by

Somnuk Wechasitt

| ABSTRACT |

| A method is described for cleaning the interior canals of brackishwater ponds by using a high pressure hose to flush out accumulated debris. |

One of the traditional methods of pond construction in Southeast Asis is to make a dike by taking the soil from the area next to the dike. This process leaves a shallow canal adjacent to the dike all around the pond. It is thought that the deeper water in the canal is useful in maintaining cool temperatures for penaeid shrimp. Consequently, even in more modern pond design a “sheltering canal” is provided, sometimes down the middle of a pond instead of at the edges.

While the interior canals do provide good protection from high temperature, all the debris in the pond tends to collect there. This includes soil eroded from the dikes, sedimentation of particulate matter from new water, uneaten food particles and dead plankton. After some time, sediment at the bottom of the canals becomes foul and contributes to deterioration of water quality in the pond. In many places the sedimented material in the canal is removed by hand once a year. This is a time-consuming, costly procedure and is not feasible in places like Malaysia where labour is scarce and well paid. A disadvantage of hand-cleaning is that a great deal of the debris thrown on the dike soon washes back into the pond. As an alternative, a simple method utilizing a high pressure water jet to stir up the bottom sediments so that they can be flushed from the pond, has been found effective in cleaning the canals with much less labour.

The procedure requires a high pressure water jet to stir up the sediments and another source of water flowing through the pond to carry out the suspended sediments. The system works best in ponds with two gates where water can be kept high in one canal and water flowed through the pond on low tide. Ponds supplied with pumped water at one end of a pond and gravity drainage at the other end would also be well suited. In ponds with a single gate water must be pumped from adjacent ponds, canals, or from outside the main dike. A propeller-type longtail pump from Thailand has been used for this purpose at the Brackishwater Aquaculture Research Centre, Gelang Patah, Johor. The pump is 4.9 m long with a diameter of 15 cm and powered by a 9 hp engine. It is easily carried from place to place. In practice, the pump is placed in an adjacent canal or pond. A chute is made from galvanized iron roofing material to carry the water from the pump into the pond to be cleaned. To prevent excessive erosion of the bottom where the water runs into the pond a sheet of corrugated asbestos roofing is placed on the bottom. A divider made from scrap pieces of wood or roofing material is placed in the interior canal to keep the water flowing down only one side of the pond. After one canal is cleaned the divider is moved to the other side of the pump so that water flows down the other side of the pond.

The high pressure water jet is supplied by a 5 cm water pump powered by a 3.3 hp petrol engine. The pump is placed on top of the dike. The intake is from a 4 m section of reinforced hard rubber hose which extends to the adjacent pond or water canal. If there is no water source near to the side of the pond, it should be possible to use the water pumped in at the end by placing the intake hose in the canal upstream from the working area. Water is discharged through a 15 m section of flexible (5 cm) hose which has a nozzle attached. The nozzle is brass with an opening of 1.1 cm.

The pond is drained, and water is flowed through to clean the canal. Cleaning starts at the discharge gate. The high pressure hose is used to cut a narrow channel (38–40 cm) wide in the middle of the canal. This process continues the full length of the canal. The high pressure pump is moved along the dike as the work proceeds down the pond. Clearing the narrow channel is necessary to maintain a flow rate great enough to prevent the detritus from settling again once it is stirred up. If the whole width of the canal (typically 5 m) is cleaned initially, the flow rate through the cleaned portion is very slow and it is not long before material starts settling. Then the section already cleaned must be cleaned again.

After the narrow canal is finished, work starts to clean the whole width of the canal. This is done by stirring up the sediments at the point where the large volume flow is entering the pond. All the debris is forced in the narrow channel, which has a flow rate sufficient to keep it in suspension. Work continues back down the pond until the whole side is clean. At the station a work force of our persons has been able to clean a 5 m wide canal of 20–30 cm of sedimented debris at a rate of 30–40 m of canal per hour.

As the silt-laden water runs out of the pond a great deal of the silt settles in the water canal. This can be flushed out of the canal if other ponds in the system are kept at full level, and then water is discharged from them to clear the canal.

Photograph 1. Water running into pond before cleaning

|  | |

| Photograph 2. Longtail pump to supply water to flush loosened sediment from pond | ||

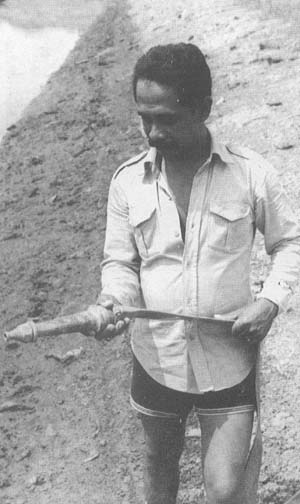

| Photograph 3. Worker with hose nozzle |

Photograph 4. Small channel already dug. Starting to clean 5 m wide canal

|  |

| Photograph 5. Starting to form 50 cm wide channel | |

| Photograph 6. Canal 5 m wide after cleaning |