Small-ScaleDairy Farming Manual |

Volume 3 |

|

|

|

SILAGE MAKING |

|

|

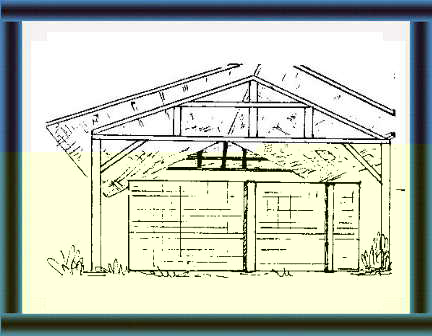

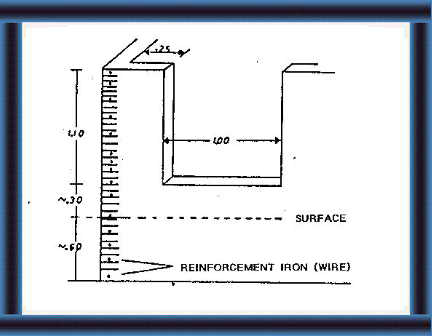

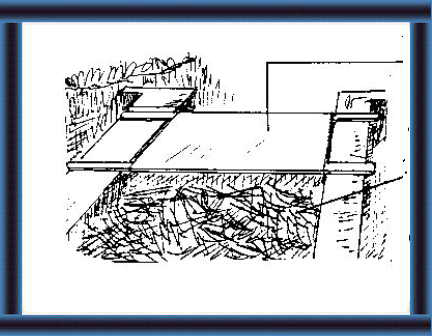

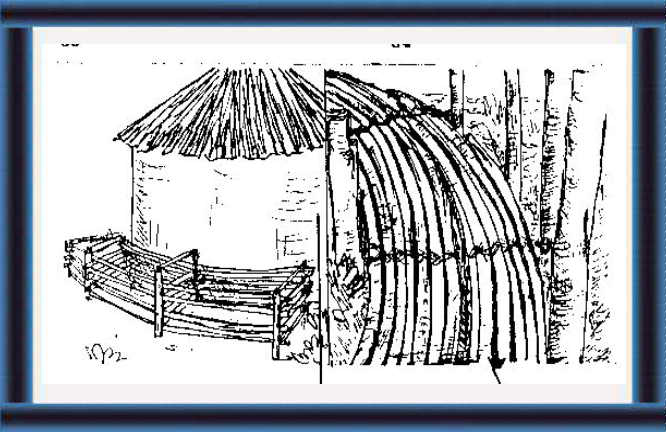

50 Chamber silo with 4 chambers and roof.

This type of silo is quite expensive, but the silo can last for many years. You can fill and close each chamber separately so you can fill quickly and reduce losses. You can add or remove slats at the front of each room. This makes it easy to fill the plant matter into the silo as well as remove the silage from the silo. |

|

|

|

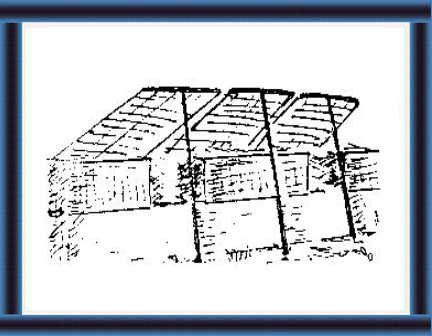

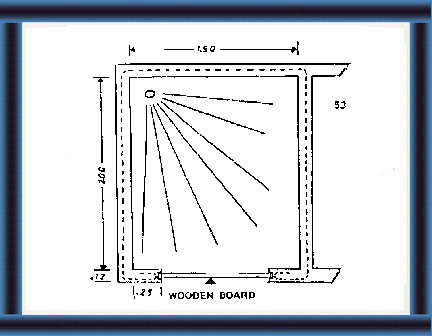

| 52 Specifications:

