There are several types of equipment available for marine construction. The high cost of buying this equipment, however, puts most of it beyond the reach of village cooperatives, artisanal contractors and small general building contractors.

In this book it is assumed that most of the heavy plant will be available through the government or public works department or from local contractors. When planning a marine related project, it is useful to know in advance what type and size of construction plant is available in the vicinity of the village or landing.

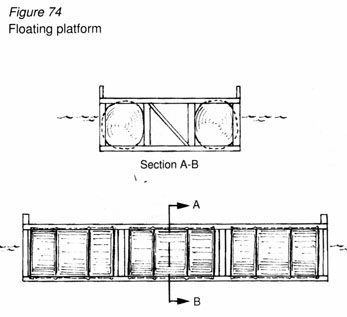

Figure 64 shows a typical crawler crane. As its name implies, a crawler crane crawls forward on steel tracks. This is the ideal type of crane for building breakwaters because it is very stable, requires no outriggers (the stabilizers that extend from the crane chassis of rubber-tyred cranes) and is unlikely to bounce off an uneven rubble surface into the water. The most important characteristic to consider is the nominal lifting capacity. This dictates the maximum outreach that the crane can handle with a given jib size.

Figure 65 shows some of the lifting attachments that can be hooked-up to a crawler crane:

- A rock grapple is used to pick up and place heavy pieces of rock.

- A clam-shell is used to dredge the sea-bottom. Most clamshells have a soft metal (usually lead) lip to make them as watertight as possible. Without this lip, the clam-shell will leak and cannot be used to dredge fine sand, silt or mud. A clamshell should not be used to place rocks on a break-water.

- The sling in Figure 65 has a quick release attachment that enables the crane driver to open the sling and release a large rock underwater.

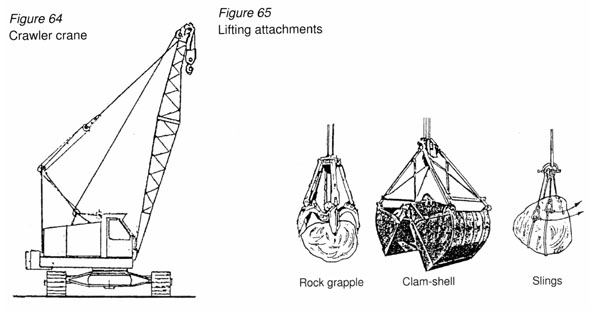

Figure 66 shows a crawler crane with a drag-line attachment. A drag-line consists of a sliding bucket that is dragged along the ground or sea-bottom for dredging.

The drag-line used to be the standard form of near-shore dredging until the hydraulic excavator (a far smaller machine that is more compact to transport over long distances) made its appearance.

Figure 67 shows a typical hydraulic excavator. This machine is very adaptable and now forms the backbone of most marine work.

Most makes of hydraulic excavator have interchangeable buckets and forearm lengths; for normal marine work a long forearm is required to reach as faraway as possible. Hydraulic excavators can also be mounted on special barges (Figure 69) to act as dredgers, in which case a large bucket should be attached to the forearm.

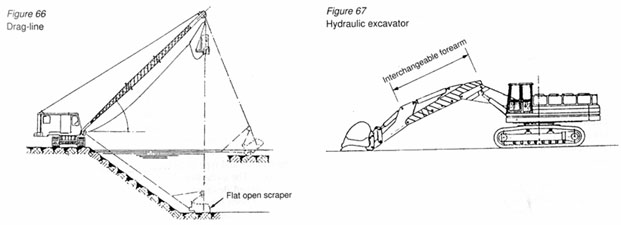

Figure 68 shows a typical cutter-suction dredger. A cuttersuction dredger consists of a rotary cutter coupled to a suction pipe. The cutter cuts through soft rock (such as coral) and the suction pipe draws the broken rock through pipes and dischar-ges it some distance away. This piece of equipment is very costly and should only be used when a lot of dredging is required. A dismountable cutter-suction dredger can be broken down into four or more pieces for transport, but it has no propulsion and has to be assisted by a tug boat or fishing boat.

Figure 69 shows a hydraulic excavator mounted on a steel pontoon. This combination of equipment is ideally suited for shallow excavations and general marine work. Before choosing or building a pontoon for a particular excavator, an experienced engineer should make stability calculations. These will determine whether or not the barge is suitable for the size of the excavator. Stability calculations will also help to decide the number and type of lashings needed to hold the excavator in place. The excavator should not be operated without first being lashed down securely to the pontoon deck. A second vessel or open barge is usually required to collect the dredged material arid haul it away from the excavator.

