by

Emara H.S.; Moustafa, E.K.; Attia, R.S.; and El-Sahn,

M.A.

Department of Food Science and Technology, Faculty of

Agriculture,

Alexandria University, Alexandria, Egypt

|

Abstract This study is aimed at developing new smoke cured products from the most important catfish genera in Egypt. Length/weight relationship, trunk percentage in relation to overall length, and filleting yield in relation to live weight are given. The organoleptic properties of wet fish entering the processing operations were evaluated on wet fish (external and internal) as well as by using the steaming test. Brining (before processing) with H2O2 as a bleaching agent improved the appearance of the karmout fillets before and after smoking. This was not necessary for the bayad fillets. The different hot smoking unit operations (drying, cooking, and the intensive hot smoking unit operation) were optimised for each fish and the logistic of the best processing operations are given. According to the organoleptic evaluation of the end products the consumers preferred the hot smoke cured bayad fillets than the karmout fillets. |

1. INTRODUCTION

Developing new products is of utmost importance, first to extend the range of new products, and second to use raw material with improved methods (Kreuzer, 1974). Azeza (1977) stated that smoked fish seems to be the most important type of fish products consumed in many African countries. A brined and smoked catfish fillets has been developed in Malawi (Mathorothe and Rogers, 1977). Eun et al. (1994) reported that the demand for catfish has grown dramatically in the USA.

The technology, or the known how, of hot smoke curing of fish is a dynamic technology depending on the raw material used, its form and size (whole, gutted or fillets) and last but not least on the hot smoking regime adopted (time and temperature optimum for the different hot smoking operations: drying, cooking, and the intensive hot smoking operation.

|

Logistics (flow sheet) of best processing operations for the production of hot smoke cured karmout and bayad fillets. |

This comparative study was carried out on one of the major indigenous freshwater fish i.e. the catfish using its two most important representatives, namely the karmout (Clarias lazera) and the bayad (Bagrus bayad). The aim of this study was to set-up the processing logistic for the hot smoke curing operations for each which will give the best end product judged by its organoleptic properties.

2. MATERIALS AND METHODS

2.1 Materials

Fish samples

Samples of karmout (Clarias lazera) and bayad (Bagrus bayad) were taken from El-Nozha Fish Farm at Alexandria, Egypt, during December- April for karmout; and November-March for bayad. Samples were transported directly after catching in insulated iceboxes to the lab.

Smoking kiln

A semi-automatic AFOS Kiln was used. Temperature inside samples was monitored during each processing operation: drying, cooking, and the intensive smoking unit operation by means of thermocouples.

2.2 Methods

Fish length and weight and composition of live fish was carried out according to Zaitsev et al. (1969).

Brining

Karmout fillets were smaller in size than the bayad fillets, hence it needed 30 min brining while the bayad fillets needed 40 min brining at the same brine strength 15 % salt = 0.5 saturated brine. Being darker in color the karmout fillets were brined in presence of H2O2 as a bleaching agent. 33 ml H2O2 (30 %) in one litre.

Salt content

According to A.O.A.C. (1980).

Sensory evaluation

According to the method adopted at the Alexandria Fish Technology Centre based on the method of Antonacopoulos (1973) and NRI (1996). Means and standard deviation were computed according to NRI (1996).

3. RESULTS AND DISCUSSION

Length/weight relationship

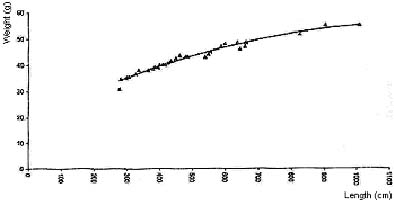

The length/weight relationship of karmout and bayad fish is illustrated in Figs 1 and 2. As it can be deduced from these results it takes a curved shape and is in accordance with Cutting (1962) concerning this relationship in fish in general. The data revealed that a relatively wide range of overall length was covered (35-55 cm in kamout and 32-65 cm in bayad) in order to try to find out which overall length was the most feasible from the processing point of view.

Fig. 1 Length/weight relationship of karmout (trials I and II)

Fig. 2 Length/weight relationship of bayad (trials I, II and II)

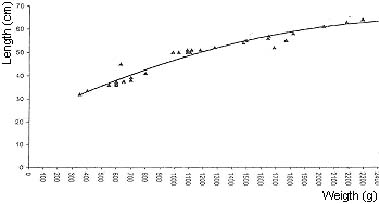

Trunk percentage in relation to overall length

The results illustrated in Fig 3a and 3b show clearly that there was a positive correlation between trunk percentage in relation to the overall length. However, this was more uniform and less dependent on the fish overall length in the karmout than the bayad and this is most probably a genotype effect. The results showed clearly that the smaller fish (less than 1 kg weight karmout) gave a filleting percentage slightly above 30 % fillets, those between 1 and 1.5 kg slightly below 40 % fillets, while those between 1.5 and 2 kg weight gave a better filleting yield exceeding 40 %. Bayad having more than 2 kg in weight gave about 1 % more fillets than those between 1.5 and 2 kg total weight. This empirical results mean that the most feasible weight of bayad, if filleted, is that fish having at least 1.5 kg total weight.

|

Fig. 3 Trunk percentage related to total length an filleting

yield related to total weight of wet karmout and bayad. |

Organoleptic properties of wet karmout and bayad entering the processing operations

Careful examination of Tables 1 and 2 reveals that both wet karmout and bayad fish entering the processing operations was of a very high quality = predicate: very fresh fish. The following remarks maybe deduced from Tables 1 and 2.