Silage requirements: To feed 3 milking cows for 30 days. Silo measurements : 2.00 m x 1.50 m x 2.00 m= 6.00 m3 (per chamber) |

|

|

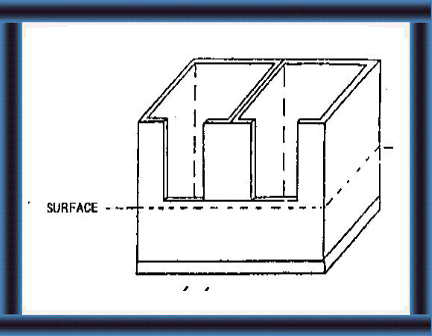

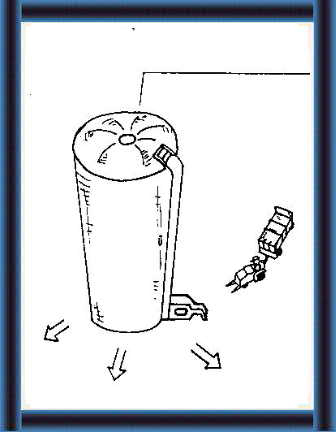

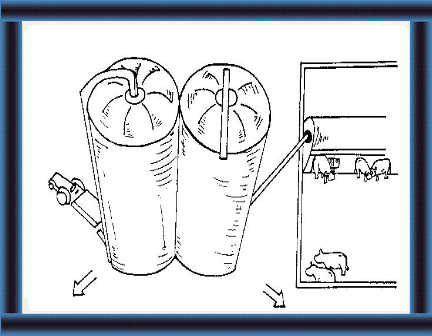

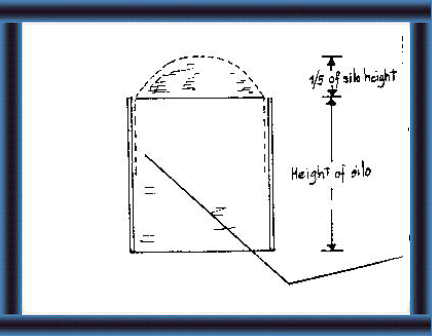

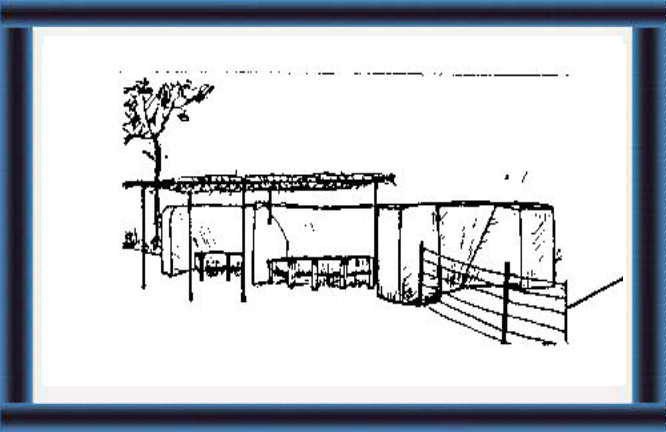

54 Large upright silos are convenient and not

expensive if labour costs are high. They

keep air out to reduce losses. Unloading structures and mechanical

feed handling systems make it easy to fill and feed.

Important 1 Locate silos carefully, plan the location of other structures. 2 Fill and feed out quickly to avoid top spoilage. 3 Arrows show drainage away from silo. Investment (1986): First cost US$ 12-16 per ton capacity |

|

|

Cutting Cut the crop at the right time to get the best feed value. Here are some examples: Crop

Cutting Time

Wilting Check the dry

matter content of the crop. If necessary, wilt the crop to 30-35%

dry matter content. This improves the feed value.

|

|

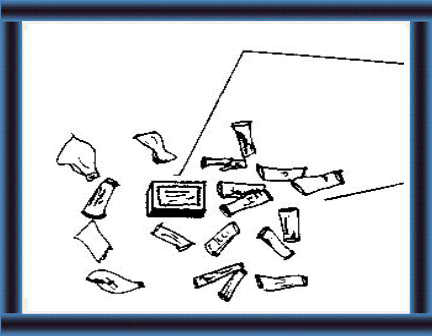

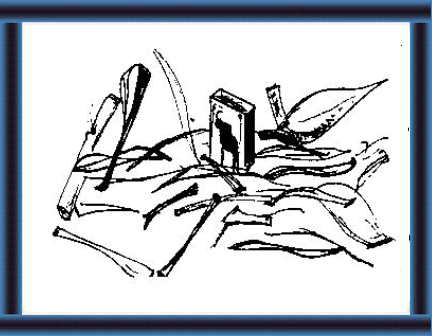

Chopping

Chop the crop to a length of 30-35 cm. 56 This crop is chopped to the length of a match box. It is easy to compact and remove the air. |

