized under a Regional Irrigation Modernization Training Programme using RAP shows that system performance and service delivered to farmers are poor but could be improved significantly with changes in design, operation and management that can easily be introduced. The level of chaos (difference between stated policies and actual policies) and of anarchy (subversion of policies) in the appraised systems is high. Lack of discipline and institutional issues contribute greatly to this situation. However, many of the problems can be traced to: problems in initial design; exporting of design concepts outside of their area of validity; difficulty of controlling and operating the systems; layouts with confused hierarchies; serious flaws in operation strategies; inconsistencies between operating rules at various levels and between operating rules and farmers’ requirements; changes in farmers’ requirements not reflected by changes in system policies; poor quality of water delivery service to farms; and lack of flexibility at all levels. Improving the efficiency of service delivery and the level of service delivered by these systems will require addressing these issues by identifying and effecting appropriate changes.

Benchmarking is defined as a systematic process for achieving continued improvement in the irrigation sector through comparisons with relevant and achievable internal or external goals, norms, and standards. The overall aim of benchmarking is to improve the performance within an irrigation scheme by measuring its performance against its peers and its own mission and objectives. The benchmarking process should be a continuous series of measurement, analysis, and changes to improve the performance of the schemes. The evaluation and analysis stages of the “holistic” benchmarking promoted by the World Bank form three legs of the benchmarking stool: evaluation of technical indicators (both internal and external); appraisal of the system processes; evaluation of service to users and their satisfaction with that service. RAP, which was included as a component of the “holistic” benchmarking, concentrates on the evaluation of the system processes and the evaluation of the service at all levels in the system, from water supply to the scheme to the farm. It also assists in the evaluation of the International Programme for Technology and Research in Irrigation and Drainage (IPTRID) benchmarking indicators.

For benchmarking to go beyond the measurement and analysis stages, and on to the implementation of changes and improvement stages, there must be significant acceptance by project personnel. The data collection and analysis are thus incorporated into a training programme that integrally involves local management and operation and maintenance staff. Staff learn the concepts of modernization and are provided with a toolbox of options. Then they evaluate their own project with RAP. At the end of the training, internal and external indicators are developed for the project and the local staff develop a priority list for changes in software and hardware based on the internal process and service indicators, which appraise all factors that affect system performance and service delivery in a systematic and standardized manner. The purpose of the appraisal is to improve specific characteristics and levels of service delivery, and to achieve improvement objectives as defined by the external performance indicators.

It has been argued that RAP cannot be considered as performance benchmarking on the grounds that it focuses on planning investment in modernization of water control infrastructure, requires well-trained and experienced engineers, does not lend itself to regular application on a large number of schemes and does not use comparison, over time and between schemes, as the basis for identifying performance gaps and planning improvements. RAP does use comparison over time and between schemes and assesses all processes of management and operation as well as hardware and can be and is applied over a large number of schemes. It can therefore be a useful and critical component of a national benchmarking programme aiming at improvement of sectoral performance if used at the inception of the programme, or to evaluate the impact of improvement projects. It does require well-trained and experienced engineers; but significant improvement in the sector’s performance in Asia will require well-trained and experienced planners, designers, managers and operators. For this reason, FAO and national irrigation agencies have introduced RAP within a training programme where trainees appraise their own systems with the support of a team of expert appraisers and trainers from the central office.

It has been affirmed that the benchmarking process will only be applied where managers “embrace the goal of pursuing best management practices within a service oriented management system” and that this implies a focus on the quality and cost-effectiveness of service delivery. This is the most original feature and central message of RAP. By appraising service quality at all levels of system management and concentrating on service interfaces between the different levels, RAP facilitates taking into account the objectives and concerns of most stakeholders at all levels, from the upper level managers, to the Water Users Associations (WUAs), to the farmers who receive service from them and provides a common language to discuss performance and system objectives. RAP is also a useful addition to asset management methodologies which focus on asset condition and serviceability.

Future development of the tool will focus on developing additional indicators to better address drainage and water disposal services, the multiple roles provided by the irrigation systems, including those concerning the environment and biodiversity, and water users from sectors other than agriculture, in order to better serve multistakeholder participatory or strategic planning and management processes. RAP has been an effective performance appraisal tool which has been consistent with FAO’s concepts of modernization adopted to this date. RAP will evolve as these evolve in the future.

Introduction

The performance of irrigation systems is the subject of a vast and fast expanding body of literature. As the debate on irrigation and its reputed poor performance intensifies and involves broadening circles of stakeholders and disciplines, the many different points of view are reflected in new evaluation procedures, methodologies and indicators that focus on the perspectives of their proponents.

The use of any particular set of performance indicators is thus the object of a radical critique by some on the grounds that these reflect the point of view of a dominant group and are, furthermore, based on very dubious data sets. For this reason, international institutions are now cooperating on the development of stakeholder-oriented valuation methods and decision-making processes reflecting the multiple roles of and perspectives on irrigation systems.

Meanwhile, specific indicators, methodologies for their assessment, and their values, continue to be among the favorite topics for argument within each discipline, and particularly the indicators related to efficiency and productivity.

The performance of irrigation systems is therefore a controversial, complex and evolving topic, which is central to the debate on the future evolution of irrigation systems. The selection of a set of performance indicators and how these are assessed is now understood to be non-neutral and to influence to a large extent the objectives, planning and design of interventions meant to improve the performance of the systems, as well as the actions taken by system managers.

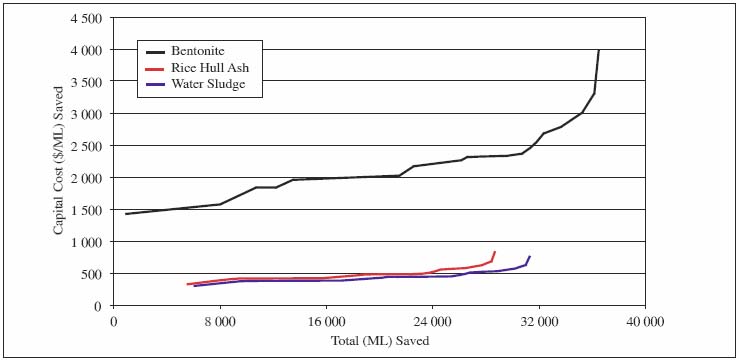

On a more practical level, the understanding of the notion of irrigation efficiency by irrigation engineers and managers is very important in shaping investment in the sector. For instance, the estimation of the efficiency of an irrigation system as the product of the conveyance efficiencies of the successive levels of distribution of an irrigation system and of the on-farm application efficiency, was the foundation for irrigation projects based on the reduction of conveyance losses in the conveyance and distribution network, mostly through canal lining, and on the improvement of on-farm application efficiency. Although this approach has long been discarded by specialists in favour of water accounting/water balance based system efficiency indicators, it is still widely prevalent in a number of irrigation agencies’ design manuals and continues to be the basis for project planning and design.

FAO’s promotion of irrigation modernization and the importance of performance assessment

FAO, particularly in Southeast Asia, has concentrated its efforts in recent years on the promotion of the modernization of irrigation systems.

At a regional consultation in Bangkok, 1996 (FAO, 1997), the following definition was proposed for the modernization of irrigation systems:

“Irrigation modernization is a process of technical and managerial upgrading (as opposed to mere rehabilitation) of irrigation schemes with the objective to improve resource utilization (labour, water, economic resources, environmental resources) and the water delivery service to farms.”

This definition of the modernization of irrigation systems, which focuses on the provision of water delivery service to farmers, on service-oriented management, on the improvement of utilization of all resources, and on modernization as a process of technical and managerial (including institutional) change to meet farmers’ evolving service requirements, has been the guiding principle for FAO’s activities in the region and, quite naturally, for the selection and development of performance appraisal tools and methodologies.

In particular, FAO has been calling for a massive retraining of engineers and managers in irrigation agencies, consulting firms and irrigation service providers in Asia (FAO, 2002) in order to introduce and provide knowledge and ways and means to design, manage and operate irrigation systems economically for improved performance and adequate service to farmers as they aspire to improved socio-economic well-being, evolve toward more commercial forms of agriculture and face the challenges of globalization, the move towards integrated water resources management in the river basins, and intensifying competition for water from other sectors.