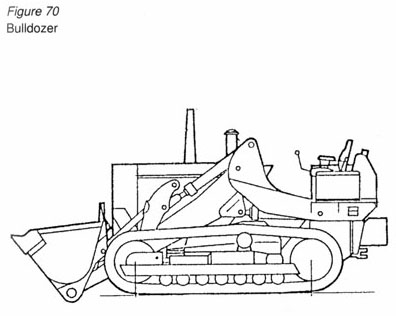

Figure 70 shows a typical bulldozer that comes with either a bucket or a simple blade. This kind of machine is essential when building a breakwater by dumping rubble at sea because the core material of the breakwater is kept level when using a bulldozer. This brings us to the end of the list of the most common types of machine required for marine construction. A special point to notice is that all of these machines run on tracks and not on rubber wheels. It is good practice to rinse the tracks with fresh water at the end of a working day if they have come into contact with sea water.

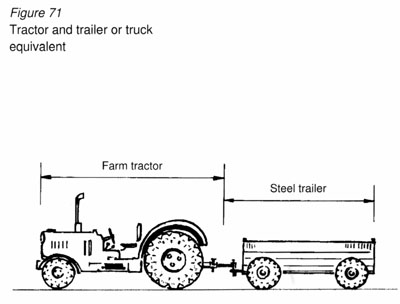

If heavy-duty tipper trucks are not available, normal agricultural tractors and trailers (Figure 71) may be used for delivering rubble, aggregate or sand to a construction site. Considerably more labour is required than when tipper trucks are used, but at local village level finding extra workers is not usually difficult. The trailers should preferably be made of steel protected on the inside with timber planking. The timber prolongs the life of the trailer by absorbing the impact of individual stones thrown on to the trailer. With any rubber-tyred vehicle, care should be taken when crossing the uneven surface of a rubble core.

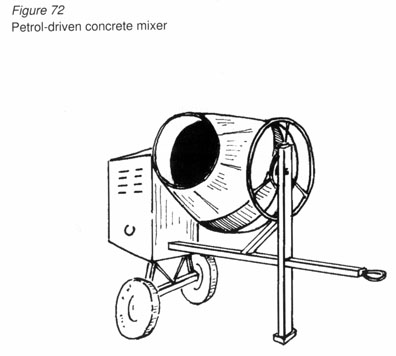

If possible, concrete should always he mixed in a proper concrete mixer. Concrete mixers come in various sizes. For normal villagelevel use, a small mixer like the one shown in Figure 72 should be purchased. Such mixers run on either a petrol- or diesel-driven engine and, if maintained properly, provide many years of troublefree use. Extreme care should be taken to ensure that all traces of set concrete are cleaned off the mixing drum. Pieces of old, set concrete impair the efficiency of the mixing operation of fresh concrete.

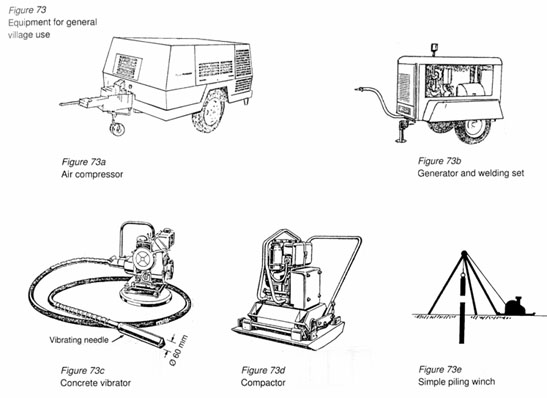

Figure 73 shows a range of equipment that may be worth purchasing and keeping for general village use:

- A small diesel-driven air-compressor can be used to power a number of air-tools such as chisels, drills, hammers, saws and pumps. A compressor usually supplies about 5 000 litres of air per minute. For marine work, air-driven tools are safer to use than electric-powered tools.

- A portable diesel-driven generator and welding unit will supply about 12 KVa.

- A petrol-driven concrete vibrator with a 60-mm diameter vibrating needle is indispensable for all types of concrete work

- A petrol-driven compactor is used for compacting pavements and road-beds.

- A piling winch or rig comes with a drop-weight that can be released quickly for pile-driving purposes.

Another useful item of equipment is an oxyacetylene cutting torch consisting of an oxygen and an acetylene cylinder mounted side-byside on a portable frame. Two oxygen cylinders are usually required for every acetylene cylinder.

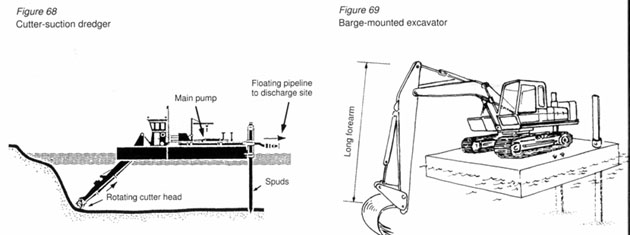

Figure 74 shows a floating platform constructed from used oil drums. Floating platforms can also be constructed from timber with plastic drums as additional floats.

If a welding generator is available on-site, a welded steel platform on oil drums can be constructed.

Platforms are used to transport materials and light machinery to inaccessible places. Chapter 8 tells you how to protect steel from corroding.