A1.1 ITINERARIES AND PERSONS MET

| Mr L. Berg and Mr R. Vétillart (Common Programme) | |

| 1–2 August 1988 | |

| Briefing at FAO Headquarters, Rome | |

| 2 August 1988 | |

| Departure from Rome. Arrival in Frankfurt | |

| 3 August 1988 | |

| Departure from Frankfurt. Arrival in Ankara Meeting with FAO Representative's Assistant | Mr Bernhard P. Reufels |

| 4 August 1988 | |

| Meeting at Ministry of Agriculture, Forestry and Rural Affairs, General Directorate of Projects and Implementation General Director Ichthyologist (Fisheries Division) | Mr Hasim Ogut Mr Akil Yildiz Mr Bernhard P. Reufels |

| Meeting at UNDP Field Office. Resident Representative | Mr W. Holzhausen Mr Bernhard P. Reufels |

| 5 August 1988 | |

| Departure from Ankara. Arrival in Antalya Meeting with Project Coordinator (Provincial Directorate of Ministry of Agriculture) | Mr Oktay Atilâ |

| 6 August 1988 | |

| Departure from Antalya. Visit to harbour facilities (seaworks) of Antalya, Kemer and Finike. Arrival in Demre. Visit of existing project facilities of the Beymelek Lagoon Aquaculture Centre. Meeting with President of Beymelek Fishermen's Cooperative | Mr Güngör Kusakgi Mr Oktay Atilâ |

| 7 August 1988 | |

| First survey on project site, lagoon mouth and existing fish barrier, seashore, bathymetry. Departure from Demre. Arrival in Antalya | |

| 8 August 1988 | |

| Meeting at Provincial Directorate of Ministry of Agriculture. Director Deputy Director Head of Project and Statistic Division | Mr Süleyman Evren Mr Ahmet Kuzucu Mr Ginar Aybak Mr Oktay Atilâ Mr Akil Yildiz |

| Project discussion at Provincial Directorate | Mr Oktay Atilâ Mr Akil Yildiz |

| 9 August 1988 | |

| Project discussion at Provincial Directorate and meetings at following organizations | Mr Oktay Atilâ Mr Akil Yildiz |

| Representative of Project and Statistic Division | Mr Adil Bazoglu |

| Project Manager, Turkish Electricity Company (TEK) Ministry of Transport | Mr Aykut Taylan Mr Sadik Köseoglu |

| 10 August 1988 | |

| Departure from Antalya. Arrival in Demre | |

| 10–14 August 1988 | |

| Site surveys, guidelines for topographical (11–12 August) and pedological (12 August) surveys, preparation of provisional design, cost estimate and interim report | |

| 15 August 1988 | |

| Department from Demre. Arrival in Antalya Meeting with Project Coordinator | |

| 16–17 August 1988 | |

| Meetings at Provincial Directorate - Final collection of cost information and data. Final discussion of project proposal with Deputy Director and Project Coordinator | |

| Mr L. Berg | |

| 18 August 1988 | |

| Departure from Antalya. Arrival in Ankara | |

| 19 August 1988 | |

| Meetings at UNDP/FAO Office in Ankara, with FAO Representative Representative of State Planning Organization | Mr P. Rosenegger Mr Altan Acara Mr Bernhard P. Reufels Mr J.L. Bock Mr W. Holzhausen |

| UNDP Resident Representative | |

| Meeting at the Ministry of Agriculture General Director of Projects and Implementation | Mr H. Ögur Mr P. Rosenegger Mr Bernhard P. Reufels Mr J.L. Bock |

| Departure from Ankara. Arrival in Istanbul | |

| 20 August 1988 | |

| Departure from Istanbul. Arrival in Milan | |

| 19–24 September 1988 | |

| Debriefing in Rome | |

| Mr R. Vétillart | |

| 18–22 August 1988 | |

| Final preparation of drawings and technical documents. Meetings at the Provincial Directorate of the Ministry of Agriculture in Antalya | |

| 23 August 1988 | |

| Departure from Antalya. Arrival in Ankara | |

| 24–25 August 1988 | |

| Meetings at FAO/UNDP Offices and at the Ministry of Agriculture in Ankara Research of local equipment suppliers, especially for centrifugal pumps | |

| 26 August 1988 | |

| Departure from Ankara. Arrival in Rome | |

| 29–30 August 1988 | |

| Debriefing in Rome |

A1.2 MISSION PROGRAMME

| Period | Project Steps/Activities | Personnel/Institution Involved |

| August 1988 | Preliminary mission of experts Outline design, provisional costs, workplan | Aquaculture/hatchery expert Aquaculture engineer (FAO) |