This emphasis on training and capacity building arose from: i) the results of a large-scale evaluation of the performance of the introduction on modern water control and management practices carried out for the World Bank (FAO, 1999), which indicated that the lack of knowledge of proper options was a main reason for the mitigated success of irrigation modernization projects; ii) the disappointing performance of irrigation management transfer and participatory irrigation management projects, which was partly attributed to the failure of these reforms to improve the service to farmers, and lack of attention to operation, design and other technical aspects (Barker and Molle, 2005) of irrigation systems. Intensified and ongoing training programmes for both professionals in the reformed irrigation agencies and consulting firms who would provide advisory services to WUAs, and to the managers of WUAs and the technical staff that they may employ for operation and maintenance of their irrigation schemes, were thus understood as one of the conditions of the sustained success of the transfer programmes.

An appraisal of initial conditions and performance of the systems to be transferred was estimated to be instrumental in allowing both a better design and strategic planning of physical improvements together with a definition of the service to be provided both by the irrigation service provider to WUAs and by WUAs to their members, with indications on ways and means to achieve these service goals and improve them in the future.

FAO’s regional training programme on irrigation modernization and benchmarking

FAO has developed over recent years a regional training programme on irrigation modernization. This programme aims at disseminating modern concepts of service-oriented management of irrigation systems in member countries with a view to promoting the adoption of effective irrigation modernization strategies in support of agricultural modernization, improvement of water productivity and integrated water resources management. FAO has developed training materials and detailed curricula, as well as specific tools for the appraisal of irrigation systems for benchmarking and the development of appropriate modernization plans for irrigation systems. The first training workshop under the programme was organized in Thailand in 2000. Since then India (Andhra Pradesh), Indonesia, Malaysia, Nepal, Pakistan, the Philippines, Thailand, Turkmenistan and Viet Nam have had the support of the regional training programme to organize national training workshops on irrigation modernization and benchmarking. More than 500 engineers and managers have now been trained with support from the programme.

The programme is starting to have an impact in member countries. The Royal Irrigation Department of Thailand is using the tools and methodologies introduced by the programme for the appraisal of projects, and has included the training workshops in its regular training programme. In Viet Nam, a World Bank funded investment project (the Viet Nam Water Resources Assistance Project) has a large irrigation modernization component based on the concepts introduced through initial training at project preparation stage, which was instrumental in the adoption of revised design criteria. The Department of Irrigation and Drainage (DID) of Malaysia has included the training programme and its tools in its quality and modernization strategies: proposals for modernization of the rice granary systems of the country now have to be submitted to decision-makers based on modernization plans developed by system managers following their training and the appraisal of their systems with the FAO rapid appraisal process (RAP). RAP has been adopted by the World Bank as one of the three elements of its holistic benchmarking methodology for irrigation systems. In the World Bank sourcebook for investment in agricultural water management (World Bank, 2005), the training programme is suggested to agencies wishing to invest in improving operations and maintaining large irrigation systems.

Providing the services needed by the farmers, now and in the future, is a considerable challenge for irrigation planners and managers. This paper proposes recommendations based on the lessons learned from the FAO training programme, focusing on details and aspects of the systems that are not frequently analyzed: the appraisal of the irrigation systems by the programme’s trainees using RAP; their proposals for improvement of the systems; and the use of RAP itself.

RAP, the training programme and benchmarking

RAP and why it was selected and introduced

RAP was originally developed by the Irrigation Training and Research Centre of California Polytechnic University in 1996/97 as a diagnostic and evaluation tool for a research programme financed by the World Bank on the evaluation of the impact of the introduction of modern control and management practices in irrigation on the performance of irrigation systems (FAO, 1999).

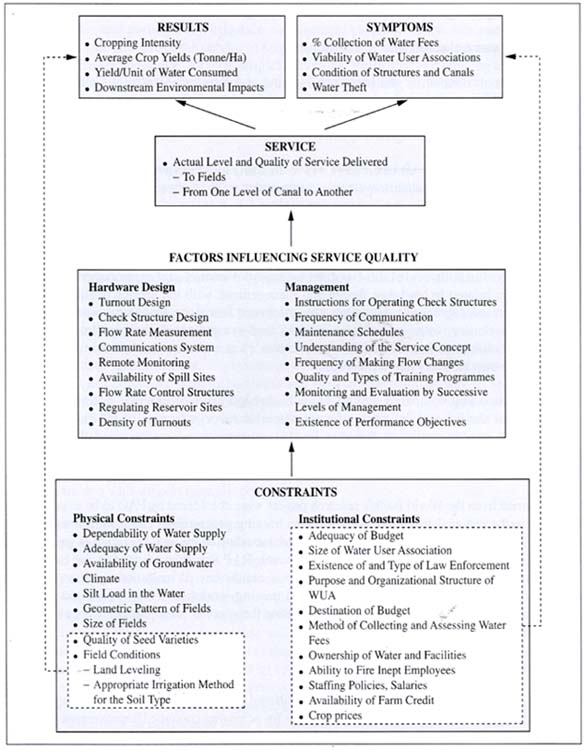

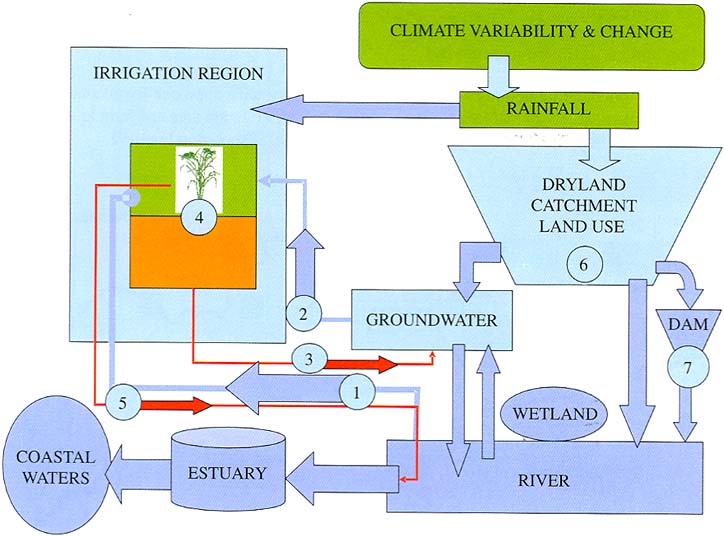

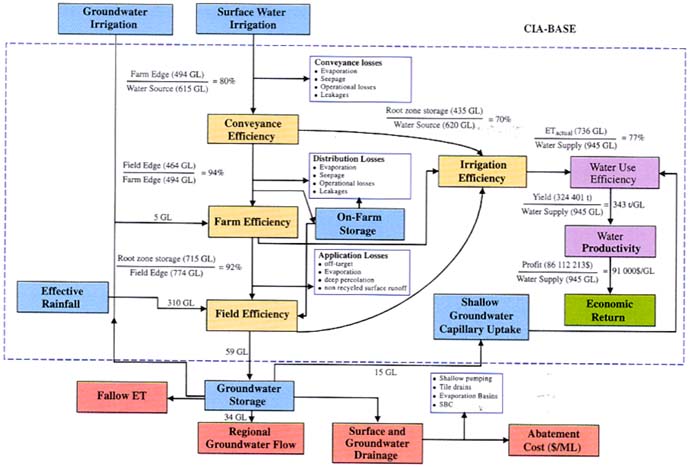

The conceptual framework of RAP (see Figure 1) for the analysis of the performance of irrigation systems can be explained as follows: irrigation systems operate under a set of physical and institutional constraints and with a certain resource base; the systems are analyzed as a series of management levels, each level providing a water delivery service through the system’s internal management and control processes to the next lower level, from the bulk water supply to the main canals down to the individual farm or field; the service quality delivered at the interface between the management levels can be appraised in terms of its components (equity, flexibility, reliability) and the accuracy of control and measurement, and depends on a number of factors related to hardware design and management; with the service quality delivered to the farm and under economic, agronomic constraints, the system and farmers’ management produces results (crops yields, irrigation intensity, water use efficiency etc.), and symptoms of poor system performance and institutional constraints are manifested as social chaos (water thefts, vandalism), poor condition of infrastructure, poor cost recovery and weak WUAs.

Results are evaluated and compared among projects through a set of external performance indicators (see Appendix 1 for the list and definition of external performance indicators of RAP), while constraints, factors influencing service quality at different levels, and symptoms are appraised through a series of standardized internal process indicators (see Appendix 2 for the list of internal process indicators of RAP, and Appendix 3 for a typical service quality indicator).

