Following previous mission, to review and complete (if necessary) the final documents prepared by the Turkish engineers and make sure that they are suitable for the farm construction and equipment orders:

Detailed working drawings;

Conditions of contracts (specifications), in particular to check the conditions of carrying out special works:

Other buildings

Specifications for equipment orders.

At the end of the assignment to prepare a report on main findings and recommendations.

R. Vétillart

19 February 1989

Departure from France. Arrival in Rome

20 February

Departure from Rome. Arrival in Antalya

L. Berg

20 February

Departure from Milan. Arrival in Antalya

L. Berg and R. Vétillart

21–24 February

Office work at the Provincial Directorate of the Ministry of

Agriculture (Antalya), meetings with National Project Coordinator

(O. Atila) and engineers involved in project design.

25–26 February

Survey on project site with J.L. Bock (F.A.O., Ankara), meeting

with President of Fishermen Cooperative, G. Kusakci

26 February - 4 March

Office work at the Ministry of Agriculture (Antalya), to complete

revision and final specifications of detailed design.

5 March

Departure from Antalya. Arrival in Ankara

6 March

Office work in F.A.O. office, Ankara. Meeting at the Ministry of

Agriculture with:

Representative of F.A.O., J.L. Bock

7 March

Office work in F.A.O. offices, Ankara and meeting with A. Açara,

F. Coskun, O. Atila, S. Saylan and J.L. Bock.

L. Berg

8 March

Departure from Ankara. Arrival in Rome

8–10 March

Debriefing in F.A.O. Head Quarters

10 March

Departure from Rome. Arrival in Venice

11–19 March

Office work in Padova

R. Vétillart

9 March

Departure from Ankara. Arrival in Rome

10 March

Debriefing in F.A.O. Head Quarters

11 March

Departure from Rome. Arrival in France

1. TOPOGRAPHIC PLANS

1.1.1 Topographic plan (eliminated) 1:2.000

1.1.2 Topographic plan 1:1.000

2. GENERAL PLAN OF THE FARM

2.1.1 General plan

3. WATER INLET FACILITIES

3.1 MAIN CHANNELS

3.1.1A Water inlet channels. Transversal cuts

3.2 SEA WATER RESERVOIR

3.2.1A Sea water reservoir. Cut

4. REARING TANKS AND PONDS

4.1 INTENSIVE REARING TANKS AND CHANNEL

4.1.1A General plan

4.1.2A Longitudinal and transversal cuts

4.1.3A Plans and transversal cuts

4.1.4 Construction details

4.2 SEMI-INTENSIVE REARING PONDS AND CHANNELS

4.2.1 General cuts (eliminated)

4.2.2 Transversal cuts

4.3 BROODSTOCK PONDS

4.3.1A General plan and cut

5. OTHER WATER CHANNELS

5.1 WATER SUPPLY CHANNELS

5.1.1A Channel to intensive rearing tanks. Plans and cuts

5.1.2A Channels to semi-intensive rearing and broodstock

ponds (start from pumping station). Plan

5.1.3 Concrete channels: construction details

5.2 WATER DISCHARGE CHANNELS

5.2.1A Channels from intensive and semi-intensive rearing

tanks and ponds. Transversal cuts.