| Topographical and pedological surveys Collection of data required | Ministry of Agriculture NPC, experts (FAO) | |

| October-December 1988 | Survey of lagoon specialist Detailed design for construction Orders of equipment (imported and locally available) | Aquaculture experts (FAO) and national staff (Ministry of Agriculture) |

| Fence installation and control of project site and completion of Directorate building | Ministry of Agriculture | |

| October 1988–March 1989 | Selection/recruitment of Associate Professional Officers and Senior Aquaculture Expert | FAO |

| Collection of broodstock and stocking in temporary facilities (if possible) | NPC, Beymelek Fishermen's Cooperative | |

| December 1988– April 1989 | Setting-up of all necessary administrative and supervisory procedures for selection of construction companies, work assignments and supervision | Ministry of Agriculture |

| Provision of financing | Ministry of Agriculture | |

| Provision of accommodation for Senior and Associate Professional Officers | Ministry of Agriculture | |

| Preparation of temporary facilities for stocking wild fry (if possible) | NPC, Beymelek Fishermen's Cooperative, Ministry of Agriculture | |

| April 1989 | Beginning of construction of farm facilities with first priority for water intake and hatchery (to be ready for operation by October 1989) | Construction companies Ministry of Agriculture |

| Supervision of construction works Beginning of Senior Expert's contract: supervision during construction, coordination, technical tests, etc. | Ministry of Agriculture FAO | |

| April-October 1989 | Organization of training to begin by the end of 1989: selection, recruitment, accommodation, etc., of trainees | Ministry of Agriculture |

| Preparation of training programmes | NPC, Senior Expert | |

| Organization of fellowships and training abroad | NPC, Senior Expert | |

| June-October 1989 | Beginning of hatchery specialist's contract | FAO |

| Beginning of Associate Professional Officer's contract for hatchery | FAO | |

| Start-up of the hatchery (phyto-zooplankton unit) | FAO experts and consultants, NPC, national personnel | |

| On-the-job training | Ministry of Agriculture | |

| February-May 1990 | Start-up of pre-growing/on-growing operations | FAO experts/consultants |

| Shrimp reproduction | NPC, national personnel | |

| On-the-job training | Ministry of Agriculture | |

| Beginning of Associate Professional Officer's contract for fry collection/on-growing | FAO | |

| January 1990 | Beginning of Associate Professional Officer's contract for economics/marketing | FAO |

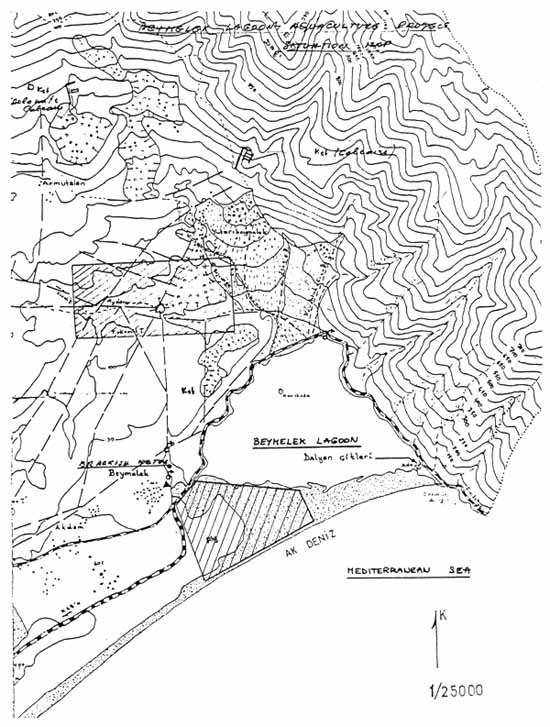

A2.1 Project location map

A2.2 Main meteorological data of Demre (4–11 years of observation)

| J | F | M | A | M | J | J | A | S | O | N | D | Average/total | |

| Air temperature (°C) | |||||||||||||

| Average | 10.5 | 10.7 | 12.8 | 16.1 | 19.9 | 24.7 | 26.7 | 26.8 | 23.8 | 19.7 | 14.7 | 12.1 | 18.2 |

| Average maximum | 15.8 | 14.8 | 17.1 | 20.4 | 25.5 | 29.2 | 32.1 | 32.6 | 30.8 | 26.0 | 20.6 | 17.0 | 23.4 |

| Average minimum | 5.2 | 4.4 | 6.3 | 9.5 | 13.2 | 16.7 | 19.2 | 19.7 | 16.8 | 12.1 | 9.6 | 5.8 | 11.5 |