The lessons learned from the World Bank’s research project were considered by FAO to be important elements to be included in the regional irrigation modernization training programme. The RAP framework itself and its indicators were found to be consistent with FAO’s understanding of the modernization of irrigation systems as reflected in the Bangkok definition of 1996 (see above): RAP was thus adopted as the methodology for performance appraisal as well as assessment of initial conditions of irrigation systems in its training programme. After a first version used in the Thailand training workshop, ITRC developed for FAO more user-friendly versions of RAP, where the tools for estimating the systems’ water balance were also considerably expanded2 (Burt, 2003).

Benchmarking and beyond

Benchmarking is defined in documents of the International Programme for Technology and Research in Irrigation and Drainage (IPTRID) as a systematic process for achieving continued improvement in the irrigation sector through comparisons with relevant and achievable internal or external goals, norms, and standards (IPTRID, 2001). The overall aim of benchmarking is to improve the performance within an irrigation scheme by measuring its performance against its peers and its own mission and objectives. The benchmarking process should be a continuous series of measurement, analysis, and changes to improve the performance of the schemes.

RAP was later adopted as a component of the “holistic” benchmarking promoted by the World Bank. The evaluation and analysis stages of the “holistic” benchmarking form three legs of the benchmarking stool: evaluation of technical indicators (both internal and external); appraisal of the system processes; evaluation of service to users and their satisfaction with that service. RAP concentrates on the evaluation of the system processes and the evaluation of the service at all levels in the system, from water supply to the scheme to the farm, but also assists in the evaluation of the IPTRID benchmarking indicators, as the successive versions of RAP took care to use, as far as possible, the same project descriptors and performance indicators as the International Benchmarking Programme.3

Figure 1. Conceptual framework of rapid appraisal process (RAP)

For benchmarking to go beyond the measurement and analysis stages, however, and on to the implementation of changes and improvement stages, there must be significant acceptance by project personnel, identification of weaknesses and potential changes, and knowledge of options for change. The data collection and analysis of RAP are thus incorporated into the training programme that integrally involves local management and operation and maintenance staff. Staff learn the concepts of modernization and are provided with a toolbox of options and then evaluate their own project with RAP. At the end of the training:

The external performance indicators (the IPTRID benchmarking indicators are essentially external performance indicators) allow the comparison of a project’s performance with its peers and to identify possible objectives in terms of productivity, efficiency, economic and environmental performance, but do not provide assistance in identifying specific changes in processes and hardware to improve performance. This is the essential contribution of the internal process indicators.

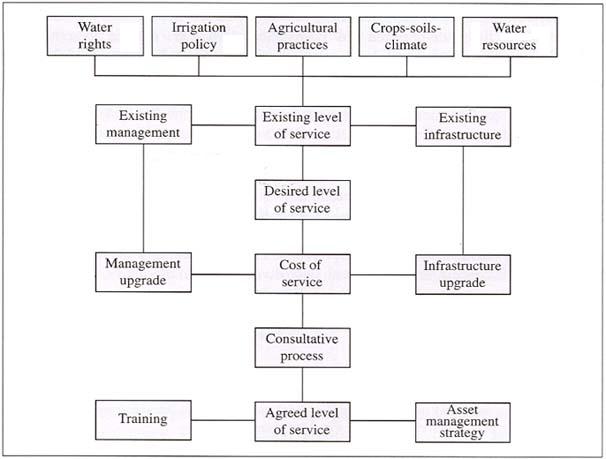

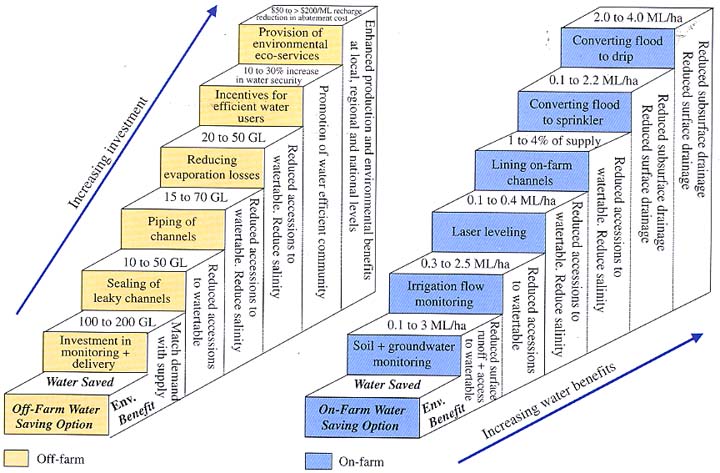

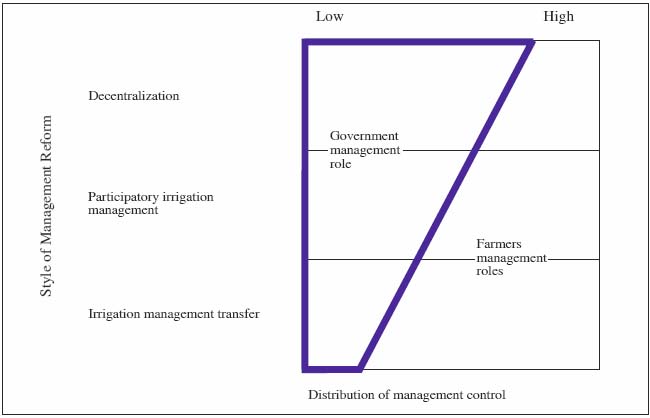

In the management process for existing irrigation and drainage schemes managed with a service orientation as proposed by Malano and Van Hofwegen (1999), which is essentially a strategic planning and management process for a service organization (see Figure 2), RAP allows the trainees to make an assessment (with the data that are available) of the context, resource base and constraints of the system, to appraise the existing level of service, management and infrastructure, to define a desired level of service corresponding to specific performance objectives, and to design an initial costed modernization strategy and priority actions related to management upgrade and infrastructure upgrade.

Figure 2. Management process for existing irrigation and drainage schemes managed with a service orientation (from Malano and Van Hofwegen, 1999)

The irrigation systems as they were appraised4

Type of systems

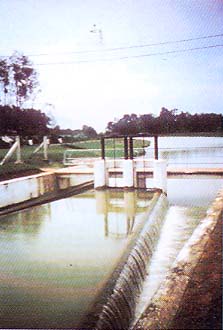

All irrigation systems appraised at the regional training programme were large-scale rice-based systems.5 They were typically designed for supplementary irrigation of rice during the rainy season (with the exception of Turkmenistan, which is under an arid desert climate). They are under public management under a supply-driven mode. WUAs have been created in a number of countries but they do not play a meaningful role in the management of the systems. The systems are generally in a poor condition because of insufficient maintenance and provide poor service to farmers. Service provided by the main canals to the secondary canals and command areas is generally unreliable and inequitable, with the exception of Malaysia. Water level control in the canals is poor and is a main factor in poor service delivery. Some systems had not received support for many years whereas substantial investment had recently been completed or was under way for other systems.

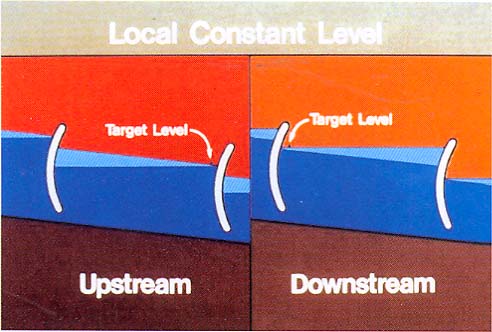

Design standards and control structures

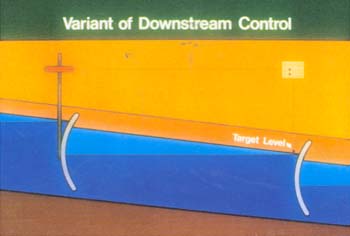

Design standards and operation have not changed in many countries for 20 to 30 years (Plusquellec, 2002). The systems have been generally designed for upstream control, but few are actually operated under pure upstream control. The extreme case is the Dau Tieng system in Southern Viet Nam, which is now operated under manual downstream control. Wave travel times in the canals are frequently of the order of one or two days, and are increased by the operation of the cross-regulators. Buffer storage to increase system responsiveness is absent in all systems. Specific flow rates of the canals are calculated for supplemental irrigation, and are therefore quite small, and decrease from the main canals to the lower level canals. This does not allow flexibility of operations and large variations in flow rates. It is a particular constraint when farmers wish to synchronize their farming activities for mechanization and thus need large amounts of water for land preparation at the same time.