Table 1. Organoleptic properties of whole wet karmout

|

External attributes (whole fish) |

|

|

1. Appearance (body color) |

Uniform black-grey color, shiny wet skin, free of slime, fins intact, no color bleaching and shining appearance. |

|

2. Eyes |

Convex black pupil, translucent cornea and without any blood diffusion. |

|

3. Gill color |

Bright red, free of slime |

|

4. Smell |

No fishy smell, free of any objectionable smell. |

|

5. Texture |

Elastic texture and firm. |

|

Internal quality attributes (fresh flesh) |

|

|

A. Flesh odor |

Odorless, free of rancid odor, putrefactive odor, ammonia, or any other objectionable odor. |

|

B. Flesh color |

Reddish brown, not uniform, has some dark blood color, especially near the backbone. |

|

C. Texture |

No gaping, firm and elastic (springs back quickly on pressing by thumb). |

|

Predicate |

Very fresh |

Table 2. Organoleptic properties of whole wet bayad.

|

External attributes (whole fish) |

|

|

1. Appearance (body color) |

Uniform in color, grey on the back and white on the abdomen, Wet shiny skin, free of slime and fins intact. |

|

2. Eyes |

Convex black pupil, clear of blood and not turbid. |

|

3. Gill color |

Bright red, free of discoloration, lamella intact, no slime, free of any putrid or other objectionable odor. |

|

4. Smell |

No fishy smell, free of any objectionable smell. |

|

5. Texture |

Elastic texture and firm. |

|

Internal quality attributes (fresh flesh) |

|

|

A. Flesh odor |

Odorless, free of rancid odor, putrefactive odor, ammonia, or any other objectionable odor. |

|

B. Flesh color |

Creamish-white, uniform, without blood (stained areas). |

|

C. Texture |

No gaping, firm, not loose and elastic (springs back quickly on pressing by thumb). |

|

Predicate |

Very fresh |

External quality attributes

1-The bayad fish had always better appearance and were lighter in body color than the karmout. This is a genus dependent attribute.

2-Eyes and gills of both genera were of similar conditions reflecting a state of a very fresh fish.

Internal quality attributes

The bayad fillets were, in general, of better appearance due to the color of the fillets (creamish-white) while the karmout fillets were reddish brown and not uniform in color, having some dark blood color, especially near the backbone site; a feature that was not the case in the bayad. This is a genus dependent characteristic and is attributed to the rich blood supply within the fish muscles = active fish (Lisac,H. 1974).

Table 3. Organoleptic properties of cooked karmout (the steaming test)

|

Quality attributes |

Descriptive judgment |

Quality category |

|

|

1. Odor of flesh and exudate |

Like boiled egg or bouillon, smell free of putrefactive odors, rancid odor, ammonia or any other objectionable odor. |

Excellent |

|

|

2. Taste |

|

|

|

| |

2.1 Taste of flesh |

Cooked meat taste, cooked boiled egg taste, free of rancid taste, putrefactive taste, sweetish taste, sour, bitter or salty taste, or any other objectionable taste. |

Very good |

| |

2.2 Taste of exudate |

Like chicken, free of any objectionable taste |

|

|

3. Texture |

Flesh: firm and juicy. Exudate: fresh butter aroma, clear fat droplets, exudate light yellow without any sediment or flocking parts. No denatured proteins, odorless, free of rancidity and of a pleasant taste. |

Excellent |

|

|

4. Color |

|

|

|

| |

4.1 Color of flesh |

Light brown with dark areas around the lateral line (backbone area) |

Good |

| |

4.2 Color of exudate |

White-creamish in color, fat droplets on the surface free of any coagulate particles (proteins). |

Good |

|

Results (overall quality) = of prime quality = very good |

|||

Organoleptic properties of cooked fresh flesh (steaming test) of karmout and bead entering the processing operations

The results obtained from the different batches of fish (karmout and bayad) entering the processing operations are summarized and given in Tables 3 and 4 for karmout and bayad, respectively. The data revealed that:

(i) Both fish after cooking (without any additions) were of a pleasant odor (free of any objectionable odor).

(ii) Cooked fillets excreted a very little amount of exudate (solution separated from muscle mass). It was quite easy to distinguish the karmout from the bayad exudates in that the bayad exudate had some floating fat droplets. This is due to the fact that bayad fillets were more fatty than karmout ones. In all tested samples the exudate was of a pleasant taste (broth like) and free of any objectionable odor (i.e. not rancid).