| Snowy days | 2.2 | 2.8 | 0.2 | - | - | - | - | - | - | - | - | 1.2 | 6.5 |

| Humidity (%) | 76 | 71 | 74 | 72 | 67 | 62 | 58 | 60 | 63 | 70 | 79 | 78 | 69 |

| Rain (mm) | 227.2 | 129.6 | 110.3 | 32.0 | 15.8 | 10.7 | 0.0 | 0.2 | 4.1 | 60.2 | 113.7 | 204.4 | 908.3 |

| Evaporation (mm) | 68.0 | 69.5 | 97.8 | 122.0 | 163.0 | 236.0 | 268.0 | 271.0 | 200.0 | 148.0 | 61.8 | 67.8 | 1 774.6 |

| Rainy days | 14.6 | 10.3 | 9.3 | 5.4 | 2.3 | 1.2 | 0.1 | 0.2 | 0.7 | 4.8 | 8.5 | 13.9 | 71.3 |

A2.3 Compass card - windspeed and frequency

A2.4 Yearly temperature curve of spring and lagoon water

A2.5 Yearly dissolved oxygen curve for spring and lagoon water

A2.6 Yearly salinity curve of spring and lagoon water

A3.1 General layout of the project (1:7 000)

A3.2 Hatchery layout

A3.3 Layout of the technical service building

A3.4 Seawater intake

(a) general plan

BEYMELSK LAGOON AQUACULTURE PROJECT

SEAWATER INTAKE

A3.4 Seawater intake

(b) dikes/cuts

BEYMELSK LAGOON AQUACULTURE PROJECT

SEAWATER INTAKE

A3.4 Seawater intake

(c) longitudinal outline

A3.5 Seawater/brackishwater inlet channels: cuts

BEYMELSK LAGOON AQUACULTURE PROJECT

BRACKISH WATER INTAKE

INTAKE WORK

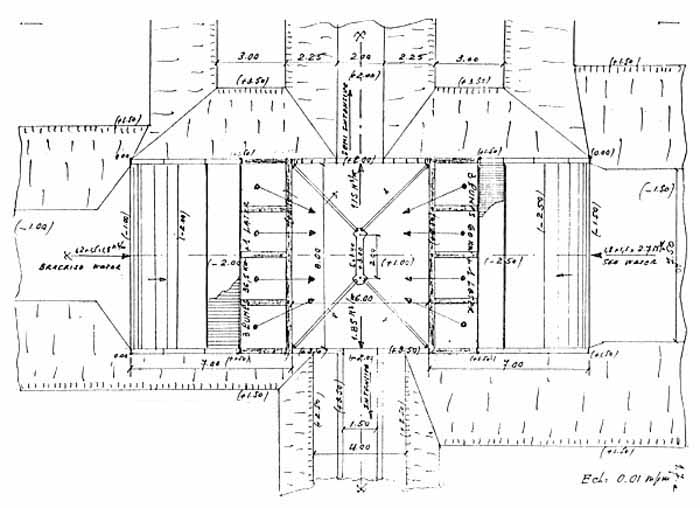

A3.6 Brackishwater intake: plan/cut

BEYMELSK LAGOON AQUACULTURE PROJECT

MIXING/LUMPING RESERVOIR

A3.7 Mixing/pumping reservoir

(a) general plan

BEYMELSK LAGOON AQUACULTURE PROJECT

MIXING/LUMPING RESERVOIR

A3.7 Mixing/pumping reservoir

(b) longitudinal cut

BEYMELSK LAGOON AQUACULTURE PROJECT

MIXING/LUMPING RESERVOIR

A3.7 Mixing/pumping reservoir

(c) transversal cut

BEYMELSK LAGOON AQUACULTURE PROJECT

INTENSIVE TANKS

A3.8 Intensive rearing tanks

(a) cuts 1.1

A3.8 Intensive rearing tanks and channels

(b) cuts 2.2

A3.9 Semi-intensive ponds

(a) cuts

A3.9 Semi-intensive ponds

(b) cuts

A3.9 Semi-intensive ponds

(c) cuts

A3.10 Fish barrier

(a) general plan

A3.10 Fish barrier module

(b) general plan

A3.10 Fish barrier module

(c) cuts

A3.10 Fish barrier

(d) details

A3.11 Lagoon outlet channel: cut

A3.12 Lagoon outlet

(a) general plan

A3.12 Lagoon outlet

(b) dikes/cuts

A3.12 Lagoon outlet

(c) long outline

A4.1 Aquaculture/Hatchery Expert (2.5 m/m)