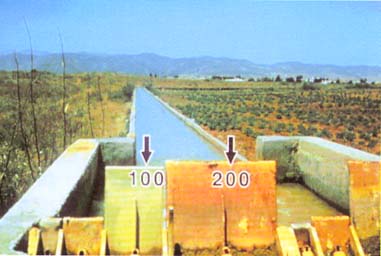

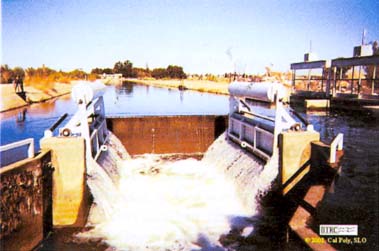

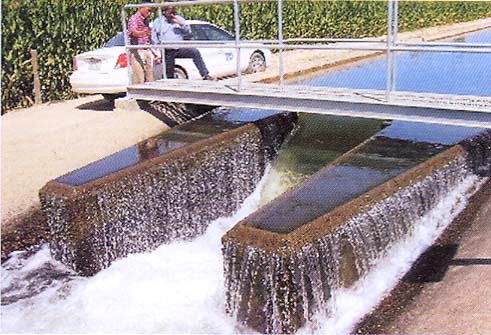

Cross-regulators are, with a few exceptions, manually operated underflow structures, in combination with underflow offtakes, and generally very sensitive to fluctuations in water supply. In the Philippines, duckbill weirs have been introduced for water level control. However, most of them have been vandalized as the systems have large variations in their water supply. During shortage periods, the upstream offtakes receive their allocation until available flows are depleted and downstream offtakes are shorted. In some cases, offtakes are of the overflow type (Rominj gates in Indonesia), which exacerbates fluctuations of flow rates into the minor canals.

Gates are rarely calibrated. The most common measurement method for flow rates is the orifice formula through (non-calibrated) gates. This formula is applied by staff whether the gates actually function as submerged, free flow orifices or are fully open and function as free-flow or submerged weirs (Andhra Pradesh Krishna Western Delta). Other measurement devices have been introduced (broad-crested weirs), but they are typically poorly designed (too broad) and inaccurate, or submerged. Recirculation of drainage is practised in a large number of schemes, but none is equipped with buffer or regulating reservoirs.

Near-farm, and on-farm infrastructure is underdeveloped. The introduction of command area development on the structured design concept or proportional flow division as an alternative to previous fully-gated distribution network designs has not been successful. The systems are immediately subverted by the farmers (Sunsari Morang Project, Nepal).

Operation

Operation follows a standard seasonal schedule that is adjusted on average every week, usually following qualitative assessments of demand by managers or qualitative requests by farmers. Main structures are operated typically three times a day according to a set schedule, very often following instructions from a central office on gate positions. Although system managers often issue instructions on flow rate targets at each offtake, these are rarely followed and most field operators adjust gates based on water levels in the canals, which correspond to a situation where farmers do not complain but do not in general correspond to a specific flow rate because of the poor condition of the canals. Farmers often operate the gates themselves and operators and managers have capitulated to this situation. A typical response to this lack of discipline is the “rotational supply”: water levels are raised in canal reaches during “on rotation” periods and lowered during “off rotation” periods.

Development of pumping

Low-cost pumping technology and energy subsidies have allowed farmers to free themselves from the constraints of poor canal system performance or inadequate scheduling through groundwater pumping, illegal pumping from the canals, water scavenging or subversion of system policies and obtain more reliable or frequent supply, switch to other crops and more effective on-farm water management strategies and techniques. Conjunctive use is not managed by anyone but usually allows farmers to adopt highly productive farming systems. As a result, tailenders may often practise more intensive and diversified farming systems.

Management policies

General management policies are typical of public institutions in the region, with few effective systems for rewarding or sanctioning performance. Field level operators are often very poorly paid and it is difficult for management and engineers to control how they actually operate the structures, which often differs from official rules and policies. How structures are actually managed is often directly responsible for instability of the system. In the Sunsari Morang (Nepal) system, main canal operators, when trying to provide a target flow rate into a secondary canal, make an initial setting at the offtake of the secondary canal, then operate the cross-regulator of the main canal to lower or raise the water level in the main canal to adjust the flow rate into the secondary canal. If they have raised the water level in the main canal too much, they then open a safety structure to divert the “excess” water supply into a drain. This example, although extreme, illustrates the importance of all details of canal operation and of instructions to operators.

The administrative setup of the operating agency frequently hinders effective operation. In Thailand, the responsibility for operation of long canals is divided into reaches under the control of different operation and maintenance projects that follow district boundaries. Although water allocation is officially to each secondary canal, in practice there is a flow rate target at the interface between each project. As a result, the projects focus their energy on disputes on flow rates at these interfaces, operate the cross-regulators as flow control structures (which creates water level fluctuations in the main canals), neglect flow rate targets into the secondary canals (which thus fluctuate wildly), and no specific office is responsible in the case of a water deficit in the lower reaches of the main canals. Although project managers already frequently integrate into their operation plans water supply to other users (municipalities, industrial customers), none of the projects appraised has specific environmental targets or goals.

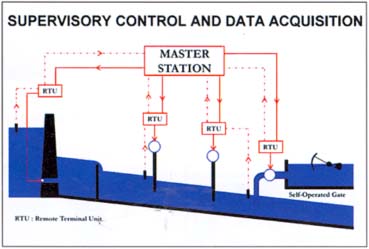

Pre-training ideas for system improvement

Proposals and ideas of the training workshop trainees for improvement of their systems (and project proposals prepared by local consulting firms) — prior to the training — usually follow a standard menu of rehabilitation following prevailing standard designs, transfer of operation and maintenance costs to farmers, and substantial investments in rigid canal lining. The introduction of supervisory control and data acquisition (SCADA) systems and information technology is frequently considered or already at an early stage of introduction. However, details of selection of sensors and of control logic are frequently inadequate and the purpose of the introduction of SCADA systems to improve performance is unclear. In general, pre-training modernization proposals rarely address management, operation, scheduling and ordering procedures, communication and training.

System managers rarely have in place effective monitoring and evaluation systems. When these are in place, they are rarely used for immediate feedback for operation. Flow rates at spills and in drains are not monitored and managers do not have a proper water balance and estimation of the system’s efficiency (with the exception of Malaysia thanks to DID’s national benchmarking programme). There is, however, a gradual shift to performance-oriented management and the definition of performance indicators (Thailand). However, norms and budget allocations are often uniform nationally, not reflecting the constraints and potentials of projects, which may vary significantly across projects (Philippines). Some projects (Philippines) are piloting demand management with the introduction of volumetric water pricing. However, investment in the upgrading of the systems has not been geared towards improving control to customer WUAs, and proposed volumetric rates, based on current service fees, are not likely to yield expected water efficiency gains (de Fraiture and Perry, 2002, FAO, 2004).

Chaos, anarchy and poor service

In summary, the level of chaos (difference between stated policies and actual policies) and of anarchy (subversion of policies) varies from system to system, but is generally high, particularly at the lower levels of management. Recent investments following standards or investment strategies (command area development) have poor results in terms of performance, control and service. Although lack of discipline and institutional issues contribute greatly to this situation, many of the problems can be traced to:

Standard project improvement projects, as reflected in pre-training proposals, usually fail to address these issues. In this respect, irrigation planners, understood as central agency staff in planning and design branches, and irrigation managers, understood as system level field staff in charge of system operation, are two different groups. The former are not necessarily aware of the specific difficulties which managers face every day. Planning and design procedures, as well as terms of reference for consulting firms that are frequently assigned the tasks of planning and designing system improvements, are typically not centred on the concerns of managers and farmers. Participatory design procedures are progressively being introduced, but they frequently focus on details such as layout of the canal networks or positions of the offtakes, rather than on more general (and more important) issues of service and performance objectives and design criteria.

The challenges

The need for change

Asian large surface irrigation systems suffer from a legacy of poor design, degraded infrastructure and poor management and stagnation in the face of rapid transformations of agriculture and pressure on their water supply. The challenge is to transform these systems from supply-driven to demand-driven responsive systems, improve their financial, environmental, technical and service performance to significantly increase control, reliability, equity and flexibility to allow these systems to adapt to changing or more variable water allocations, enable farmers to boost agricultural and water productivity, be more responsive to market opportunities, and therefore adopt new and diversified water management practices on their farms. Water-related system-level objectives need to be determined case-by-case based on water balances and basin-level considerations on the one hand and agriculture-related service objectives on the other hand.