|

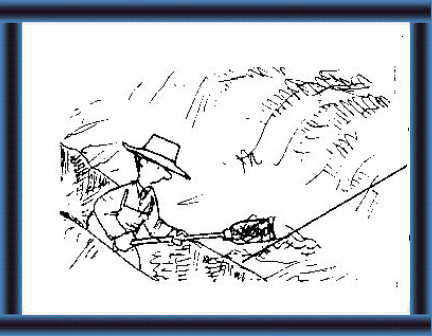

57 You can chop by hand but

it is slow.

This is a problem because you must fill the silo quickly. |

|

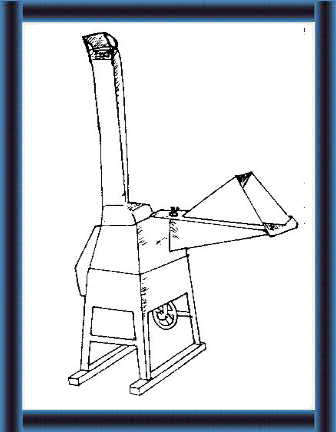

58 Machines are expensive but you can

share them with your neighbours.

This one can chop 1,500 - 1,800 kg of crop per hour and fill a 10,000 kg silo in one day. |

|

Silage Additives You can add substances to the crop to make your silage better and more quickly. Molasses

|

|

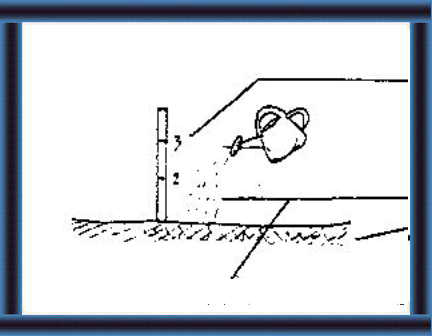

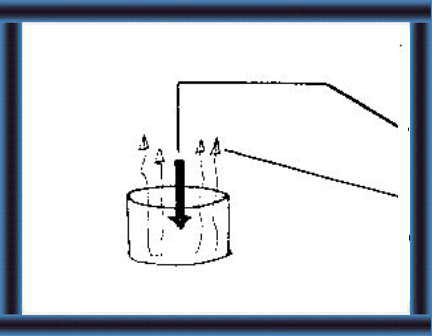

59 Mix 1 part of molasses with 2 parts

of water.

Put the mixture in a large sprinkling can.

|

|

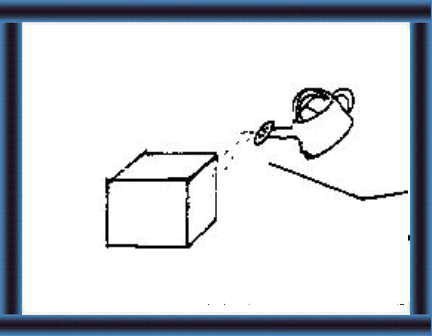

60 Add 35 l of the mixture for every 1 m3 of crop (less for short, leafy grass, more for legume crops). |

|

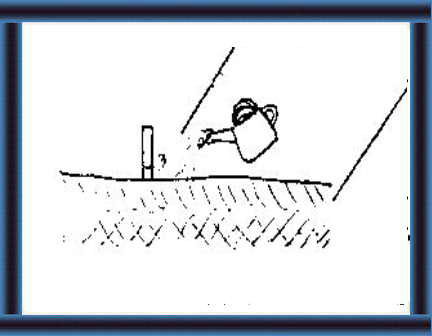

61 Measure the amounts of crop by marking

a pole along the silo wall.