(October-December 1988)

to advise on detailed engineering/design of the “Beymelek Lagoon Aquaculture Centre”, in close collaboration with the National Project Coordinator, local engineering staff, and hydraulic engineering expert

to prepare in own office a detailed list and specifications of equipment to be imported, and in particularly to advise on the order of equipment to be purchased by FAO (see UNDP contribution)

to prepare in own office full data, specifications, costings and documents needed for detailed engineering, design and costing of the Centre

to assist, in Antalya (Turkey), local staff (engineers, experts, draftsmen, etc.), in preparing final detailed drawings, specifications, bill of quantities and budget costings needed for the construction of the Centre

to prepare a final report

A4.2 Hydraulic Engineering Expert (2 m/m)

(October-December 1988)

to advise on detailed engineering/design on the following work of the “Beymelek Lagoon Aquaculture Centre”, according to the specifications of the aquaculture expert: sea dikes for water inlets and lagoon outlets, brackishwater intake, water channels, concrete tanks and earth ponds complete with water inlet/outlet works and the fish barrier at the lagoon outlet

to prepare in own office full data, specifications, documents and costings needed for detailed engineering and design of the above-mentioned work

to assist in Antalya (Turkey), local staff (engineers, experts, draftsmen, etc.), in preparing final detailed drawings, specifications, bill of quantities and budget costings needed for the construction of the Centre

to give the necessary input for a final report to be prepared by the aquaculture/hatchery expert

A4.3 Lagoon Specialist (3 weeks)

(November-December 1988)

In collaboration with the aquaculture/hatchery expert:

to survey the Beymelek Lagoon (Turkey), and to assess the present state of the ecosystem and its biological potentials for fishing/aquaculture purposes

to advise on the lagoon management in order to improve fishing activity according to the specific requirements of the “Beymelek Lagoon Aquaculture Centre”

to advise on the design of the lagoon fish barrier

to prepare a final report

A4.4 Associate Professional Officer

Hatchery/Fry Rearing

Under the general supervision of the Senior Aquaculture Adviser:

to assist in the establishment and daily operation of the new Marine Hatchery as well as the production of seeds of fish, and crustaceans including pre-growing of fish fry

to assist in the training programmes undertaken by the project for the national staff in hatchery/nursery techniques

Associate Professional Officer

Fry Collection

Under the general supervision of the Senior Aquaculture Adviser:

to assist in the study on the local availability of wild fry of aquaculture species

to assist in the collection, transport, storage and distribution of wild fry to fish-farmers

to assist in the training programmes undertaken by the project for the national staff, in wild fry collection and transport, and in on-growing techniques

to assist in the fish/shrimp on-growing operation of the Centre

Associate Professional Officer

Economics/Marketing

Under the general supervision of the Senior Aquaculture Adviser:

to assist in the economic evaluation of the farm activity: production operations, different technologies, results, etc.

to assist in the market analysis, local, national and international, and in the evaluation of an own product distribution

to assist in the software data treatment

A5.1 CAPITAL COSTS (LT)

| UNIT | QUANTITY | UNIT COST | TOTAL (× 1 000) | |||

| 1. | ELECTRICITY | |||||

| 1.1 | Line | km | 0 8 | 7 500 000 | 6 000 | |

| 1.2 | Transformer 400 kVA | 1 | 17 600 000 | 17 600 | ||

| 1.3 | Electrical Generators 180–240 kVA | 2 | 54 950 000 | 109 900 | ||

| 1.4 | Farm network complete with equipment, transport and assembling | 20 000 | ||||

| Sub-total 1 | 153 500 | |||||

| 2. | SEA DIKES AND LAGOON WORKS | |||||

| 2.1 | Sea dikes for lagoon outlet Rocks, complete with load, transport, unloading, placement | |||||

| - mixed + 4th category | t | 1 100 | 1 960 | 2 156 | ||

| - mixed + 4th + 3rd cat. | t | 9 630 | 1 960 | 18 875 | ||

| - 3rd cat. | t | 1 680 | 1 960 | 3 293 | ||

| - 2nd cat. | t | 9 020 | 2 012 | 18 148 | ||

| - 1st cat. | t | 10 475 | 2 578 | 27 005 | ||

| - off cat. | t | 3 100 | 3 062 | 9 492 | ||

| 78 969 | ||||||

| 2.2 | Sea dikes for seawater intake Rocks, complete with load, transport, unloading, placement | |||||