Climate change combined with competition from other sectors will entail not only increased variations in rainfall and longer dry spells during the growing seasons, but also increased variations in water allocation to the schemes from season to season, as agriculture will most likely be considered the residual water user after priority needs from other sectors have been met. This will call for flexibility in changing operational policies from year to year, and increased participation of farmers in comanagement of the systems.

However, in practise, existing water allocations and their future evolutions are difficult to anticipate for irrigation planners and managers, as the present systems of administrative or de facto allocation are yet to evolve into river basin allocation and rights systems. Furthermore, managers as well as river basin planners very rarely have accurate and operational information on irrigation system efficiencies. Although, generally, system achievements in terms of service quality are overestimated by management, system efficiencies are usually underestimated, both by managers and by agency-level planners.

Deficiencies in strategic landscapes for planning result in poor planning

Although, thanks to recent international and national efforts in visioning and strategic processes in the water sector, there is a general notion of the future landscape of agricultural water management, in practise, these visions are not sufficiently detailed for planners and managers to visualize the practical changes that would be required to meet future water-related and agriculture-related challenges — the basis of which would be an analysis of services required by farmers in the future. An exception is Malaysia, where strategic thinking processes have been adopted for a relatively long time, and where DID has adopted specific performance targets and goals both for rice and for water management performance and where system-level, institutional, and farm-level changes are viewed holistically in a transformational modernization process.

Modernization proposals for the irrigation systems that were appraised, prior to the training workshops, usually failed to establish a linkage between system-level objectives and proposals and stated objectives for the introduction of improved or innovative irrigation technologies at farm level, or between new performance objectives and proposed reform of the management and institutional setup. Structured design, proportional water division and rotational supply are not compatible with new water saving technologies developed for rice, which require frequent or on-demand irrigation water delivery. Some designs and operation concepts which seem to allow rice to reach its yield potential (Japan, Korea, Southern China — melon-on-the-vine design concept — (Plusquellec, 2002, Barker and Molle, 2005)) were not represented in the sample of projects appraised in the regional training programme. They are, however, the object of increased interest from irrigation professionals. At the institutional level, the challenge is to develop new frameworks that can manage the complexity of the hydrological cycle, the multiple roles of irrigation systems and deliver irrigation and drainage services to farmers in a responsive, accountable and efficient manner.

Financing all this would require considerable investments whereas rice prices are expected to remain low in the medium term and present financing arrangements do not cover operation and maintenance costs, let alone investments in upgrading of management capacity and infrastructure. However, increasing climate variability may increase the profitability of irrigation systems by reducing the risk of crop failure. The investment strategies of the countries in the region should have clear strategic objectives, whether production objectives concentrating on areas with competitive advantage (Malaysia for instance has this strategy) and/or poverty reduction and food security objectives targeting marginal systems.

In these circumstances, it is imperative that increased attention should be paid to the quality and type of investment. At policy level, the challenge is to align and harmonize water and irrigation policies with agricultural and environmental policies and integrate them into overall socio-economic development policies.

Response options

Water management response options need to explicitly address scale issues (farm, irrigation system and basin-level institutions, law, policy and supporting infrastructure). A systems approach is essential to determine water balance-related objectives and water management strategies to achieve them. These strategies and changes should aim at improving water control, equity, reliability and flexibility of service to give farmers water management and crop choices.

Improvement strategies should be supported by strategic planning and management approaches with a service orientation (Malano and van Hofwegen, 1999). Participatory planning and design processes would assist in focusing management goals on farmers’ needs. This would require increased decentralization of irrigation bureaucracy towards system managers and farmers’ representative institutions.

Previous irrigation modernization projects have been partly successful at best, but better options and strategies now exist. Major options include conjunctive use of surface and groundwater, recirculation of drainage, buffer reservoirs at appropriate levels in the systems, improved design of control structures, investment in drainage, operation and ordering procedures, piping of near-farm delivery, and intensification of irrigation system management. Feasible and field-tested options exist. The gap is in capacity building of the irrigation profession at large and a critical action is the revision of design standards (FAO, 1998, Plusquellec, 2002, Facon, 2002, 2005).

The regional training programme has shown that when irrigation planners and managers are presented with these options, which they were not aware of, and when, furthermore, they work together in developing proposals based on a detailed appraisal of the systems, they enthusiastically embrace them — the irrigation modernization plans that trainees prepare at the conclusion of the training workshops differ very significantly from their plans prior to the workshop. These plans include new technical options (in particular, buffer storage is seen as a powerful design feature), propose balanced investment in upgrading the capacity of management and farmers and in infrastructure, communication and mobility for operation staff; planned investment in infrastructure focuses much more on control and measurement as a priority. Plans also typically include as priorities changes in instructions to field staff for operation of control structures, changes in internal organization, improved procedures for ordering of deliverables, and an initial focus on restoring and improving water level control in the upper levels of the systems as prerequisites for further improvements and investments in the lower levels.

Information and control technology and software is now robust and available off-the-shelf and costs are decreasing everyday. Their introduction through careful strategies would make an important contribution. A priority often found in the proposals of the trainees is the remote monitoring of spills, drains, and flow rates at major offtakes as a basis for the establishment of feedback mechanisms, as well as for a better understanding of the water balance of the systems.

A business approach to institutions is the key to the future sustainability of rice-based irrigation systems, in the sense that institutions should be tailored to deliver specific performance goals in addition to governance and representation goals, and should generally improve service orientation and accountability, move towards decentralized management, and reflect the diversity of stakeholders and water uses. Models of farmers’ organizations may need to change towards professionalized institutions that can provide new ranges of delivery and other services and reduce transaction costs for farmers, as labour costs are increasing and labour and management shortages are to be further expected. Options for overhauling public management institutions include financial autonomy, incorporation, making them more professional, public-private partnerships, privatization and transfer to farmers’ organizations. New promising models are emerging in China and other countries.

New financial instruments are required to cover not only O&M but also upgrading of management and infrastructure assets at all levels of agricultural water management, from farm, to users organizations, to system-level irrigation service providers and the river basin. Public investment support will still be needed to assist in the transformation of systems and institutions in their transition from present condition towards more agile and performing systems. The observation is that this strategic investment may not be more expensive that previous infrastructure rehabilitation or canal lining programmes.

Further work is needed by international and national researchers on interactions between design standards, operation strategies, service level and water pricing. Volumetric delivery/pricing at the tertiary level is an achievable medium-term objective for gated systems provided that they are modernized (Thailand and Viet Nam, for example). Systems based on proportional flow division may well limit options to flat-rate area-based or crop-based irrigation charges if users cannot have control over water deliveries and pre-empt long-term goals of volumetric water pricing.

Policies and investments in the future need to be rice-aware rather than rice-centric (FAO Regional Strategic Framework, 2005). Aligning water and irrigation strategies and policies with agricultural and environmental policies and overall socio-economic development policies can be facilitated through the dissemination of strategic planning and management and more inclusive policy development approaches (ESCAP, 2004).

Conclusions

General conclusion

The challenges faced by irrigation planners, managers and farmers in Asia are numerous and complex. Uncertainties abound, but the uncertainty itself is an important piece of information available for planners and managers to consider in the decisions they have to take today to face the challenges of tomorrow. Irrigation systems and their management have to evolve towards flexibility to adapt on a continuous basis to face increasing variability in water supply, climate and markets.

The main lesson from the FAO regional modernization training programme is a paradox: this challenge is both underestimated and overestimated. It is underestimated because there has been in the recent past excessive reliance on policy reform, institutional reform, improved control technology, improved management, economic incentives and instruments or on-farm water management as measures that would single-handedly deliver improved performance or service. The detailed appraisals of the irrigation systems which were investigated through the regional training programme indicate that a complex and articulated mix of changes in all these fields would be in fact required. It has been underestimated also because the actual performance of the systems, particularly in terms of service delivery, is frequently overestimated.6 The challenge is overestimated because there exists a considerable potential for significantly improving system performance and service with the adoption of simple and low-cost measures, provided that an increased focus on all details of operation, management and design is adopted, and that planners and managers are aware of better options that are now available through training and capacity building.