After adding each layer of crop, sprinkle on the molasses mixture.

|

|

62 Note

Molasses is not so necessary:

|

|

63 Salt

Salt helps the silage process in the same way as wilting. Add 1-2% of salt to the crop (less if the crop is dry, more if it is not so dry). |

|

64 Keeping out soil

Do not put any crops with soil or other dirty material into the silo. This will slow down or spoil the

silage process.

|

|

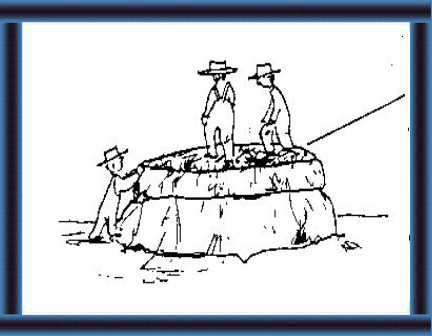

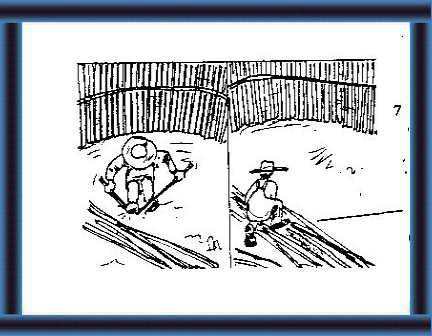

65 Compacting

Compact the crop all the time as

you fill the silo.

|

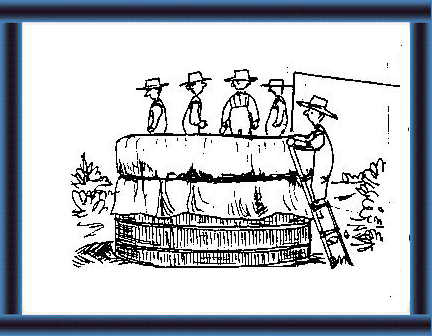

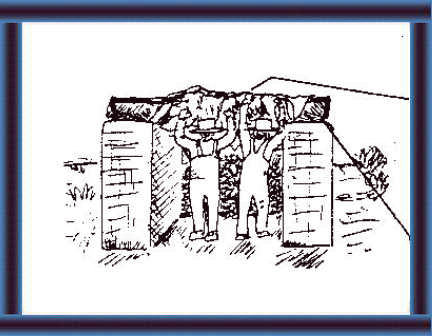

| 66&67

Compact the crop by continuous treading.

|

|

68 This farmer compacted his crop

well.

The silage is good.

|

|

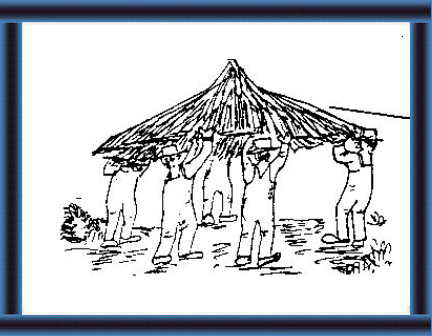

69 This farmer did not compact his crop

well.

The silage is poor. It is difficult to harvest with a spade and there is a lot of waste. You can also compact the crop by machine. |

|

How long does it take to fill a silo?

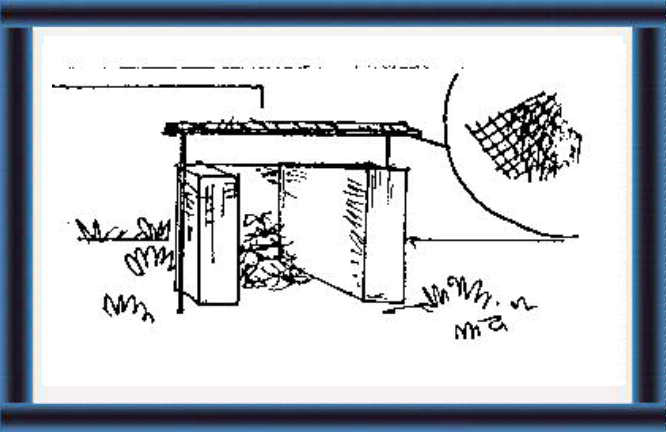

70 Fill your silo in one day and seal quickly. This will improve and speed up the silage process. |

| Important when planning:

1 How long to chop the crop? 2 How long to put the chopped crop into the silo? If necessary, ask your neighbours to help fill the silo in one day. |

|

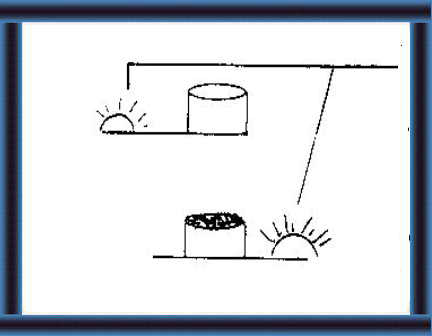

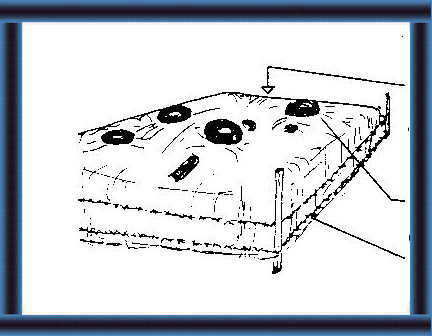

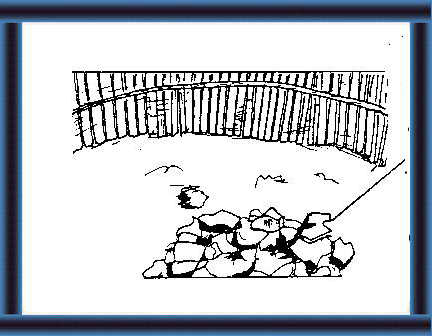

71 Fill the silo to 1 - 1.5

m from the top.

Fix the plastic cover inside the silo walls. |

|

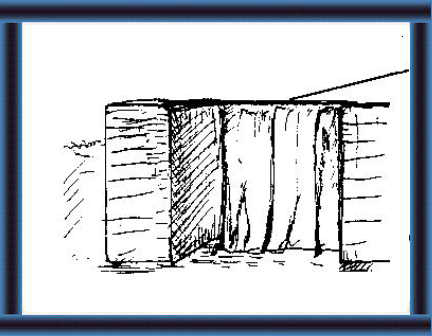

72 Upright silo with plastic cover.

The plastic sheeting follows the inner side of the silo wall 1-1.5 m. |

|

73 Fill the silo above the level of the

edge.

Cover the silo with the plastic and seal quickly. |

|

74 Place a layer of soil or daub

on top.

This protects the plastic against animals and sunlight. The weight also compacts the silage. You can use old tyres for weight and a barbed wire fence to protect the cover against animals.

|

|

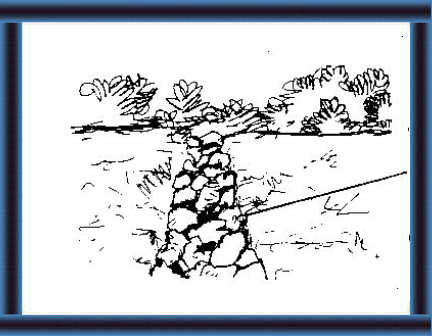

75 Dig drains to carry

the waste away from the silo.

Make sure the waste does not go near your drinking water. |

|

76 Fill the drains with stones or crushed rocks. |

|

77 |

|

78 If there are no stones or rocks, fill the

drains with branches or twigs.

|

\ |

79 Make a wooden platform to protect the top part of the silo against sunlight.You can move the platform as you remove silage from the silo. |

|

80 Nail gunny bags onto

the wooden platform.

This shades the front part of the silo. The plastic sheet (from sealing) also covers the silo. |

|

81 Make a curtain of gunny bags.

This is easy to lift. Record feeding instructions in the black area. |

|

82 You can remove

the

roof

on

this "wattle" silo.

This shades the silage surface during feeding time.

|

| 83 You can use a filled wattle-and-daub

silo.

84 Make the feeder from twigs.  |

| Brickwall trench silo

85 Build a barb wire fence to protect your silo.

|

|

86 Cut oil drums in half to make feed troughs. |

|

87 Make a simple shade

for silo.

Use wire-mesh and cover with straw.

|

|

The feeding value of silage depends on the type of crop and the success of the silage process. |

|

Appearance

|

| Dry Matter Content

Take a wad

of silage.

|

|

|