| - mixed + 4th cat. | t | 818 | 1 960 | 1 603 | ||

| - mixed + 4th + 3rd cat. | t | 6 560 | 1 960 | 12 858 | ||

| - 3rd cat. | t | 1 400 | 1 960 | 2 744 | ||

| - 2nd cat. | t | 7 015 | 2 012 | 14 114 | ||

| - 1st cat. | t | 8 000 | 2 578 | 20 624 | ||

| - off cat. | t | 2 665 | 3 062 | 8 160 | ||

| 60 103 | ||||||

| 2.3 | Lagoon outlet channel | |||||

| - digging under water level | m3 | 5 940 | 2 991 | 17 767 | ||

| - digging above water level | m3 | 5 787 | 806 | 4 664 | ||

| 22 431 | ||||||

| 2.4 | Lagoon fish barrier | |||||

| - filling up | m3 | 1 560 | 713 | 1 112 | ||

| - digging under water level | m3 | 1 280 | 2 991 | 3 828 | ||

| - digging above soil level | m3 | 357 | 806 | 288 | ||

| - water extraction | days | 60 | 38 400 | 2 304 | ||

| - bottom regulation/ compacting | m2 | 155 | 142 | 22 | ||

| - foundation | t | 120 | 1 960 | 235 | ||

| - reinforced concrete (350 kg/m3, 130 kg/m3 iron) | m3 | 77 | 111 000 | 8 547 | ||

| - footbridge (wood) | m | 40 | 7 500 | 300 | ||

| - grates (flat and V-shaped) | 36 | 54 000 | 1 944 | |||

| 18 580 | ||||||

| Sub-total 2 | 180 083 | |||||

| 3. | MAIN EARTHWORKS | |||||

| 3.1 | Sea water inlet channel | |||||

| - digging under water level | m3 | 3 656 | 2 991 | 10 936 | ||

| - digging above water level | m3 | 3 375 | 806 | 2 720 | ||

| 13 656 | ||||||

| 3.2 | Brackishwater inlet channel | |||||

| - digging under water level | m3 | 5 225 | 2 991 | 15 628 | ||

| - digging above water level | m3 | 8 075 | 806 | 6 508 | ||

| 22 136 | ||||||

| 3.3 | Earth ponds, dikes and channels (semi-intensive) | |||||

| - pond digging over water level | m3 | 190 000 | 589 | 111 910 | ||

| - channel digging over water level | m3 | 14 000 | 806 | 11 284 | ||

| - dike construction | m3 | 190 000 | 713 | 135 470 | ||

| - pond bottom regulation/ compacting | m2 | 500 000 | 142 | 71 000 | ||

| 329 664 | ||||||

| Sub-total 3 | 365 456 | |||||

| 4. | OTHER WATER SYSTEMS | |||||

| 4.1 | Brackishwater intake | |||||

| - digging under water level | m3 | 54 | 2 991 | 162 | ||

| - water extraction | days | 20 | 38 400 | 768 | ||

| - reinforced concrete (350 kg/m3, 100 kg/m3 iron) | m3 | 25 | 98 890 | 2 472 | ||

| 3 402 | ||||||

| 4.2 | Mixing/pumping reservoir | |||||

| - digging under water level | m3 | 810 | 2 991 | 2 423 | ||

| - water extraction | days | 60 | 38 400 | 2 304 | ||

| - filling-up | m3 | 300 | 713 | 214 | ||

| - reinforced concrete (350 kg/m3, 100 kg/m3 iron) | m3 | 32 | 156 600 | 5 011 | ||

| 9 952 | ||||||

| 4.3 | Distribution channel to intensive tanks | |||||

| - filling-up + regulation/ compacting | m3 | 2 670 | 1 302 | 3 476 | ||

| - foundation | m2 | 570 | 2 730 | 1 556 | ||

| - reinforced concrete (350 kg/m3, 100 kg/m3 iron) | m3 | 329 | 112 110 | 36 884 | ||

| 41 916 | ||||||

| 4.4 | Concrete tanks (No 14, 2nd year) | |||||

| - foundation | m2 | 231 | 24 700 | 5 706 | ||

| - reinforced concrete ( 350 kg/m3, 100 kg/m3 iron) | m3 | 808 | 102 410 | 82 747 | ||