(iii) Both cooked fillets were of a good taste. However the taste examiners preferred the cooked bayad than the cooked karmout fillets. This is again a genus dependent attribute and also a matter of taste (consumer preference).

Table 4: Organoleptic properties of cooked bayad (the steaming test)

|

Quality Attributes |

Descriptive judgement |

Quality category |

|

|

1- Odor of flesh and exudates |

Bouillon-like, free of any rancidity or sourness or any other objectionable odor. |

Excellent |

|

|

2- Taste |

|

|

|

| |

2.1 Taste of flesh |

Pleasant taste, egg like, free of bitterness, sourness, saltiness, sweaty taste or any other objectionable taste. |

Excellent |

| |

2.2 Taste of exudate |

Like chicken broth and free of any objectionable taste. |

|

|

3- Texture of flesh |

Less juicy but soft, firm and no gaping in appearance, still of a very good quality. Not all having excellent quality. Loss of some juiciness, coincide with the somewhat turbid exudates after cooking. Being still of a very good quality. |

Very good |

|

|

4- Color |

|

|

|

| |

4.1 Color of flesh |

White yellow (unless along backbone site) at the outer upper (dorsal) and lower (ventral) fillet surfaces. |

Very good |

| |

4.2 Color of exudate |

White-creamish in color, fat droplets on the surface, small all amounts of dispersed coagulated particles (proteins) |

|

|

Results (overall quality) = of prime quality = very good |

|||

The brining operations

Table 5: Salt content of karmout and bayad after brining and smoking

|

Sample |

Brine strength and time |

|||

| |

½ Sat./20 min |

½ Sat./30 min |

½ Sat/40 min |

|

|

1-Karmout |

|

|

|

|

| |

Fresh |

0.31 |

0.29 |

- |

| |

Brined |

1.07 |

1.65 |

- |

| |

Smoked |

1.8 |

2.50 |

- |

|

2-Bayad |

|

|

|

|

| |

Fresh |

0.22 |

0.25 |

0.22 |

| |

Brined |

0.98 |

1.32 |

1.77 |

| |

Smoked |

1.39 |

2.30 |

2.98 |

|

Salt content % w/w = 15% meaning half saturated. \ Concentration of saturated salt solution

= |

||||

Table 5 represents the salt content in fresh karmout and bayad fillets before and after the brining operation. This data revealed that the salt content in the fresh samples of karmout was (0.29-0.31 %) and (0.22-0.25 %) in bayad fillets. This is in accordance with the normal salt content in fresh-water fish (Zaitsev et al., 1969) and this difference is genus dependent.

The aim of the brining operation was to impart a lightly salted taste in the finished (smoked fillets) rather than to have a preservative effect as it is the case in the cold smoking products. Karmout fillets were smaller in size than the bayad fillets, hence it needed only 30 min brining while the bayad fillets needed 40 min brining at the same brine strength (15 % salt). After smoking the finished product had a salt content of 2.5 % in karmout and 3 % in bayad fillets.

The technology of hot smoking of karmout and bayad

Hot smoking process is a combined unit process. It can be broken down into three unit operations (or steps). Each of these unit operations has a direct influence on the following end products quality and/or end products consumer preference:

|

Appearance: |

Represented in the color of the end product. |

|

Texture: |

Being hard or soft. |

|

Flavor: |

Having a light, moderate or heavy smoking flavour. Hence, time and temperature of each of these unit operations are of a paramount important in order to reach the desired end product characteristics. These unit-operations are the drying operation, the cooking operation and the intensive hot smoking operation. The experience gained from the review of literature reveals that nowadays (especially in the developed countries) fish smoking in general has experienced a paradigms shift. It is no longer regarded as a method for obtaining an end product having the maximum shelf life (except in tropical Africa) but as a method for obtaining an end product having the highest quality = quality oriented production. However, the definition highest quality is a subjective and not an objective one and is also closely related to consumer safety. No doubt that lightly smoked and lightly salted hot smoked products are much appreciated, from the health point of view, than heavily salted and/or heavily smoked end product. Thus setting up the optimum time and temperature for each of this unit operations i.e. drying, cooking and the intensive hot smoking operations was called on. This was achieved during the course of this study by means of trial and error concept, which is still a legitimate scientific approach for problem solving. |