This does not mean that far-ranging and comprehensive reform or substantial investment will not be needed. This means that it is possible to initiate a process of transformational change with immediate benefits to farmers, in terms of service, and managers, in terms of ease of operation, that will allow the necessary reform agenda and investment programmes to be more strategically focused, achievable in a realistic step-wise approach, more easily implemented, acceptable to the various stakeholders and able to adapt to rapidly changing circumstances.

RAP and benchmarking

It has been argued (Cornish, 2005) that RAP cannot be considered as performance benchmarking on the grounds that it focuses on planning investment in modernization of water control infrastructure, requires well-trained and experienced engineers, does not lend itself to regular application on a large number of schemes and does not use comparison, over time and between schemes, as the basis for identifying performance gaps and planning improvements.

In reality, RAP uses comparison over time and between schemes as explained above, assesses all processes of management and operation as well as hardware, can be and is applied over a large number of schemes (Malaysia, Thailand, Viet Nam). It can therefore be a useful and critical component of a national benchmarking programme aiming at the improvement of sectoral performance if used at the inception of the programme when systems managers develop their strategic plans or system upgrading plans, or to evaluate the impact of improvement projects, as is the case in Malaysia.

RAP does require well-trained and experienced engineers. Any significant improvement in the sector’s performance in Asia will require well-trained and experienced planners, designers, managers and operators. For this reason, FAO and national irrigation agencies such as the Royal Irrigation Department of Thailand and the Department of Irrigation and Drainage of Malaysia introduce RAP within a training programme where trainees appraise their own systems with the support of a team of expert appraisers and trainers from the central office. The experience from the FAO regional training programme is that this support from a core team of expert appraisers and trainers, who are also external to the system, is essential for quality control of RAP.

RAP and service orientation: service orientation of management and assets

Furthermore, it has been affirmed that the benchmarking process will only be applied where managers “embrace the goal of pursuing best management practices within a service oriented management system” and that this implies a focus on the quality and cost-effectiveness of service delivery (Malano, 2004). This is the most original feature and central message of RAP.

In addition, by appraising service quality at all levels of system management and concentrating on service interfaces between the different levels, RAP facilitates taking into account the objectives and concerns of the operators at all levels, from the upper-level managers, to the WUAs that may exist in the system, to the farmers who receive service from them.

In RAP, the focus on control infrastructure (and how it is operated) is viewed from the perspective of service delivery, control, operating rules, and management responsiveness. The appraisal of the numerous systems under the regional training programme confirms that poor selection and operation of the systems’ control structures play a decisive role in system service performance. Decisions on control structures (their maintenance, their operation, their replacement) are therefore critical management decisions, as are, more generally, decisions on investment in infrastructure upgrade. Poor decisions on infrastructure or sterile investment programmes that will not yield desired performance or service improvements are simply poor management decisions.

In this respect, RAP, which focuses on quality of control with and interactions between control structures, and on actual operation of these structures, is a useful and critical addition to asset management methods that focus on asset serviceability. The notion of serviceability is deemed to be important as:

“ …the serviceability of an asset (that is, its ability to perform its function) is often assumed to be directly related to its condition. But this can be a misleading assumption. In practise, assets very often continue to perform their functions quite satisfactorily even though their condition has significantly deteriorated.

On the other hand, there are frequent instances when an asset which is generally in excellent condition is rendered unserviceable by a very minor fault. It is the serviceability therefore which dictates the urgency of the work needed to restore the asset to its fully functional state” (IIS-ODA, 1995).

Asset surveys assessing the condition and serviceability of structures are therefore focused on the asset’s condition and needs for repairs or maintenance. However, an asset, such as an offtake, or a measurement device, can be brand new and perform poorly because of poor design (a Rominj gate in combination with an undershot cross-regulator for instance, or a measuring flume which is too wide) and any decision that does not lead to the replacement with a different design (Rominj gate) or modification (measuring flume) of the asset will be a poor asset management decision, or of poor operation, and changes in instructions to the operators will not lead to an improved serviceability of the asset.

RAP as support for decision-making

RAP is not as of itself a decision-making procedure, but a tool to facilitate decision-making.

The array of external performance indicators allows decision-makers to examine the various possible major objectives of a modernization process: water balance-related objectives, environmental (limited to water quality, waterlogging, salinity and efficiency) objectives, agricultural production and economic objectives (related to on-farm and resource limitations), economic and financial sustainability objectives, and to a certain extent social objectives.

The combination of external and internal indicators also allows a first representation of the interests of a number of stakeholders: central-level decision-makers, water resource managers, system managers, operators and staff at various levels, water users associations and farmers, and, to a limited extent, environmentalists concerned with the performance of the systems. Equally importantly, RAP provides a common language between central decision-makers, managers and water users, to examine the present performance of the system and future performance and change objectives, in terms of service and its characteristics, at all levels of management.

RAP can therefore be a very valuable input (but not the only one) to multistakeholder decision-making and strategic planning and management processes.

As the systems are increasingly considered as providing multiple roles and likely to evolve towards multiple use systems, future development of the tool will focus on developing additional indicators to address drainage and water disposal services better, as well as the multiple roles provided by the irrigation systems. RAP is a performance appraisal tool which is consistent with FAO’s concepts of irrigation modernization adopted until now. RAP will evolve as these evolve in the future.

References

Barker, R. & Molle, F. 2005. Evolution of irrigation in South and Southeast Asia. Comprehensive assessment research report 5. IWMI, Colombo (available at http://www.iwmi.cgiar.org).

Burt, C. 2003. Rapid Appraisal Process (RAP) and benchmarking explanation and tools (available at http://www.watercontrol.org).

Cornish, G. 2005. Performance benchmarking in the irrigation and drainage sector, experiences to date and conclusion. HR Wallingford and DFID.

De Fraiture, C. & Perry, C. 2002. Why is irrigation water demand inelastic at low price ranges? Paper presented at the Conference on Irrigation Water Policies: Micro and Macro Considerations, Agadir, Morocco, 15–17 June 2002 (available at (http://lnweb18.worldbank.org).

ESCAP. 2004. Proceedings of the concluding workshop of the regional programme on capacity building in strategic planning for natural resources management, 2004.

Facon, T. 2002. Downstream of irrigation water pricing: The infrastructure design and operational management considerations. Paper presented at the Conference on Irrigation Water Policies: Micro and Macro Considerations, Agadir, Morocco, 15–17 June 2002 (available at (http://lnweb18.worldbank.org).

Facon, T. 2005. Asian irrigation in transition — service orientation, Institutional aspects and design/operation/ infrastructure issues. In Asian irrigation in transition: responding to challenges. Ganesh Shivakoti, D. Vermillion, W. Fung Lam, E. Ostrom, U. Pradhan & R. Yoder, eds. New Delhi, Sage Publications.

FAO. 1997. Modernization of irrigation schemes: past experiences and future options. FAO-RAP 1997/22, Water Report Series 12, Bangkok.

FAO. 1999. Modern water control and management practices. In Irrigation impact on performance. FAO Water Reports 19 (also available at http://www.watercontrol.org).

FAO. 2002. Investment in Land and Water. FAO-RAP Publication 2002/09, Bangkok.

FAO. 2004. Towards a food-secure Asia and Pacific — regional strategic framework for Asia and Pacific, Bangkok (also available at http://www.fao.org).

IIS-ODA. 1995. Asset management procedures for irrigation schemes — preliminary guidelines for the preparation of an asset management plan for irrigation infrastructure. Institute of Irrigation Studies, University of Southampton) and Overseas Development Administration, UK.

IPTRID. 2001. Guidelines for benchmarking performance in the irrigation and drainage sector. International Programme for Technology and Research in Irrigation and Drainage, Rome (also available at http://www.fao.org).

Malano, H. 2004. Benchmarking in the irrigation and drainage sector. Position paper. ICID, Task force 4, New Delhi.

Malano, H. & van Hofwegen, P. 1999. Management of irrigation and drainage systems, a service approach. IHE Monograph 3, A.a. Balkema Brookfield, Rotterdam.

Plusquellec, H. 2002. How design, management and policy affect the performance of irrigation projects: emerging modernization procedures and design standards. Bangkok, FAO (available at www.watercontrol.org).

World Bank. 2005. Shaping the future of water for agriculture: a sourcebook for investment in agricultural water management. Washington, DC, The World Bank Agriculture and Rural Development Department.