| 88 453 | ||||||

| 4.5 | Concrete tanks (No 16, 1st year) | |||||

| - foundation | m2 | 86 | 24 000 | 2 064 | ||

| - reinforced concrete | m3 | 408 | 108 822 | 44 399 | ||

| 46 463 | ||||||

| 4.6 | Earth tanks (No 10, 2nd year) | |||||

| - filling-up (dikes), regulation/compacting | m3 | 5 515 | 1 302 | 7 181 | ||

| - bottom regulation/compacting | m2 | 3 800 | 142 | 540 | ||

| 7 721 | ||||||

| 4.6 | Earth tanks (No 12, 1st year) | |||||

| - filling-up (dikes), regulation/compacting | m3 | 3 020 | 1 302 | 3 932 | ||

| - bottom regulation/compacting | m2 | 1 320 | 142 | 187 | ||

| 4 119 | ||||||

| 4.7 | Discharge channel of intensive tanks | |||||

| - digging | m3 | 3 880 | 806 | 3 127 | ||

| 4.8 | Monks, pipes, grates for ponds and tanks | 20 000 | ||||

| Sub-total 4 | 225 153 | |||||

| 5. | BUILDINGS | |||||

| 5.1 | Hatchery | |||||

| - building (civil works) | m2 | 1 120 | 136 000 | 152 320 | ||

| - electrical/heating/ piping systems | 164 680 | |||||

| 317 000 | ||||||

| 5.2 | Directorate building | |||||

| - furniture for library room, etc. | 20 000 | |||||

| 5.3 | Social building (trainees, restaurant) | |||||

| - civil works, electricity, heating, water | m2 | 650 | 136 000 | 88 400 | ||

| - furniture | 20 000 | |||||

| 108 400 | ||||||

| 5.4 | Technical service building | |||||

| - civil works, electricity, water, conditioning | m2 | 435 | 100 000 | 43 500 | ||