5.2.2A Channel from intensive rearing tanks: siphon

6. TAIL PONDS

6.1 SETTLING POND

6.1.1A Plan and cut

6.2 LAGOONING POND (HATCHERY)

6.2.1A Cut

7. MONKS

7.1 WATER SUPPLY MONKS

7.1.1A Monks (types A1, A2, A3). Plans and cuts

7.2 WATER DISCHARGE MONKS

7.2.1A Monks (types E1, E2, E3, E4). Plans and cuts

8. LAGOON FISH BARRIER

8.1.1 General plan and cuts

8.1.2 Construction details

9. SEA WORKS (DIKES)

9.1 SEA WATER INTAKE

9.1.1A Plan

9.1.2A Cuts

9.2 LAGOON-SEA COMMUNICATION

9.2.1A Plan

9.2.2A Cuts

10. BRACKISHWATER INTAKE

10.1.1. Water intake and level regulator. Plan and cuts

11. WATER PUMPING/MIXING STATION

11.1.1A Plan and trasversal cut

11.1.2A Longitudinal cut

11.1.3A Construction details

12. ELECTRIC/GENERATOR STATION

12.1 CIVIL ENGINEERING

12.1.1A Plan and cut

12.1.2 Construction details: plan

12.1.3 Construction details: platform and pillars

12.1.4 Construction details: roof

12.1.5 Construction details: fuel tanks

12.2 ELECTRIC PLANT

12.2.1 E1 General lighting system

12.2.1 E2 General panels: details

12.2.1 E3 Control boards TA1-TA2: details

13. HATCHERY

13.1 CIVIL ENGINEERING

13.1.1A General plan

13.1.2A Transversal and longitudinal cuts

13.1.3 Construction details: platform

13.1.4 Construction details: pillars basis

13.1.5 Construction details: roof support

13.1.6 Construction details: spawning unit ceiling

13.1.7 Construction details: laboratory floor

13.1.8 Construction details: spawning unit floor

13.1.9 Construction details: laboratory ceiling

13.1.10 Construction details: roof

13.1.11 Construction details: roof

13.1.12 Construction details: draining system

13.2 ELECTRIC PLAN

13.2.1A General lighting plan

13.2.1 E2 General outlet plan

13.2.1 E3 TT1, TT2 boards/cables: detailed plan

13.2.1 E4 TT3, TT4 boards/cables: detailed plan

13.2.1 E5 TT5, TT6 boards/cables: detailed plan

13.2.1 E6 TT7, TT8 boards/cables: detailed plan

13.2.1 E7 General board/cables: detailed plan

13.2.1 E8 Alarm system: detailed plan

13.2.1 E9 Transversal and longitudinal cuts

13.3 HEATING/CONDITIONING/FRESHWATER SYSTEMS

13.3.1 IS1 Heating system plan

13.3.1 IS2 Heating system scheme

13.3.1 IS3 Heat exchangers system plan

13.3.1 IS4 Heat exchangers system: functional plan

13.3.1 IS5 Boilers system plan

13.3.2 Conditioning system plan

13.3.3 Freshwater/Hot water/Wastewater and air compressor

systems plan

13.4 PIPING SYSTEM

13.4.1 SB1 Water piping systems. Plan

13.4.1 SB2 Water piping systems: details

13.4.1 SB3 Water piping systems: details

13.4.1 SB4 Water piping systems: details

13.4.2 Air/oxygen piping systems. Plan

13.5 OUTDOOR FACILITIES

13.5.1A General plan and detailed plans and cuts

13.5.2A Sea water intake. Plan and cut

13.5.3A Brackishwater intake. Plan and cut

13.5.4 Construction details

13.6 EQUIPMENT

13.6.1 Fiberglass tanks

14. SERVICE BUILDING

14.1 CIVIL ENGINEERING

14.1.1 General plan

14.1.2 Construction details: platform

14.1.3 Construction details: floor

14.1.4 Construction details: ceiling

14.1.5 Construction details: pillars basis

14.1.6 Construction details: roof

14.2 ELECTRIC PLANT

14.1.1 E1 General plan

14.2.1 E2 Detailed plan

14.3 CONDITIONING/FRESHWATER SYSTEMS

14.3.1 Freshwater/Wastewater systems plans

14.3.2 Conditioning/Cool stores systems plans

15. GENERAL DEVICES

15.1 FRESHWATER SYSTEM

15.1.1 General plan

15.2 OUTDOOR ELECTRIC SYSTEMS

15.2.1 Lightning conductor system

15.2.2 E1 Outdoor lighting systems plan

15.2.2 E2 Outdoor lighting detailed plans

15.2.3 Electric system plan for intensive rearing sector

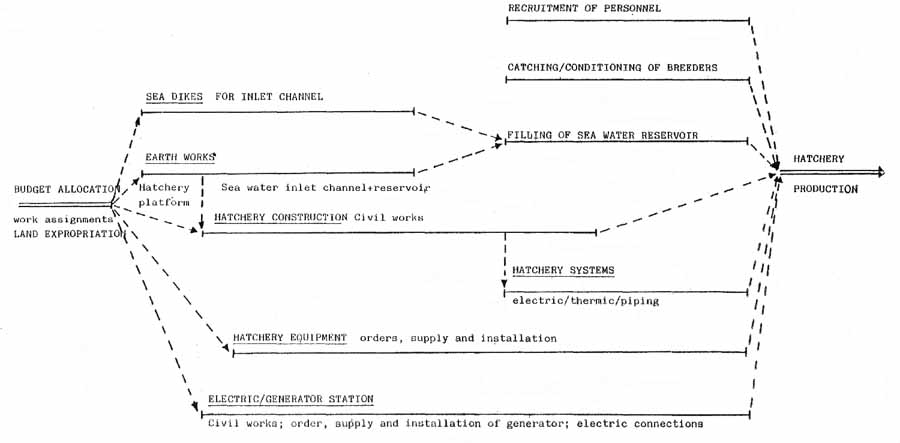

| APRIL | MAY | JUNE | JULY | AUGUST | SEPTEMBER | OCTOBER | NOVEMBER | DECEMBER |

| 1989 |  | |||||||

| Calculated Cost 1988 (π × 1000) | Inflation rate (1) (%) | Estimated G.O.T. contribution 1989 | |||