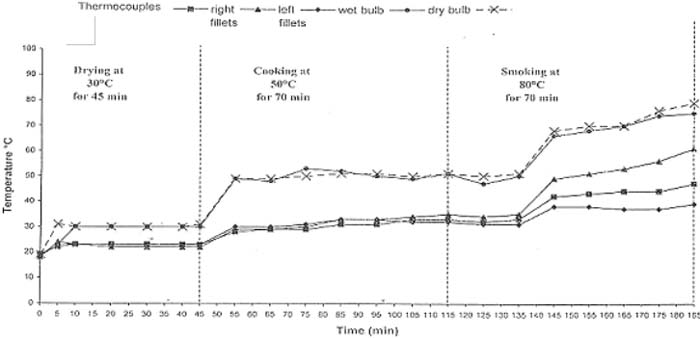

The drying unit operation

It is a necessary unit operation. Its aim is to render the product surface suitable for acceptance and/or deposition of smoke particles and/or active components. On the contrary wet surface is not efficient in this aspect. It is usually done at ambient temperature or at temperature not exceeding +30°C. Time needed to end this operation depends on raw material chemical composition: Fat/moisture content, on product specific area; area/weight relationship, on temperature used and on ambient RH percent. Fatty raw material, low ambient temperature and high ambient RH percent elongate the time needed to end this operation. The time needed has to be empirically established for each raw material type (Fennema, 1975). Tables 6 and 7 gave the matrix of operations and their results obtained during the course of this study. This operation is usually ended when the raw material surface is no longer wet (not saturated with water, meaning P<Po = water vapor pressure of the product surface becomes less than water vapour pressure of pure water). This is easily observed by the phenomena that the raw material surface becomes waxy in appearance.

Table 6: Effect of hot smoke curing operations on product quality, karmout fillets

|

Trials |

T1 1995 |

T2 1997 best regime |

||||

|

Operation |

D |

C |

IHS |

D |

C |

IHS |

|

Temperature |

30 |

50 |

70 |

30 |

50 |

80 |

|

Time min |

45 |

60 |

50 |

45 |

70 |

70 |

|

Product main characteristics |

||||||

|

Color |

Light brown, not well developed, not homogeneous |

Homogenous dark brown, species typical (myoglobin interaction) |

||||

|

Smell |

Lightly smoke smell |

Mild smoky, typical for hot smoked products. |

||||

|

Texture |

Chewy, medium done, fibery |

Firm, juicy, well done |

||||

|

Saltiness |

Accepted a lightly salted |

Accepted as lightly salted |

||||

|

Taste |

Lightly salted and lightly smoked |

Lightly salted, good smoky taste |

||||

|

Overall quality Predicate: very good |

Not satisfactory mainly because of color and texture |

Very satisfactory with no deficient features NOD |

||||

D = Drying

C = Cooking

IHS = Intensive hot smoking

NOD = No observed defect

The cooking unit operation

It is the necessary unit operation which leads to render the raw material eatable by converting the native muscles to the denatured state suitable for mastication and digestion when consigned. Belitz and Grosch (1982) stated that fish muscle proteins are less heat stable than terrestrial animals muscle proteins and that the shrinking temperature of fish muscle collagen are also obviously lower (45°C compared to 65°C in terrestrial animals). Thus, cooking of fish muscle proteins can be successfully done at temperature < 50°C. The time needed depends on fish species and the size of fillets to be cooked. Bayad fillets do contain fewer amounts of stroma proteins (connective tissues) and this was reflected in the time/temperature regime needed for cooking. Table 7 reveals that cooking of bayad fillets was completed at 60°C for 60 min while the karmout fillet (Table 6) needed 50°C for 70 min (lower temperature but for longer time due to the high connective tissue).

Table 7: Effect of hot smoke curing operations on product quality, bayad fillets - best regime

|

Trials |

T1 1994 |

T2 1996 |

T3 1998 |

||||||

|

Operation |

D |

C |

IHS |

D |

C |

IHS |

D |

C |

HIS |

|

Temperature ºC |

30 |

50 |

80 |

30 |

60 |

80 |

30 |

60 |

90 |

|

Time min |

60 |

60 |

60 |

75 |

60 |

60 |

60 |

60 |

60 |

|

Product main characteristics |

|||||||||

|

Color |

Light brown, not well developed |

Well developed, brown, typical for smoked white meat, homogenous and attractive. |

Well developed, brown, typical for smoked white meat, homogenous and attractive |

||||||

|

Smell |

Lightly smoky smell |

Good smoky smell |

Richy smoky smell, typical for hot smoked products |

||||||

|

Texture |

Chewy, medium done, watery |

Juicy, well done, but tail ends dry and hard |

Juicy, well done, homogenous along the fillets pieces |

||||||

|

Saltiness |

Very lightly salty |

Accepted lightly salty |

Typical for lightly cured products |

||||||

|

Taste |

Lightly salted and lightly smoked |

Lightly slated and lightly smoked |

Lightly salted, good smoky taste, delicious |

||||||

|

Overall quality Predicate: very good |

Not satisfactory mainly because of color and texture |

Not satisfactory texture characteristics not homogenous |

Very satisfactory with no deficient features NOD |

||||||

D = Drying

C = Cooking

HIS = Intensive hot smoking

NOD = No observed defect

The intensive hot smoking unit operation

It is the most sensitive and/or crucial unit operation in hot smoking process in general. Its aim is to round-up the product, meaning completing its smoke ingredients uptake leading to color improving and giving the product its specific smoky taste as well. It has to be done at temperature > 70°C depending on species form and size of the raw material to be processed e.g. in form of whole gutted or fillets of fish. Its temperature limit for lightly smoked products seldom exceed 90°C, for heavily smoked products it can reach up to 120°C. Time needed depends on form of raw material and on fish species specially its fat and connective tissues content (Burt, 1989). Table 7 reveals that for the bayad fillets the best regime for this unit operation was 90°C for 60 min while this unit operation for the karmout fillets was 80°C for 70 min (best treatment, respectively).

