M. Adel El-Sayed Assal, expert égyptien retraité, spécialiste des fibres, a effectué une mission auprès de l'Organisme du coton et des oléagineux, dépendant du Ministère iranien de l'agriculture, pour résoudre des problèmes techniques dans les laboratoires de pointe de cet organisme. La mission était coordonnée par le Service des agro-industries et de gestion après récolte de la FAO (AGSI).

Au cours de sa mission d'un mois organisée dans le cadre du Programme pour l'utilisation d'experts retraités, M. Assal a mis à profit son expérience dans le domaine des fibres pour déterminer les causes du dysfonctionnement du matériel de laboratoire. Après avoir pris contact avec les fabricants aux États-Unis pour obtenir des pièces de rechange, il mis à jour les manuels et organisé l'envoi d'agents d'entretien par les correspondants des fabricants des pays voisins.

El experto en fibras jubilado, Adel El-Sayed Assal llevó a cabo una misión sobre los problemas en los laboratorios de alta tecnología algodonera del Organismo del Algodón y Semillas Oleaginosas del Ministerio de Agricultura. La consulta de Assal en Irán estuvo coordinada por el Servicio de Industrias Agrícolas y Alimentarias de la FAO (AGSI).

Durante su misión, que duró un mes, en el ámbito del Programa de Expertos Jubilados, el Dr. Assal aprovechó su amplia experiencia para individuar los problemas que hace que el equipo de los laboratorios funcione mal. Mantuvo contactos con los fabricantes americanos para organizar la entrega de piezas de recambio, de manuales actualizados para los operadores y tuvo acceso a técnicos de mantenimiento de agencias de servicios de los países vecinos.

![]()

Retired fibres expert Adel El-Sayed Assal undertook a troubleshooting mission to the high-technology cotton laboratories of the Cotton and Oilseeds Organization (C&OO) of the Iranian Ministry of Agriculture. His consultancy in Iran was coordinated by FAO's Agro-Industries and Post-Harvest Service (AGSI).

Assal worked for more than 40 years in the cotton industries of Egypt, the Syrian Arab Republic, Afghanistan and, most recently, Pakistan, where he was Chief

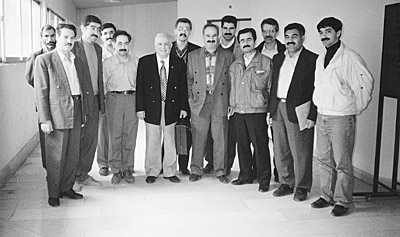

Adel El-Sayed Assal with staff he trained at the Cotton and Oilseeds Organization of the Ministry of Agriculture in Tehran |

The analytical fibres laboratory also plays a crucial role in the redevelopment of cotton standards in Iran, which is an important cotton producer. The sizeable Iranian cotton industry has approximately 250 000 ha under the crop and produces 140 000 tonnes of cotton per year. In an attempt to update its quality standards for cotton fibres, Iran recently installed a high-volume instrumentation (HVI) fibres laboratory at C&OO. This equipment is linked with sophisticated computer software to enable the technicians involved to ensure that the fibre samples comply with industrial standards and norms.

The problems that the C&OO laboratories were experiencing with their computer-based analytical equipment exemplify the complexity and lack of information that characterizes the cotton industry in Iran. During his month-long assignment under the Retired Experts Programme, Assal drew upon his extensive experience to identify the problems causing the equipment to malfunction. He made contact with the American manufacturers to organize delivery of replacement parts, updated manuals for operators and gained access to maintenance technicians from the service agents in neighbouring countries.

Training in management of the laboratories' sophisticated computer systems is essential, and Assal arranged for a technician from C&OO to undergo appropriate training to avoid a reoccurrence of such problems. Upon the re-establishment of laboratory functions, he made a number of recommendations to the Iranian Ministry of Agriculture. These included suggestions on how to exploit the costly HVI equipment better, with training, the maintenance of links between Iran and industrial standards organizations in other countries, improved contact with the HVI equipment manufacturer and, most important, a shift towards the establishment of a modern, HVI standards-based method of grading cotton in Iran.