| in local currency (π × 1000) | in foreign currency (USD) | ||||

| A. WORKS | |||||

| A.1 | Sea dikes for water inlet | 259.000 | 60 | 414.400 | |

| A.2 | Earth Works | 41.000 | 60 | 65.600 | |

| A.3 | Generator building | 26.000 | 60 | 41.600 | |

| A.4 | Generator installation | 42.000 | 20 | 59.000 | |

| A.5 | Electric line + connections | 46.000 | 60 | 74.000 | |

| A.6 | Hatchery building + indoor sys. | 418.400 | 60 | 669.500 | |

| SUB TOTAL A | 832.400 | 1.315.100 | |||

| B. EQUIPMENT | |||||

| B.1 | Hatchery (Imported) (2) | 290.000 | |||

| B.2 | Hatchery (purchased locally) | 182.000 | 60 | 291.000 | |

| B.3 | Generator (imported) | 64.000 | |||

| B.4 | Directorate build. (furniture) | 40.000 | 30 | 52.000 | |

| SUB TOTAL B | 222.000 | 343.000 | 354.000 | ||

| TOTAL | 1.054.400 | 1.658.100 | 354.000 | ||

(1) Estimated 10 % for month

(2) In addition to UNDP contribution equipment (USD 112.000)

This revised list is aiming to the establishment of the hatchery with a 50% production capacity, ready for operation at the end of 1989, according to the priority work plan proposed.

| Equipment specification | Quant. | Unit price | Total cost for 50% cap. | Total cost for 100% cap. |

| Imported (in U.S.D.) | ||||

| 1. U.V. sterilizers | 2 | 22.600 | 45.200 | 104.000 |

| 2. Hatchery pumps | 49.500 | 88.500 | ||

| 3. Filters | ||||

| - gravel filter | 1 | 17.700 | 17.700 | 35.400 |

| - diatom filter | 2 | 2.900 | 5.800 | 8.700 |

| 4. Air blowers | 4 | 3.000 | 12.000 | 12.000 |

| 5. Piping (PVC) | 25.000 | 50.000 | ||

| 6. Special equipment | 10.000 | 20.000 | ||

| 7. Generator (non-automatic) | 1 | 30.000 | 94.000 | |

| 8. Laboratory equipment | 5.000 | 35.500 | ||

| 9. Miscellaneous | 13.000 | 26.500 | ||

| TOTAL | USD | 213.200 | 474.600 | |

| Purchased Locally (in π × 1000) | ||||

| - Fiberglass tanks | 60.000 | 100.000 | ||

| - Refrigerators/freezers | 5.000 | 10.000 | ||

| - Furniture | 15.000 | 20.000 | ||

| - Glassware | 10.000 | 10.000 | ||

| - Consumables | 20.000 | 20.000 | ||

| - Homogenizer/Grinder | 5.000 | 5.000 | ||

| - Tools | 1.000 | 2.000 | ||

| - Miscellaneous | 29.800 | |||

| TOTAL | π × 1000 | 145.800 | 167.000 |

It is assumed that the costs for the establishment of the sea dikes for the inlet water channel (approx. 415 Mill. π) will be covered by a special budget, allocated directly to the Ministry of Transport, Harbour Directorate of Antalya.

| Work specification | Expected Implementation date | Total cost (estimated 89 in π × 1000) |

| 1. Earth works for inlet channel, water reservoir and hatchery platform. | May-August 1989 | 65.600 |

| 2. Electric supply systems and generator installation | Sept.-Oct. 1989 | 99.000 |