| - area covered with light roof | m2 | 120 | 20 000 | 2 400 | ||

| 45 900 | ||||||

| 5.5 | Experts/visitors houses | |||||

| - 10 living units | m2 | 1 000 | 136 000 | 136 000 | ||

| - furniture for foreigners | 20 000 | |||||

| 156 000 | ||||||

| 5.6 | Watchmen buildings | |||||

| - improvement works to existing building | 5 000 | |||||

| 5.7 | Electric generators shelter | m2 | 50 | 41 200 | 2 060 | |

| Sub-total 5 | 654 360 | |||||

| 6. | EQUIPMENT | |||||

| 6.1 | Pumps | |||||

| - pumps of 60 kW, 0.9 m3/sec, H = 5 m | 3 | 63 800 000 | 191 400 | |||

| - pumps of 37 kW, 0.6 m3/sec, H = 4,5 m | 3 | 51 200 000 | 153 600 | |||

| 345 000 | ||||||

| 6.2 | Hatchery equipment | |||||

| - fibreglass tanks | 23 600 000 | 23 600 | ||||

| - pumps | 61 400 000 | 61 400 | ||||

| - U.V. sterilizers (Hg - high pressure lamps) | 122 000 000 | 122 000 | ||||

| - mechanical filters (sand/diatom) | 1 | 19 600 000 | 19 600 | |||

| - air blowers | 5 | 2 000 000 | 10 000 | |||

| - oxygen generator | 1 | 15 000 000 | 15 000 | |||

| - biofilter medium | m3 | 12 | 700 000 | 8 400 | ||

| - tank vacuum cleaner | 2 | 1 500 000 | 3 000 | |||

| - homogenizer/grinder | 2 | 2 000 000 | 4 000 | |||

| - miscellaneous | 267 000 | |||||

| 6.3 | Laboratory equipment (in brackets: already purchased) | |||||

| - microscopes (1) | 2 | 2 500 000 | 5 000 | |||

| - stereo microscopes (1) | 2 | 1 500 000 | 3 000 | |||

| - analytical/technical balances (1 + 1) | 1 | 2 000 000 | 2 000 | |||

| - oven (1) | ||||||

| - refrigerator (1) and freezer | 2 | 1 500 | ||||

| - incubator with thermostat/light | 1 | 2 000 000 | 2 000 | |||

| - oxygen meters YSI + probes (1) | 2 | 2 000 000 | 4 000 | |||

| - pH meter (1) | 1 | 300 000 | 300 | |||

| - salinometers/refractometers (2) | 2 | 500 000 | 1 000 | |||

| - temperature probes | 4 | 250 000 | 1 000 | |||

| - furniture | 5 000 | |||||

| - glassware | 6 000 | |||||

| - ammonia analysis kits | 1 500 | |||||

| - miscellaneous | 4 400 | |||||

| 36 700 | ||||||

| 6.4 | Office/didactic equipment | |||||

| - audio-visual equipment (already purchased) | ||||||

| - telephone central system | 20 000 | |||||

| - telefax and telex | 6 000 | |||||

| - computer + monitor + printer | 4 000 | |||||

| - typewriters | 2 000 | |||||

| - slide projectors + screen | 1 000 | |||||

| - transparent sheet projector (already purchased) | ||||||

| - books and periodicals | 4 000 | |||||

| 37 000 | ||||||

| 6.5 | Special equipment | |||||

| - automatic data acquisition system | 35 000 | |||||

| - 20 m2 chilled room (0°C) + 8 m2 deep freezer (-23°C) | 27 000 | |||||

| - ice machine | 22 500 | |||||

| - mixers/extruders | 18 850 | |||||

| - workshop equipment/tools | 5 000 | |||||

| - solar powered feeders (intensive tanks) | 150 | 640 000 | 96 000 | |||

| - weighscales | 3 000 | |||||

| - outboard motor boat (already purchased) | ||||||

| - small fibreglass boats, 3 m | 3 | 500 000 | 1 500 | |||

| - tractor pumps | 4 | 500 000 | 2 000 | |||

| - fishing equipment | 2 000 | |||||

| - miscellaneous | 10 000 | |||||

| 222 850 | ||||||

| 6.6 | Vehicles | |||||

| - truck for fry transport 3.5 t | 1 | 25 000 000 | 25 000 | |||

| - refrigerated truck 3.5 t | 1 | 30 000 000 | 30 000 | |||

| - multi-purpose tractor | 1 | 28 000 000 | 28 000 | |||

| - tractor and trailer + crane | 1 | 28 000 000 | 28 000 | |||

| - small tractor | 1 | 15 000 000 | 15 000 | |||

| - minibus (14 persons) | 1 | 21 000 000 | 21 000 | |||

| - pick-up 4 × 4, 1.5 t | 1 | 20 000 000 | 20 000 | |||

| - cars | 2 | 12 500 000 | 25 000 | |||

| 192 000 | ||||||

| Sub-total 6 | 1 100 550 | |||||

| 7. | CONTINGENCIES (10%) | |||||

| Sub-total 7 | 267 910 | |||||

| TOTAL | 2 947 012 | |||||

A5.2 OPERATING COSTS

(notes to table in the text p. 12)

Personnel

(See table next page)

Feed

| Biomass increase/year (t) | Conversion | Total feed | ||||

| factor (CF) | quantity (t) | |||||

| 1st year | from 2nd year | 1st year | from 2nd year | |||

| - sea bass | (1 year old) | 25 | 3.5:1 | 3:1 | 87.5 | 75 |

| (2 years old) | 75 | 3.5:1 | 3:1 | 262.5 | 225 | |

| - sea bream | (1 year old) | 15 | 3.5:1 | 3:1 | 52.5 | 45 |

| (2 years old) | 35 | 1.5:1 | 1.5:1 | 52.5 | 52.5 | |

| - hatchery: | allow 500 kg at LT 140 000/kg of Artemia cysts | |||||

| allow 3 t of crumble feed at LT 3 200/kg | ||||||

Maintenance

Assume: - no maintenance costs in 1989

- 0.5% of capital costs in 1990

- 1% of capital costs in 1991

Administration

Allow LT 20 000 000/year for telephone/telex/telefax expenses

Training

Allow, from 1990 on, LT 10 000 000/year, for government budget and total LT 127 500 000 (US$ 85 000) from UNDP budget.

Power

Electricity: Assume following yearly consumptions: hatchery, 240 000 kWh, on-growing 1 250 000 kWh and miscellaneous 220 000 kWh. Total 1 710 000 kWh at LT 43/kWh

In 1989, only hatchery consumption of 100 000 kWh. In 1990 on-growing consumption of 625 000 kWh

Heating (gasoline): Assume 100 000 kg/year for hatchery (mainly) and directorate/ social buildings, 20 000 kg for 1989, at LT 400/kg

Packaging/distribution

Assume for exported fresh product: LT 350/kg of product for polystyrene boxes, nylon sheets, ice and carton + LT 1 600/kg for air cargo to Italy, 75 t of exported fish from 1991. Assume for distribution to local markets: LT 150/kg, 15 t of shrimp in 1990, 85 t of fish/shrimp from 1991.