Salt content of the end product

These increases in the salt content by hot smoking process agree with the results obtained by Karara et al. (1980). They found that hot smoking process of dogfish caused an increase in the content of salt from 1.3 in fresh to 1, 1.4 % in hot smoked sample on dry weight basis. Also, agree with Abu-Salem and Kalaf (1986) showed that salt increased from 0.23 % to 4.0 % on wet weight basis in hot smoked karmout and agree with Bhuiyan et al. (1986) and Bassiouny et al. (1999).

Weight losses (processing yield)

Live weight of karmout entering the processing cycle ranged between 280 and 660 g/fish in trial I and between 480 and 1010 g/fish in trial II. The data presented in Table 8 reveals that big size karmout gave lower dressing losses than small size one. Practically, there were no differences due to brining between big and small size karmout (0.75 and 80 %, respectively). After the hot smoking operations (drying, cooking and intensive smoking) the bigger the karmout the lower were the losses, despite the fact that time/temperature parameters were not the same. The overall yield of the best treatment (big karmout, trial II) was about 18 %.

Fig 4. Smoking curve of karmout - trial II (best treatment)

The live weight of bayad entering the processing cycle ranged between 350 and 800 g/fish in trial I, between 630 and 2750 g/fish in trial II and between 990 and 2200 g/fish in trial III. The data presented in Table (9) reveals the same trend observed in the karmout i.e. the bigger the bayad the lower were the dressing losses and that the brining operation did have no practical effect on the losses (ranging between 0.75 and 0.9 %). After the hot smoking operations the bigger the fish the lower were the processing losses and consequently the higher were the processing yields.

Table 8: Weight losses of hot smoke cured karmout and bayad fillets due to the different processing operations.

|

Operation |

Weight loss % |

||||

|

Trial I |

Trial II |

Trial III |

|||

|

Karmout |

Bayad |

Karmout |

Bayad |

Bayad |

|

|

Dressing |

62.1 |

68.1 |

60.5 |

61.6 |

61.2 |

|

Brining |

0.8 |

0.9 |

0.75 |

0.7 |

0.8 |

|

Smoking |

26.8 |

24.5 |

20.0 |

30.5 |

27.3 |

|

Total |

89.7 |

93.52 |

81.25 |

92.81 |

89.3 |

|

Yield (%) |

10.22 |

6.48 |

18.75 |

7.2 |

10.7 |

Table 9: Sensory evaluation of hot smoke cured karmout (best treatment and not stored)

|

Descriptive/Hedonic rating |

|||

|

Quality attributes |

Characteristic of the different attributes |

Degree from (9) |

Predicate |

|

Odor |

Smoky, free of any objectionable odors |

8.3±0.1 |

Excellent |

|

Color |

Reddish brown, not homogeneous, some parts darker than others (blood residues) |

7.7±0.3 |

Very good |

|

Taste |

Lightly salted, lightly smoked free of other objectionable tastes |

6.9±0.5 |

Very good |

|

Texture |

Firm, juicy, skin easily separated from muscles. |

6.7±0.2 |

Good |

|

Overall quality |

Typical according to type of fish and to hot smoked product. |

7.8±0.3 |

Very good |

9 point scale: 9 excellent; >7.5 = very good; >6.5 = good; >5 = border line; <5 = have a product failure After Antonacopoulos 1973

Tabel 10: Sensory evaluation of hot smoke cured bayad (best treatment and not stored)

|

Descriptive/Hedonic rating |

|||

|

Quality attributes |

Characteristic of the different attributes |

Degree from (9) |

Predicate |

|

Odor |

Smoky, free of any objectionable odors, free of rancid odor, putrefactive odor |

8.8±0.3 |

Excellent |

|

Color |

Light brown, free of burnt areas, free of any spots, uniform color |

8.8±0.3 |

Excellent |

|

Taste |

Lightly smoked taste, low salt contented, free of any objectionable tastes |

8.7±0.2 |

Excellent |

|

Texture |

Smooth, juicy, not chewy, outer crust is chewy |

8.4±0.1 |

Excellent |

|

Overall quality |

Typical for hot smoked product |

8.5-9±0.4 |

Excellent |

Effect of hot smoke curing operations on the organoleptic properties of end products