| 3. Hatchery construction (civil works) | May-Oct. 1989 | 496.000 |

| 4. Hatchery electric plant | Sept.-Oct. 1989 | 93.000 |

| 5. Heating/freshwater plants | Sept.-Oct. 1989 | 73.000 |

| TOTAL | π × 1000 | 826.600 |

| (π × 1000) | Budget available | Total cost |

| A. EQUIPMENT | ||

- Ministry Agric 420 Mill. π - 11.5 % | 372.000 | |

- UNDP Equiv. 100.000 USD | 200.000 | |

| TOTAL | 572.000 | |

- Imported equipment Equiv. 213.200 USD | 426.400 | |

| - Local Equipment | 145.800 | |

| TOTAL | 572.200 | |

| Balance A | 0.000 | |

| B. WORKS | ||

| - 650 Mill. π - 11.5 % | 575.200 | |

| - Work costs | 826.600 | |

| Balance B | - 251.400 | |

| TOTAL BALANCE | -251.400 |

| 1989 | 1990 | 1991 | |

| HATCHERY | ******* | **** | |

| SEA DIKES (WATER INTAKE) | **** | ||

| SEA WATER INLET CHANNEL | **** | ||

| SEA WATER RESERVOIR | **** | ||

| GENERATOR STATION | **** | ||

| BRACKISHWATER INTAKE | **** | ||

| BRACKISHWATER CHANNEL | **** | ||

| PUMPING STATION | ***** | ||

| INTENSIVE REARING SECTOR | ******* | ||

| SEMI-INTENSIVE R. SECTOR | ********* | ||

| PERSONNEL/TRAINEE BUILDINGS | ******* | ||

| SERVICE BUILDING | ***** | ||

| FISH BARRIER | **** | ||

| LAGOON-SEA COMMUNICATION | ***** |

Costs have been calculated by Turkish Engineers, on the basis of end 1988 prices

In brackets : estimated costs (under calculation)

| 1. SEA DIKES | (T.L. × 1.000) |

| - for inlet channel | 258.600 |

| - for lagoon outlet | 139.800 |

| SUB TOTAL 1 | 398.400 |

| 2. EARTH WORKS | |

| SUB TOTAL 2 | (430.000) |

| 3. CONCRETE WORKS | |

| - Pumping/mixing station | 38.000 |

| - Intensive rearing sector + channels | 650.000 |

| - Hatchery outdoor facilities | 160.000 |

| - Fish barrier | (30.000) |

| - Monks | 36.800 |

| - Brackishwater inlet regulator | 5.000 |

| - Bridges/syphons, others | (50.000) |

| SUB TOTAL 3 | 969.800 |

| 4. HATCHERY | |

| - Civil works | 310.000 |

| - Electric | 57.900 |

| - Thermic/conditioning/fresh water | 60.400 |

| - Equipment (excluding UNDP contribution) | 762.000 |

| SUB TOTAL 4 | 1.190.300 |

| 5. TECHNICAL SERVICE BUILDING | |

| - Civil Works | 54.700 |

| - Electric System | 8.600 |

| - Thermic/conditioning/piping systems | 53.200 |

| - Equipment | 46.500 |

| SUB TOTAL 5 | 163.000 |

| 6. ELECTRIC PLANTS | |

| - Electric/generators station (civil works) | 26.200 |

| - Supply systems | 24.900 |

| - Generators | 176.400 |

| - Outdoor lighting system | 121.200 |

| - Lightning conductor system | 2.000 |

| - Intensive rearing sector system | 29.400 |

| - Others | 10.000 |

| SUB TOTAL 6 | 390.100 |

| 7. FARM EQUIPMENT | |

| - Pumps | 410.000 |

| - Piping | (20.000) |

| - Feeders | (96.000) |

| - Grates | (5.000) |

| - Vehicles | (192.000) |

| - Data Aquisition System (hatchery) | (35.000) |

| - Miscellaneous | (18.500) |

| SUB TOTAL 7 | 776.500 |

| 8. GENERAL DEVICES | |

| - Freshwater system | 6.300 |

| - Draining system | (10.000) |

| - Roads | (50.000) |

| SUB TOTAL 8 | 66.300 |

| 9. CONTINGENCIES | |

| - 10 % | |

| SUB TOTAL 9 | 438.440 |

| TOTAL | 4.822.800 |

U.V. lamps.

flow capacity: minimum 14 m3/h

dosage efficiency: 24 mJ/cm2 min., penetration factor: 0.8

stainless steel or plastic materials exclusively

manual cleaning system of the U.V. lamp

dosage measurement system

working time recorder

complete electric board

No. 2

Pumps

submersible electric pumps

stainless steel. (AISI 316)

minimum flow: 45 m3/h; head: 6 m No. 3

" " : 21 m3/h; head: 30 m No. 2

vertical plastic pumps

minimum flow: 10 m3/h; head: 12 m No.3

Diatom filter

AISI 304 stainless steel body, epoxy coated and PP

operating pressure: minimum: 1 atm

maximum: 2.5 atm

maximum flow: 10 m3/h

filtering surface: 1.6 m2

pressure control system equipped with self-cleaning candles

filtering material: diatom powder

No. 2

200 Kg of diatom powder

1 Gravel filter

CULLIGAN ITALIANA Spa

Via Gandolfi, 6

40057 CADRIANO DI GRANAROLO (BO), Italy

Tel. (0)51 766614

Fax (0)51 765032

Tlx 510330 CUIT

Model: UF 60 No: 1

Characteristics:

water volume treated: 27.3 m3/h minimum

52.2 m3/h maximum

counter washing volume: 61.3 m3/h

maximum head lost: 1 atm

dimension: (1500 × 1760 × 2210) mm

weight: shipment 3550 Kg

working 5000 Kg

2. Air blowers

To be purchased in Turkey.

SIEMENS

Model: 2BH61 10-OHC22-5 (in Italy) No: 4

Characteristics:

flow: 140 to 258 m3/h; pressure difference: 0,28 to 0,1 bar

3 Kw; 220/380 V; 50 Hz

Accessories:

filter, pressure regulating valve, muffler and flanges

3. Tank vacuum cleaners

POMPEO CATELLI

via Roma, 55

22029 UGGIATE (CO), Italy

Tel. (0) 31 948737

Tlx. 300484 att. Pompeo Catelli

Model: fry tank cleaner No. 2

4. Biofilter foam

IMAR Spa

Via Trieste, 51

35035 MESTRINO (PD), Italy

Tel. (0)49 9000252

Fax (0)49 9000257

Characteristics:

FILTREN T 10: reticulated polyurethane foam

density (ISO 845): 20 – 24 Kg/m3

compression resistance (CDH at 40%): 3 – 5

ultimate elongation (ER %): > 100

tensile strenght (RR kPa): > 60

tear resistance (TR N/cm): > 6

porosity (pores per inch): 7 – 15

dimensions: (900 × 1260 × 125) mm No. 15 pieces

5. Generator

See offers already collected. CATERPILLAR is the most reliable and with best offer.

OTHER SUPPLIERS

(see equipment lists prepared by engineers, Antalya)

PVC material and fittings

P.M. snc di PEVERATI Mario

Via A. Toscanini, 26

44100 FERRARA, Italy

Tel (0)532 94452, 92300

Fax (0)532 92300

Heating/conditioning equipment

DITTA CIPRIANI SCAMBIATORI S.R.L.

Via 25 Aprile

37020 CORRUBBIO (VR)

Tel (0)45 7725466

Fax (0)45 7725530

Electric equipment

IMER Materiale Elettrico Spa

Via delle Industrie, 88

48100 RAVENNA

Tel (0)544 35544

Fax (0)544 39888

Tlx 550858 IMER-I

The Senior Aquaculture Advisor will have:

to prepare a short report on main findings and recommendations.

A. PERSONNEL

A1. Coordination

Senior Aquaculture Advisor (F.A.O.), Ruggero Guidastri

A2. Aquaculture Technical Staff (KEPEZ)

Duygu Turgut

A3. Construction Supervision

1 mechanical engineer

A4. Other Personnel

2 drivers

B. MAIN EQUIPMENT AND FACILITIES

B1. Living Facilities

Living facilities for 1–2 watchmen (existing prefabricate building)

B2. Offices

2–3 offices equipped with telephone, fax and typewriter (Directorate building)

B3. Equipment

a walkye-talkye system

| M/M | 1988 | UNTIL MARCH 1989 | AFTER MARCH 1989 | 1990 | 1991 | TOTAL |

| 1) AQUACULTURE/HATCHERY | 3.5 | 1 (*) | - | - | - | 4.5 |

| 2) HYDRAULIC ENGINEERING | - | 1 (*) | - | - | - | 4 |

| 3) LAGOON | 0.75 | - | - | 0.75 | 0.5 | 2 |

| 4) FRY COLLECTION | - | - | - | 1 | 1 | 2 |

| 5) PLANCTON CULTURE | - | - | 2 | - | - | 2 |

| 6) NUTRITION | - | - | - | 1.5 | - | 1.5 |

| 7) PATHOLOGY | - | - | - | 1 | - | 1 |

| 8) SENIOR ADVISOR (+) | - | - | 7 | 11 | - | 18 |

| 9) HATCHERY SPECIALIST | - | - | 2 | 4 | - | 6 |

| TOTAL | 7.25 | 2 | 11 | 19.25 | 1.5 |

(*) Additional: these 2M/M were not planned at the time of the meeting of Nov. 8,1988

(+) Including mission of assistance to coordination and construction supervision