Appendix 1. Rapid appraisal procedure external performance indicators

|

Item description |

Units |

|

Stated efficiencies |

|

|

Stated conveyance efficiency of imported canal water (accounts for seepage and spills and tail-end flows) |

% |

|

Weighted field irrigation efficiency from stated efficiencies |

% |

|

Areas |

|

|

Physical area of irrigated cropland in the command area (not including multiple cropping) |

ha |

|

Irrigated crop area in the command area, including multiple cropping |

ha |

|

Cropping intensity in the command area including double cropping |

none |

|

External sources of water for the command area |

|

|

Surface irrigation water inflow from outside the command area (gross at diversion and entry points) |

MCM |

|

Gross precipitation in the irrigated fields in the command area |

MCM |

|

Effective precipitation to irrigated fields (not including salinity removal) |

MCM |

|

Net aquifer withdrawal as a result of irrigation in the command area |

MCM |

|

Total external water supply for the project — including gross ppt and net aquifer withdrawal, but excluding internal recirculation |

MCM |

|

Total external irrigation supply for the project |

MCM |

|

“Internal” water sources |

|

|

Internal surface water recirculation by farmer or project in command area |

MCM |

|

Gross groundwater pumped by farmers within command area |

MCM |

|

Groundwater pumped by project authorities and applied to the command area |

MCM |

|

Gross total annual volume of project authority irrigation supply |

MCM |

|

Total groundwater pumped and dedicated to the command area |

MCM |

|

Groundwater pumped by project authorities and applied to the command area, minus net groundwater withdrawal (this is to avoid double counting. Also, all of net is applied to this term, although some might be applied to farmers) |

MCM |

|

Estimated total gross internal surface water + groundwater |

MCM |

|

Irrigation water delivered to users |

|

|

Internal authority water sources are stated to have a conveyance efficiency of: |

% |

|

Delivery of external surface irrigation water to users — using stated conveyance efficiency |

MCM |

|

All other irrigation water to users (surface recirculation plus all well pumping, with stated conveyance efficiencies, using 100% for farmer pumping and farmer surface diversions) |

MCM |

|

Total irrigation water deliveries to users (external surface irrigation water + internal diversions and pumping water sources), reduced for conveyance efficiencies |

MCM |

|

Total irrigation water (internal plus external) — just for intermediate value |

MCM |

|

Overall conveyance efficiency of project authority delivered water |

% |

|

Net field irrigation requirements |

|

|

ET of irrigated fields in the command area |

MCM |

|

ET of irrigation water in the command area (ET - effective precipitation) |

MCM |

|

Irrigation water needed for salinity control (net) |

MCM |

|

Irrigation water needed for special practices |

MCM |

|

Total NET irrigation water requirements (ET - eff. ppt + salt control + special practices) |

MCM |

|

Other key values |

|

|

Flow rate capacity of main canal(s) at diversion point(s) |

m3/s |

|

Actual peak flow rate of the main canal(s) at diversion point(s) this year |

m3/s |

|

Peak NET irrigation requirement for field, including any special requirements |

m3/s |

|

Peak GROSS irrigation requirement, including all inefficiencies |

m3/s |

|

ANNUAL or one-time external indicators for the command area |

|

|

Peak litres/sec/ha of surface irrigation inflows to canal(s) this year |

l/s/ha |

|

Relative water supply (RWS) for the irrigated part of the command area (Total external water supply)/(Field ET during growing seasons + water for salt control - effective precipitation) |

none |

|

Annual command area irrigation efficiency [100 x (crop ET + Leaching needs - Effective ppt)/ (surface irrigation diversions + Net groundwater)] |

% |

|

Field irrigation efficiency (computed) = [crop ET - effective ppt + LR water]/ [total water delivered to users] x 100 |

% |

|

Relative gross canal capacity (RGCC) — (peak monthly net irrigation requirement)/ (main canal capacity) |

none |

|

Relative actual canal flow (RACF) — (peak monthly net irrigation requirement)/ (peak main canal flow rate) |

none |

|

Gross annual tonnage of agricultural production by crop type |

M tonnes |

|

Total annual value of agricultural production |

US$ |

Appendix 2. Rapid appraisal procedure internal process indicators

|

Indicator label |

Primary indicator and sub-indicator name |

|

Service and social order | |

|

I-1 |

Actual water delivery service to individual ownership units (e.g. field or farm) |

|

I-1A |

Measurement of volumes |

|

I-1B |

Flexibility |

|

I-1C |

Reliability |

|

I-1D |

Apparent equity |

|

I-2 |

Stated water delivery service to individual ownership units (e.g. field or farm) |

|

I-2A to I-2B |

Same sub-indicators as for I–1 |

|

I-3 |

Actual water delivery service at the most downstream point in the system operated by a paid employee |

|

I-3A |

Number of fields downstream of this point |

|

I-3B |

Measurement of volumes |

|

I-3C |

Flexibility |

|

I-3D |

Reliability |

|

I-3E |

Apparent equity |

|

I-4 |

Stated water delivery service at the most downstream point operated by a paid employee |

|

I-4A to I-4E |

Same sub-indicators as for I–3 |

|

I-5 |

Actual water delivery service by the main canals to the second level canals |

|

I-5A |

Flexibility |

|

I-5B |

Reliability |

|

I-5C |

Equity |

|

I-5D |

Control of flow rates to the sub-main as stated |

|

I-6 |

Stated water delivery service by the main canals to the second level canals |

|

I-6A to I-6D |

Same sub-indicators as for I–5 |

|

I-7 |

Social “order” in the canal system operated by paid employees |

|

I-7A |

Degree to which deliveries are NOT taken when not allowed, or at flow rates greater than allowed |

|

I-7B |

Noticeable non-existence of unauthorized turnouts from canals |

|

I-7C |

Lack of vandalism of structures |

|

Main canal | |

|

I-8 |

Cross-regulator hardware (main canal) |

|

I-8A |

Ease of cross-regulator operation under the current target operation |

|

I-8B |

Level of maintenance of the cross-regulators |

|

I-8C |

Lack of water level fluctuation |

|

I-8D |

Travel time of a flow rate change throughout this canal level |

|

I-9 |

Turnouts from the main canal |

|

I-9A |

Ease of turnout operation under the current target operation |

|

I-9B |

Level of maintenance |

|

I-9C |

Flow rate capacities |

|

I-l0 |

Regulating reservoirs in the main canal |

|

I-10A |

Suitability of the number of location(s) |

|

I-10B |

Effectiveness of operation |

|

I-10C |

Suitability of the storage/buffer capacities |

|

I-10D |

Maintenance |

|

I-11 |

Communications for the main canal |

|

I-11A |

Frequency of communications with the next higher level |

|

I-11B |

Frequency of communications by operators or supervisors with their customers |

|

I-11C |

Dependability of voice communications by phone or radio |

|

I-11D |

Frequency of visits by upper-level supervisors to the field |

|

I-11E |

Existence and frequency of remote monitoring (either automatic or manual) at key spill points, including the end of the canal |

|

I-11F |

Availability of roads along the canal |

|

I-12 |

General conditions for the main canal |

|

I-12A |

General level of maintenance of the canal floor and canal banks |

|

I-12B |

General lack of undesired seepage (note: if deliberate conjunctive use is practised, some seepage may be desired) |

|

I-12C |

Availability of proper equipment and staff to adequately maintain this canal |

|

I-12D |

Travel time from the maintenance yard to the most distant point along this canal (for crews and maintenance equipment) |

|

I-13 |

Operation of the main canal |

|

I-13A |

How frequently does the headworks respond to realistic real time feedback from the operators/ observers of this canal level? |

|

I-13B |

Existence and effectiveness of water ordering/delivery procedures to match actual demands |

|

I-13C |

Clarity and correctness of instructions to operators |

|

I-13D |

How frequently is the whole length of this canal checked for problems and reported to the office? |

|

Second-level canals | |

|

I-14 to I-19 |

Same indicators as for main canal |

|

Third-level canals | |

|

I-20 to I-25 |

Same indicators as for main and second-level canals |

|

Budgets, employees, WUAs | |

|

I-26 |

Budgets |

|

I-26A |

What percentage of the total project (including WUA) O&M is collected as in-kind services, and/or water fees from water users? |

|

I-26B |

Adequacy of the actual dollars and in-kind services that is available (from all sources) to sustain adequate Operation and Maintenance (O&M) with the present mode of operation |

|

I-26C |

Adequacy of spending on modernization of the water delivery operation/structures (as contrasted to rehabilitation or regular operation) |