The products obtained during the course of this study were the output of the hot smoking process. Product quality is the resultant and not the mere-some of its specific attributes. Quality is not an accumulative result. It is a dynamic result and is directly affected by the interaction between the specific quality attributes to each other and upon each other. The results of the organoleptic properties of the end products before being frozen stored are given in Tables 9 and 10. They reveal that the hot smoked karmout fillets were rated (evaluated) somewhat different than the corresponding bayad fillets. This may be attributed to the following remarks:

|

(i) Odor: |

Both end products were similarly rated concerning product odor i.e. both had the desirable smoky odor free of any objectionable odor. |

|

(ii) Color: |

The hot smoked bayad fillets had a better color than that hot smoked kannout fillets. This is attributed to the somewhat darker color of the hot smoked karmout fillets and this is most probably due to the original dark color of the fresh karmout fillets which had more blood after filleting and this attribute was improved by using a bleaching agent (H2O2) in the brining operation i.e. a species dependent attribute. |

|

(iii) Taste: |

Taste of the hot smoked bayad fillets was rated 1.5 points higher than the taste of the hot smoked karmout fillets and this is a genus dependent characteristic and reflected subjective consumer preference. |

|

(iv) Texture: |

Texture of the hot smoked bayad fillets was somewhat better than the corresponding karmout fillets, being more juicy and is again a genus-dependant characteristic. |

|

(v) Overall quality: |

The overall quality of the hot smoked bayad fillets were better rated than the hot smoked kannout fillets and this related to the effect of fish genus and the hot smoking process adopted to give the best treatment for each fish. |

4. BIBLIOGRAPHY

Abu-Salem, F.M. and Kalaf, H.H. (1986). Changes in microbiological and chemical properties of smoked karmout (Clarias lazera) during storage: Proceedings of the 11th International Conference on Statistics and Sociological Research: Cairo, Egypt.

Antonacopoulos, N. 1973. In: Fische und Fischerzeugnisse pp.190 (Ed. W. Ludorff and V.Meyer-Veri-paul parey, Berlin and Hamburg.

A.O.A.C. (1980). Official Methods of Analysis. 13 Ed. Association of Official Methods of Analytical Chemists, Washington, DC., USA.

Azeza, N.I. (1977). Fish handling, processing and marketing in the Chad Basin, in: Handling, Processing and Marketing of Tropical Fish pp.349: Tropical Products Inst., London, England.

Bassiouny, S.S., Abu-EL-Maati, S.M. and Zakar, A. (1999). Chemical and microbiological changes of smoked common carp fish during frozen storage. The 4th Alexandria conference on Food Science and Technology, pp. 11 1-124. Fac. Agric. Alex. Univ. March 1999.

Belitz, H.D. and Grosch, W. (1982). Lehrbuch der Lebensmitteln. Chem. Springer-Verlag-Berlin.

Bhuiyan, A.K.M., Ratnayake, W.N. and Ackman, R.G. (1986). Stability of lipids and polyunsaturated fatty acids during smoking of Atlantic mackerel (Scomber scombrus L.). J. Am. Oil Chem. Soc., 63:324-328.

Clement, S. and Lovell, R.T. (1994). Comparison of processing yield and nutrient composition of cultured Nile tilapia (Oreochromis niloticus) and channel catfish (Ictalurus punctatus). Aquaculture, 1 19:313.

Cutting, C.L. (1962). The influence of drying, salting and smoking on the nutritive value of fish. In: Fish in Nutrition, E.Hean and R.Kreuzer (Eds), Fishing News (Books), London, pp. 161-179.

Fennema, O.R. (1975). Principles of Food Sci. Part II. Physical principles of food preservation. Marcel Dekker, Inc. New York.

Huang, Y.W., Lovell, R.T. and Dunham, R.A. (1994). Carcass characteristics of channel and hybrid catfish and quality changes during refrigerated storage. J. Food Sci., 59:64.

Karara, H.A., Moustafa, E.K., Zouell, M.E. and Abdel-Rahman, A.Y. (1980). Effect of smoke curing on the chemical composition and the hygienic quality of hot smoked dogfish fillets. Alex. J. Agric. Res., 28:517.

Kim, J.M., Liu, C.H., Eun, J.B., Park, J.W., Oshimi, R., Hayshi, K., Ott,B., Aramaki, T., Seki De, M., Horikita,Y., Fujimoto, K., Aikawa, T., Welch, L. and Long, R. (1996). Surimi from fillets frames of channel catfish. J. Food Sci., 61:428.

Kreuzer, R. and Day, C. (1974). The practice of product development: In Fishery Products. pp. 278., Edited Rudolf Kreuzer, FAO, Fishing News (Books), Surrey, England.

Lisac, H. (1974). Upgrading and Adapting Fishery Products Lower Market Value In: Fishery Products pp. 160. Ed. R.Kreuzer, FAO, Fishing News Books, Surrey, England.

Mathorothe, A.J. and Rogers, J.F. (1977). Fisheries development in Malawi: In "Handling, Processing and Marketing of Tropical Fish". Tropical Product Inst., London, England.

NRI., (1996). Postharvest fisheries development: A guide to handling, preservation, processing and quality, Natural Resources Institute NRI, Overseas-Development Administration. Chatham. Maritime, Kent, England.