A5.3 PERSONNEL COSTS

| LT (× 1 000) | 1989 | 1990 | 1991 | 1992 | TOTAL | ||||||

| 1. Specialist | m/m | m/m | m/m | m/m | |||||||

| 1.1 | Centre director | 1 | 6 | 2 340 | 12 | 6 084 | 12 | 7 909 | 6 | 5 141 | |

| 1.2 | Hatchery director | 1 | 6 | 2 028 | 12 | 5 272 | 12 | 6 854 | 6 | 4 455 | |

| 1.3 | On-growing species | 1 | 6 | 1 560 | 12 | 4 056 | 12 | 5 273 | 6 | 3 428 | |

| 1.4 | Phyto-zooplank. spec. | 1 | 6 | 1 560 | 12 | 4 056 | 12 | 5 273 | 6 | 3 428 | |

| 1.5 | Economist | 1 | 6 | 1 560 | 12 | 4 056 | 12 | 5 273 | 6 | 3 428 | |

| 1.6 | Lagoon spec. | 1 | 6 | 1 560 | 12 | 4 056 | 12 | 5 273 | 6 | 3 428 | |

| Sub total | 6 | 36 | 10 608 | 72 | 27 580 | 72 | 35 854 | 36 | 23 305 | 97 347 | |

| 2. Support personnel | m/m | m/m | m/m | m/m | |||||||

| 2.1 | Technicians | 9 | 54 | 14 462 | 108 | 37 602 | 108 | 48 883 | 54 | 31 774 | |

| 2.2 | Specialized workers | 2 | 12 | 3 120 | 24 | 8 112 | 24 | 10 546 | 12 | 6 855 | |

| 2.3 | Workers | 5 | 30 | 7 020 | 60 | 18 252 | 60 | 23 728 | 30 | 15 423 | |

| 2.4 | Watchmen | 2 | 12 | 2 340 | 24 | 6 084 | 24 | 7 909 | 12 | 5 141 | |

| 2.5 | Admin. serv. | 1 | 6 | 585 | 12 | 1 521 | 12 | 1 977 | 6 | 1 285 | |

| 2.6 | Drivers | 2 | 12 | 3 120 | 24 | 8 112 | 24 | 10 546 | 24 | 6 855 | |

| Sub total | 21 | 126 | 30 647 | 252 | 79 683 | 252 | 103 589 | 126 | 67 333 | 281 252 | |

| Component total | 27 | 162 | 41 255 | 324 | 107 263 | 324 | 139 443 | 262 | 90 638 | 378 589 | |

A5.4 FEED COSTS

| LT (× 1 000) | 1989 | 1990 | 1991 | 1992 | ||||

| Q (t) | t (× 1 000) | Q (t) | t (× 1 000) | Q (t) | t (× 1 000) | Q (t) | t (× 1 000) | |

| Intensive rearing | ||||||||

| Sea bass | ||||||||

| 1st year fish | 87.5 | 105 000 | 75 | 90 000 | 75 | 90 000 | ||

| 2nd year fish | 265 | 318 000 | 225 | 270 000 | ||||

| Semi-intensive | ||||||||

| Sea bream | ||||||||

| 1st year fish | 52.5 | 63 000 | 45 | 54 000 | 45 | 54 000 | ||

| 2nd year fish | 52.5 | 63 600 | 52.5 | 63 600 | ||||

| Hatchery | ||||||||

| Artemia cysts | 0.5 | 70 000 | 0.5 | 70 000 | 0.5 | 70 000 | 0.5 | 70 000 |

| Crumble feed | 3 | 9 600 | 3 | 9 600 | 3 | 9 600 | ||

| TOTAL | 70 000 | 247 600 | 605 200 | 557 200 | ||||

A5.5 UNDP CONTRIBUTION EQUIPMENT LIST

| 1. | Hatchery equipment | US$ |

| - pumps (plastic) | 44 000 | |

| - oxygen generator | 10 700 | |

| - mechanical filters | 14 000 | |

| - tank vacuum cleaners | 2 200 | |

| - homogenizer/grinder | 2 900 | |

| 73 800 | ||

| 2. | Laboratory equipment | |

| - 1 microscope | 1 800 | |

| - 1 stereomicroscope | 1 100 | |

| - 1 technical balance | 1 500 | |

| - 1 incubator | 1 500 | |

| - 2 oxygen meters + probes | 1 500 | |

| - 2 refractometers | 700 | |

| - 4 temperature probes | 700 | |

| - 1 pH meter | 200 | |

| 9 000 | ||

| 3. | Didactic equipment | 2 800 |

| - computer + monitor + printer | 2 800 | |

| - typewriters | 1 500 | |

| - slide projectors | 700 | |

| - books and periodicals | 2 800 | |

| 7 800 | ||

| 4. | Special equipment | |

| - data acquisition system | 25 000 | |

| - mixers/extruders | 13 600 | |

| 38 600 | ||

| TOTAL | 129 200 | |