|

I-27 |

Employees |

|

I-27A |

Frequency and adequacy of training of operators and middle managers (not secretaries and drivers) |

|

I-27B |

Availability of written performance rules |

|

I-27C |

Power of employees to make decisions |

|

I-27D |

Ability of the project to dismiss employees with cause |

|

I-27E |

Rewards for exemplary service |

|

I-27F |

Relative salary of an operator compared to a day labourer |

|

I-28 |

Water user associations (WUAs) |

|

I-28A |

Percentage of all project users who have a functional, formal unit that participates in water distribution |

|

I-28B |

Actual ability of the strong WUAs to influence real-time water deliveries to the WUA |

|

I-28C |

Ability of the WUA to rely on effective outside help for enforcement of its rules |

|

I-28D |

Legal basis for the WUAs |

|

I-28E |

Financial strength of WUAs |

|

I-29 |

Mobility and size of operations staff, based on the ratio of operating staff to the number of turnouts. |

|

I-30 |

Computers for billing and record management: The extent to which computers are used for billing and record management |

|

I-31 |

Computers for canal control: The extent to which computers (either central or on-site) are used for canal control |

| Special indicators that do not have a 0–4 rating scale | |

| I-35 | Turnout density: Number of water users downstream of employee-operated turnouts |

| I-36 | Turnouts/Operator: (Number of turnouts operated by paid employees)/(paid employees) |

| I-37 | Main canal chaos: (actual/stated) overall service by the main canal |

| I-38 | Second-level chaos: (actual/stated) overall service at the most downstream point operated by a paid employee |

| I-39 | Field-level chaos: (actual/stated) overall service to the individual ownership units |

Appendix 3. Example of rapid appraisal procedure service indicator

|

No. |

Primary indicator |

Sub-indicator |

Ranking criteria |

Wt |

|

I–1 |

Actual water delivery service to individual ownership units (e.g. field or farm) |

|||

|

I–1A |

Measurement of volumes to the individual units (0–4) |

4 – Excellent measurement and control devices, properly operated and recorded. |

1 | |

|

I–1B |

Flexibility to the individual units (0–4) |

4 – Unlimited frequency, rate, and duration, but arranged by users within a few days. |

2 | |

|

I–1C |

Reliability to the individual units (0–4) |

4 – Water always arrives with the frequency, rate, and duration promised. Volume is known. |

4 | |

|

I–1D |

Apparent equity to individual units (0–4) |

4 – All fields throughout the project and within tertiary units receive the same type of water delivery service. |

4 |

Appendix 4. External performance indicators

|

Item Description |

Units |

Malaysia |

Indonesia |

Viet Nam |

Philippines |

Nepal |

Pakistan |

India | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

Stated efficiencies | |||||||||||||||

|

Stated conveyance efficiency of imported canal water (accounts for seepage and spills and tail end flows) |

% |

84 |

61 |

80 |

60 |

57 |

50 |

50 |

60 |

75 |

70 |

80 |

80 |

80 |

70 |

|

Weighted field irrigation efficiency from stated efficiencies |

% |

70 |

70 |

89 |

68 |

78 |

75 |

77 |

75 |

68 |

65 |

70 |

74 |

66 |

67 |

|

Areas | |||||||||||||||

|

Physical area of irrigated cropland in the command area (not including multiple cropping) |

ha |

96 474 |

23 560 |

6 888 |

12 232 |

18 288 |

44 000 |

24 140 |

43 131 |

64 000 |

28 700 |

215 511 |

403 103 |

400 000 |

201 600 |

|

Irrigated crop area in the command area, including multiple cropping |

ha |

192 948 |

44 405 |

13 776 |

32 232 |

33 317 |

106 300 |

42 706 |

82 172 |

136 040 |

58 163 |

56 056 |

70 163 |

224 478 |

300 000 |

|

Cropping intensity in the command area including double cropping |

none |

2.00 |

1.88 |

2.00 |

2.64 |

2 |

2.42 |

1.77 |

1.91 |

2.13 |

2.03 |

0.26 |

0.17 |

0.56 |

1.49 |

|

External sources of water for the command area | |||||||||||||||

|

Surface irrigation water inflow from outside the command area (gross at diversion and entry points) |

Mm3 |

1 155 |

568 |

197 |

280 |

210 |

1 104 |

235 |

1 728 |

751 |

314 |

1 386 |

3 718 |

3 117 |

2 180 |

|

Gross precipitation in the irrigated fields in the command area |

Mm3 |

1 922 |

667 |

167 |

162 |

257 |

774 |

336 |

455 |

1 247 |

506 |

395 |

0 |

472 |

1 723 |

|

Effective precipitation to irrigated fields (not including salinity removal) |

Mm3 |

214 |

61 |

17 |

70 |

63 |

213 |

73 |

131 |

193 |

100 |

66 |

0 |

192 |

823 |

|

Net aquifer withdrawal as a result of irrigation in the command area |

Mm3 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Total external water supply for the project — including gross ppt and net aquifer withdrawal, but excluding internal recirculation |

Mm3 |

3 077 |

1 235 |

365 |

442 |

467 |

1 878 |

571 |

2 183 |

1 998 |

821 |

1 781 |

3 718 |

3 589 |

3 903 |

|

Total external irrigation supply for the project |

Mm3 |

1 728 |

751 |

314 |

1 386 |

3 718 |

3 117 |

2 180 | |||||||

|

“Internal” Water Sources | |||||||||||||||

|

Internal surface water recirculation by farmer or project in command area |

Mm3 |

125 |

89 |

0 |

1 |

79 |

276 |

116 |

286 |

137 |

0 |

0 |

0 |

0 |

0 |

|

Gross groundwater pumped by farmers within command area |

Mm3 |

0 |

0 |

0 |

3 |

0 |

0 |

0 |

0 |

24 |

14 |

0 |

0 |

9 |

1 |

|

Groundwater pumped by project authorities and applied to the command area |

Mm3 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

474 |

0 |

|

Gross total annual volume of project authority irrigation supply |

Mm3 |

2 014 |

841 |

314 |

1 386 |

3 718 |

3 591 |

2 180 | |||||||

|

Total groundwater pumped and dedicated to the command area |

Mm3 |

0 |

24 |

14 |

0 |

0 |

483 |

1 | |||||||

|

Groundwater pumped by project authorities and applied to the command area, minus net groundwater withdrawal (this is to avoid double counting. Also, all of net is applied to this term, although some might be applied to farmers) |

Mm3 |

0 |

0 |

0 |

0 |

0 |

474 |

0 | |||||||

|

Estimated total gross internal surface water + groundwater |

Mm3 |

125 |

89 |

0 |

5 |

79 |

276 |

116 |

286 |

162 |

14 |

0 |

0 |

483 |

1 |

|

Irrigation water delivered to users | |||||||||||||||

|

Internal authority water sources are stated to have a conveyance efficiency of: |

% |

95 |

87 |

93 |

87 |

86 |

83 |

83 |

60 |

75 |

90 |

80 |

80 |

80 |

80 |

|

Delivery of external surface irrigation water to users — using stated conveyance efficiency |

Mm3 |

967 |

349 |

158 |

168 |

118 |

552 |

118 |

1 037 |

563 |

220 |

1 109 |

2 974 |

2 494 |

1 526 |

|

All other irrigation water to users (surface recirculation plus all well pumping, with stated conveyance efficiencies, using 100% for farmer pumping and farmer surface diversions) |

Mm3 |

172 |

139 |

14 |

0 |

0 |

388 |

1 | |||||||

|

Total irrigation water deliveries to users (external surface irrigation water + internal diversions and pumping water sources), reduced for conveyance efficiencies |

Mm3 |

1 083 |

426 |

158 |

172 |

186 |

782 |

214 |

1 208 |

702 |

234 |

1 109 |

2 974 |

2 882 |

1 527 |

|

Total irrigation water (internal plus external) — just for intermed. value |

Mm3 |

2 014 |

913 |

328 |

1 386 |

3 718 |

3 601 |

2 181 |

|||||||

|

Overall conveyance efficiency of project authority delivered water |

% |

60 |

75 |

70 |

80 |

80 |

80 |

70 |

|||||||

|

Net field irrigation requirements |

|||||||||||||||

|

ET of irrigated fields in the command area |

Mm3 |

481 |

265 |

94 |

166 |

183 |

552 |

226 |

449 |

550 |