Zaitsev, V., Kizevetter, L., Lacunov, L., Makarova, T., Minder, L., and Podsevalov, V. (1969). Fish curing and processing. Moscow, Mir Publ. Co.

by

Kofi Manso Essuman

Development Manager

Unilever Ghana

Limited Tema

|

Abstract In response to the increasing demand for good quality, authentic local seasonings, Unilever Ghana carried out an extensive study into food habits and cooking ingredients in Ghana. Several varieties of local natural food flavours were identified. Consumers expressed interest in having these local seasonings developed into convenience foods for easy use and longer shelf life. Smoked shrimp powder was found to be one of the traditional cooking ingredients used to add flavour to local sauces and stews. Studies were carried out to establish processing procedures that will yield good quality shrimp powder. The product was further developed into a bouillon cube. Over 1 500 tonnes of the final product, Royco Shrimp Cube, has been produced. The product has been well received by consumers and is presently the market leader in Ghana. |

1. INTRODUCTION

Spices, herbs and condiments are widely as cooking ingredients to enhance the flavour of traditional sauces and soups throughout West Africa. Some of the common cooking aids very popular in Ghana and indeed West Africa, include common salt, Monosodium Glutamate salt, tomato paste and puree, fermented fish, bouillon cubes, curry and chilli powder. These food components constitute nearly 90% of the cooking ingredients market. Cold sauces like salad dressings, mayonnaise, tomato ketchup and other traditional hot sauces make up the remaining 10%.

The cooking ingredient market in Ghana is estimated at about 50 000 tonnes per annum and valued at over $60 000. Women using artisanal methods produce about 75% of cooking aids in Ghana with about 25% coming from the large manufacturing industries. These companies manufacture branded seasonings like ROYCO, MAGGI, JUMBO, KNORR, AJINOMOTO (A-1) and ADOBO. These products are available in various types of flavours such as beef, shrimp, chicken and fish. Unilever and Nestle are the 2 major companies that manufacture bouillon cubes in West Africa with over 80 % of the market share.

Rapid urbanisation and the growing number of itinerant workers, have in recent years, resulted in an increase in the number of people who eat outside the home. Patronage of convenience, semi-processed and ready-to-eat foods have also been increasing. Consequently, the number of out of home eating places (restaurants, fast food shops and chop bars) has been rising especially in the urban areas. These food outlets use a lot of flavour enhancing cooking ingredients to appeal to customers. Consumers are however becoming concerned about quality, health and hygiene and therefore tend to be selective in their choice of street foods as well as food ingredients for preparation of meals at home. Despite the increasing trend of out of home eating, Ghanaians love meals with traditional taste. These trends present a huge opportunity for the culinary market in Ghana.

Unilever successfully launched Royco, its culinary master Brand in June 1996 with the Beef bouillon cube. The product became very successful and in less than 5 years became the market leader in a very competitive culinary market. Over the years Nestle and Knorr launched new flavours and other brands in Ghana-Maggi by BestFoods.

Four years ago, Unilever carried out an extensive consumer research to identify common local flavours with a view to strengthening the Royco brand and maintain dominance in the bouillon market. The research identified shrimp powder, onions, garlic, fermented/salted fish, Dawadawa, nutmeg and aniseed as some of the local cooking ingredients commonly used to enhance the flavour of sauces and stews. Studies carried out in Accra, Kumasi and Tamale showed that shrimp powder is widely used in the preparation of local gravy, sauces, vegetable stews and soups. Indeed Maggi Shrimp Cube was reported to enjoy a lot of patronage. Consumers overwhelmingly expressed great interest in having local flavours in convenient form such as a bouillon cube.

Realising the huge market opportunities in the traditional flavours market, Unilever Ghana successfully developed and launched a shrimp bouillon cube using local smoked/dried shrimp powder to meet the growing demand for hygienically prepared indigenous cooking ingredients. This paper reviews the development process.

2. SHRIMP POWDER PRODUCTION

Development of the production of shrimp powder

Several trips were carried out to the major shrimp producing areas along the beach in Accra, Tema, Ada and the Nzima district in the Western Region of Ghana. Samples of smoked-dried shrimps were also purchased from Cote d'Ivoire for evaluation. One processor from Chokor in Accra was hired temporarily to carry out shrimp smoke-drying trials in the factory. By this arrangement a method for the production of good quality smoked shrimp was developed (Fig 1). Optimum processing conditions that gave the best quality shrimp powder were established. Product specifications indicating quality characteristics of shrimp powder were established (Table 1). After this exercise two key processors - FLOKAN Ltd., and SYLVIA'S CATERING SERVICES - were contracted to produce smoke/dried shrimp powder. They were trained and assisted to establish processing facilities using local metal ovens to produce shrimp powder in accordance with established standards and good manufacturing practice. According to one of the suppliers, 1 tonne of fresh shrimps can be smoked in a day during the peak season.

Figure 1. Processing of good quality smoke dried shrimp powder.

Availability of fresh shrimps is seasonal therefore one of the major difficulties was getting good quality fresh shrimps all year round. Shrimp powder was imported from Norway but the taste was found to be significantly different from locally produced shrimp powder and therefore not accepted.

Key factors in the production of good quality shrimp powder

Fresh shrimps should be purchased from registered seafood supplier.

Supplier must have a cold store to store shrimps at -20°C

Cold stored shrimps must be washed in 20% Sodium Chloride solution in a clean room painted with anti-fungus paint. Good housekeeping must be ensured.

All persons handling shrimps during washing must wear rubber gloves. All operators handling shrimps must wash their hands frequently with detergent to prevent bacterial spread.

Shrimps should be spread on a wire mesh suspended over a wood/coconut husk fire for smoking.

Smoking should be done on a low fire for 8 hours and dried to a moisture content of not more than 10.5%

Smoke/dried shrimps should be ground using a hammer mill with mesh size 2.5 mm

Grinding must be done in a separate area from washing. The grinding area must be tiled with terrazzo floors for easy cleaning and wiping.

Hammer mill must be cleaned at the end of each day. Once a week the mill must be dismantled and properly washing with a suitable detergent and rinsed with ethanol.

Dried shrimp may be treated by Gamma radiation with an absorbed dose of 10kGy for microbial load reduction.

After milling shrimp power should be mixed with salt at a 50%/50% ww.

10-20 kg of the Shrimp and iodised salt mixture should then be packed into woven polypropylene sacks with an inner lining of 100 micron polythene film and stored on pallets in a cool dry area (15-20ºC) free from insects and rodents.

The bags should be labelled with product name, name and address of manufacturer, date of production and batch number.

Table 1. Quality standards of shrimp powder

|

Parameter |

Standard |

|

Flavour |

Characteristic smoked shrimp taste and aroma |

|

Appearance |

Light orange/brown and free flowing |

|

Moisture |

Average 6% (10% max) |

|

Salt |

50-55% |

|

TVC |

5000 cfu (colony forming units) |

|

Moulds and yeasts |

100 cfu |

|

Enterobacteriaceae |

10 cfu |

|

Salmonella |

Absent |

|

Clostridium |

Absent |

|

Benzpyrene |

1ppb max. |

3. BOUILLON CUBE DEVELOPMENT

Formulation

Several formulations with different levels of shrimp powder were produced and tested in the laboratory. These were tested extensively by sensory evaluation using trained and untrained panels. The results were confirmed further by consumer test. Bouillon cubes were produced from the preferred formulation following the procedure used in the manufacture of Royco beef cube. The Royco Shrimp Cube obtained was used to prepare various meals and evaluated by a number of internal and external consumer sensory panels in comparison with other known competitor samples. In general, panellists ranked Royco shrimp cube very high for taste, aroma, convenience and other quality characteristics. Fig 2 is a flow chart showing the manufacture of Royco Shrimp cube.

Storage

Figure 2. Flow chart for the production of shrimp bouillon cube

Raw Shrimp powder and Royco shrimp cubes were stored for 6 months, under simulated market and kitchen conditions, to evaluate the effect of storage on the quality of the products. Sensory and analytical tests conducted on the cubes after storage did not reveal any significant deterioration in the quality of the product. Following these trials a shelf life of 12 months was established for the product Royco Shrimp Cube. The shelf life of shrimp powder was prolonged to 9 months by mixing with iodised salt.

Sourcing of fresh shrimps

From the visits to the main shrimp producing areas, it was established that the peak period for shrimps coincides with the main Sardinella season, which occurs from June to September. During this period, fresh shrimp is relatively cheap. In the lean season however, the price of shrimp powder can double.

Packaging

The cube measured 14mm x 14mm x 14mm. The primary packaging consisted of 8 mic Aluminium foil/22 gsm tissue paper. The key distinguishing feature of the wrapper design was a pair of shrimps on each side of a cooking pot. 100 pieces of the wrapped cubes are packed into a printed polythene bag and sealed. 20 of these polythene bags are then packed into a corrugated box and sealed.

4. DISCUSSION

Royco shrimp bouillon cube was launched in 1996 with a total sale of about 200 tonnes. Over the past five years the product has shown tremendous growth and is clearly the market leader today. Sales have more than doubled and are set to exceed 500 tonnes this year. Consumers, especially restaurant and chop bar users have expressed interest in bigger packs, consequently a 100 g sachet was launched. Early this year, a 10 g tablet was also launched. To date nearly 100 tonnes of locally smoked shrimp powder valued at about $400 000 have been purchased and used to produce Royco shrimp bouillon cube.

5. CONCLUSION

The development of a bouillon cube based on the natural flavour of smoked dried shrimps has been a successful project. This is evidenced by the fact that Royco shrimp cube is undoubtedly the most popular bouillon seasoning in Ghana today. One major issue has been the availability of shrimp powder from the suppliers. Attempts to use imported shrimp powder from Scandinavia was not successful because consumers detected the difference in taste and did not accept the change.

Poor hygiene, lack cold storage facilities at many landing sites and processing of poor quality shrimps lead to high bacteria count of the product. This limits the source of good quality smoke/dried shrimps that can be used in the manufacture of high value products. This project clearly demonstrates that big multinational companies can collaborate with traditional food processors to develop local flavours for local consumption and possibly for export.